ASTM F478-14a(2019)

(Specification)Standard Specification for In-Service Care of Insulating Line Hose and Covers

Standard Specification for In-Service Care of Insulating Line Hose and Covers

ABSTRACT

This specification covers the in-service care, inspection, testing, and use voltage of insulating line hose and covers for protection from electrical shock. Line hose covered in this specification are designed as Type I or Type II; Class 0, Class 1, Class 2, Class 3 or Class 4; Style A, Style B, Style C or Style D. Covers covered in this standard are designated as Type I or Type II; Class 0, Class 1, Class 2, Class 3 or Class 4; Style A, Style B, Style C, Style D or Style E. Electrodes, ac test, and dc tests shall be performed to conform with the specified requirements.

SCOPE

1.1 This specification covers the in-service care, inspection, testing, and use voltage of insulating line hose and covers for protection of workers from accidental contact with energized electrical wires or equipment.

1.2 The following safety hazards caveat applies only to the test method portion, Section 7, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 7.2.1.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F478 −14a (Reapproved 2019)

Standard Specification for

In-Service Care of Insulating Line Hose and Covers

ThisstandardisissuedunderthefixeddesignationF478;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C 39.5 Safety Requirements for Electrical and Electronic

Measuring and Controlling Instrumentation

1.1 This specification covers the in-service care, inspection,

testing, and use voltage of insulating line hose and covers for 2.3 IEEE Standard:

protection of workers from accidental contact with energized IEEE Standard 4 Techniques for High Voltage Testing

electrical wires or equipment.

3. Terminology

1.2 The following safety hazards caveat applies only to the

test method portion, Section 7, of this specification: This

3.1 breakdown—the electrical discharge or arc occurring

standard does not purport to address all of the safety concerns,

betweentheelectrodesandthroughtheequipmentbeingtested.

if any, associated with its use. It is the responsibility of the user

3.2 bulk storage— the storage of hose or covers together

of this standard to establish appropriate safety, health, and

with one or more layers piled neatly, but without the benefit of

environmental practices and determine the applicability of

spacers, supports, or special protective containers.

regulatory limitations prior to use. Specific precautionary

3.3 cover—an electrically insulated enclosure designed to

statements are given in 7.2.1.

be installed temporarily on various types of irregularly shaped

1.3 This international standard was developed in accor-

electrical equipment to protect personnel and equipment work-

dance with internationally recognized principles on standard-

ing in the close proximity.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3.4 designated person—an individual who is qualified by

mendations issued by the World Trade Organization Technical

experience or training to perform an assigned task.

Barriers to Trade (TBT) Committee.

3.5 distorted—physically changed from the natural and

original shape, caused by stress of any type.

2. Referenced Documents

3.6 electrical testing facility—a location with qualified

2.1 ASTM Standards:

personnel,testingequipment,andproceduresfortheinspection

D1049 Specification for Rubber Insulating Covers

and electrical testing of electrical insulating protective equip-

D1050 Specification for Rubber Insulating Line Hose

ment.

D2865 Practice for Calibration of Standards and Equipment

3.7 electrode—the energized or grounded conductor portion

for Electrical Insulating Materials Testing

of electrical test equipment which is placed near or in contact

F819 Terminology Relating to Electrical Protective Equip-

with the material or equipment being tested.

ment for Workers

3.8 flashover—the electrical discharge or arc occurring be-

2.2 ANSI Standards:

tween electrodes and over or around, but not through, the

C 84.1 Voltage Ratings for Electric Power Systems and

equipment being tested.

Equipment (60 Hz)

3.9 hose—an electrical insulating tube with a longitudinal

slit designed to be installed temporarily on energized electrical

1 wires.

This specification is under the jurisdiction of ASTM Committee F18 on

Electrical Protective Equipment for Workers and is the direct responsibility of

3.10 ozone—a very active form of oxygen that may be

Subcommittee F18.25 on Insulating Cover-Up Equipment.

produced by corona, arcing, or ultraviolet rays.

Current edition approved April 1, 2019. Published April 2019. Originally

approved in 1976. Last previous edition approved in 2014 as F478 – 14a. DOI:

3.11 ozone cutting and checking —cracks produced by

10.1520/F0478-14AR19.

