ASTM C1521-08

(Practice)Standard Practice for Evaluating Adhesion of Installed Weatherproofing Sealant Joints

Standard Practice for Evaluating Adhesion of Installed Weatherproofing Sealant Joints

SIGNIFICANCE AND USE

Many parameters contribute to the overall performance of a sealant application. Some of the most significant parameters are sealant bead size and configuration, joint movement, quality of workmanship, the quality of the adhesive bond, and the quality of the sealant material.

A sealant usually fails to perform as a weatherseal when it experiences cohesive or adhesive failure.

If a sealant bead fails, an evaluation of the total joint movement may be needed to determine if the joint sealant was strained beyond design or if the sealant failed within design parameters.

If a sealant bead fails adhesively, there is no straightforward procedure for determining the cause. The adhesive failure may be due to workmanship, the specific surface preparation used, the specific sealant used, poor “installed” joint design, poor bond chemistry and other causes.

Because of the complex nature of the performance of a sealant bead, an understanding of the quality of the adhesive bond is instrumental in any evaluation of sealant performance. It is critical that the test procedures used truly evaluate the quality of the adhesive bond and do not simply take advantage of the tear resistance of the sealant.

This method does not evaluate the performance of a sealant joint as a weatherseal. It only evaluates the characteristics of the adhesive bond relative to the cohesive strength of the sealant in a particular installation. Since any failures that result from use of this test method are intentionally induced, they do not necessarily mean that the sealant joint will not perform as a weatherseal.

The method results are most useful in identifying sealant joints with poor adhesion. The results of these methods can be used to assess the likely performance of the sealant joint and to compare performance against other joints.

SCOPE

1.1 This practice describes field tests to determine the adhesive and cohesive characteristics of an installed sealant joint, by manually placing a strain on the sealant. The sealant to be tested shall be fully cured. The results of this method can be used in conjunction with other information to determine the overall performance of the sealant joint. The user of this practice should define the other parameters to be evaluated such as cleaning of the substrate, depth control of the sealant, sealant profile, etc. This method describes both nondestructive and destructive procedures.

1.2 The destructive procedure stresses the sealant in such a way as to cause either cohesive or adhesive failure of the sealant or cohesive failure of the substrate where deficient substrate conditions exist. The objective is to characterize the adhesive/cohesive performance of the sealant on the specific substrate by applying whatever strain is necessary to effect failure of the sealant bead. It is possible that the strain applied to the sealant bead may result in the failure of a deficient substrate before effecting a failure in the sealant.

Note 1—The destructive procedure requires immediate repair of the sealant bead. Appropriate materials and equipment should be available for this purpose.

Note 2—Sealant formulations may fail in cohesion or adhesion when properly installed, and tested by this method. The sealant manufacturer should be consulted to determine the appropriate guidelines for using this method.

1.3 The nondestructive procedure places strain on the sealant and a stress on the adhesive bond. Though termed nondestructive, this procedure may result in an adhesive failure of a deficient sealant bead, but should not cause a cohesive failure in the sealant. The results of this procedure should be either adhesive failure or no failure.

Note 3—The nondestructive procedure may require immediate repair of the sealant bead, if failure is experienced. Appropriate materials and equipment should be available for this purpose.

1.4 The non-destructive procedure can be used for continuous inspect...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 1521 – 08

Standard Practice for

Evaluating Adhesion of Installed Weatherproofing Sealant

1

Joints

This standard is issued under the fixed designation C 1521; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4 The non-destructive procedure can be used for continu-

ous inspection of 100 % of the joint(s) or for any areas where

1.1 This practice describes field tests to determine the

deficient conditions, which are inconsistent with the practices

adhesive and cohesive characteristics of an installed sealant

of Guide C 1193, are suspected.

joint, by manually placing a strain on the sealant. The sealant

1.5 The committee with jurisdiction over this practice is not

to be tested shall be fully cured. The results of this method can

aware of any comparable practices published by other organi-

be used in conjunction with other information to determine the

zations or committees.

overall performance of the sealant joint. The user of this

1.6 This standard does not purport to address all of the

practice should define the other parameters to be evaluated

safety concerns, if any, associated with its use. It is the

such as cleaning of the substrate, depth control of the sealant,

responsibility of the user of this standard to establish appro-

sealant profile, etc. This method describes both nondestructive

priate safety and health practices and determine the applica-

and destructive procedures.

bility of regulatory limitations prior to use.

