ASTM F707/F707M-94(2019)e1

(Specification)Standard Specification for Modular Gauge Boards

Standard Specification for Modular Gauge Boards

ABSTRACT

This specification covers modular gage boards for mounting dial pressure gages and dial thermometers for miscellaneous shipboard applications. Gage boards under this specification are suitable for pressure gages and dial thermometers with either turret or back flanged type cases and with either back or bottom connections. Gage boards may be furnished in two types and grades, namely: Type I, Type II, Grade a, and Grade b. Unless otherwise specified the gage boards shall be manufactured from the specified carbon steel for Grade a and form the specified aluminum alloy for Grade b. Materials shall be capable of being bent at room temperature through the prescribed angle and direction without cracking on the outside of the bent portion. Unless otherwise specified, gage boards shall be drilled for mounting the specified dial sizes. When specified, drilling shall be limited to one size gage for either Type I or Type II gage boards. The dimensional requirements for the gage boards are detailed and illustrated.

SCOPE

1.1 This specification covers modular gauge boards for mounting 89-mm [31/2-in.], 114-mm [41/2-in.], 152-mm [6-in.], and 216-mm [81/2-in.] dial size pressure gauges and dial thermometers for miscellaneous shipboard applications.

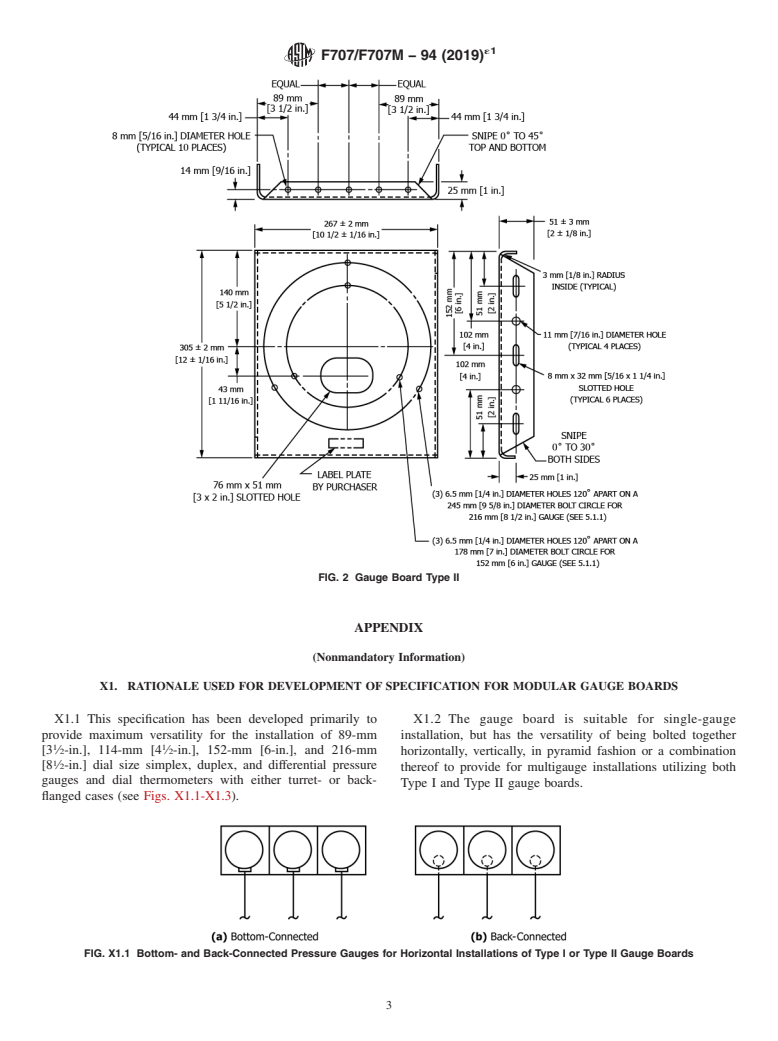

1.2 Gauge boards ordered under this specification are suitable for pressure gauges and dial thermometers with either turret or back flanged type cases and with either back or bottom connections (see Appendix X1).

1.3 Gauge mounting dimensions shall be in accordance with ASME B40.1.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

Note 1: Gauge boards covered by this specification are those normally supplied by the shipyard as opposed to the shipyard’s equipment subcontractor.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: F707/F707M −94 (Reapproved 2019) An American National Standard

Standard Specification for

Modular Gauge Boards

This standard is issued under the fixed designation F707/F707M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Editorial changes were made throughout to comply with ASTM’s policy on Units in Standards in August 2019.

1. Scope 2.2 Other Standards:

Federal Specification TT-P-645 Primer, Paint, Zinc-

1.1 This specification covers modular gauge boards for

Chromate, Alkyd Type

1 1

mounting 89-mm [3 ⁄2-in.], 114-mm [4 ⁄2-in.], 152-mm [6-in.],

Military Specification DOD-P-15328 Primer (Wash), Pre-

and 216-mm [8 ⁄2-in.] dial size pressure gauges and dial

treatment (Formula No. 117 for Metals) (Metric)

thermometers for miscellaneous shipboard applications.

1.2 Gauge boards ordered under this specification are suit-

3. Classification

able for pressure gauges and dial thermometers with either

3.1 Gauge boards are furnished in two types as follows:

turretorbackflangedtypecasesandwitheitherbackorbottom

3.1.1 Type I—Gauge boards for mounting 89-mm [3 ⁄2-in.]

connections (see Appendix X1).

and114-mm[4 ⁄2-in.]dialsizegaugesasspecifiedinSection5.