2 ozone in a material under mechanical stress.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Available from American National Standards Institute (ANSI), 25 W. 43rd St., Available from Institute of Electrical and Electronics Engineers, Inc., 445 Hoes

4th Floor, New York, NY 10036, http://www.ansi.org. Lane, Piscataway, NJ 08854-4150.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F478−14a (2019)

3.12 retest—the tests given after the initial acceptance test, 6. Washing and Inspection

usually performed at regular periodic intervals or as required

6.1 The recommended sequence of washing and inspection

because of physical inspection.

of contaminated insulating line hose and covers is as follows:

3.13 voltage, maximum retest—voltage, either ac rms or dc

6.1.1 Washing,

average, that is equal to the proof test voltage for new

6.1.2 Drying,

protective equipment.

6.1.3 Inspection,

3.14 voltage, nominal design—a nominal value consistent

6.1.4 Marking, and

with the latest revision of ANSI C84.1, assigned to the circuit

6.1.5 Packing for storage and shipment.

or system for the purpose of conveniently designating its

6.2 The hose and covers may be washed with a soap, mild

voltage class.

non-bleaching detergent, or a cleaner recommended by the

3.15 voltage, retest— voltage, either ac rms or dc average,

equipment manufacturer. After washing, the hose and covers

that used protective equipment must be capable of withstand-

shall be rinsed thoroughly with water.

ing for a specific test period without breakdown.

6.2.1 The cleaning agent shall not degrade the insulating

3.16 For definitions of other terms, refer to Terminology qualities of the line hose and covers.

F819.

6.2.2 A commercial tumble-type washing machine may be

used, where practicable, but caution must be observed to

4. Significance and Use

eliminate any interior surfaces or edges that will cut, abrade,

puncture, or pinch the hose or covers.

4.1 Compliance with this specification should continue to

provide personnel with insulating line hose and covers of

6.3 The hose and covers shall be air dried. The air tempera-

known and acceptable quality after initial acceptance in accor-

ture shall not be over 150°F (65.5°C). They may be suspended

dance with Specifications D1050 and D1049. The standards

to allow drainage and air circulation or dried in a commercial

herein are to be considered as minimum requirements.

tumble-type automatic dryer. In an automatic dryer, caution

must be observed to eliminate any ozone-producing lamps and

4.2 A margin of safety shall be provided between the

interior surfaces that will cut, abrade, puncture, or pinch the

maximum use voltage and their class proof voltage in accor-

hose and covers.

