ASTM F956-91(2006)

(Specification)Standard Specification for Bell, Cast, Sound Signalling

Standard Specification for Bell, Cast, Sound Signalling

ABSTRACT

This specification covers cast sound-signalling bells, together with bulkhead mounting plates for the smaller bells, for use on ships, boats, and other marine craft, for compliance with the rules in the convention on the International Regulations for Preventing Collisions at Sea. Bell bodies, clappers, and other cast fittings and parts shall be copper alloy. Fittings such as bolts, nuts, washers, pins, and supporting lugs shall be of copper alloy compatible with the bell castings. Bells shall have full, clear, round, and farreaching tones. The sound pressure level shall not be less than 110 dB at a distance of 1 m from it. Acoustic tests shall be conducted only for the 200 mm heavy and larger bells to check the requirements prescribed.

SCOPE

1.1 This specification covers cast sound-signalling bells, together with bulkhead mounting plates for the smaller bells, for use on ships, boats, and other marine craft, for compliance with the rules in the convention on the International Regulations for Preventing Collisions at Sea (commonly called Colregs). See Appendix X1.

1.2 Bells and bulkhead mounting plate shall be sized as indicated in Section 4 (see Appendix X2).

1.3 For consistency with International Regulations, all measurements are in SI units.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F956 – 91 (Reapproved 2006)

Standard Specification for

1

Bell, Cast, Sound Signalling

ThisstandardisissuedunderthefixeddesignationF956;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4.1.2 200 mm (2.2 kg),

4.1.3 200 mm (4.5 kg),

1.1 This specification covers cast sound-signalling bells,

4.1.4 250 mm,

together with bulkhead mounting plates for the smaller bells,

4.1.5 300 mm,

for use on ships, boats, and other marine craft, for compliance

4.1.6 360 mm,

with the rules in the convention on the International Regula-

4.1.7 400 mm, and

tions for Preventing Collisions at Sea (commonly called

2

4.1.8 550 mm.

Colregs). See Appendix X1.

4.2 Bulkhead mounting plates shall be furnished for the

1.2 Bells and bulkhead mounting plate shall be sized as

following bell sizes:

indicated in Section 4 (see Appendix X2).

4.2.1 150 mm, and

1.3 For consistency with International Regulations, all mea-

4.2.2 200 mm.

surements are in SI units.

5. Ordering Information

2. Referenced Documents

3

5.1 Orders for materials under this specification shall in-

2.1 ASTM Standards:

clude the following information:

B584 Specification for Copper Alloy Sand Castings for

5.1.1 ASTM designation and year of issue.

General Applications

5.1.2 Number of bells.

2.2 Other Documents:

2

5.1.3 Size of bell(s) (see 4.1).

CFR 33 Part 81–72 Implementing Rules

2

5.1.4 Additional bulkhead mounting plates (see 4.2 and

CFR 33 Part 86, Subpart B, Bell or Gong

6.2.2).

3. Terminology 5.1.5 Inscription required (see 12.1).

5.1.6 Packaging, if other than commercial (see Section13 ).

3.1 Definitions:

3.1.1 bell, n—a hollow metal instrument that rings when

6. Materials and Manufacture

struck.

6.1 Material:

3.1.2 cast, v—to form by molding in a hollow form for

6.1.1 Bell bodies, clappers, and other cast fittings and parts

shaping a liquid or plastic substance.

shall be copper alloy conforming to Specification B584, UNS

3.1.3 clapper, n—the hammer like object inside a bell.

C8720.

4. Classification 6.1.2 Fittings such as bolts, nuts, washers, pins, and sup-

porting lugs shall be of copper alloy compatible with the bell

4.1 Bells shall be furnished in the following sizes, based on

castings.

bellmouth diameter in millimetres (see Appendix X2):

