ASTM B258-02(2008)

(Specification)Standard Specification for Standard Nominal Diameters and Cross-Sectional Areas of AWG Sizes of Solid Round Wires Used as Electrical Conductors

Standard Specification for Standard Nominal Diameters and Cross-Sectional Areas of AWG Sizes of Solid Round Wires Used as Electrical Conductors

ABSTRACT

This specification prescribes the standard nominal diameters and cross-sectional areas of American Wire Gage (AWG) sizes of solid round wires, used as electrical conductors, and gives equations and rules for the calculation of standard nominal mass and lengths, resistances, and breaking or rated strengths of such wires. All wire dimensions and properties shall be considered as occurring at the internationally standardized reference temperature and all calculations shall be rounded in the final value only.

SCOPE

1.1 This specification prescribes standard nominal diameters and cross-sectional areas of American Wire Gage (AWG) sizes of solid round wires, used as electrical conductors, and gives equations and rules for the calculation of standard nominal mass and lengths, resistances, and breaking strengths of such wires (Explanatory Note 1).

1.2 The values stated in inch-pound or SI units are to be regarded separately as standard. Each system shall be used independently of the other. Combining values of the two systems may result in nonconformance with the specification. For conductor sizes designated by AWG or kcmil sizes, the requirements in SI units have been numerically converted from the corresponding values stated or derived, in inch-pound units. For conductor sizes designated by SI units only, the requirements are stated or derived in SI units.

1.2.1 For density, resistivity and temperature, the values stated in SI units are to be regarded as standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B258 −02(Reapproved 2008)

Standard Specification for

Standard Nominal Diameters and Cross-Sectional Areas of

AWG Sizes of Solid Round Wires Used as Electrical

Conductors

This standard is issued under the fixed designation B258; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope B2 Specification for Medium-Hard-Drawn Copper Wire

B3 Specification for Soft or Annealed Copper Wire

1.1 This specification prescribes standard nominal diam-

B9 Specification for Bronze Trolley Wire

eters and cross-sectional areas ofAmerican Wire Gage (AWG)

B33 Specification for Tin-Coated Soft or Annealed Copper

sizes of solid round wires, used as electrical conductors, and

Wire for Electrical Purposes

gives equations and rules for the calculation of standard

B47 Specification for Copper Trolley Wire

nominal mass and lengths, resistances, and breaking strengths

B105 Specification for Hard-Drawn CopperAlloy Wires for

of such wires (Explanatory Note 1).

Electric Conductors

1.2 The values stated in inch-pound or SI units are to be

B189 Specification for Lead-Coated and Lead-Alloy-Coated

regarded separately as standard. Each system shall be used

Soft Copper Wire for Electrical Purposes

independently of the other. Combining values of the two

B193 Test Method for Resistivity of Electrical Conductor

systems may result in nonconformance with the specification.

Materials

For conductor sizes designated by AWG or kcmil sizes, the

B227 Specification for Hard-Drawn Copper-Clad Steel Wire

requirements in SI units have been numerically converted from

B230/B230M Specification for Aluminum 1350–H19 Wire

thecorrespondingvaluesstatedorderived,ininch-poundunits.

for Electrical Purposes

For conductor sizes designated by SI units only, the require-

B314 Specification forAluminum 1350 Wire for Communi-

ments are stated or derived in SI units.

cation Cable (Withdrawn 1994)

1.2.1 For density, resistivity and temperature, the values

B396 Specification forAluminum-Alloy 5005-H19 Wire for

stated in SI units are to be regarded as standard.

Electrical Purposes (Withdrawn 2003)

B398/B398M Specification for Aluminum-Alloy 6201-T81

2. Referenced Documents

Wire for Electrical Purposes

2.1 ASTM Standards:

B415 Specification for Hard-Drawn Aluminum-Clad Steel

A111 Specification for Zinc-Coated (Galvanized) “Iron”

Wire

Telephone and Telegraph Line Wire

B609/B609M Specification for Aluminum 1350 Round

A326 Specification for Zinc-Coated (Galvanized) High Ten-

Wire, Annealed and Intermediate Tempers, for Electrical

sile Steel Telephone and Telegraph Line Wire (Withdrawn

Purposes

1990)

B800 Specification for 8000 Series Aluminum Alloy Wire

B1 Specification for Hard-Drawn Copper Wire

for Electrical Purposes—Annealed and Intermediate Tem-

pers

This specification is under the jurisdiction of ASTM Committee B01 on E29 Practice for Using Significant Digits in Test Data to

Electrical Conductors and is the direct responsibility of Subcommittee B01.02 on

Determine Conformance with Specifications

Methods of Test and Sampling Procedure.

