ASTM D6669-01a(2007)e1

(Practice)Standard Practice for Selecting and Constructing Exposure Scenarios for Assessment of Exposures to Alkyd and Latex Interior Paints

Standard Practice for Selecting and Constructing Exposure Scenarios for Assessment of Exposures to Alkyd and Latex Interior Paints

SIGNIFICANCE AND USE

Increasing attention is being paid to human exposure to airborne chemicals from products or materials used indoors, for two reasons:

5.1.1 Individuals spend substantial fractions of their time indoors.

5.1.2 Such exposures can occur repeatedly throughout one’lifetime.

The primary objectives of this practice are as follows:

5.2.1 To list the elements that need to be considered in developing a scenario to describe how exposure occurs to chemicals emitted from alkyd or latex interior paints.

5.2.2 To discuss procedures and alternatives for choosing and describing these elements.

Elements of an exposure scenario, in turn, are used to practice a subsequent step of estimating exposures through monitoring studies or computer modeling exercises.

Once exposures have been estimated, the results can be used to assess the potential impacts of a specific paint formulation on the health of exposed individuals, or to compare the relative impacts of alternative formulations.

Estimation of exposures, or comparisons of estimated exposures across alternative paint formulations, can lead to development of environmentally preferable products by minimizing adverse health effects for exposed individuals.

SCOPE

1.1 This practice provides procedures for constructing scenarios for assessment of inhalation exposure to airborne emissions of chemicals released from alkyd or latex paints that are used indoors.

1.2 The indoor environments covered in this practice, in terms of considerations for developing exposure scenarios, are residences and office buildings.

1.3 Elements of the exposure scenarios include the product and chemical(s) to be assessed, the indoor environment where the product is applied, application of the product, chemical emissions during and after product application, and location/activity patterns of individuals who may be exposed to the airborne chemical emissions.

1.4 Steps to be performed after developing exposure scenarios, such as monitoring, modeling and exposure/risk assessment, also are described.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:D6669–01a (Reapproved 2007)

Standard Practice for

Selecting and Constructing Exposure Scenarios for

Assessment of Exposures to Alkyd and Latex Interior

Paints

This standard is issued under the fixed designation D6669; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Editorially updated the References section in May 2007.

1. Scope D1356 Terminology Relating to Sampling and Analysis of

Atmospheres

1.1 This practice provides procedures for constructing sce-

D5116 Guide for Small-Scale Environmental Chamber De-

narios for assessment of inhalation exposure to airborne

terminations of Organic Emissions from Indoor Materials/

emissions of chemicals released from alkyd or latex paints that

Products

are used indoors.

D6178 Practice for Estimation of Short-term Inhalation

1.2 The indoor environments covered in this practice, in

Exposure to Volatile Organic Chemicals Emitted from

terms of considerations for developing exposure scenarios, are

Bedding Sets

residences and office buildings.

D6485 GuideforRiskCharacterizationofAcuteandIrritant

1.3 Elements of the exposure scenarios include the product

Effects of Short-Term Exposure to Volatile Organic

and chemical(s) to be assessed, the indoor environment where

Chemicals Emitted from Bedding Sets

the product is applied, application of the product, chemical

E741 Test Method for Determining Air Change in a Single

emissions during and after product application, and location/

Zone by Means of a Tracer Gas Dilution

activity patterns of individuals who may be exposed to the

airborne chemical emissions.

3. Terminology

1.4 Steps to be performed after developing exposure sce-

3.1 Definitions—For definitions of terms used in this prac-

narios, such as monitoring, modeling and exposure/risk assess-

tice refer to Terminology D1356.

ment, also are described.

3.2 Definitions of Terms Specific to This Standard:

1.5 This standard does not purport to address all of the

3.2.1 emission profile, n—a time-series of emission rates of

safety concerns, if any, associated with its use. It is the

one or more compounds.

responsibility of the user of this standard to establish appro-

3.2.2 exposure scenario, n—adescriptionofhowandwhere

priate safety and health practices and determine the applica-

an estimated exposure occurs, including (1) the location and

bility of regulatory limitations prior to use.

emission profile of the product or material that causes expo-

2. Referenced Documents sure, (2) the indoor environment where the individual is

exposed to airborne emissions from the product or material,

2.1 ASTM Standards:

and (3) the location and activity patterns of the exposed

D1005 Test Method for Measurement of Dry-Film Thick-

individual.

ness of Organic Coatings Using Micrometers

3.2.3 potential inhaled dose, n—the product of air concen-

D1212 Test Methods for Measurement of Wet Film Thick-

tration to which an individual is exposed times breathing rate

ness of Organic Coatings

times duration of exposure.

