ASTM F562-02

(Specification)Standard Specification for Wrought 35Cobalt-35Nickel-20Chromium-10Molybdenum Alloy for Surgical Implant Applications (UNS R30035)

Standard Specification for Wrought 35Cobalt-35Nickel-20Chromium-10Molybdenum Alloy for Surgical Implant Applications (UNS R30035)

SCOPE

1.1 This specification covers requirements of wrought 35cobalt-35nickel-20chromium-10molybdenum alloy (UNS R30035) in the form of bar and wire, used for the manufacture of surgical implants. This alloy depends on combinations of work-strengthening, and work-strengthening and aging to attain a variety of combinations of strength and ductility.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI equivalents of the inch-pound units may be approximate.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 562 – 02

Standard Specification for

Wrought 35Cobalt-35Nickel-20Chromium-10Molybdenum

1

Alloy for Surgical Implant Applications (UNS R30035)

This standard is issued under the fixed designation F 562; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

7

1. Scope* Nickel Alloys and Cobalt Alloys

2.4 American Society for Quality Standard:

1.1 This specification covers requirements of wrought

ASQ C1 Specification of General Requirements for a Qual-

35cobalt-35nickel-20chromium-10molybdenum alloy (UNS

8

ity Program

R30035) in the form of bar and wire, used for the manufacture

2.5 Society of Automotive Engineers:

of surgical implants. This alloy depends on combinations of

SAE J1086 Practice for Numbering Metals and Alloys

work-strengthening, and work-strengthening and aging to at-

7

(UNS)

tain a variety of combinations of strength and ductility.

1.2 The values stated in inch-pound units are to be regarded

3. Classification

asthestandard.TheSIequivalentsoftheinch-poundunitsmay

3.1 Bar—Round Bars and Flats from 0.1875 in. (4.75 mm)

be approximate.

to 4.00 in. (101.60 mm) in diameter or thickness (other shapes

2. Referenced Documents by special order).

3.2 Wire—Rounds less than 0.1875 in. (4.75 mm) in diam-

2.1 ASTM Standards:

eter.

A 751 Test Methods, Practices, and Terminology for

2

Chemical Analysis of Steel Products

4. Ordering Information

3

E8 TestMethodsforTensionTestingofMetallicMaterials

4.1 Inquiries and orders for material under this specification

E112 Test Methods for Determining the Average Grain

3 shall include the following information:

Size

4.1.1 Quantity,

E 354 Test Methods for Chemical Analysis of High-

4.1.2 ASTM designation and date of issue,

Temperature, Electrical, Magnetic, and Other Similar Iron,

4 4.1.3 Mechanical properties (Section 7),

Nickel, and Cobalt Alloys

4.1.4 Form (bar or wire),

F 981 Practice for Assessment of Compatibility of Bioma-

4.1.5 Applicable dimensions, including size, thickness,

terials for Surgical Implants with Respect to Effect of

5 width, and length (exact, random, multiples), or drawing

Materials on Muscle and Bone

number,

2.2 ISO Standards:

4.1.6 Condition (5.1),

ISO 5832/6 Implants for Surgery—Metallic Materials Part

6 4.1.7 Finish (5.2),

6: Wrought cobalt-nickel-chromium-molybdenum alloy

4.1.8 Special tests, if applicable, and

ISO 6892 Metallic Materials—Tensile Testing at Ambient

6 4.1.9 Other requirements.

Temperature

2.3 Aerospace Material Specification:

5. Materials and Manufacture

AMS 2269 Chemical Check Analysis Limits—Wrought

5.1 Condition—Bar and wire shall be furnished, as speci-

fied, in the solution-annealed, cold-worked, or cold-worked

1

and aged condition.

This specification is under the jurisdiction of ASTM Committee F04 on

Medical and Surgical Materials and Devices and is the direct responsibility of

5.2 Finish—Types of finish available in bar and wire

Subcommittee F04.12 on Metallurgical Materials.

productsarecolddrawn,pickled,ground,groundandpolished,

Current edition approved April 10, 2002. Published June 2002. Originally

or as specified by the purchaser.

published as F 562 – 78. Last previous edition F 562 – 00.

2

Annual Book of ASTM Standards, Vol 01.03.

3

Annual Book of ASTM Standards, Vol 03.01.

4 7

Annual Book of ASTM Standards, Vol 03.05. Available from Society of Automotive Engineers, Inc., 400 Commonwealth

5

Annual Book of ASTM Standards, Vol 13.01. Drive, Warrendale, PA 15096–0001.

6 8

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700 Available from American Society for Quality, 600 N. Plankinton Ave.,

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. Milwaukee, WI 53203.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F562–02