F205 Test Method for Measuring Diameter of Fine Wire by

Current edition approved Sept. 1, 2008. Published September 2008. Originally

Weighing

approved in 1951. Last previous edition approved in 2002 as B258 – 02. DOI:

10.1520/B0258-02R08.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3. Standard Reference Temperature

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

3.1 Forthepurposeofthisspecification,allwiredimensions

the ASTM website.

3 and properties shall be considered as occurring at the interna-

The last approved version of this historical standard is referenced on

www.astm.org. tionally standardized reference temperature of 20°C (68°F).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B258−02 (2008)

TABLE 1 Standard Nominal Diameters and Cross-Sectional Areas of AWG Sizes of Solid Round Wires at 20°C

Size Diameter Cross-Sectional Area Size Diameter Cross-Sectional Area

2 2

AWG mils mm cmils mm AWG mils mm cmils mm

4/0 460.0 11.684 211 600 107.2 29 11.3 0.287 128 0.0647

3/0 409.6 10.404 167 800 85.0 30 10.0 0.254 100 0.0507

2/0 364.8 9.26 133 100 67.4 31 8.9 0.226 79.2 0.0401

1/0 324.9 8.25 105 600 53.5 32 8.0 0.203 64.0 0.0324

1 289.3 7.35 83 690 42.4 33 7.1 0.180 50.4 0.0255

2 257.6 6.54 66 360 33.6 34 6.3 0.160 39.7 0.0201

3 229.4 5.82 52 620 26.7 35 5.6 0.142 31.4 0.0159

4 204.3 5.19 41 740 21.1 36 5.0 0.127 25.0 0.0127

5 181.9 4.62 33 090 16.8 37 4.5 0.114 20.2 0.0103

6 162.0 4.11 26 240 13.3 38 4.0 0.102 16.0 0.00811

7 144.3 3.67 20 820 10.6 39 3.5 0.0890 12.2 0.00621

8 128.5 3.26 16 510 8.37 40 3.1 0.0787 9.61 0.00487

9 114.4 2.91 13 090 6.63 41 2.8 0.0711 7.84 0.00397

10 101.9 2.59 10 380 5.26 42 2.5 0.0635 6.25 0.00317

11 90.7 2.30 8 230 4.17 43 2.2 0.0559 4.84 0.00245

12 80.8 2.05 6 530 3.31 44 2.0 0.0508 4.00 0.00203

13 72.0 1.83 5 180 2.63 45 1.76 0.0447 3.10 0.00157

14 64.1 1.63 4 110 2.08 46 1.57 0.0399 2.46 0.00125

15 57.1 1.45 3 260 1.65 47 1.40 0.0356 1.96 0.000993

16 50.8 1.29 2 580 1.31 48 1.24 0.0315 1.54 0.000779

17 45.3 1.15 2 050 1.04 49 1.11 0.0282 1.23 0.000624

18 40.3 1.02 1 620 0.823 50 0.99 0.0252 0.980 0.000497

19 35.9 0.904 1 290 0.653 51 0.88 0.0224 0.774 0.000392

20 32.0 0.813 1 020 0.519 52 0.78 0.0198 0.608 0.000308

21 28.5 0.724 812 0.412 53 0.70 0.0178 0.490 0.000248

22 25.3 0.643 640 0.324 54 0.62 0.0158 0.384 0.000195

23 22.6 0.574 511 0.259 55 0.55 0.0140 0.302 0.000153

24 20.1 0.511 404 0.205 56 0.49 0.0125 0.240 0.000122

25 17.9 0.455 320 0.162

26 15.9 0.404 253 0.128

27 14.2 0.361 202 0.102

28 12.6 0.320 159 0.0804

4. Standard Rules for Rounding the following equations and shall be rounded in accordance

withSection4tothesamenumberofsignificantfiguresasused

4.1 All calculations for the standard nominal dimensions

inexpressingthestandarddiameters,butinnocasetolessthan

andpropertiesofsolidroundwiresshallberoundedinthe final

three significant figures:

value only, in accordance with rounding method of Practice

E29. Area, cmil 5 d

2 2 24

Area, mm 5 d 35.067 310

5. Standard Nominal Diameters

where:

