ASTM F790-02

(Guide)Standard Guide for Testing Materials for Aerospace Plastic Transparent Enclosures

Standard Guide for Testing Materials for Aerospace Plastic Transparent Enclosures

SCOPE

1.1 This guide is intended to summarize the standard test methods available on individual and composite materials utilized in fabrication of aerospace plastic transparent enclosures. As such, it is intended to specifically include transparent thermoplastics, transparent elastomers, and reinforced plastics, whether thermoplastic or thermosetting.

1.2 This guide is intended as an aid in the search for test methods pertinent to Aerospace Plastic Transparent Enclosures. It should be understood that all methods listed may not apply to all enclosures.

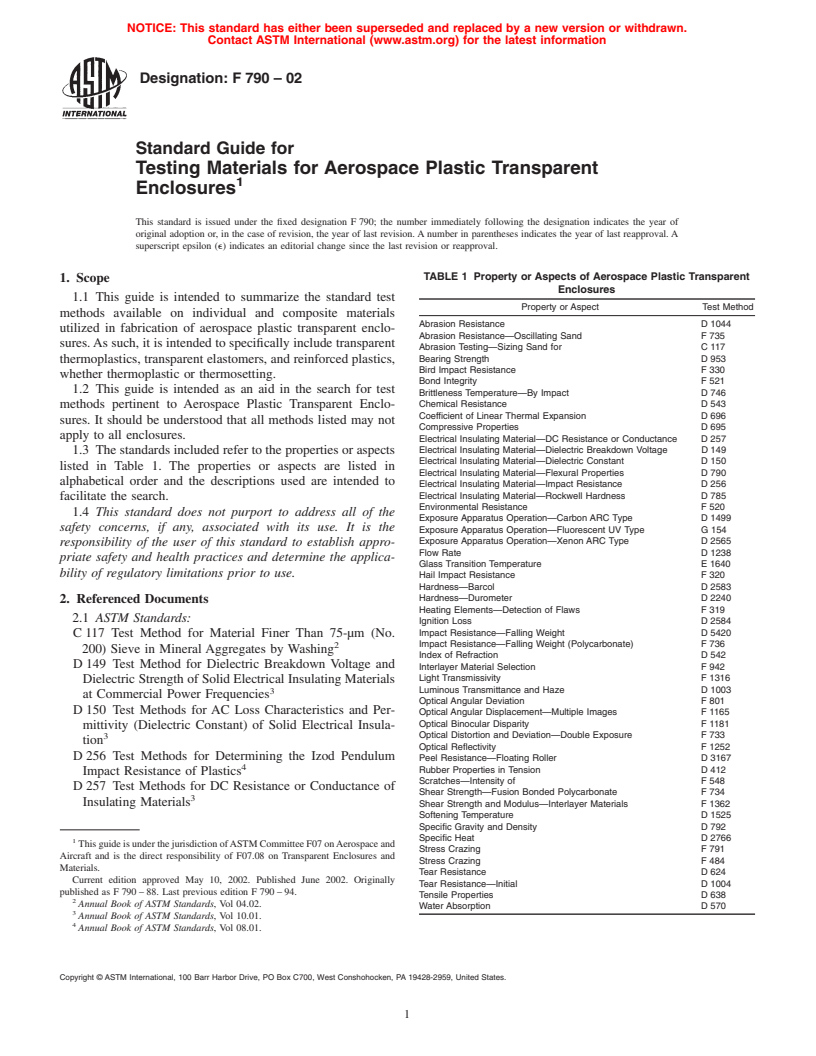

1.3 The standards included refer to the properties or aspects listed in Table 1. The properties or aspects are listed in alphabetical order and the descriptions used are intended to facilitate the search.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F790–02

Standard Guide for

Testing Materials for Aerospace Plastic Transparent

1

Enclosures

This standard is issued under the fixed designation F790; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

TABLE 1 Property or Aspects of Aerospace Plastic Transparent

1. Scope

Enclosures

1.1 This guide is intended to summarize the standard test

Property or Aspect Test Method

methods available on individual and composite materials

Abrasion Resistance D 1044

utilized in fabrication of aerospace plastic transparent enclo-

Abrasion Resistance—Oscillating Sand F 735

sures.As such, it is intended to specifically include transparent

Abrasion Testing—Sizing Sand for C 117

thermoplastics, transparent elastomers, and reinforced plastics, Bearing Strength D 953

Bird Impact Resistance F 330

whether thermoplastic or thermosetting.