6.2 Manufacture:

4.1.1 150 mm,

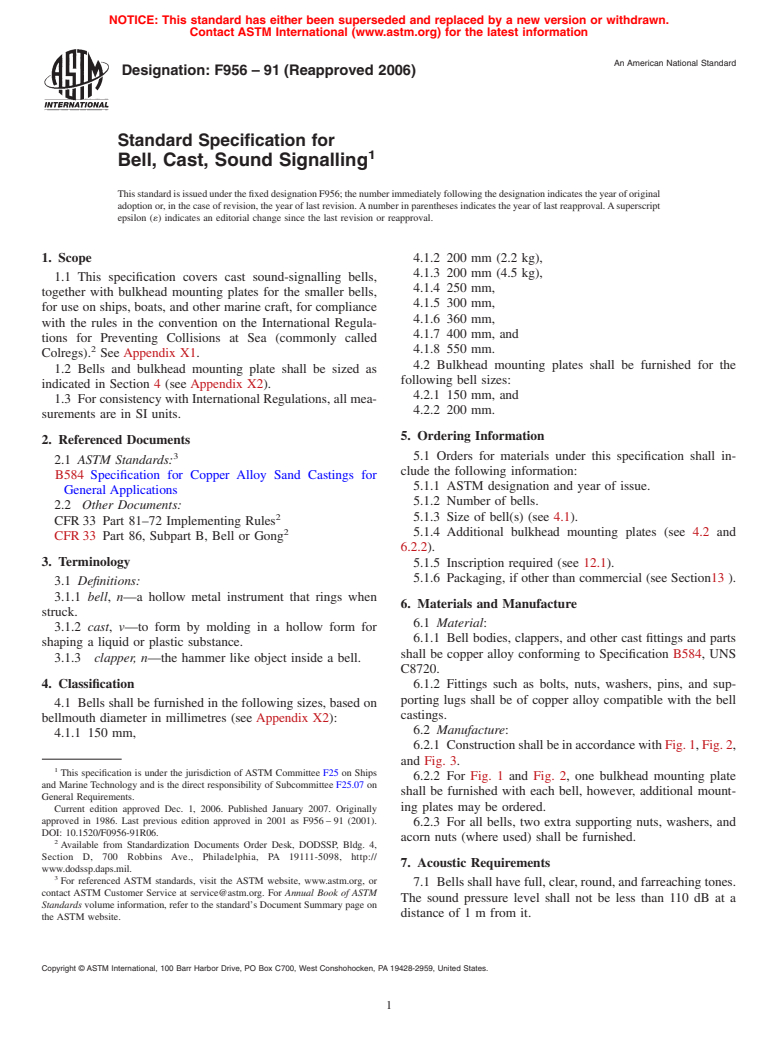

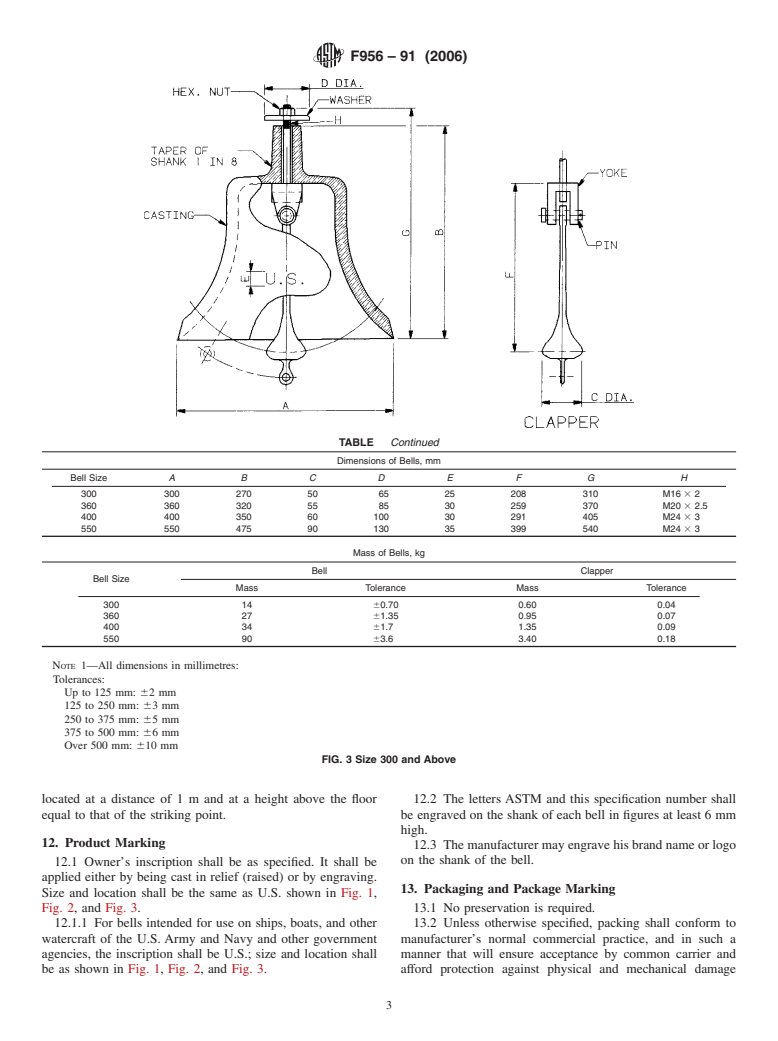

6.2.1 ConstructionshallbeinaccordancewithFig.1,Fig.2,

and Fig. 3.

1

This specification is under the jurisdiction of ASTM Committee F25 on Ships

6.2.2 For Fig. 1 and Fig. 2, one bulkhead mounting plate

and Marine Technology and is the direct responsibility of Subcommittee F25.07 on

shall be furnished with each bell, however, additional mount-

General Requirements.

ing plates may be ordered.

Current edition approved Dec. 1, 2006. Published January 2007. Originally

approved in 1986. Last previous edition approved in 2001 as F956 – 91 (2001).

6.2.3 For all bells, two extra supporting nuts, washers, and

DOI: 10.1520/F0956-91R06.

acorn nuts (where used) shall be furnished.

2

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

7. Acoustic Requirements

www.dodssp.daps.mil.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

7.1 Bells shall have full, clear, round, and farreaching tones.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The sound pressure level shall not be less than 110 dB at a

Standards volume information, refer to the standard’s Document Summary page on

distance of 1 m from it.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F956 – 91 (2006)

Mass and Dimensions of Bells

Dimensions, mm

NOTE 1—All dimensions in millimetres.

Bell Size, Bell Mass,

Tolerances:

AB

mm kg

Up to 125 mm: 62mm

Over 125 mm: 63mm

150 1.4 150 105

200 2.2 200 133 Mass of bell: 9 6 0.45 kg.

200 4.5 200 152

Mass of Clapper: 0.5 6 0.05 kg.

FIG. 2 Size 250

NOTE 1—All dimensions in millimetres.

Tolerances:

11. Inspection and Testing

Up to 150 mm: 62mm

Over 150 mm: 63mm

11.1 Responsibility—Unless otherwise specified in the or-

Mass of Bell: 60.2 kg (60.3 kg for 4.5 kg bell).

der, the manufacturer is responsible for the performance of all

Mass of Clapper: No less than 3 % of bell mass.

inspection requirements specified herein. The manufacturer

FIG. 1 Sizes 150 and 200

may utilize his own facilities or any commercial facilities

acceptable to the purchaser. The purchaser reserves the right to

8. Dimensions, Mass, and Permissibl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.