5.1 Standard nominal diameters of AWG sizes of solid

d = diameter of the wire in mils as given in Table 1.

round wires shall be calculated in accordance with the conven-

tional mathematical law of the American Wire Gage (see

Standard nominal cross-sectional areas in circular mils and

Explanatory Note 1) and in accordance with Section 4.

square millimetres have been calculated in accordance with the

foregoing rules and are given in Table 1 for convenient

5.2 For wire sizes 4/0 to 44 AWG, inclusive, nominal

reference.

diameters shall be expressed in no more than four significant

figures but in no case closer than the nearest 0.1 mil (0.0001

7. Rules for Calculations Involving Mass and Length

in.).

7.1 Standard nominal mass and lengths shall be calculated

5.3 For wire sizes 45 to 56 AWG, inclusive, nominal

from the standard wire diameters specified in Table 1,in

diameters shall be expressed to the nearest 0.01 mil (0.00001

accordance with the following equations. They shall be

in.).

rounded in the final value only, in accordance with Section 4,

5.4 The standard nominal diameters expressed in mils have to the same number of significant figures as used in expressing

been calculated in accordance with these rules and are given in

the standard diameters, but in no case to less than three

Table 1 for convenient reference (Explanatory Note 2). significant figures:

2 23

W 5 d 3 δ 30.34049 310

6. Standard Nominal Cross-Sectional Areas

2 6

L 5 1/d 3 1/δ 32.9369 310

~ ! ~ !

6.1 Standard nominal cross-sectional areas in circular mils

and square millimetres shall be calculated in accordance with where:

B258−02 (2008)