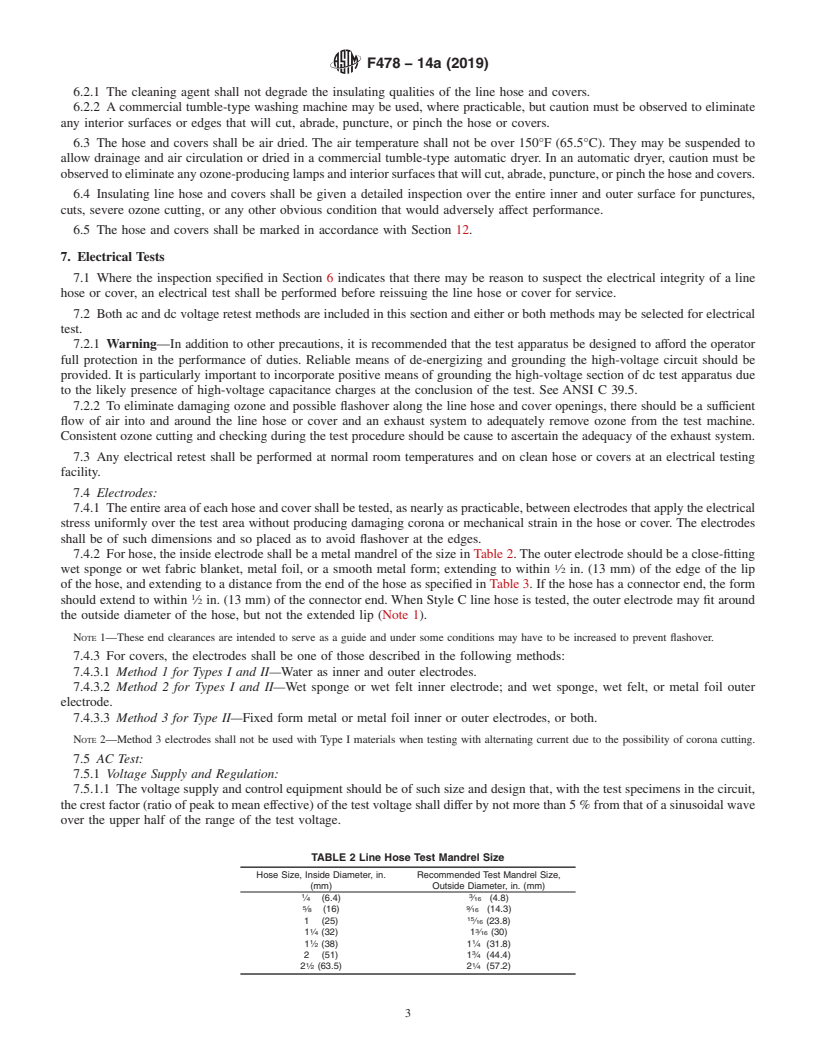

dance with Specifications D1050 and D1049, as shown in

Table 1.

6.4 Insulating line hose and covers shall be given a detailed

4.3 The user of this type of protective equipment shall be inspectionovertheentireinnerandoutersurfaceforpunctures,

knowledgeable of and instructed in the correct and safe cuts, severe ozone cutting, or any other obvious condition that

inspection and use of this equipment. would adversely affect performance.

6.5 The hose and covers shall be marked in accordance with

5. Classification

Section 12.

5.1 Line hose covered in this specification are designed as

Type I or Type II; Class 0, Class 1, Class 2, Class 3 or Class 4;

7. Electrical Tests

Style A, Style B, Style C or Style D. Covers covered in this

7.1 Where the inspection specified in Section 6 indicates

standard are designated as Type I or Type II; Class 0, Class 1,

that there may be reason to suspect the electrical integrity of a

Class 2, Class 3 or Class 4; Style A, Style B, Style C, Style D

line hose or cover, an electrical test shall be performed before

or Style E.

reissuing the line hose or cover for service.

5.1.1 Type I—High-grade cis-1,4-polyisoprene rubber com-

pound of natural or synthetic origin, properly vulcanized.

7.2 Both ac and dc voltage retest methods are included in

5.1.2 Type II—Ozone resistant, made of any elastomer or

this section and either or both methods may be selected for

combination of elastomeric compounds.

electrical test.

5.1.3 The class designations are based on the electrical

7.2.1 Warning—In addition to other precautions, it is

properties in Specifications D1050 and D1049.

recommended that the test apparatus be designed to afford the

5.1.4 The style designations are based on the designs and

operator full protection in the performance of duties. Reliable

descriptions in Specifications D1050 and D1049.

means of de-energizing and grounding the high-voltage circuit

should be provided. It is particularly important to incorporate

positive means of grounding the high-voltage section of dc test

TABLE 1 Voltage Requirements Line Hose and Covers apparatus due to the likely presence of high-voltage capaci-

tance charges at the conclusion of the test. See ANSI C 39.5.

Class

AC Use DC Max

Designation of AC Retest DC Retest

7.2.2 To eliminate damaging ozone and possible flashover

Voltage, rms, Use Voltage

Hose and Voltage, rms Voltage, avg

max avg, V

along the line hose and cover openings, there should be a

Covers

sufficient flow of air into and around the line hose or cover and

0 1000 1500 5000 20 000

1 7500 11250 10 000 40 000 an exhaust system to adequately remove ozone from the test

2 17 000 25500 20 000 50 000

machine. Consistent ozone cutting and checking during the test

3 26 500 39750 30 000 60 000

procedure should be cause to ascertain the adequacy of the

4 36 000 54000 40 000 70 000

exhaust system.

F478−14a (2019)