1.2 The destructive procedure stresses the sealant in such a

way as to cause either cohesive or adhesive failure of the

2. Referenced Documents

sealant or cohesive failure of the substrate where deficient

2

2.1 ASTM Standards:

substrate conditions exist. The objective is to characterize the

C 717 Terminology of Building Seals and Sealants

adhesive/cohesive performance of the sealant on the specific

C 1193 Guide for Use of Joint Sealants

substrate by applying whatever strain is necessary to effect

failure of the sealant bead. It is possible that the strain applied

3. Terminology

to the sealant bead may result in the failure of a deficient

3.1 Definitions—For definitions of terms used in this rec-

substrate before effecting a failure in the sealant.

ommended procedure, see Terminology C 717.

NOTE 1—The destructive procedure requires immediate repair of the

3.2 Definitions of Terms Specific to This Standard:

sealant bead.Appropriate materials and equipment should be available for

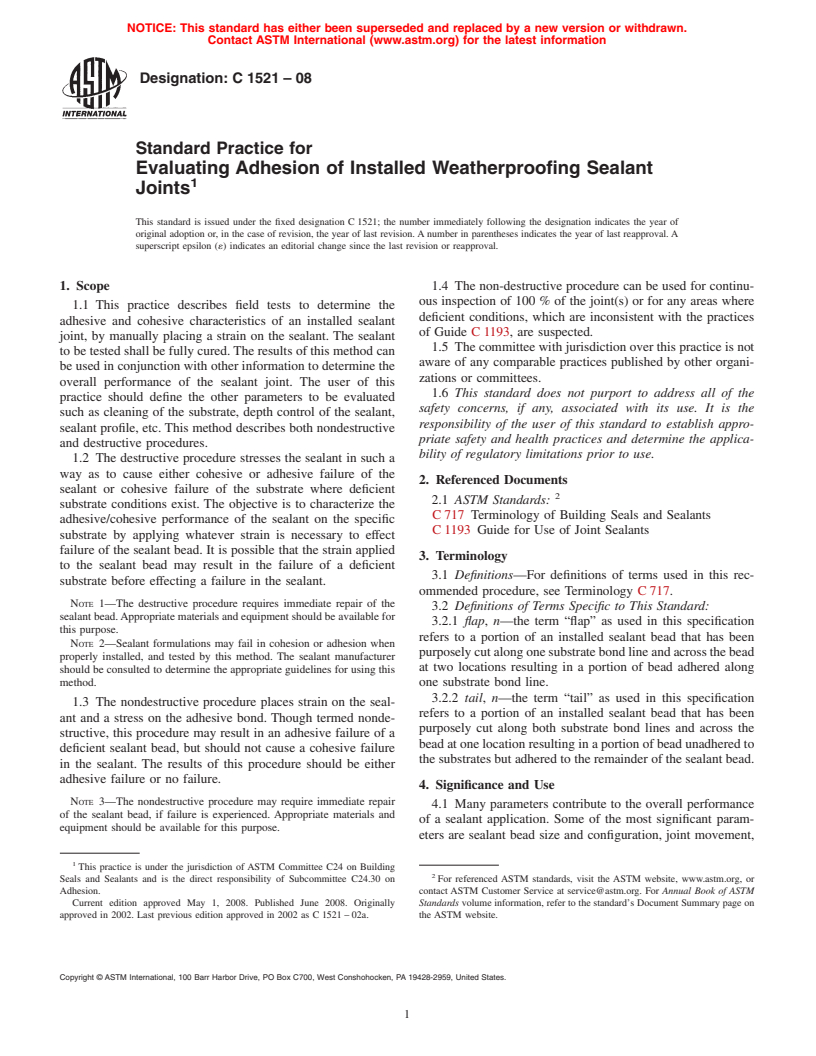

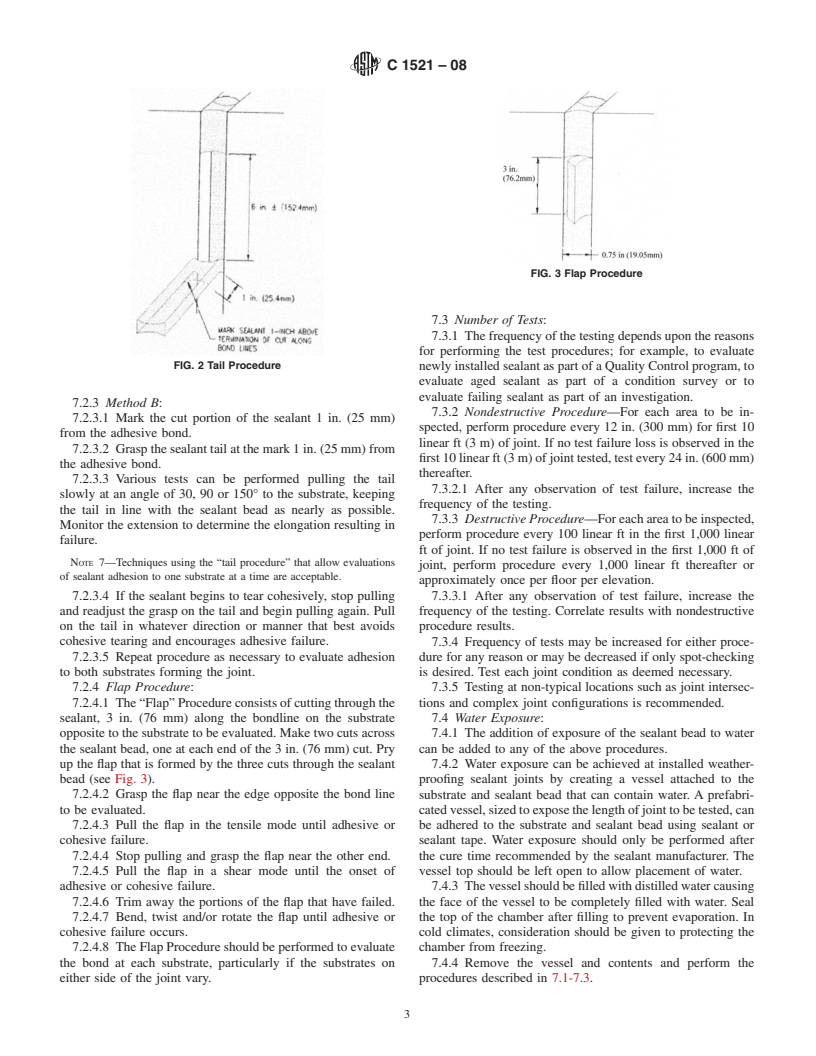

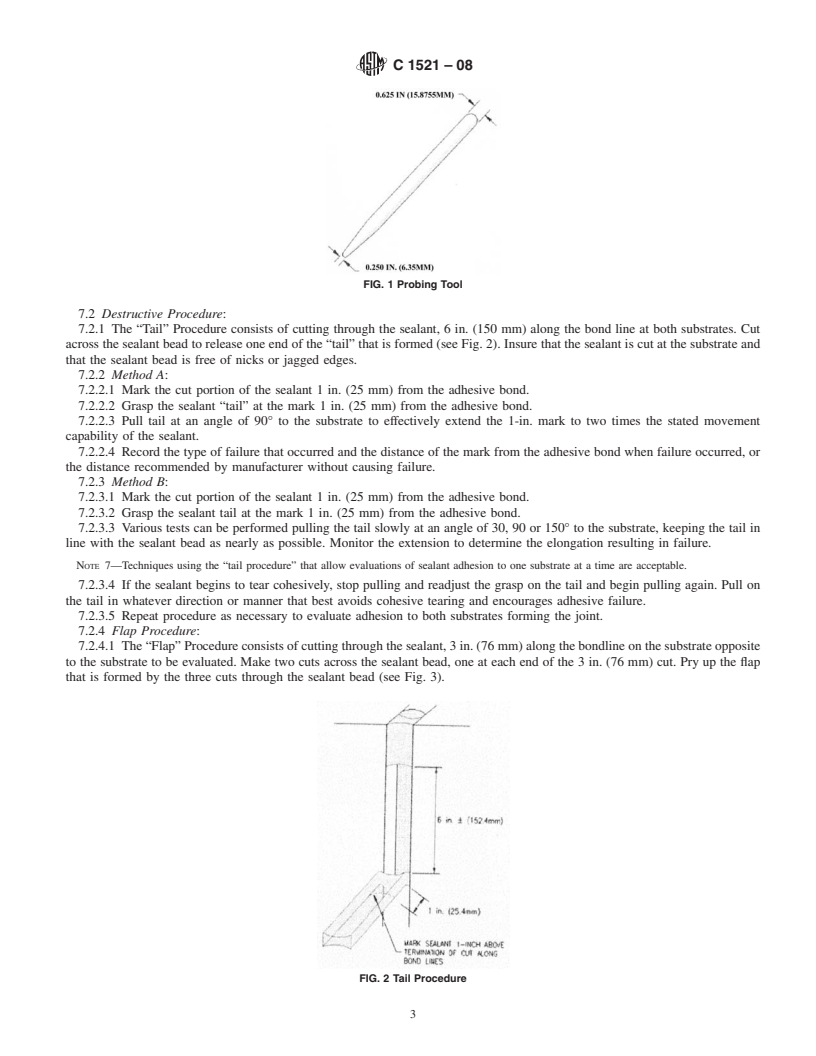

3.2.1 flap, n—the term “flap” as used in this specification

this purpose.

refers to a portion of an installed sealant bead that has been

NOTE 2—Sealant formulations may fail in cohesion or adhesion when

purposelycutalongonesubstratebondlineandacrossthebead

properly installed, and tested by this method. The sealant manufacturer

at two locations resulting in a portion of bead adhered along

should be consulted to determine the appropriate guidelines for using this

method. one substrate bond line.

