ASTM C911-06(2011)

(Specification)Standard Specification for Quicklime, Hydrated Lime, and Limestone for Selected Chemical and Industrial Uses

Standard Specification for Quicklime, Hydrated Lime, and Limestone for Selected Chemical and Industrial Uses

ABSTRACT

This specification covers lime and limestone products that are suitable for chemical and industrial uses such as in waste acid neutralization, agricultural liming, soil stabilization, asphalt, flue gas desulfurization, drinking water softening, waste and wastewater neutralization, and wastewater treatment plant residuals stabilization. The required chemical composition of quicklime, hydrated lime, and limestone for each selected end use are on the bases of the weight sample taken at the place of manufacture. Quicklime should be free of unslakable residues and should be capable of disintegrating in water to form suspensions of finely divided material.

SCOPE

1.1 This specification covers lime and limestone products suitable for the following chemical and industrial uses:

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C911 −06 (Reapproved 2011)

Standard Specification for

Quicklime, Hydrated Lime, and Limestone for Selected

Chemical and Industrial Uses

This standard is issued under the fixed designation C911; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

1.1 This specification covers lime and limestone products 2.1 ASTM Standards:

suitable for the following chemical and industrial uses: C25 Test Methods for Chemical Analysis of Limestone,

Quicklime, and Hydrated Lime

Cooking rags

Sulfite pulp

C50 Practice for Sampling, Sample Preparation, Packaging,

Silica brick

and Marking of Lime and Limestone Products

Other water treatment uses

C110 Test Methods for Physical Testing of Quicklime,

Calcium carbide

Grease

Hydrated Lime, and Limestone

Calcium silicate products

C400 Test Methods for Quicklime and Hydrated Lime for

Hypochlorite (bleach)

Neutralization of Waste Acid

The following uses are addressed in otherASTM standards:

C602 Specification for Agricultural Liming Materials

Use Standard(s)

C977 Specification for Quicklime and Hydrated Lime for

Neutralization of Waste Acid (Test C400

Soil Stabilization

Methods)

Agricultural Liming Materials C602

C1097 Specification for Hydrated Lime for Use in Asphalt

Soil Stabilization C977

Cement or Bituminous Paving Mixtures

Asphalt C1097

C1318 Test Method for Determination of Total Neutralizing

Flue Gas Desulfurization (Test Meth- C1318

ods)

Capability and Dissolved Calcium and Magnesium Oxide

Drinking Water Softening C1529

in Lime for Flue Gas Desulfurization (FGD)

Waste and Wastewater Neutralization C1529

C1529 Specification for Quicklime, Hydrated Lime, and

Wastewater Treatment Plant Residuals C1529 and D6249

(Biosolids) Stabilization

Limestone for Environmental Uses

D6249 GuideforAlkalineStabilizationofWastewaterTreat-

1.2 The type designations in Table 1 signify the following:

ment Plant Residuals

Limestone, high-calcium—CL

Limestone, dolomitic—DL

Limestone, magnesian—ML 3. Chemical Composition

Quicklime, high-calcium—CQ

3.1 The requirements for quicklime, hydrated lime, and

Quicklime, dolomitic—DQ

Quicklime, magnesian—MQ

limestonefortheselectedendusesareasshowninTable1,and

Hydrated lime, high-calcium—CH

are on the basis of the weight of sample taken at the place of

Hydrated lime, dolomitic—DH

manufacture, except as noted in footnote B after the require-

Hydrated lime, magnesian—MH

ment. In this case, the requirement is on a moisture and carbon

1.3 The buyer shall designate the use, as listed in Table 1,

dioxide-free basis.

and may specify one or more of the type designations in 1.1.

NOTE 1—Rags are cooked for the manufacture of paper in a digester

1.4 This standard does not purport to address all of the

under steam pressure with lime or with lime and soda ash. They are then

safety concerns, if any, associated with its use. It is the washed to eliminate as much of the noncellulose material as possible. A

standard composition without rejection limits is specified for the reason

responsibility of the user of this standard to establish appro-

that lime of either higher or lower total oxides, available lime, calcium

priate safety and health practices and determine the applicabil-

oxide, or calcium hydroxide than the standard, may safely be used under

ity of regulatory limitations prior to use.

suitable conditions for the purpose herein specified, depending primarily

upon economic considerations. In the present state of the art, it is believed

that the more serviceable type of specification for the product herein

This specification is under the jurisdiction of ASTM Committee C07 on Lime

and is the direct responsibility of Subcommittee C07.02 on Specifications and

Guidelines. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedJune1,2011.PublishedJuly2011.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 1979. Last previous edition approved in 2006 as C911 – 06. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