A

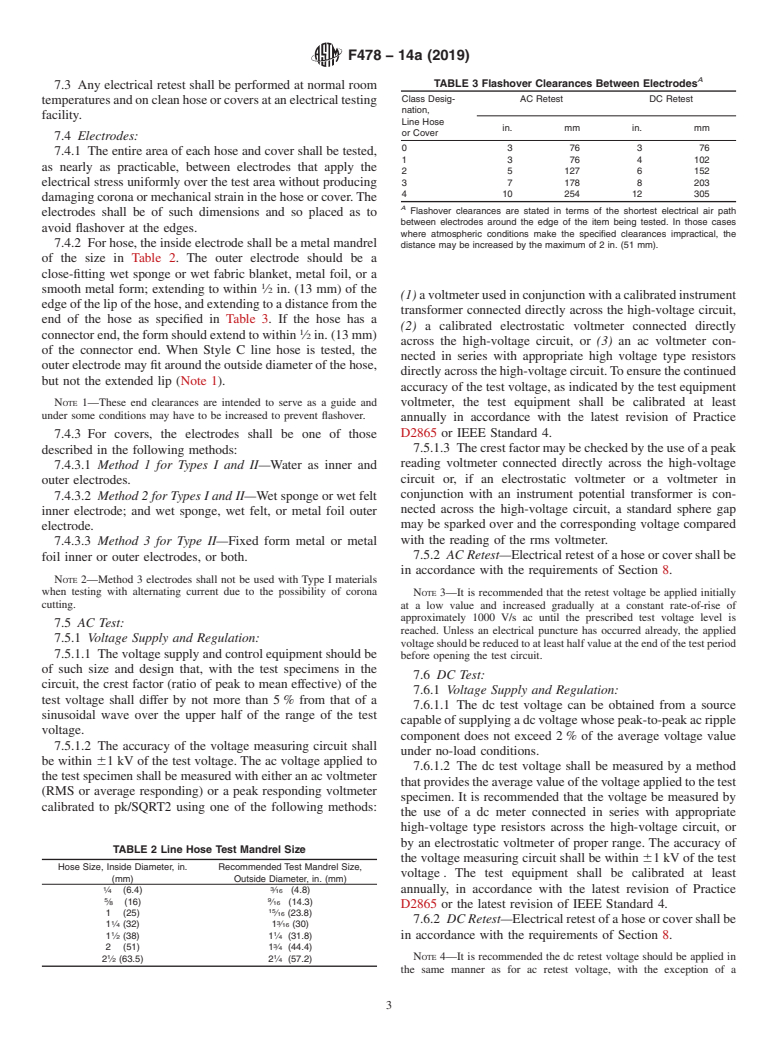

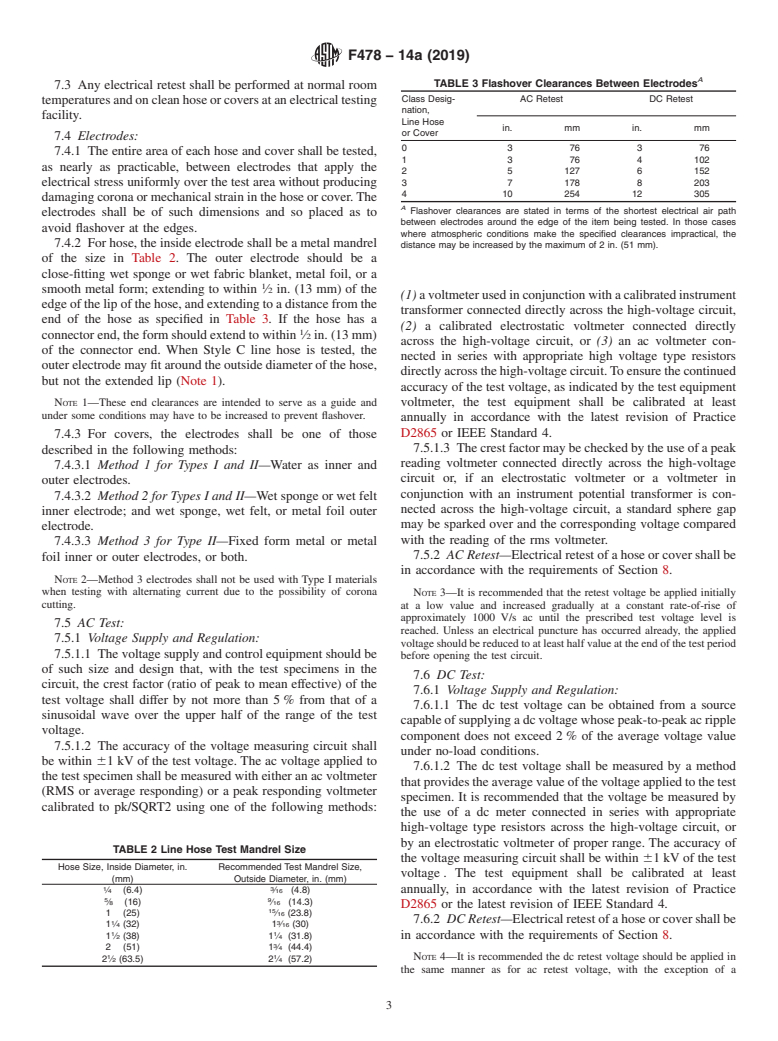

TABLE 3 Flashover Clearances Between Electrodes

7.3 Any electrical retest shall be performed at normal room

Class Desig- AC Retest DC Retest

temperaturesandoncleanhoseorcoversatanelectricaltesting

nation,

facility.