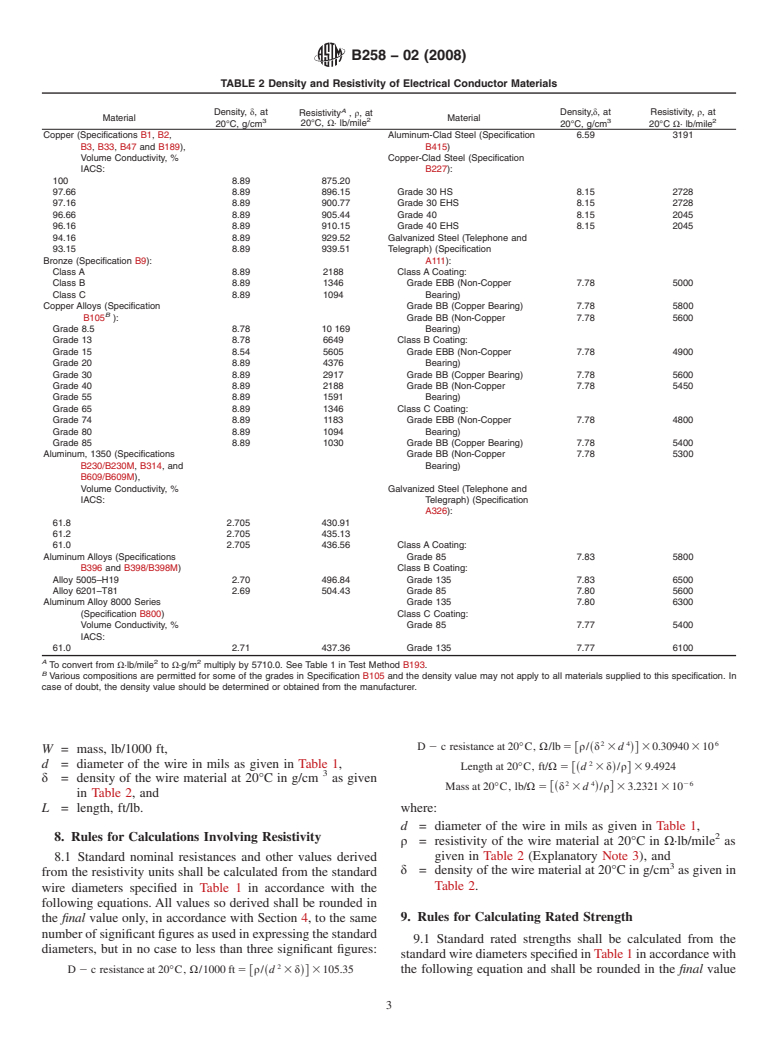

TABLE 2 Density and Resistivity of Electrical Conductor Materials

A

Density, δ,at Density,δ,at Resistivity, ρ,at

Resistivity , ρ,at

Material 2 Material

3 3 2

20°C, Ω· lb/mile

20°C, g/cm 20°C, g/cm 20°C Ω· lb/mile

Copper (Specifications B1, B2, Aluminum-Clad Steel (Specification 6.59 3191

B3, B33, B47 and B189), B415)

Volume Conductivity, % Copper-Clad Steel (Specification

IACS: B227):

100 8.89 875.20

97.66 8.89 896.15 Grade 30 HS 8.15 2728

97.16 8.89 900.77 Grade 30 EHS 8.15 2728

96.66 8.89 905.44 Grade 40 8.15 2045

96.16 8.89 910.15 Grade 40 EHS 8.15 2045

94.16 8.89 929.52 Galvanized Steel (Telephone and

93.15 8.89 939.51 Telegraph) (Specification

Bronze (Specification B9): A111):

Class A 8.89 2188 Class A Coating:

Class B 8.89 1346 Grade EBB (Non-Copper 7.78 5000

Class C 8.89 1094 Bearing)

Copper Alloys (Specification Grade BB (Copper Bearing) 7.78 5800

B

B105 ): Grade BB (Non-Copper 7.78 5600

Grade 8.5 8.78 10 169 Bearing)

Grade 13 8.78 6649 Class B Coating:

Grade 15 8.54 5605 Grade EBB (Non-Copper 7.78 4900

Grade 20 8.89 4376 Bearing)

Grade 30 8.89 2917 Grade BB (Copper Bearing) 7.78 5600

Grade 40 8.89 2188 Grade BB (Non-Copper 7.78 5450

Grade 55 8.89 1591 Bearing)

Grade 65 8.89 1346 Class C Coating:

Grade 74 8.89 1183 Grade EBB (Non-Copper 7.78 4800

Grade 80 8.89 1094 Bearing)

Grade 85 8.89 1030 Grade BB (Copper Bearing) 7.78 5400

Aluminum, 1350 (Specifications Grade BB (Non-Copper 7.78 5300

B230/B230M, B314, and Bearing)

B609/B609M),

Volume Conductivity, % Galvanized Steel (Telephone and

IACS: Telegraph) (Specification

A326):

61.8 2.705 430.91

61.2 2.705 435.13

61.0 2.705 436.56 Class A Coating:

Aluminum Alloys (Specifications Grade 85 7.83 5800

B396 and B398/B398M) Class B

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B 258–02 Designation: B 258 – 02 (Reapproved 2008)

Standard Specification for

Standard Nominal Diameters and Cross-Sectional Areas of

AWG Sizes of Solid Round Wires Used as Electrical

Conductors

This standard is issued under the fixed designation B 258; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification prescribes standard nominal diameters and cross-sectional areas ofAmerican Wire Gage (AWG) sizes of

solid round wires, used as electrical conductors, and gives equations and rules for the calculation of standard nominal mass and

lengths, resistances, and breaking strengths of such wires (Explanatory Note 1).

1.2 The values stated in inch-pound or SI units are to be regarded separately as standard. Each system shall be used

independently of the other. Combining values of the two systems may result in nonconformance with the specification. For

conductor sizes designated by AWG or kcmil sizes, the requirements in SI units have been numerically converted from the

corresponding values stated or derived, in inch-pound units. For conductor sizes designated by SI units only, the requirements are

stated or derived in SI units.