C0911-06R11. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

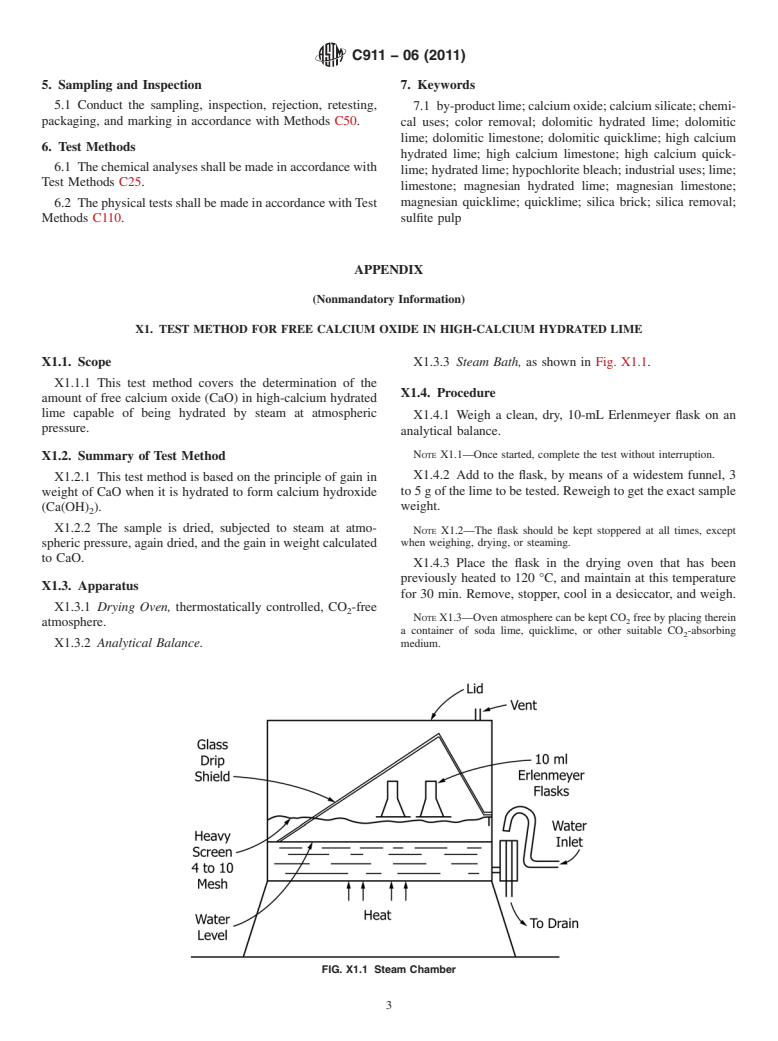

C911−06 (2011)

TABLE 1 Lime and Limestone for Chemical and Industrial Uses

Chemical Requirements, %

Approved

SiO +

ASTM Notes

SiO Avail-

Types of

CaO, insolu- Al O +

2 3

Use Specifi- Refer-

CaO +Fe O , MgO, CO , able Fe O , Chemical

2 3 2 2 3

Lime or

A +MgO ble Fe O ,

2 3

cation enced

min +Al O , max max CaO, max Other

2 3

Stone

min matter, max

max min

max

B

Cooking rags C45 1 CH . . . . . . . 64.3 . .

B

Cooking rags C45 1 CQ . . . . . . . 90.0 . .

C C

Sulfite pulp C46 2 CQ, MQ . 95.0 3.0 . . . . . . .

C C

Sulfite pulp C46 2 CL, ML . 95.0 3.0 . . . . . . .

C C C C

Silica brick C49 3 CH 90 . . 2.5 2.5 3.0 1.5 . .

h

Free CaO

C C C C

Silica brick C49 3 CQ 90 . . 2.5 2.5 3.0 1.5 . . #1.5

Other water C53 4 CQ, DQ, . 93.0 . . . . . . .

treatment MQ .

uses

C

Other water C53 4 CH, DH, . 93.0 . . . . . . .

treatment MH .

uses

C

P# 0.02

C C C C

Calcium C258CQ92 . . 1.75 4.0 2.0 1.0 . 0.5

h C

S# 0.2

Carbide

available

Grease C259 CH . . . 1.5 . 1.0 . . 0.5

h

Ca (OH)

$90

C C C C

Calcium sili- C415 CH 90 . . 1.3 2.5 3.0 1.5 . .

...

cate products

C C C C

Calcium sili- C415 CQ 90 . . 1.3 2.5 3.0 1.5 . .

...

cate products

C

Hypochlorite C433 5 CH . . . . . . . 68 0.3

...

(bleach)

Hypochlorite C433 5 CQ . . . . . . . 90 .

...

(bleach)

A

These specifications have all been incorporated into the current issue of this specification and are now discontinued. The discontinued specifications are available

through Global Engineering Documents, 15 Inverness Way, East Englewood, CO 80112–5704.

C45 Specification for Quicklime and Hydrated Lime for Cooking of Rags in Paper Manufacture

C46 Specification for Quicklime and Limestone for Sulfite Brick Manufacture

C49 Specification for Quicklime and Hydrated Lime for Silica Brick Manufacture

C53 Specification for Quicklime and Hydrated Lime for Water Treatment

C258 Specification for Quicklime for Calcium Carbide Manufacture

C259 Specification for Hydrated Lime for Grease Manufacture

C415 Specification for Quicklime and Hydrated Lime for Calcium Silicate Products

C433 Specification for Quicklime and Hydrated Lime for Hypochlorite Bleach Manufacture

B

Standard composition.

C

On a nonvolatile basis.

specified is that which defines a reasonable standard rather than one that moisture content, and the shapes are molded and dried. They are then

fixes actual rejection limits. It is generally recogni

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.