ASTM D1510-12

(Test Method)Standard Test Method for Carbon Black—Iodine Adsorption Number

Standard Test Method for Carbon Black—Iodine Adsorption Number

SIGNIFICANCE AND USE

4.1 The iodine adsorption number is useful in characterizing carbon blacks. It is related to the surface area of carbon blacks and is generally in agreement with nitrogen surface area. The presence of volatiles, surface porosity, or extractables will influence the iodine adsorption number. Aging of carbon black can also influence the iodine number.

SCOPE

1.1 This test method covers the determination of the iodine adsorption number of carbon black.

1.1.1 Method A is the original test method for this determination and Method B is an alternate test method using automated sample processing and analysis.

1.2 The iodine adsorption number of carbon black has been shown to decrease with sample aging. New SRB HT Iodine Standards have been produced that exhibit stable iodine number upon aging. One or more of these SRB HT Iodine Standards are recommended for daily monitoring (x-charts) to ensure that the results are within the control limits of the individual standard. Use all SRB HT Iodine Standards for standardization of iodine testing (see Section 8) when target values cannot be obtained.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1510 − 12

StandardTest Method for

1

Carbon Black—Iodine Adsorption Number

This standard is issued under the fixed designation D1510; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Standards in the Rubber and Carbon Black Manufacturing

Industries

1.1 This test method covers the determination of the iodine

D4821 Guide for Carbon Black—Validation of Test Method

adsorption number of carbon black.

Precision and Bias

1.1.1 MethodAis the original test method for this determi-

nation and Method B is an alternate test method using

3. Summary of Test Methods

automated sample processing and analysis.

3.1 In Test Method A, a weighed sample of carbon black is

1.2 The iodine adsorption number of carbon black has been

treated with a portion of standard iodine solution and the

shown to decrease with sample aging. New SRB HT Iodine

mixture shaken and centrifuged. The excess iodine is then

Standards have been produced that exhibit stable iodine

titrated with standard sodium thiosulfate solution, and the

number upon aging. One or more of these SRB HT Iodine

adsorbed iodine is expressed as a fraction of the total mass of

Standards are recommended for daily monitoring (x-charts) to

black.

ensure that the results are within the control limits of the

3.2 In Test Method B, a weighed sample of carbon black is

individual standard. Use all SRB HT Iodine Standards for

treated with a portion of standard iodine solution using an

standardization of iodine testing (see Section 8) when target

automated sample processor where the mixture is stirred,

values cannot be obtained.

settled and aliquoted for automatic titration. The excess iodine

1.3 The values stated in SI units are to be regarded as

is titrated with standard sodium thiosulfate solution, and the

standard. No other units of measurement are included in this

adsorbed iodine is expressed as a fraction of the total mass of

standard.

black.

1.4 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.1 Theiodineadsorptionnumberisusefulincharacterizing

priate safety and health practices and determine the applica-

carbon blacks. It is related to the surface area of carbon blacks

bility of regulatory limitations prior to use.

and is generally in agreement with nitrogen surface area. The

presence of volatiles, surface porosity, or extractables will

2. Referenced Documents

influence the iodine adsorption number.Aging of carbon black

2

can also influence the iodine number.

2.1 ASTM Standards:

D1799 Practice for Carbon Black—Sampling Packaged

5. Apparatus

Shipments

D1900 Practice for Carbon Black—Sampling Bulk Ship- 5.1 Vials, glass, optically clear type, with polyethylene

3

stoppers, 45 cm .

ments

D4483 Practice for Evaluating Precision for Test Method

5.2 Gravity Convection Drying Oven, capable of maintain-

ing 125 6 5°C.

5.3 Buret, either of the following may be used:

1

This test method is under the jurisdiction ofASTM Committee D24 on Carbon 3 3

5.3.1 Digital Buret, 25-cm capacity, with 0.01-cm incre-

Black and is the direct responsibility of Subcommittee D24.21 on Carbon Black

ment counter and zero reset control, or

Surface Area and Related Properties.

3

Current edition approved June 1, 2012. Published August 2012. Originally 5.3.2 Buret, glass 25-cm , Class A, side-arm filling, gradu-

3

approved in 1957. Last previous edition approved in 2011 as D1510 – 11a. DOI:

ated in 0.05 cm and with automatic zero.

10.1520/D1510-12.

3

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 5.4 Repetitive Dispenser, 25-cm capacity, 60.1% repro-

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ducibility and calibrated to within 60.03-cm accuracy.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 5.5 Balance, analytical, with 0.1-mg sensitivity.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1510 − 12

5.6 Centrifuge, with minimum speed of 105 rad/s (1000 r/ 6.9 Deionized Water.

min).