Line Hose

in.mmin. mm

or Cover

7.4 Electrodes:

03 76 3 76

7.4.1 The entire area of each hose and cover shall be tested,

1 3 76 4 102

as nearly as practicable, between electrodes that apply the

2 5 127 6 152

electrical stress uniformly over the test area without producing 3 7 178 8 203

4 10 254

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F478 − 14a (Reapproved 2019)

Standard Specification for

In-Service Care of Insulating Line Hose and Covers

This standard is issued under the fixed designation F478; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C 39.5 Safety Requirements for Electrical and Electronic

Measuring and Controlling Instrumentation

1.1 This specification covers the in-service care, inspection,

testing, and use voltage of insulating line hose and covers for 2.3 IEEE Standard:

protection of workers from accidental contact with energized IEEE Standard 4 Techniques for High Voltage Testing

electrical wires or equipment.

3. Terminology

1.2 The following safety hazards caveat applies only to the

test method portion, Section 7, of this specification: This

3.1 breakdown—the electrical discharge or arc occurring

standard does not purport to address all of the safety concerns,

between the electrodes and through the equipment being tested.

if any, associated with its use. It is the responsibility of the user

3.2 bulk storage— the storage of hose or covers together

of this standard to establish appropriate safety, health, and

with one or more layers piled neatly, but without the benefit of

environmental practices and determine the applicability of

spacers, supports, or special protective containers.

regulatory limitations prior to use. Specific precautionary

3.3 cover—an electrically insulated enclosure designed to

statements are given in 7.2.1.

be installed temporarily on various types of irregularly shaped

1.3 This international standard was developed in accor-

electrical equipment to protect personnel and equipment work-

dance with internationally recognized principles on standard-

ing in the close proximity.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3.4 designated person—an individual who is qualified by

mendations issued by the World Trade Organization Technical

experience or training to perform an assigned task.

Barriers to Trade (TBT) Committee.

3.5 distorted—physically changed from the natural and

original shape, caused by stress of any type.

2. Referenced Documents

3.6 electrical testing facility—a location with qualified

2.1 ASTM Standards:

personnel, testing equipment, and procedures for the inspection

D1049 Specification for Rubber Insulating Covers

and electrical testing of electrical insulating protective equip-

D1050 Specification for Rubber Insulating Line Hose

ment.

D2865 Practice for Calibration of Standards and Equipment

3.7 electrode—the energized or grounded conductor portion

for Electrical Insulating Materials Testing

of electrical test equipment which is placed near or in contact

F819 Terminology Relating to Electrical Protective Equip-

with the material or equipment being tested.

ment for Workers

3.8 flashover—the electrical discharge or arc occurring be-

2.2 ANSI Standards:

tween electrodes and over or around, but not through, the

C 84.1 Voltage Ratings for Electric Power Systems and

equipment being tested.

Equipment (60 Hz)

3.9 hose—an electrical insulating tube with a longitudinal

slit designed to be installed temporarily on energized electrical

1 wires.

This specification is under the jurisdiction of ASTM Committee F18 on

Electrical Protective Equipment for Workers and is the direct responsibility of

3.10 ozone—a very active form of oxygen that may be

Subcommittee F18.25 on Insulating Cover-Up Equipment.

produced by corona, arcing, or ultraviolet rays.

Current edition approved April 1, 2019. Published April 2019. Originally

approved in 1976. Last previous edition approved in 2014 as F478 – 14a. DOI:

3.11 ozone cutting and checking —cracks produced by

10.1520/F0478-14AR19.

2 ozone in a material under mechanical stress.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Available from American National Standards Institute (ANSI), 25 W. 43rd St., Available from Institute of Electrical and Electronics Engineers, Inc., 445 Hoes

4th Floor, New York, NY 10036, http://www.ansi.org. Lane, Piscataway, NJ 08854-4150.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F478 − 14a (2019)

3.12 retest—the tests given after the initial acceptance test, 6. Washing and Inspection

usually performed at regular periodic intervals or as required

6.1 The recommended sequence of washing and inspection

because of physical inspection.

of contaminated insulating line hose and covers is as follows:

3.13 voltage, maximum retest—voltage, either ac rms or dc

6.1.1 Washing,

average, that is equal to the proof test voltage for new

6.1.2 Drying,

protective equipment.

