ASTM D6487-04

(Practice)Standard Practice for Preparing Prints of Paste Printing Inks by Rollouts on a Laboratory Flat-Bed Press

Standard Practice for Preparing Prints of Paste Printing Inks by Rollouts on a Laboratory Flat-Bed Press

SIGNIFICANCE AND USE

Laboratory proofing of ink is necessary to establish a reproducible prediction of print appearance and performance properties, most of which are highly sensitive to ink film thickness. The apparatus described in this practice has found wide use for routine control proofing because it provides an economical method for producing reasonably large prints at film thicknesses comparable to those obtained on production presses.

This practice does not duplicate the dynamics of a high speed press, nevertheless, it is useful for quality control and for specification acceptance between the producer and the user.

SCOPE

1.1 This practice covers the procedure for preparing prints of paste inks using rollouts on a flat-bed laboratory proof press. The initial method was developed by the National Printing Ink Research Institute.

1.2 This practice is applicable to the preparation of single-color solid-area prints by the dry offset process (also known as Letterset) on a flat substrate such as paper or metal. It can readily be adapted to print by direct letterpress.

Note 1—The proofing press described in this practice can also be used with printing gages in accordance with Practice D 6846.

1.3 This practice is applicable primarily to lithographic and letterpress inks that dry by oxidation or penetration. With the addition of appropriate drying or curing equipment, it is also applicable to other systems such as heat-set or energy-curable.

1.4 The instructions in this practice are intended to minimize the within-print and among-operator variability inherent in hand operations.

1.5 This practice does not measure the actual film thickness on the print, but evaluates film thickness equivalence by visual or instrumental comparisons of optical density.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the users of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautions are given in Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6487 – 04

Standard Practice for

Preparing Prints of Paste Printing Inks by Rollouts on a

1

Laboratory Flat-Bed Press

This standard is issued under the fixed designation D6487; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

3

1.1 This practice covers the procedure for preparing prints 2.1 ASTM Standards:

ofpasteinksusingrolloutsonaflat-bedlaboratoryproofpress. D6073 Test Method for Relative Setting of Heatset Printing

The initial method was developed by the National Printing Ink Inks

2

Research Institute. D6846 Practice for Preparing Prints of Paste Printing Inks

1.2 This practice is applicable to the preparation of single- with a Printing Gage

4

color solid-area prints by the dry offset process (also known as 2.2 ANSI Standards:

Letterset) on a flat substrate such as paper or metal. It can PH 2.17 Geometric Conditions for Reflection Density

readily be adapted to print by direct letterpress. PH 2.18 Spectral Conditions for the Measurement of Opti-

cal Density

NOTE 1—The proofing press described in this practice can also be used

PH 2.30 Viewing Conditions for Graphic Arts and

with printing gages in accordance with Practice D6846.

Photography—Color Prints,Transparencies and Photome-

1.3 This practice is applicable primarily to lithographic and

chanical Reproductions

letterpress inks that dry by oxidation or penetration. With the

CGATS.4 Graphic Technology–Graphic Arts Reflection

addition of appropriate drying or curing equipment, it is also

Densitometry Measurements—Terms, Equations, Image

applicable to other systems such as heat-set or energy-curable.

Elements and Procedures

1.4 The instructions in this practice are intended to mini-

CGATS.5 Graphic Technology–Spectral Measurements and

mize the within-print and among-operator variability inherent

Colormetric Computation for Graphics Arts Images

in hand operations.