Bond Integrity F 521

1.2 This guide is intended as an aid in the search for test

Brittleness Temperature—By Impact D 746

Chemical Resistance D 543

methods pertinent to Aerospace Plastic Transparent Enclo-

Coefficient of Linear Thermal Expansion D 696

sures. It should be understood that all methods listed may not

Compressive Properties D 695

apply to all enclosures.

Electrical Insulating Material—DC Resistance or Conductance D 257

Electrical Insulating Material—Dielectric Breakdown Voltage D 149

1.3 The standards included refer to the properties or aspects

Electrical Insulating Material—Dielectric Constant D 150

listed in Table 1. The properties or aspects are listed in

Electrical Insulating Material—Flexural Properties D 790

alphabetical order and the descriptions used are intended to

Electrical Insulating Material—Impact Resistance D 256

Electrical Insulating Material—Rockwell Hardness D 785

facilitate the search.

Environmental Resistance F 520

1.4 This standard does not purport to address all of the

Exposure Apparatus Operation—Carbon ARC Type D 1499

safety concerns, if any, associated with its use. It is the

Exposure Apparatus Operation—Fluorescent UV Type G 154

Exposure Apparatus Operation—Xenon ARC Type D 2565

responsibility of the user of this standard to establish appro-

Flow Rate D 1238

priate safety and health practices and determine the applica-

Glass Transition Temperature E 1640

bility of regulatory limitations prior to use.

Hail Impact Resistance F 320

Hardness—Barcol D 2583

Hardness—Durometer D 2240

2. Referenced Documents

Heating Elements—Detection of Flaws F 319

2.1 ASTM Standards:

Ignition Loss D 2584

Impact Resistance—Falling Weight D 5420

C117 Test Method for Material Finer Than 75-µm (No.

2 Impact Resistance—Falling Weight (Polycarbonate) F 736

200) Sieve in Mineral Aggregates by Washing

Index of Refraction D 542

D149 Test Method for Dielectric Breakdown Voltage and

Interlayer Material Selection F 942

Light Transmissivity F 1316

Dielectric Strength of Solid Electrical Insulating Materials

Luminous Transmittance and Haze D 1003

3

at Commercial Power Frequencies

Optical Angular Deviation F 801

D150 Test Methods for AC Loss Characteristics and Per-

Optical Angular Displacement—Multiple Images F 1165

Optical Binocular Disparity F 1181

mittivity (Dielectric Constant) of Solid Electrical Insula-

Optical Distortion and Deviation—Double Exposure F 733

3

tion

Optical Reflectivity F 1252

D256 Test Methods for Determining the Izod Pendulum

Peel Resistance—Floating Roller D 3167

4

Rubber Properties in Tension D 412

Impact Resistance of Plastics

Scratches—Intensity of F 548

D257 Test Methods for DC Resistance or Conductance of

Shear Strength—Fusion Bonded Polycarbonate F 734

3

Insulating Materials

Shear Strength and Modulus—Interlayer Materials F 1362

Softening Temperature D 1525

Specific Gravity and Density D 792

Specific Heat D 2766

1

ThisguideisunderthejurisdictionofASTMCommitteeF07onAerospaceand

Stress Crazing F 791

Aircraft and is the direct responsibility of F07.08 on Transparent Enclosures and

Stress Crazing F 484

Materials.

Tear Resistance D 624

Current edition approved May 10, 2002. Published June 2002. Originally

Tear Resistance—Initial D 1004

published as F790–88. Last previous edition F790–94.

Tensile Properties D 638

2

Annual Book of ASTM Standards, Vol 04.02.

Water Absorption D 570

3

Annual Book of ASTM Standards, Vol 10.01.

4

Annual Book of ASTM Standards, Vol 08.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F790

D412 Test Methods for Vulcanized Rubber and Thermo- E1640 Test Method forAssignment of the GlassTransition

5 10

plastic Rubb

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.