6.1.3 Inspection,

3.14 voltage, nominal design—a nominal value consistent 6.1.4 Marking, and

with the latest revision of ANSI C84.1, assigned to the circuit

6.1.5 Packing for storage and shipment.

or system for the purpose of conveniently designating its

6.2 The hose and covers may be washed with a soap, mild

voltage class.

non-bleaching detergent, or a cleaner recommended by the

3.15 voltage, retest— voltage, either ac rms or dc average,

equipment manufacturer. After washing, the hose and covers

that used protective equipment must be capable of withstand-

shall be rinsed thoroughly with water.

ing for a specific test period without breakdown.

6.2.1 The cleaning agent shall not degrade the insulating

3.16 For definitions of other terms, refer to Terminology qualities of the line hose and covers.

F819.

6.2.2 A commercial tumble-type washing machine may be

used, where practicable, but caution must be observed to

4. Significance and Use

eliminate any interior surfaces or edges that will cut, abrade,

puncture, or pinch the hose or covers.

4.1 Compliance with this specification should continue to

provide personnel with insulating line hose and covers of

6.3 The hose and covers shall be air dried. The air tempera-

known and acceptable quality after initial acceptance in accor-

ture shall not be over 150°F (65.5°C). They may be suspended

dance with Specifications D1050 and D1049. The standards

to allow drainage and air circulation or dried in a commercial

herein are to be considered as minimum requirements.

tumble-type automatic dryer. In an automatic dryer, caution

must be observed to eliminate any ozone-producing lamps and

4.2 A margin of safety shall be provided between the

interior surfaces that will cut, abrade, puncture, or pinch the

maximum use voltage and their class proof voltage in accor-

hose and covers.

dance with Specifications D1050 and D1049, as shown in

Table 1.

6.4 Insulating line hose and covers shall be given a detailed

4.3 The user of this type of protective equipment shall be inspection over the entire inner and outer surface for punctures,

knowledgeable of and instructed in the correct and safe cuts, severe ozone cutting, or any other obvious condition that

inspection and use of this equipment. would adversely affect performance.

6.5 The hose and covers shall be marked in accordance with

5. Classification

Section 12.

5.1 Line hose covered in this specification are designed as

Type I or Type II; Class 0, Class 1, Class 2, Class 3 or Class 4;

7. Electrical Tests

Style A, Style B, Style C or Style D. Covers covered in this

7.1 Where the inspection specified in Section 6 indicates

standard are designated as Type I or Type II; Class 0, Class 1,

that there may be reason to suspect the electrical integrity of a

Class 2, Class 3 or Class 4; Style A, Style B, Style C, Style D

line hose or cover, an electrical test shall be performed before

or Style E.

reissuing the line hose or cover for service.

5.1.1 Type I—High-grade cis-1,4-polyisoprene rubber com-

pound of natural or synthetic origin, properly vulcanized.

7.2 Both ac and dc voltage retest methods are included in

5.1.2 Type II—Ozone resistant, made of any elastomer or

this section and either or both methods may be selected for

combination of elastomeric compounds.

electrical test.

5.1.3 The class designations are based on the electrical

7.2.1 Warning—In addition to other precautions, it is

properties in Specifications D1050 and D1049.

recommended that the test apparatus be designed to afford the

5.1.4 The style designations are based on the designs and

operator full protection in the performance of duties. Reliable

descriptions in Specifications D1050 and D1049.

means of de-energizing and grounding the high-voltage circuit

should be provided. It is particularly important to incorporate

positive means of grounding the high-voltage section of dc test

TABLE 1 Voltage Requirements Line Hose and Covers apparatus due to the likely presence of high-voltage capaci-

tance charges at the conclusion of the test. See ANSI C 39.5.

Class

AC Use DC Max

Designation of AC Retest DC Retest

7.2.2 To eliminate damaging ozone and possible flashover

Voltage, rms, Use Voltage

Hose and Voltage, rms Voltage, avg

max avg, V

along the line hose and cover openings, there should be a

Covers

sufficient flow of air into and around the line hose or cover and

0 1000 1500 5000 20 000

1 7500 11250 10 000 40 000 an exhaust system to adequately remove ozone from the test

2 17 000 25500 20 000 50 000

machine. Consistent ozone cutting and checking during the test

3 26 500 39750 30 000 60 000

procedure should be cause to ascertain the adequacy of the

4 36 000 54000 40 000 70 000

exhaust system.

