ASTM B877-96

(Test Method)Standard Test Method for Gross Defects and Mechanical Damage in Metallic Coatings by the Phosphomolybdic Acid (PMA) Method

Standard Test Method for Gross Defects and Mechanical Damage in Metallic Coatings by the Phosphomolybdic Acid (PMA) Method

SCOPE

1.1 This test standard covers equipment and methods for using phosphomolybdic acid (PMA) to detect gross defects and mechanical damage including wear through in metallic coatings of gold, silver, or palladium. These metals comprise the topmost metallic layers over substrates of nickel, copper, or copper alloys.

1.2 Recent reviews of porosity testing, which include those for gross defects, and testing methods can be found in the lierature. An ASTM guide to the selection of porosity and gross defect tests for electrodeposits and related metallic coatings is available as Guide B 765. Other related porosity and gross defects test standards are Test Methods B 735, B 741, B 798, B 799, B 809, and B 866.

1.3 The values stated in SI units are the preferred units. Those in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued. NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information. Contact ASTM International (www.astm.org) for the latest information.

Designation: B 877 – 96

Standard Test Method for

Gross Defects and Mechanical Damage in Metallic Coatings

by the Phosphomolybdic Acid (PMA) Method

This standard is issued under the fixed designation B 877; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope B 735 Test Method for Porosity in Gold Coatings on Metal

Substrates by Nitric Acid Vapor

1.1 This test standard covers equipment and methods for

B 741 Test Method for Porosity in Gold Coatings on Metal

using phosphomolybdic acid (PMA) to detect gross defects and

Substrates by Paper Electrography

mechanical damage including wear through in metallic coat-

B 765 Guide to the Selection of Porosity Tests for Elec-

ings of gold, silver, or palladium. These metals comprise the

trodeposits and Related Metallic Coatings

topmost metallic layers over substrates of nickel, copper, or

B 798 Test Method for Porosity in Gold or Palladium

copper alloys.

Coatings on Metal Substrates by Gel-Bulk Electrography

1.2 Recent reviews of porosity testing, which include those

B 799 Test Method for Porosity in Gold and Palladium

for gross defects, and testing methods can be found in the

,

2 3 Coatings by Sulfurous Acid/Sulfur-Dioxide Vapor

literature. An ASTM guide to the selection of porosity and

B 809 Test Method for Porosity in Metallic Coatings by

gross defect tests for electrodeposits and related metallic

Humid Sulfur Vapor (“Flowers-of-Sulfur”)

coatings is available as Guide B 765. Other related porosity

B 866 Test Method for Gross Defects and Mechanical

and gross defects test standards are Test Methods B 735,

Damage in Metallic Coatings by Polysulfide Immersion

B 741, B 798, B 799, B 809, and B 866.

1.3 The values stated in SI units are the preferred units.

3. Terminology

Those in parentheses are for information only.

3.1 Definitions—Many terms in this test method are defined

1.4 This standard does not purport to address all of the

in Terminology B 374 or B 542.

safety concerns, if any, associated with its use. It is the

3.2 Definitions of Terms Specific to This Standard:

responsibility of the user of this standard to establish appro-

3.2.1 base metal, n, is any metal other than gold, silver,

priate safety and health practices and determine the applica-

platinum, palladium, iridium, or rhodium. Typical base metals

bility of regulatory limitations prior to use.

used as underplates or substrates are copper, nickel, tin, lead,

2. Referenced Documents and their alloys.

3.2.2 defect indications, n—colored droplets resulting from

2.1 ASTM Standards:

the reaction between the PMA reagent and the underlying

B 374 Terminology Relating to Electroplating

metal.

B 488 Specification for Electrodeposited Coatings of Gold

3.2.3 gross defects, n, are those breaks in the coating that

for Engineering Use

expose relatively large areas of underlying metal to the

B 542 Terminology Relating to Electrical Contacts and

environment. Gross defects include those produced by me-

Their Use

chanical damage and wear, as well as as-plated large pores with

B 679 Specification for Electrodeposited Coatings of Palla-

diameters an order of magnitude greater than intrinsic porosity

dium for Engineering Use

and networks of microcracks.