1.2.1 For density, resistivity and temperature, the values stated in SI units are to be regarded as standard.

2. Referenced Documents

2.1 ASTM Standards:

A 111 Specification for Zinc-Coated (Galvanized) “Iron”Iron Telephone and Telegraph Line Wire

A 326 Specification for Zinc-Coated (Galvanized) High Tensile Steel Telephone and Telegraph Line Wire

B 1 Specification for Hard-Drawn Copper Wire

B 2 Specification for Medium-Hard-Drawn Copper Wire

B 3 Specification for Soft or Annealed Copper Wire

B 9 Specification for Bronze Trolley Wire

B 33 Specification for Tinned Soft or Annealed Copper Wire for Electrical Purposes

B 47 Specification for Copper Trolley Wire

B 105 Specification for Hard-Drawn Copper Alloy Wires for ElectricalElectric Conductors

B 189 Specification for Lead-Coated and Lead-Alloy-Coated Soft Copper Wire for Electrical Purposes

B 193 Test Method for Resistivity of Electrical Conductor Materials

B 227 Specification for Hard-Drawn Copper-Clad Steel Wire

B 230/B 230M Specification for Aluminum 1350-H19 Wire for Electrical Purposes Specification for Aluminum 1350H19

Wire for Electrical Purposes

B 314 Specification for Aluminum 1350 Wire for Communication Cable

B 396 Specification for Aluminum-Alloy 5005-H19 Wire for Electrical Purposes

B 398/B 398M Specification for Aluminum-Alloy 6201-T81 Wire for Electrical Purposes

B 415 Specification for Hard-Drawn Aluminum-Clad Steel Wire

B 609/B 609M Specification for Aluminum 1350 Round Wire, Annealed and Intermediate Tempers, for Electrical Purposes

B 800 Specification for 8000 Series Aluminum Alloy Wire for Electrical Purposes—Annealed and Intermediate Tempers

E 29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.02 on Methods of

Test and Sampling Procedure.

Current edition approved April 10, 2002. Published June 2002. Originally published as B258–51T. Last previous edition B258–01.

Current edition approved Sept. 1, 2008. Published September 2008. Originally approved in 1951. Last previous edition approved in 2002 as B 258 – 02.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 01.06.volume information, refer to the standard’s Document Summary page on the ASTM website.

Discontinued, see 1990 Annual Book of ASTM Standards , Vol 01.06.

Withdrawn

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 258 – 02 (2008)

F 205 Test Method for Measuring Diameter of Fine Wire by Weighing

3. Standard Reference Temperature

3.1 For the purpose of this specification, all wire dimensions and properties shall be considered as occurring at the

internationally standardized reference temperature of 20°C (68°F).

4. Standard Rules for Rounding

4.1 All calculations for the standard nominal dimensions and properties of solid round wires shall be rounded in the final value

only, in accordance with rounding method of Practice E 29.

5. Standard Nominal Diameters

5.1 Standard nominal diameters of AWG sizes of solid round wires shall be calculated in accordance with the conventional

mathematical law of the American Wire Gage (see Explanatory Note 1) and in accordance with Section 4.

5.2 For wire sizes 4/0 to 44AWG, inclusive, nominal diameters shall be expressed in no more than four significant figures but

in no case closer than the nearest 0.1 mil (0.0001 in.).

5.3 For wire sizes 45 to 56 AWG, inclusive, nominal diameters shall be expressed to the nearest 0.01 mil (0.00001 in.).

5.4 ThestandardnominaldiametersexpressedinmilshavebeencalculatedinaccordancewiththeserulesandaregiveninTable

1 for convenient reference (Explanatory Note 2).

6. Standard Nominal Cross-Sectional Areas

6.1 Standard nominal cross-sectional areas in circular mils and square millimetres shall be calculated in accordance with the

following equations and shall be rounded in accordance with Section 4 to the same number of significant figures as used in

expressing the standard diameters, but in no case to less than three significant figures:

Area, cmil 5 d

2 2 24

Area, mm 5 d 3 5.067 3 10

where:

d = diameter of the wire in mils as given in Table 1.