3.2.4 short-term exposure, n—an exposure of one week or

less in duration.

This practice is under the jurisdiction ofASTM Committee D22 onAir Quality

and is the direct responsibility of Subcommittee D22.05 on Indoor Air.

4. Summary of Practice

Current edition approved May 1, 2007. Published June 2007. Originally

4.1 This practice documents the items that need to be

approved in 2001. Last previous edition approved in 2001 as D6669 - 01a. DOI:

10.1520/D6669-01AR07E01.

described when developing an exposure scenario for assess-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ment of exposures to chemicals released indoors from alkyd or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

latex paints. Important considerations are discussed for each

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. item, along with examples or alternatives where appropriate.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D6669–01a (2007)

4.2 An exposure scenario—a description of how and where

an estimated exposure occurs—includes the following ele-

ments for paints used indoors (that is, interior paints):

4.2.1 The product and chemical(s) to be assessed.

4.2.2 The indoor environment where the product is applied,

including properties such as volume and airflow rate.

4.2.3 The amount and rate of product use.

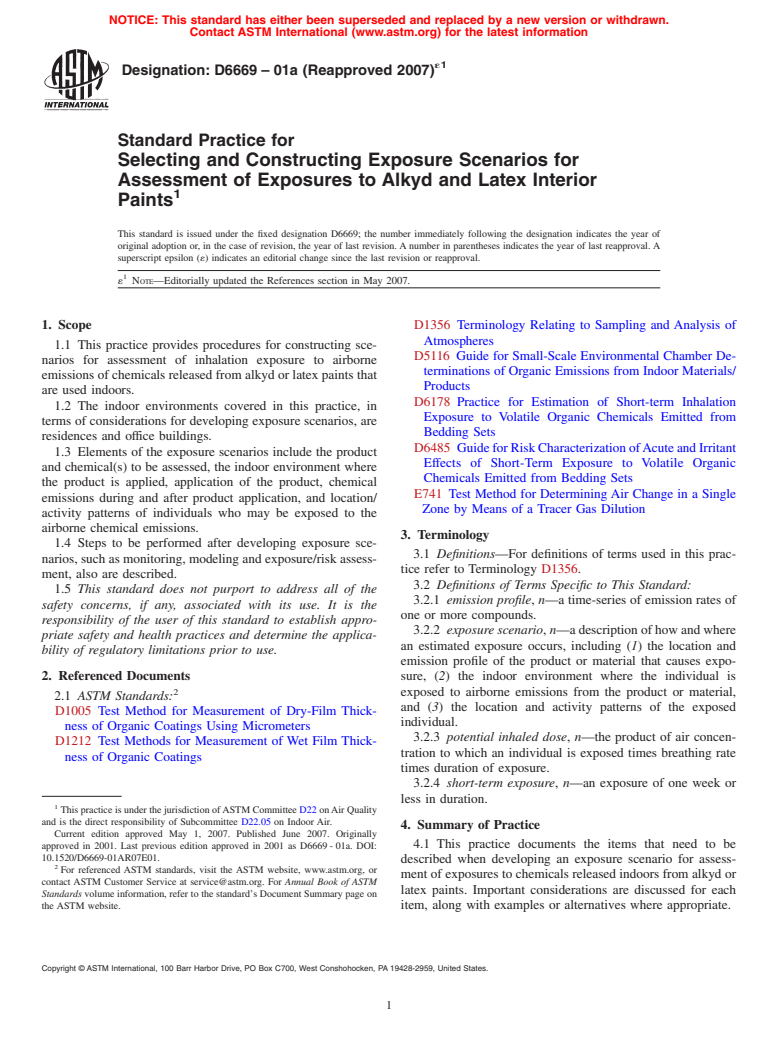

FIG. 1 Conceptualization of a Painted Building

4.2.4 Chemicalemissionsduringandafterpaintapplication.

4.2.5 Locations and breathing rates of an individual, or

6.1.2 The pattern and potential impact of chemical emis-

individuals, who may be exposed to the airborne chemical

sions over time can vary by chemical. Describe the following:

emissions.