B 689 Specification for Electroplated Engineering Nickel

Coatings

NOTE 1—Large pores and microcrack networks indicate serious devia-

tions from acceptable coating practice (dirty substrates and contaminated

or out-of-balance plating baths).

This test method is under the jurisdiction of ASTM Committee B-8 on Metallic

3.2.4 intrinsic porosity, n—the normal porosity that is

and Inorganic Coatingsand is the direct responsibility of Subcommittee B08.10.

present, to some degree, in all commercial thin electrodeposits

Current edition approved Oct. 10, 1996. Published December 1996.

Clarke, M., “Porosity and Porosity Tests,” Properties of Electrodeposits, ed. by

(precious metal coatings for engineering purposes) that will

Sand, Leidheiser, and Ogburn, The Electrochemical Society, 1975, p. 122.

generally follow an inverse relationship with thickness.

Krumbein, S. J., “Porosity Testing of Contact Platings,” Trans. Connectors and

Interconnection Technology Symposium, Philadelphia, PA, October 1987, p. 47.

NOTE 2—Intrinsic porosity is due to small deviations from ideal plating

Annual Book of ASTM Standards, Vol 02.05.

and surface preparation conditions. Scanning electron microscope (SEM)

Annual Book of ASTM Standards, Vol 03.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued. NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information. Contact ASTM International (www.astm.org) for the latest information.

B877–96

studies have shown the diameter of such pores at the plating surface is 1

5.3 This test is used to detect underplate and substrate metal

to 2 μm so only small areas of underlying metal are exposed to the

exposed through normal wear during relative motions (mating

environment.

of electrical contacts) or through mechanical damage. As such,

3.2.5 measurement area, n, that portion or portions of the

it is a sensitive pass/fail test and, if properly performed, will

surface that is examined for the presence of gross defects or rapidly detect wear through to base metals or scratches that

mechanical damage and wear through. The measurement area

enter the base metal layers.

shall be indicated on the drawings of the parts or by the 5.4 This test is relatively insensitive to small pores. It is not

provision of suitably marked samples.

designed to be a general porosity test and shall not be used as

3.2.6 metallic coatings, n, include electrodeposits, clad- such. The detection of pores will depend upon their sizes and

dings, or other metallic layers applied to the substrate. The

the length of time that the reagent remains a liquid.

coating can comprise a single metallic layer or a combination 5.5 This test cannot distinguish degrees of wear through or

of metallic layers (gold over palladium).

whether the wear through is to nickel or copper. Once base

3.2.7 porosity (general), n, is the presence of any hole, metal is exposed, the colored molybdenum complex is formed.

crack, or other defect that exposes the underlying metal to the

While relatively small area defects (compared to the area of the

environment. droplet) may be seen at the bottom of the drop as tiny colored

3.2.8 underplate, n—a metallic coating layer between the

regions immediately after applying the PMA, any larger areas

substrate and the topmost metallic coating. The thickness of an of exposed base metal will cause the entire droplet to turn dark

underplate is usually greater than 1 μm, in contrast to a strike

instantly.

or flash, which is usually thinner. 5.6 The PMA test also detects mechanical damage that

3.2.9 wear through, n—the exposure of underplate or sub- exposes underplate and substrate metal. Such damage may

strate as a direct result of wear. Wear through is an observable

occur in any postplating operation or even at the end of the

phenomenon. plating operation. It can often occur in assembly operations

3.2.10 wear track, n—a mark that indicates the path along

where plated parts are assembled into larger units by mechani-

which physical contact has been made during a sliding process cal equipment.

(the mating and unmating of an electrical contact).

5.7 The PMA test identifies the locations of exposed base

metal. The extent and location of these exposed areas may or

4. Summary of Test Method

may not be detrimental to performance. The PMA test is not

4.1 This test method involves the use of a solution of

recommended for predictions of product performance, nor is it

phosphomolybdic acid (PMA), which is a solid complex of

intended to simulate field failure mechanisms. For such contact

molybdenum trioxide, Mo O , and phosphoric acid, H PO .