TABLE 1 Standard Nominal Diameters and Cross-Sectional Areas of AWG Sizes of Solid Round Wires at 20°C

Size Diameter Cross-Sectional Area Size Diameter Cross-Sectional Area

2 2

AWG mils mm cmils mm AWG mils mm cmils mm

4/0 460.0 11.684 211 600 107.2 29 11.3 0.287 128 0.0647

3/0 409.6 10.404 167 800 85.0 30 10.0 0.254 100 0.0507

2/0 364.8 9.26 133 100 67.4 31 8.9 0.226 79.2 0.0401

1/0 324.9 8.25 105 600 53.5 32 8.0 0.203 64.0 0.0324

1 289.3 7.35 83 690 42.4 33 7.1 0.180 50.4 0.0255

2 257.6 6.54 66 360 33.6 34 6.3 0.160 39.7 0.0201

3 229.4 5.82 52 620 26.7 35 5.6 0.142 31.4 0.0159

4 204.3 5.19 41 740 21.1 36 5.0 0.127 25.0 0.0127

5 181.9 4.62 33 090 16.8 37 4.5 0.114 20.2 0.0103

6 162.0 4.11 26 240 13.3 38 4.0 0.102 16.0 0.00811

7 144.3 3.67 20 820 10.6 39 3.5 0.0890 12.2 0.00621

8 128.5 3.26 16 510 8.37 40 3.1 0.0787 9.61 0.00487

9 114.4 2.91 13 090 6.63 41 2.8 0.0711 7.84 0.00397

10 101.9 2.59 10 380 5.26 42 2.5 0.0635 6.25 0.00317

11 90.7 2.30 8 230 4.17 43 2.2 0.0559 4.84 0.00245

12 80.8 2.05 6 530 3.31 44 2.0 0.0508 4.00 0.00203

13 72.0 1.83 5 180 2.63 45 1.76 0.0447 3.10 0.00157

14 64.1 1.63 4 110 2.08 46 1.57 0.0399 2.46 0.00125

15 57.1 1.45 3 260 1.65 47 1.40 0.0356 1.96 0.000993

16 50.8 1.29 2 580 1.31 48 1.24 0.0315 1.54 0.000779

17 45.3 1.15 2 050 1.04 49 1.11 0.0282 1.23 0.000624

18 40.3 1.02 1 620 0.823 50 0.99 0.0252 0.980 0.000497

19 35.9 0.904 1 290 0.653 51 0.88 0.0224 0.774 0.000392

20 32.0 0.813 1 020 0.519 52 0.78 0.0198 0.608 0.000308

21 28.5 0.724 812 0.412 53 0.70 0.0178 0.490 0.000248

22 25.3 0.643 640 0.324 54 0.62 0.0158 0.384 0.000195

23 22.6 0.574 511 0.259 55 0.55 0.0140 0.302 0.000153

24 20.1 0.511 404 0.205 56 0.49 0.0125 0.240 0.000122

25 17.9 0.455 320 0.162

26 15.9 0.404 253 0.128

27 14.2 0.361 202 0.102

28 12.6 0.320 159 0.0804

B 258 – 02 (2008)

Standard nominal cross-sectional areas in circular mils and square millimetres have been calculated in accordance with the

foregoing rules and are given in Table 1 for convenient reference.