6.1.2.1 Physical/chemical properties of the chemical(s) un-

4.3 Further considerations discussed in this practice include

derinvestigation,suchasmolecularweightandvaporpressure.

typical versus conservative assumptions, short-term versus

6.1.2.2 Role of the chemical(s) in the paint (for example,

long-termexposureperspectives,alkydversuslatexpaints,and

solvent).

residential versus office settings.

6.1.2.3 Weight fraction of the chemical(s) in the paint.

4.4 More than one exposure scenario can be constructed.

6.1.2.4 Toxicity information, such as that commonly re-

The practice also provides a list of elements to be included

ported in Material Safety Data Sheets.

when comparing multiple scenarios.

6.1.3 Chemical emissions can be affected by environmental

factors such as temperature and humidity. These factors are

5. Significance and Use

discussed in 6.2. The pattern of chemical emissions also can

5.1 Increasing attention is being paid to human exposure to

depend on factors such as the paint application method, the

airborne chemicals from products or materials used indoors,

amount of paint applied, and the rate of application. These

for two reasons:

factors are discussed in 6.3.

5.1.1 Individuals spend substantial fractions of their time

6.2 Describing the Indoor Environment Where the Product

indoors.

Is Applied:

5.1.2 Suchexposurescanoccurrepeatedlythroughoutone’s

6.2.1 Describe the size/volume and general configuration of

lifetime.

the environment (for example, a two-story residence consisting

5.2 The primary objectives of this practice are as follows:

3 3

ofeightroomswithavolumeof15000ft or425m ).Specific

5.2.1 To list the elements that need to be considered in

considerations for residential versus office buildings are dis-

developing a scenario to describe how exposure occurs to

cussed under 6.6. Distributions for volumes of U.S. residences

chemicals emitted from alkyd or latex interior paints.

are presented in the Exposure Factors Handbook (1).

5.2.2 To discuss procedures and alternatives for choosing

6.2.2 Describe the indoor-outdoor air change rate (for ex-

and describing these elements.

-1

ample, in h or air changes per hour, ACH) and associated

5.3 Elements of an exposure scenario, in turn, are used to

conditions such as opening of doors/windows and use of

practice a subsequent step of estimating exposures through

exhaust/circulation fans. Distributions for air change rates of

monitoring studies or computer modeling exercises.

U.S. residences are presented in the Exposure Factors Hand-

5.4 Once exposures have been estimated, the results can be

book (1). Persily (2) has measured air change rates in a limited

used to assess the potential impacts of a specific paint

set of office buildings.

formulation on the health of exposed individuals, or to com-

6.2.3 Discussion—When conducting an actual exposure

pare the relative impacts of alternative formulations.

assessment, as opposed to constructing an exposure scenario to

5.5 Estimation of exposures, or comparisons of estimated

guide the assessment, it may be preferable to replace assump-

exposures across alternative paint formulations, can lead to

tions regarding air change rates with actual measurements,

development of environmentally preferable products by mini-

using methods such as those described in Test Method E741.

mizing adverse health effects for exposed individuals.

6.2.4 Describe the fraction of the building (or building

volume) that is being painted. It usually is convenient to

6. Procedures for Developing Exposure Scenarios

conceptualize the building as consisting of two indoor air

6.1 Describing the Product and Chemical(s):

spaces—a painted space and an unpainted space, with commu-

6.1.1 Chemical emissions can vary according to the type of

nicating air flows between the two spaces—as illustrated in

paint and painted substrate. Describe the following:

Fig. 1.

6.1.1.1 Alkyd or latex paint.

6.2.5 Describe the airflow rates between the painted and

6.1.1.2 Flat, gloss, or semi-gloss paint.

unpainted spaces. The flows in the two directions are not

6.1.1.3 Physical properties such as paint density (for ex-

necessarilyequal,butitisoftenconvenienttoassumeso.More

ample, in pounds per gallon or grams per cm ).

than two indoor spaces can be specified, but the number of

6.1.1.4 Typical applications of the paint, in terms of (1) type

airflow rates will increase rapidly (for example, 2 rates for 2

of substrate to which it is applied (for example, gypsum

spaces, 6 rates for 3 spaces, 12 rates for 4 spaces).

wallboard vs. wood/trim vs. metal) and (2) type of room (for

example, bedroom vs. bathroom or kitchen).

6.1.1.5 Typical warnings or advice on the paint container

The boldface numbers in parentheses refer to the list of references at the end of

(for example, “Use in a well-ventilated area”). this practice.