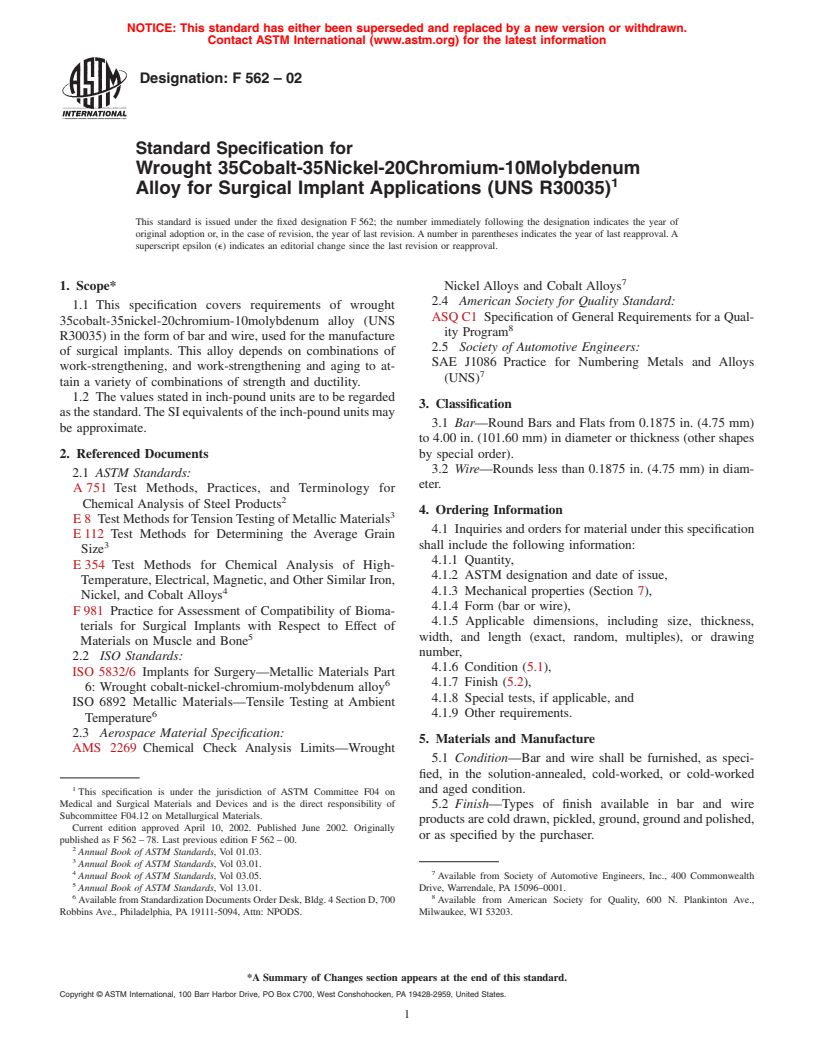

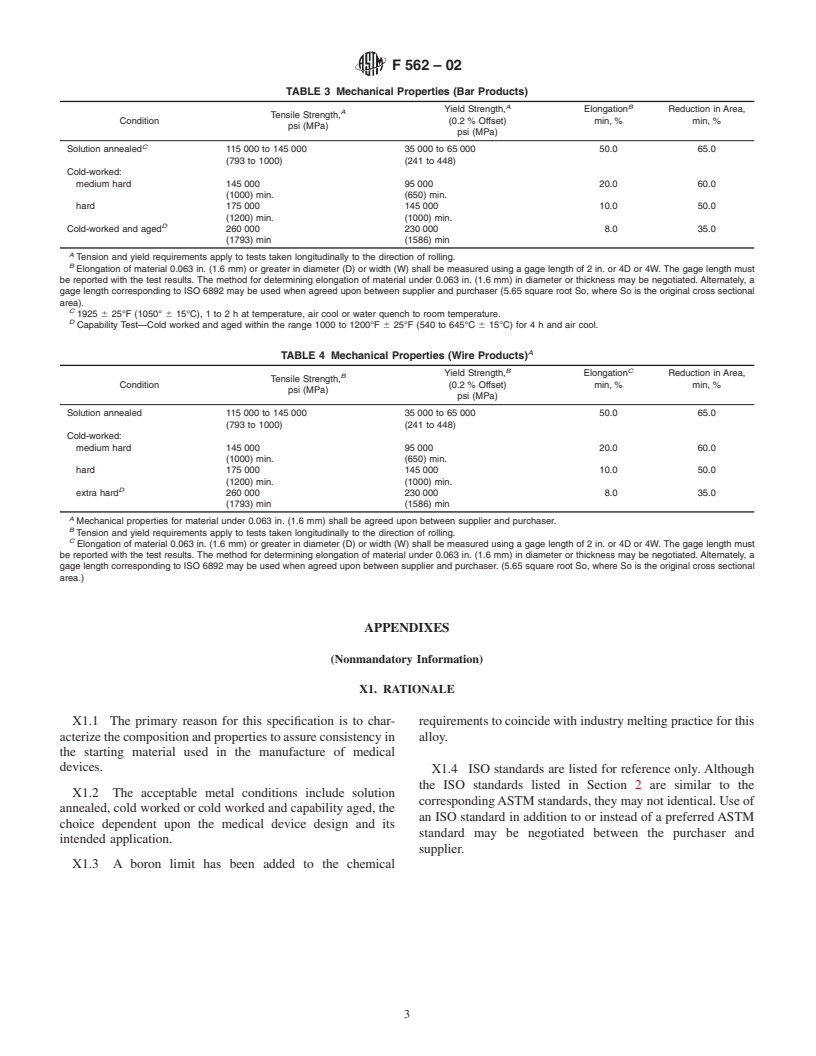

A,B

TABLE 2 Product Analysis Tolerances

6. Chemical Requirements

Tolerance Under the Minimum or

6.1 Chemical analysis shall be in accordance with Test

Element

C

Over the Maximum Limit % (mass/mass)

Methods E 354 and A 751.

Carbon 0.01

6.2 The cobalt-35nickel-20chromium-10molybdenum alloy

Manganese 0.03

shall conform to the chemical requirements prescribed inTable

Silicon 0.02

Phosphorus 0.005

1. The supplier shall not ship material that is outside the limits

Sulfur 0.005

specified in Table 1.

Chromium 0.25

6.2.1 Requirements for the major and minor elemental

Nickel 0.30

Molybdenum 0.15

constituents are listed in Table 1. Also listed are important

Iron 0.05

residual elements.Analysis for elem

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.