F478 − 14a (2019)

A

TABLE 3 Flashover Clearances Between Electrodes

7.3 Any electrical retest shall be performed at normal room

Class Desig- AC Retest DC Retest

temperatures and on clean hose or covers at an electrical testing

nation,

facility.

Line Hose

in. mm in. mm

or Cover

7.4 Electrodes:

0 3 76 3 76

7.4.1 The entire area of each hose and cover shall be tested,

1 3 76 4 102

as nearly as practicable, between electrodes that apply the

2 5 127 6 152

3 7 178 8 203

electrical stress uniformly over the test area without producing

4 10 254 12 305

damaging corona or mechanical strain in the hose or cover. The

A

Flashover clearances are stated in terms of the shortest el

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F478 − 14a F478 − 14a (Reapproved 2019)

Standard Specification for

In-Service Care of Insulating Line Hose and Covers

This standard is issued under the fixed designation F478; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the in-service care, inspection, testing, and use voltage of insulating line hose and covers for

protection of workers from accidental contact with energized electrical wires or equipment.

1.2 The following safety hazards caveat applies only to the test method portion, Section 7, of this specification: This standard

does not purport to address all of the safety problems,concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability

of regulatory limitations prior to use. Specific precautionary statements are given in 7.2.1.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D1049 Specification for Rubber Insulating Covers

D1050 Specification for Rubber Insulating Line Hose

D2865 Practice for Calibration of Standards and Equipment for Electrical Insulating Materials Testing

F819 Terminology Relating to Electrical Protective Equipment for Workers

2.2 ANSI Standards:

C 84.1 Voltage Ratings for Electric Power Systems and Equipment (60 Hz)

C 39.5 Safety Requirements for Electrical and Electronic Measuring and Controlling Instrumentation

2.3 IEEE Standard:

IEEE Standard 4 Techniques for High Voltage Testing

3. Terminology

3.1 breakdown—the electrical discharge or arc occurring between the electrodes and through the equipment being tested.

3.2 bulk storage— the storage of hose or covers together with one or more layers piled neatly, but without the benefit of spacers,

supports, or special protective containers.

3.3 cover—an electrically insulated enclosure designed to be installed temporarily on various types of irregularly shaped

electrical equipment to protect personnel and equipment working in the close proximity.

3.4 designated person—an individual who is qualified by experience or training to perform an assigned task.

3.5 distorted—physically changed from the natural and original shape, caused by stress of any type.

3.6 electrical testing facility—a location with qualified personnel, testing equipment, and procedures for the inspection and

electrical testing of electrical insulating protective equipment.

This specification is under the jurisdiction of ASTM Committee F18 on Electrical Protective Equipment for Workers and is the direct responsibility of Subcommittee

F18.25 on Insulating Cover-Up Equipment.

Current edition approved Nov. 1, 2014April 1, 2019. Published December 2014April 2019. Originally approved in 1976. Last previous edition approved in 2014 as

F478 – 14F478 – 14a. DOI: 10.1520/F0478-14A.10.1520/F0478-14AR19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Available from Institute of Electrical and Electronics Engineers, Inc., 445 Hoes Lane, Piscataway, NJ 08854-4150.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F478 − 14a (2019)

3.7 electrode—the energized or grounded conductor portion of electrical test equipment which is placed near or in contact with

the material or equipment being tested.

3.8 flashover—the electrical discharge or arc occurring between electrodes and over or around, but not through, the equipment

being tested.

3.9 hose—an electrical insulating tube with a longitudinal slit designed to be installed temporarily on energized electrical wires.

3.10 ozone—a very active form of oxygen that may be produced by corona, arcing, or ultraviolet rays.

3.11 ozone cutting and checking —cracks produced by ozone in a material under mechanical stress.

3.12 retest—the tests given after the initial acceptance test, usually performed at regular periodic intervals or as required because

of physical inspection.

3.13 voltage, maximum retest—voltage, either ac rms or dc average, that is equal to the proof test voltage for new protective

equipment.

3.14 voltage, nominal design—a nominal value consistent with the latest revision of ANSI C84.1, assigned to the circuit or

system for the purpose of conveniently designating its voltage class.

3.15 voltage, retest— voltage, either ac rms or dc average, that used protective equipment must be capable of withstanding for

a specific test period without breakdown.

3.16 For definitions of other terms, refer to Terminology F819.

4. Significance and Use

4.1 Compliance with this specification should continue to provide personnel with insulating line hose and covers of known and

acceptable quality after initial acceptance in accordance with Specifications D1050 and D1049. The standards herein are to be

considered as minimum requirements.