´1

D6669–01a (2007)

6.2.6 Discussion—In specifying air flows it is important to 6.3.5.3 If film thickness is known (see Test Methods D1005

maintain a flow balance; that is, for any air space or zone, the and D1212), it can be converted to total coverage using the

sum of air flows entering the zone should equal the sum of following formula:

exiting air flows. One relatively simple means of accomplish-

Coverage per coat ~ft /gal! 5 1600/film thickness ~mil!, or (2)

ing this is to assume that the airflow rates to/from outdoors are

Coverage per coat ~m /gal! 5 148.5/film thickness ~mil!,

proportional to the air change rate (for example, if the zone

3 -1

volume is 100 m and the air change rate is 0.5 h , then the

where:

airflow rate to/from outdoors is 50 m /h) and that the airflow

1 mil = 1/1000 in.

rates between the two zones are the same in both directions.As

The amount applied can then be calculated as in 6.3.5.2.

with other elements describing an exposure scenario, assump-

6.3.5.4 If the volume of the painted space is known and if

tions here ultimately should be replaced by measurements

walls or ceilings are being painted, then the painted surface

where possible. However, airflow measurements (typically

area can be estimated from the following relationships given in

involving the use of multiple tracer gases) are not simple to

the Exposure Factors Handbook (1) for residences:

perform. A possible alternative is to use an indoor-air model

2 3 2 3

Wall area ~ft ! ' volume ~ft ! 3 0.29 ~or m ' m 3 0.95! (3)

that can model air flows, such as CONTAM (3) or COMIS (4).

The MCCEM model (5) has a built-in library of airflow rates 2 3 2 3

Ceiling area ~ft ! ' volume ~ft ! 3 0.13 ~or m ' m 3 0.43!

for a variety of residences.

The amount applied can then be calculated as in 6.3.5.2.

6.2.7 Describe the outdoor concentration for the chemi-

6.3.6 Indicate the product application rate (for example, gal

cals(s) of concern assumed to prevail during and following the

per h). This rate can depend on factors such as application

painting event. Often the outdoor concentration of the chemi-

method (roller, brush, spray) and the number of painters.

cal(s) being assessed is low relative to that indoors, such that

Indicate the application method and number of painters along

an assumption of zero concentration outdoors is not unreason-

with the rate.

able. Even if a non-zero-concentration is assumed, the estima-

6.3.7 Indicate the total duration of the painting event. The

tion process can be simplified by assuming that the outdoor

duration can be calculated by dividing the total amount of

concentration is constant over time.

primerorpaint,orbothused(ingallons)bytheapplicationrate

6.2.8 Describe the environmental conditions of the indoor

(in gal per h), assuming a constant application rate. The drying

space where paint is to be applied. Conditions such as

time(s) between successive coats needs to be added to the

temperatureandrelativehumidityareparticularlyimportant,as

painting time to obtain the total duration. In cases where the

these can affect the rate of chemical emissions.

duration is relatively long (for example, > 8 h), indicate the

6.2.9 Indoor-air concentrations of chemicals released from

number of painting hours per day and the resultant number of

paint can be affected by certain types of materials that absorb

painting days.

(and sometimes desorb) emitted chemicals. Describe wall,

6.4 Describing the Chemical Emissions from the Paint:

ceiling and floor materials as well as furnishings such as

6.4.1 General Nature of Emissions Profile. When primer or

upholstered furniture or draperies. The preferred method for

paint is applied quickly to a small specimen (as when conduct-

documenting the presence of such materials is to note their

ing a small-chamber test to characterize emissions), the chemi-

loading rates (that is, ratio of surface area to indoor volume, in

2 3 2 3

cal emissions tend to be higher at first and then to decline over

units of ft /ft or m /m ).

time. Studies of airborne chemical concentrations in chambers

6.3 Describing the Product Application:

(6, 7), following instantaneous application of paint to a

6.3.1 Describe the substrate that is being painted—gypsum

substrate such as gypsum wallboard, indicate that the declining

wallboard, wood, metal, etc.—and indicate whether it ever has

emission rate tends to follow a single-exponential model for

been painted before.

chemicals released from alkyd paint and a double-exponential

6.3.2 Indicate whether the substrate is being painted with

model for chemicals released from latex paint.

primer only, paint only, or primer plus paint.

6.4.2 Direct Estimation of Emissions Profile. An emission

6.3.3 Indicate the number of coats of primer/paint being

profile for the chemical(s) of concern released from pr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.