3.2.2 tail, n—the term “tail” as used in this specification

1.3 The nondestructive procedure places strain on the seal-

refers to a portion of an installed sealant bead that has been

ant and a stress on the adhesive bond. Though termed nonde-

purposely cut along both substrate bond lines and across the

structive, this procedure may result in an adhesive failure of a

bead at one location resulting in a portion of bead unadhered to

deficient sealant bead, but should not cause a cohesive failure

the substrates but adhered to the remainder of the sealant bead.

in the sealant. The results of this procedure should be either

adhesive failure or no failure.

4. Significance and Use

NOTE 3—The nondestructive procedure may require immediate repair

4.1 Many parameters contribute to the overall performance

of the sealant bead, if failure is experienced. Appropriate materials and

of a sealant application. Some of the most significant param-

equipment should be available for this purpose.

eters are sealant bead size and configuration, joint movement,

1

This practice is under the jurisdiction of ASTM Committee C24 on Building

2

Seals and Sealants and is the direct responsibility of Subcommittee C24.30 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Adhesion. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved May 1, 2008. Published June 2008. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 2002. Last previous edition approved in 2002 as C 1521 – 02a. the ASTM website.

Copyright © ASTM International, 10

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1521–02a Designation: C 1521 – 08

Standard Practice for

Evaluating Adhesion of Installed Weatherproofing Sealant

1

Joints

This standard is issued under the fixed designation C 1521; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice describes field tests to determine the adhesive and cohesive characteristics of an installed sealant joint, by

manually placing a strain on the sealant. The sealant to be tested shall be fully cured. The results of this method can be used in

conjunctionwithotherinformationtodeterminetheoverallperformanceofthesealantjoint.Theuserofthispracticeshoulddefine

the other parameters to be evaluated such as cleaning of the substrate, depth control of the sealant, sealant profile, etc.This method

describes both nondestructive and destructive procedures.

1.2 The destructive procedure stresses the sealant in such a way as to cause either cohesive or adhesive failure of the sealant

orcohesivefailureofthesubstratewheredeficientsubstrateconditionsexist.Theobjectiveistocharacterizetheadhesive/cohesive

performance of the sealant on the specific substrate by applying whatever strain is necessary to effect failure of the sealant bead.

It is possible that the strain applied to the sealant bead may result in the failure of a deficient substrate before effecting a failure

in the sealant.

NOTE 1—The destructive procedure requires immediate repair of the sealant bead. Appropriate materials and equipment should be available for this

purpose.

NOTE 2—Sealant formulations may fail in cohesion or adhesion when properly installed, and tested by this method. The sealant manufacturer should

be consulted to determine the appropriate guidelines for using this method.

1.3 The nondestructive procedure places strain on the sealant and a stress on the adhesive bond.Though termed nondestructive,

this procedure may result in an adhesive failure of a deficient sealant bead, but should not cause a cohesive failure in the sealant.

The results of this procedure should be either adhesive failure or no failure.

NOTE 3—The nondestructive procedure may require immediate repair of the sealant bead, if failure is experienced. Appropriate materials and

equipment should be available for this purpose.

1.4The committee with jurisdiction over this practice is not aware of any comparable practices published by other organizations

or committees.

1.5

1.4 Thenon-destructiveprocedurecanbeusedforcontinuousinspectionof100%ofthejoint(s)orforanyareaswheredeficient

conditions, which are inconsistent with the practices of Guide C 1193, are suspected.

1.5 Thecommitteewithjurisdictionoverthispracticeisnotawareofanycomparablepracticespublishedbyotherorganizations

or committees.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C 717 Terminology of Building Seals and Sealants

C 1193 Guide for Use of Joint Sealants

3. Terminology

3.1 Definitions—For definitions of terms used in this recommended procedure, see Terminology C 717.

1

This practice is under the jurisdiction of ASTM Committee C24 on Building Seals and Sealants and is the direct responsibility of Subcommittee C24.30 on Adhesion.

Current edition approved May 10, 2002. Published July 2002. Originally published as C1521–02. Last previous edition C1521–02.

Current edition approved May 1, 2008. Published June 2008. Originally approved in 2002. Last previous edition approved in 2002 as C 1521 – 02a.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 04.07.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C1521–08

3.2 Definitions of Terms Specific to This Standard:

3.2.1 flap, n—the term “flap” as used in this specification refers to a portion of an installed sealant bead that has been purposely

c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.