1.3 Gaugemountingdimensionsshallbeinaccordancewith

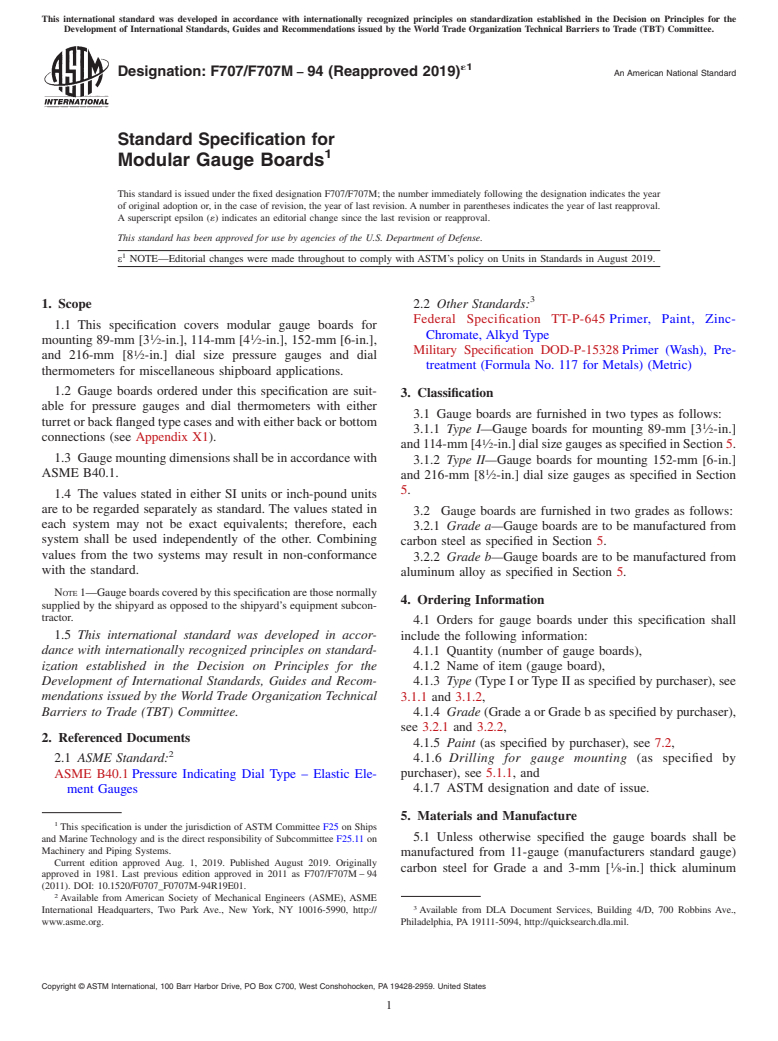

3.1.2 Type II—Gauge boards for mounting 152-mm [6-in.]

ASME B40.1.

and 216-mm [8 ⁄2-in.] dial size gauges as specified in Section

5.

1.4 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

3.2 Gauge boards are furnished in two grades as follows:

each system may not be exact equivalents; therefore, each

3.2.1 Grade a—Gauge boards are to be manufactured from

system shall be used independently of the other. Combining

carbon steel as specified in Section 5.

values from the two systems may result in non-conformance

3.2.2 Grade b—Gauge boards are to be manufactured from

with the standard.

aluminum alloy as specified in Section 5.

NOTE 1—Gauge boards covered by this specification are those normally

4. Ordering Information

supplied by the shipyard as opposed to the shipyard’s equipment subcon-

tractor.

4.1 Orders for gauge boards under this specification shall

1.5 This international standard was developed in accor-

include the following information:

dance with internationally recognized principles on standard- 4.1.1 Quantity (number of gauge boards),

ization established in the Decision on Principles for the

4.1.2 Name of item (gauge board),

Development of International Standards, Guides and Recom- 4.1.3 Type (Type I or Type II as specified by purchaser), see

mendations issued by the World Trade Organization Technical

3.1.1 and 3.1.2,

Barriers to Trade (TBT) Committee. 4.1.4 Grade (Grade a or Grade b as specified by purchaser),

see 3.2.1 and 3.2.2,

2. Referenced Documents

4.1.5 Paint (as specified by purchaser), see 7.2,

2.1 ASME Standard: 4.1.6 Drilling for gauge mounting (as specified by

ASME B40.1 Pressure Indicating Dial Type – Elastic Ele- purchaser), see 5.1.1, and

4.1.7 ASTM designation and date of issue.

ment Gauges

5. Materials and Manufacture

This specification is under the jurisdiction of ASTM Committee F25 on Ships

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on 5.1 Unless otherwise specified the gauge boards shall be

Machinery and Piping Systems.

manufactured from 11-gauge (manufacturers standard gauge)

Current edition approved Aug. 1, 2019. Published August 2019. Originally

carbon steel for Grade a and 3-mm [ ⁄8-in.] thick aluminum

approved in 1981. Last previous edition approved in 2011 as F707/F707M – 94

(2011). DOI: 10.1520/F0707_F0707M-94R19E01.

Available from American Society of Mechanical Engineers (ASME), ASME

International Headquarters, Two Park Ave., New York, NY 10016-5990, http:// Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

www.asme.org. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F707/F707M − 94 (2019)

alloy for Grade b. Materials shall be capable of being bent at 7.2 If paint is not specified by the purchaser, Grade a gauge

room temperature through 90° in any direction to an inside b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.