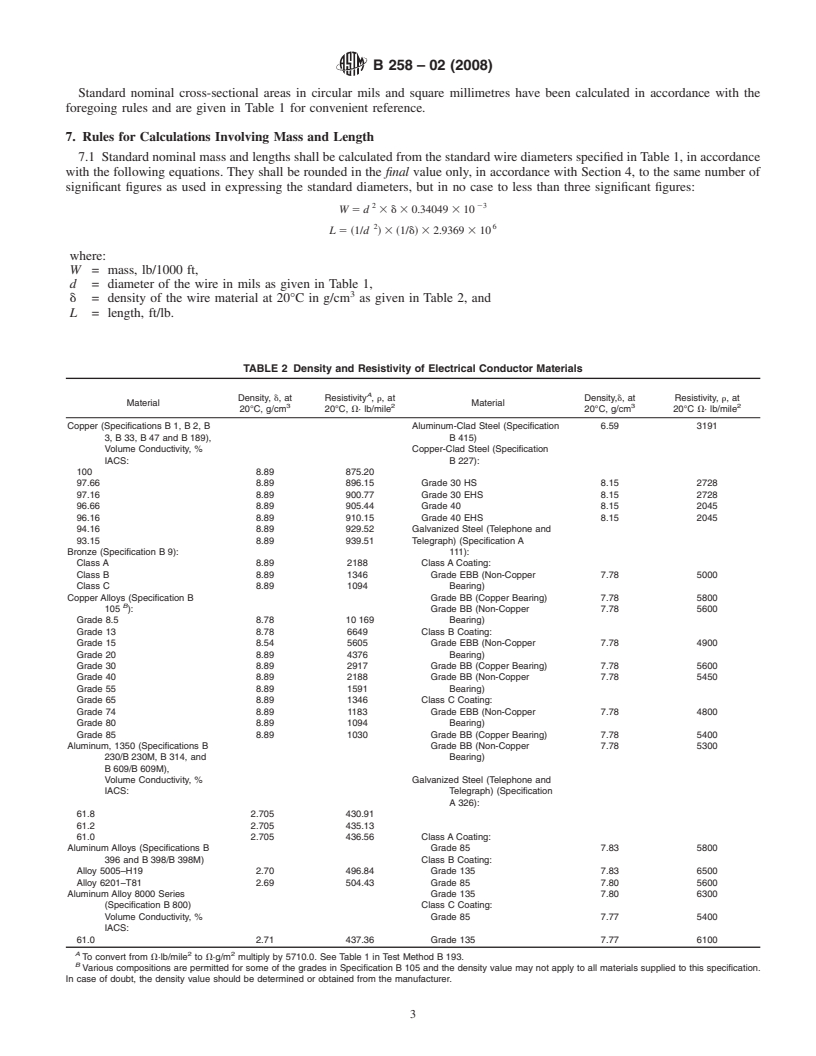

7. Rules for Calculations Involving Mass and Length

7.1 Standard nominal mass and lengths shall be calculated from the standard wire diameters specified in Table 1, in accordance

with the following equations. They shall be rounded in the final value only, in accordance with Section 4, to the same number of

significant figures as used in expressing the standard diameters, but in no case to less than three significant figures:

2 23

W 5 d 3d3 0.34049 3 10

2 6

L 5 ~1/d ! 3 ~1/d! 3 2.9369 3 10

where:

W = mass, lb/1000 ft,

d = diameter of the wire in mils as given in Table 1,

d = density of the wire material at 20°C in g/cm as given in Table 2, and

L = length, ft/lb.

TABLE 2 Density and Resistivity of Electrical Conductor Materials

A

Density, d,at Resistivity , r,at Density,d,at Resistivity, r,at

Material Material

3 2 3 2

20°C, g/cm 20°C, V· lb/mile 20°C, g/cm 20°C V· lb/mile

Copper (Specifications B 1, B 2, B Aluminum-Clad Steel (Specification 6.59 3191

3, B 33, B 47 and B 189), B 415)

Volume Conductivity, % Copper-Clad Steel (Specification

IACS: B 227):

100 8.89 875.20

97.66 8.89 896.15 Grade 30 HS 8.15 2728

97.16 8.89 900.77 Grade 30 EHS 8.15 2728

96.66 8.89 905.44 Grade 40 8.15 2045

96.16 8.89 910.15 Grade 40 EHS 8.15 2045

94.16 8.89 929.52 Galvanized Steel (Telephone and

93.15 8.89 939.51 Telegraph) (Specification A

Bronze (Specification B 9): 111):

Class A 8.89 2188 Class A Coating:

Class B 8.89 1346 Grade EBB (Non-Copper 7.78 5000

Class C 8.89 1094 Bearing)

Copper Alloys (Specification B Grade BB (Copper Bearing) 7.78 5800

B

): Grade BB (Non-Copper 7.78 5600

Grade 8.5 8.78 10 169 Bearing)

Grade 13 8.78 6649 Class B Coating:

Grade 15 8.54 5605 Grade EBB (Non-Copper 7.78 4900

Grade 20 8.89 4376 Bearing)

Grade 30 8.89 2917 Grade BB (Copper Bearing) 7.78 5600

Grade 40 8.89 2188 Grade BB (Non-Copper 7.78 5450

Grade 55 8.89 1591 Bearing)

Grade 65 8.89 1346 Class C Coating:

Grade 74 8.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.