2 3 3 4 performance evaluations, an environmental test known to

In this state, molybdenum is very reactive with many free

simulate actual failure mechanisms should be used.

metals and may be used to detect exposed underplates and

5.8 The PMA test is primarily intended for the evaluation of

substrate metals. The part is exposed briefly to fumes of

individual samples rather than large sample lots, since evalu-

hydrochloric acid to remove oxides in the defect region. A

ations are normally carried out one at a time under the

small drop of the aqueous PMA solution is applied to the spot

microscope (see Section 10).

in question using an applicator. If it contacts base metals from

5.9 This test is destructive. Any parts exposed to the PMA

exposed underplate or substrate, the Mo O will immediately

2 3

test shall not be placed in service.

be reduced to lower oxides, forming the intensely colored,

6. Apparatus

molybdenum blue complex (heteropoly blue).

4.2 This test may not be suitable for some precious metal 6.1 In addition to the normal equipment (beakers, weighing

alloy coatings that contain significant concentrations of non-

balances, funnels, etc.) that are a part of every chemical

precious metals (base metals) like nickel or copper. (See 3.2.1.) laboratory.

4.3 The reagents in this test also react with tin, lead, and

6.2 Microscope, Optical, Stereo, 10 to 303—It is preferred

tin-lead solder.

that one eyepiece contain a graduated reticle for measuring the

defect location. The reticle shall be calibrated for the magni-

5. Significance and Use

fication at which the microscope is to be used, preferably

5.1 The primary purpose of the PMA test is to determine the

103.

presence of mechanical damage, wear through, and other gross

6.3 Light source (illuminator) for microscope, incandescent.

defects in the coating. Most metallic coatings are intended to

6.4 Glass volumetric flask, 10 mL.

be protective, and the presence of gross defects indicates a

6.5 Glass bottle of a stable shape and with glass stopper. The

serious reduction of such protection.

bottle opening shall be 2.5 cm (1 in.) minimum. An example is

5.2 The protection afforded by well applied coatings may be

a 50-mL low-form weighing bottle or a flask-shaped weighing

diminished by improper handling following plating or as a

bottle.

result of wear or mechanical damage during testing or while in

6.6 Applicators (see 9.2)—Platinum wire, 32 AWG, or

service. The PMA test can serve to indicate the existence of

disposable glass micropipets, 1 or 0.5 μL size.

such damage.

Magnification standards suitable for calibrating optical microscopes may be

Van Wazer, J. P., Phosphorous and Its Compounds, Interscience Publishers, purchased from U.S. National Institute of Standards and Technology, Office of

New York, 1961. Standard Reference Materials.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued. NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information. Contact ASTM International (www.astm.org) for the latest information.

B877–96

7. Reagents and Materials 9.1.4.1 Fill the special glass bottle (see 6.4) to approxi-

mately halfway from the top.

7.1 Phosphomolybdic Acid (PMA)—Crystalline, ACS certi-

9.1.4.2 Label glass bottle with contents.

fied grade.

9.1.4.3 Keep stoppered and under a fume hood when not in

7.2 Concentrated Hydrochloric Acid— ACS analytical re-

use.

agent (AR) grade or better.

9.2 Preparation of applicators:

9.2.1 The applicator shall not react with the PMA solution.

8. Specific Safety and Health Precautions

Examples are as follows:

8.1 All the normal precautions shall be observed in handling

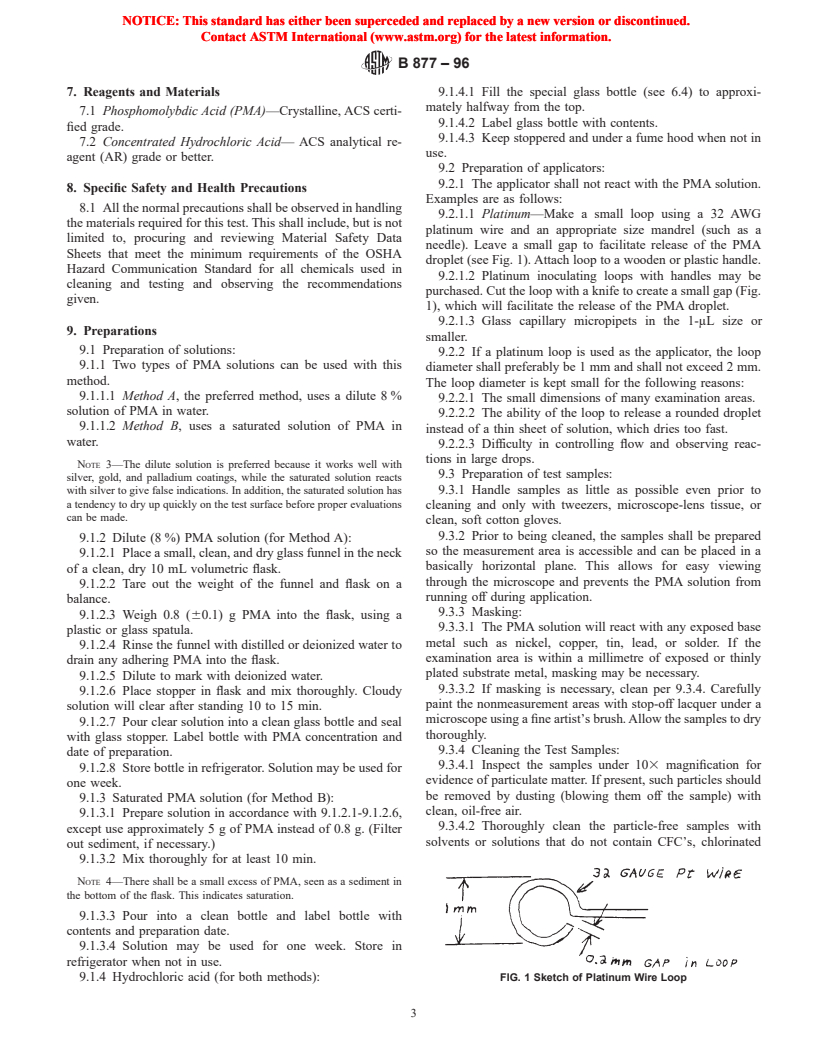

9.2.1.1 Platinum—Make a small loop using a 32 AWG

the materials required for this test. This shall include, but is not

platinum wire and an appropriate size mandrel (such as a

limited to, procuring and reviewing Material Safety Data

needle). Leave a small gap to facilitate release of the PMA

Sheets that meet the minimum requirements of the OSHA

droplet (see Fig. 1). Attach loop to a wooden or plastic handle.

Hazard Communication Standard for all chemicals used in

9.2.1.2 Platinum inoculating loops with handles may be

cleaning and testing and observing the recommendations

purchased. Cut the loop with a knife to create a small gap (Fig.

given.

1), which will facilitate the release of the PMA droplet.

9.2.1.3 Glass capillary micropipets in the 1-μL size or

9. Preparations

smaller.

9.1 Preparation of solutions:

9.2.2 If a platinum loop is used as the applicator, the loop

9.1.1 Two types of PMA solutions can be used with this

diameter shall preferably be 1 mm and shall not exceed 2 mm.

method.

The loop diameter is kept small for the following reasons:

9.1.1.1 Method A, the preferred method, uses a dilute 8 %

9.2.2.1 The small dimensions of many examination areas.

solution of PMA in water.

9.2.2.2 The ability of the loop to release a rounded droplet

9.1.1.2 Method B, uses a saturated solution of PMA in

instead of a thin sheet of solution, which dries too fast.

water.

9.2.2.3 Difficulty in controlling flow and observing reac-

tions in large drops.

NOTE 3—The dilute solution is preferred because it works well with

9.3 Preparation of test samples:

silver, gold, and palladium coatings, while the saturated solution reacts

with silver to give false indications. In addition, the saturated solution has 9.3.1 Handle samples as little as possible even prior to

a tendency to dry up quickly on the test surface before proper evaluations

cleaning and only with tweezers, microscope-lens tissue, or

can be made.

clean, soft cotton gloves.

9.3.2 Prior to being cleaned, the samples shall be prepared

9.1.2 Dilute (8 %) PMA solution (for Method A):

so the measurement area is accessible and can be placed in a

9.1.2.1 Place a small, clean, and dry glass funnel in the neck

basically horizontal plane. This allows for easy viewing

of a clean, dry 10 mL volumetric flask.

through the microscope and prevents the PMA solution from

9.1.2.2 Tare out the weight of the funnel and flask on a

running off during application.

balance.

9.3.3 Masking:

9.1.2.3 Weigh 0.8

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.