1.5 This practice does not measure the actual film thickness

3. Summary of Practice

on the print, but evaluates film thickness equivalence by visual

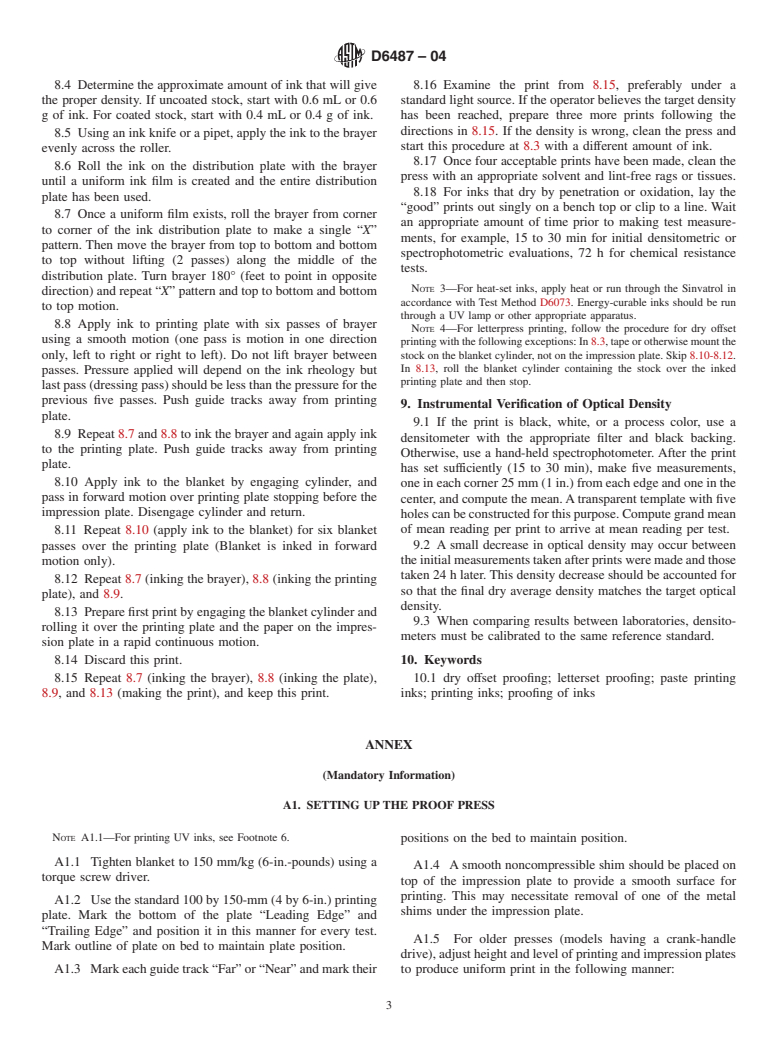

3.1 The equipment is set up as described in Annex A1.In

or instrumental comparisons of optical density.

order to make a print, the test ink is metered onto a brayer,

1.6 The values stated in SI units are to be regarded as the

rolled out evenly on the distribution plate according to a

standard. The values given in parentheses are for information

specified pattern, and then transferred to the printing plate.The

only.

appropriate stock is clipped onto the impression plate, and the

1.7 This standard does not purport to address all of the

blanket cylinder is rolled over the inked plate six times

safety concerns, if any, associated with its use. It is the

followed by once over the stock.

responsibility of the users of this standard to establish appro-

3.2 After the print is set, it is checked against the target

priate safety and health practices and determine the applica-

optical density instrumentally or by visual comparison with a

bility of regulatory limitations prior to use. Specific precau-

standard print. Subsequent prints are made until the target

tions are given in Section 7.

optical density has been achieved.

1

This practice is under the jurisdiction of ASTM Committee D01 on Paint and

3

Related Coatings, Materials, and Applications and is the direct responsibility of For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Subcommittee D01.56 on Printing Inks. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

CurrenteditionapprovedJune1,2004.PublishedJuly2004.Originallyapproved Standards volume information, refer to the standard’s Document Summary page on

in 1999. Last previous edition approved in 2001 as D6487 - 01. DOI: 10.1520/ the ASTM website.

4 th nd

D6487-04. Available from American National Standards Institute, 13 Floor, 11 W. 42

2

“The NPIRI Standard Procedure for Preparing Little Joe Prints,” American Ink Street, New York, NY 10036 or Committee on Graphic Arts Technical Standards,

Maker, March 1994, pp. 42-50. 1899 Preston White Drive, Reston, VA 20191-4367.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6487 – 04

FIG. 1 Laboratory Flat-Bed Press Equipped with Push Handle, Set Up for Dry Offset Proofing

for use with black, white, and the three process colors (yellow, magenta

4. Significance and Use

and cyan).

4.1 Laboratory proofing of ink is necessary to establ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.