4.2 A margin of safety shall be provided between the maximum use voltage and their class proof voltage in accordance with

Specifications D1050 and D1049, as shown in Table 1.

4.3 The user of this type of protective equipment shall be knowledgeable of and instructed in the correct and safe inspection

and use of this equipment.

5. Classification

5.1 Line hose covered in this specification are designed as Type I or Type II; Class 0, Class 1, Class 2, Class 3 or Class 4; Style

A, Style B, Style C or Style D. Covers covered in this standard are designated as Type I or Type II; Class 0, Class 1, Class 2, Class

3 or Class 4; Style A, Style B, Style C, Style D or Style E.

5.1.1 Type I—High-grade cis-1,4-polyisoprene rubber compound of natural or synthetic origin, properly vulcanized.

5.1.2 Type II—Ozone resistant, made of any elastomer or combination of elastomeric compounds.

5.1.3 The class designations are based on the electrical properties in Specifications D1050 and D1049.

5.1.4 The style designations are based on the designs and descriptions in Specifications D1050 and D1049.

6. Washing and Inspection

6.1 The recommended sequence of washing and inspection of contaminated insulating line hose and covers is as follows:

6.1.1 Washing,

6.1.2 Drying,

6.1.3 Inspection,

6.1.4 Marking, and

6.1.5 Packing for storage and shipment.

6.2 The hose and covers may be washed with a soap, mild non-bleaching detergent, or a cleaner recommended by the equipment

manufacturer. After washing, the hose and covers shall be rinsed thoroughly with water.

TABLE 1 Voltage Requirements Line Hose and Covers

Class

AC Use DC Max

Designation of AC Retest DC Retest

Voltage, rms, Use Voltage

Hose and Voltage, rms Voltage, avg

max avg, V

Covers

0 1000 1500 5000 20 000

1 7500 11250 10 000 40 000

2 17 000 25500 20 000 50 000

3 26 500 39750 30 000 60 000

4 36 000 54000 40 000 70 000

F478 − 14a (2019)

6.2.1 The cleaning agent shall not degrade the insulating qualities of the line hose and covers.

6.2.2 A commercial tumble-type washing machine may be used, where practicable, but caution must be observed to eliminate

any interior surfaces or edges that will cut, abrade, puncture, or pinch the hose or covers.

6.3 The hose and covers shall be air dried. The air temperature shall not be over 150°F (65.5°C). They may be suspended to

allow drainage and air circulation or dried in a commercial tumble-type automatic dryer. In an automatic dryer, caution must be

observed to eliminate any ozone-producing lamps and interior surfaces that will cut, abrade, puncture, or pinch the hose and covers.

6.4 Insulating line hose and covers shall be given a detailed inspection over the entire inner and outer surface for punctures,

cuts, severe ozone cutting, or any other obvious condition that would adversely affect performance.

6.5 The hose and covers shall be marked in accordance with Section 12.

7. Electrical Tests

7.1 Where the inspection specified in Section 6 indicates that there may be reason to suspect the electrical integrity of a line

hose or cover, an electrical test shall be performed before reissuing the line hose or cover for service.

7.2 Both ac and dc voltage retest methods are included in this section and either or both methods may be selected for electrical

test.

7.2.1 Warning—In addition to other precautions, it is recommended that the test apparatus be designed to afford the operator

full protection in the performance of duties. Reliable means of de-energizing and grounding the high-voltage circuit should be

provided. It is particularly important to incorporate positive means of grounding the high-voltage section of dc test apparatus due

to the likely presence of high-voltage capacitance charges at the conclusion of the test. See ANSI C 39.5.

7.2.2 To eliminate damaging ozone and possible flashover along the line hose and cover openings, there should be a sufficient

flow of air into and around the line hose or cover and an exhaust system to adequately remove ozone from the test machine.

Consistent ozone cutting and checking during the test procedure should be cause to ascertain the adequacy of the exhaust system.

7.3 Any electrical retest shall be performed at normal room temperatures and on clean hose or covers at an electrical testing

facility.

7.4 Electrodes:

7.4.1 The entire area of each hose and cover shall be tested, as nearly as practicable, between electrodes that apply the electrical

stress uniformly over the test area without producing damaging corona or mechanical strain in the hose or cover. The electrodes

shall be of such dimensions and so placed as to avoid flashover at the edges.

7.4.2 For hose, the inside electrode s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.