3

7. Standardization of Solutions

5.7 VolumetricFlask, 2000-cm with standard taper stopper.

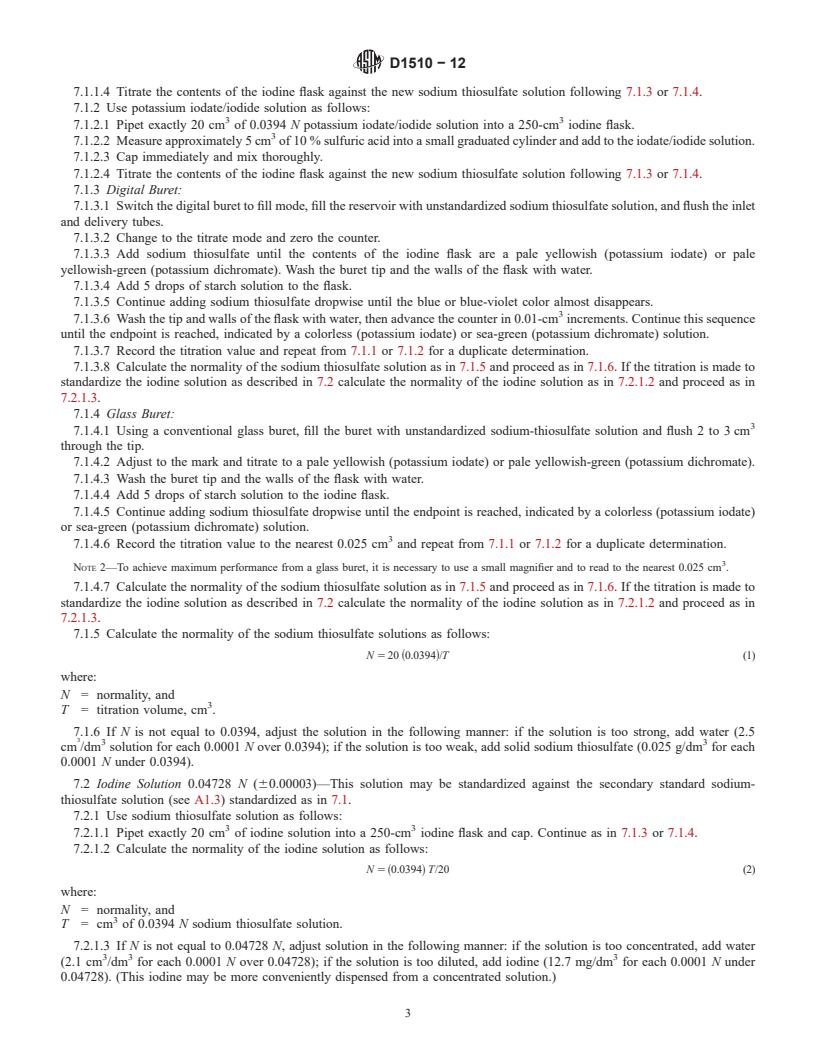

7.1 Sodium Thiosulfate, 0.0394 N (60.00008):

5.8 Funnel, large diameter, with standard taper joint to fit

3

7.1.1 Use potassium dichromate solution as follows:

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1510 − 11a D1510 − 12

Standard Test Method for

1

Carbon Black—Iodine Adsorption Number

This standard is issued under the fixed designation D1510; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method covers the determination of the iodine adsorption number of carbon black.

1.1.1 Method A is the original test method for this determination and Method B is an alternate test method using automated

sample processing and analysis.

1.2 The iodine adsorption number of carbon black has been shown to decrease with sample aging. New SRB HT Iodine

Standards have been produced that exhibit stable iodine number upon aging. One or more of these SRB HT Iodine Standards are

recommended for daily monitoring (x-charts) to ensure that the results are within the control limits of the individual standard. Use

all SRB HT Iodine Standards for standardization of iodine testing (see Section 8) when target values cannot be obtained.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1799 Practice for Carbon Black—Sampling Packaged Shipments

D1900 Practice for Carbon Black—Sampling Bulk Shipments

D4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries

D4821 Guide for Carbon Black—Validation of Test Method Precision and Bias

3. Summary of Test Methods

3.1 In Test Method A, a weighed sample of carbon black is treated with a portion of standard iodine solution and the mixture

shaken and centrifuged. The excess iodine is then titrated with standard sodium thiosulfate solution, and the adsorbed iodine is

expressed as a fraction of the total mass of black.

3.2 In Test Method B, a weighed sample of carbon black is treated with a portion of standard iodine solution using an automated

sample processor where the mixture is stirred, settled and aliquoted for automatic titration. The excess iodine is titrated with

standard sodium thiosulfate solution, and the adsorbed iodine is expressed as a fraction of the total mass of black.

4. Significance and Use

4.1 The iodine adsorption number is useful in characterizing carbon blacks. It is related to the surface area of carbon blacks and

is generally in agreement with nitrogen surface area. The presence of volatiles, surface porosity, or extractables will influence the

iodine adsorption number. Aging of carbon black can also influence the iodine number.

5. Apparatus

3

5.1 Vials, glass, optically clear type, with polyethylene stoppers, 45 cm .

5.2 Gravity Convection Drying Oven, capable of maintaining 125 6 5°C.

1

This test method is under the jurisdiction of ASTM Committee D24 on Carbon Black and is the direct responsibility of Subcommittee D24.21 on Carbon Black Surface

Area and Related Properties.

Current edition approved May 1, 2011June 1, 2012. Published June 2011August 2012. Originally approved in 1957. Last previous edition approved in 2011 as

D1510 – 11.D1510 – 11a. DOI: 10.1520/D1510-11A.10.1520/D1510-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1510 − 12

5.3 Buret, either of the following may be used:

3 3

5.3.1 Digital Buret, 25-cm capacity, with 0.01-cm increment counter and zero reset control, or

3 3

5.3.2 Buret, glass 25-cm , Class A, side-arm filling, graduated in 0.05 cm and with automatic zero.

3 3

5.4 Repetitive Dispenser, 25-cm capacity, 60.1% reproducibility and calibrated to within 60.03-cm accuracy.

5.5 Balance, analytical, with 0.1-mg sensitivity

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.