ASTM D7735-17

(Test Method)Standard Test Method for Type A Durometer Hardness Testing of Thermoplastic Pavement Marking at Elevated Temperatures

Standard Test Method for Type A Durometer Hardness Testing of Thermoplastic Pavement Marking at Elevated Temperatures

SIGNIFICANCE AND USE

5.1 This method is based on the penetration of a specific type of indentor when forced into the material under specified conditions. The indentation hardness is inversely related to the penetration and is dependent on the elastic modulus, viscoelastic behavior of the material, geometry of the indentor, the applied force and temperature at test. This test method is empirical and therefore primarily for control purposes. No simple relationship exists between indentation hardness determined by this test method and any fundamental property of the material tested.

SCOPE

1.1 This test method covers Type A Durometer hardness of thermoplastic pavement marking material at elevated temperatures.

1.2 This test method is similar to Test Method D2240 for hardness with special attention given to keeping the temperature of the test sample and instrument constant. Within the highway materials community, it is sometimes known as “indentation resistance.”

1.3 All materials, instruments or equipment used for the determination of temperature, hardness and time shall be traceable to National Institute of Standards and Technology or other internationally recognized organizations parallel in nature.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7735 − 17

Standard Test Method for

Type A Durometer Hardness Testing of Thermoplastic

1

Pavement Marking at Elevated Temperatures

This standard is issued under the fixed designation D7735; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D16 TerminologyforPaint,RelatedCoatings,Materials,and

Applications

1.1 This test method covers Type A Durometer hardness of

D2240 Test Method for Rubber Property—Durometer Hard-

thermoplastic pavement marking material at elevated tempera-

ness

tures.

D7307 PracticeforSamplingofThermoplasticTrafficMark-

1.2 This test method is similar to Test Method D2240 for

ing Materials

hardness with special attention given to keeping the tempera-

D7308 Practice for Sample Preparation of Thermoplastic

ture of the test sample and instrument constant. Within the

Pavement Marking Materials

highway materials community, it is sometimes known as

E177 Practice for Use of the Terms Precision and Bias in

“indentation resistance.”

ASTM Test Methods

1.3 All materials, instruments or equipment used for the E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

determination of temperature, hardness and time shall be

traceable to National Institute of Standards and Technology or

other internationally recognized organizations parallel in na- 3. Terminology

ture.

3.1 Definitions:

1.4 The values stated in SI units are to be regarded as

3.1.1 The terms and definitions in Terminology D16 apply

standard. The values given in parentheses are for information

to this method.

only.

3.1.2 hardness, adv—the value of resistance of a small

1.5 This standard does not purport to address all of the penetrating device. In the case of the Type A Durometer in

accordance with Test Method D2240, the presser foot/indentor

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- (spherical to 0.79 6 0.03 mm or 0.03 6 0.001 in.) is connected

priate safety and health practices and determine the applica- to a spring loaded to a total of 0.075 N/Durometer units at full

bility of regulatory limitations prior to use. deflection. For reading of Type A hardness the instruments

1.6 This international standard was developed in accor- scale reads from 0 to 100. Minimal deflection is 0 (softest) and

dance with internationally recognized principles on standard- maximum is 100 (hardest).

ization established in the Decision on Principles for the

3.1.3 thermoplastic, n—pavement marking (same as 3.1.4).

Development of International Standards, Guides and Recom-

3.1.4 thermoplastic pavement marking—a highly filled

mendations issued by the World Trade Organization Technical

100 % total solids highway marking system that when heated

Barriers to Trade (TBT) Committee.

toamoltenstatecanbeextrudedorsprayedontoaroadsurface

and when cooled forms a solid durable delineator or thermo-

2. Referenced Documents

plastic pavement marking usually melted to 220°C (425°F).

2

2.1 ASTM Standards:

4. Summary of Test Method

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

4.1 This method was developed to enable the testing of

and Related Coatings, Materials, andApplications and is the direct responsibility of

hardness or indentation resistance of thermoplastic pavement

Subcommittee D01.44 on Traffic Coatings.

marking material at ambient roadway/highway temperatures.

Current edition approved June 1, 2017. Published August 2017. Originally

Due to the speed at which basic thermoplastic pavement

approved in 2011. Last previous edition approved in 2016 as D7735 – 11 (2016).

DOI: 10.1520/7735-17.

marking cools, testing its hardness at elevated temperatures is

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

difficult, even at a relatively low 46°C (115°F). Existing

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

non-standardmethodsarenotconsistentbecausetheyallowthe

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. samples to change temperature during testing. By keeping both

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7735 − 17

the test samples and the hardness tester in a regulated environ- 9. Procedure

ment before and during testing, the results are much more

9.1 Sample the thermoplastic pavement marking in accor-

repeatable within a laboratory. The goal for this method is to

danc

...

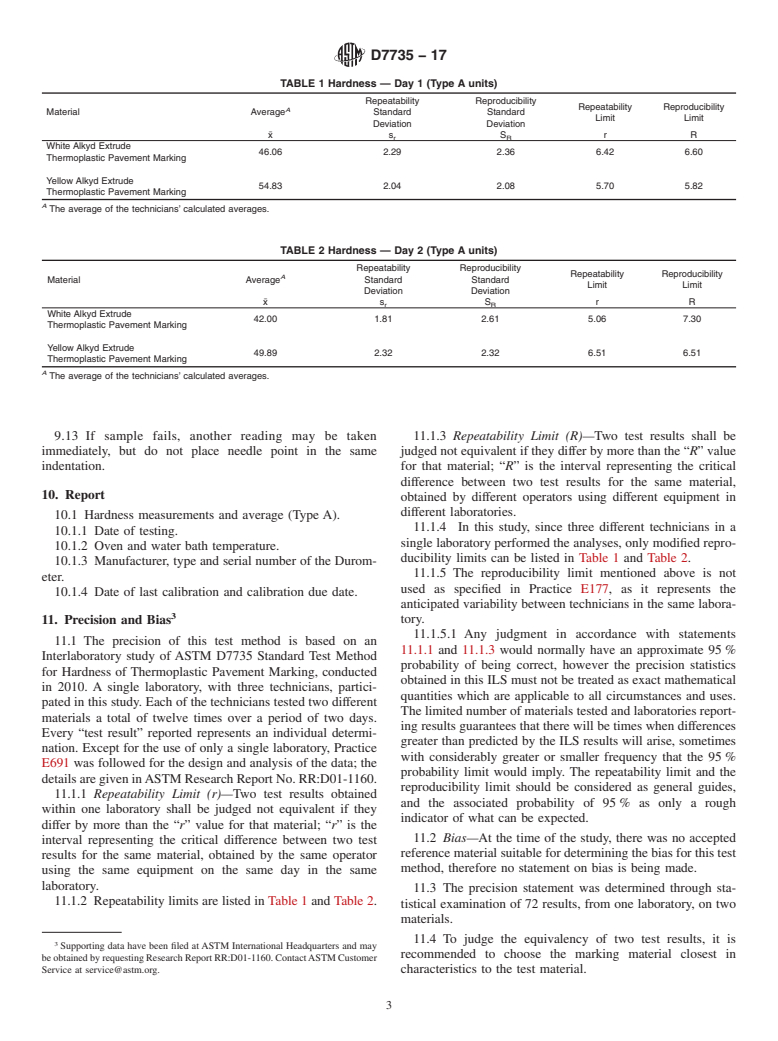

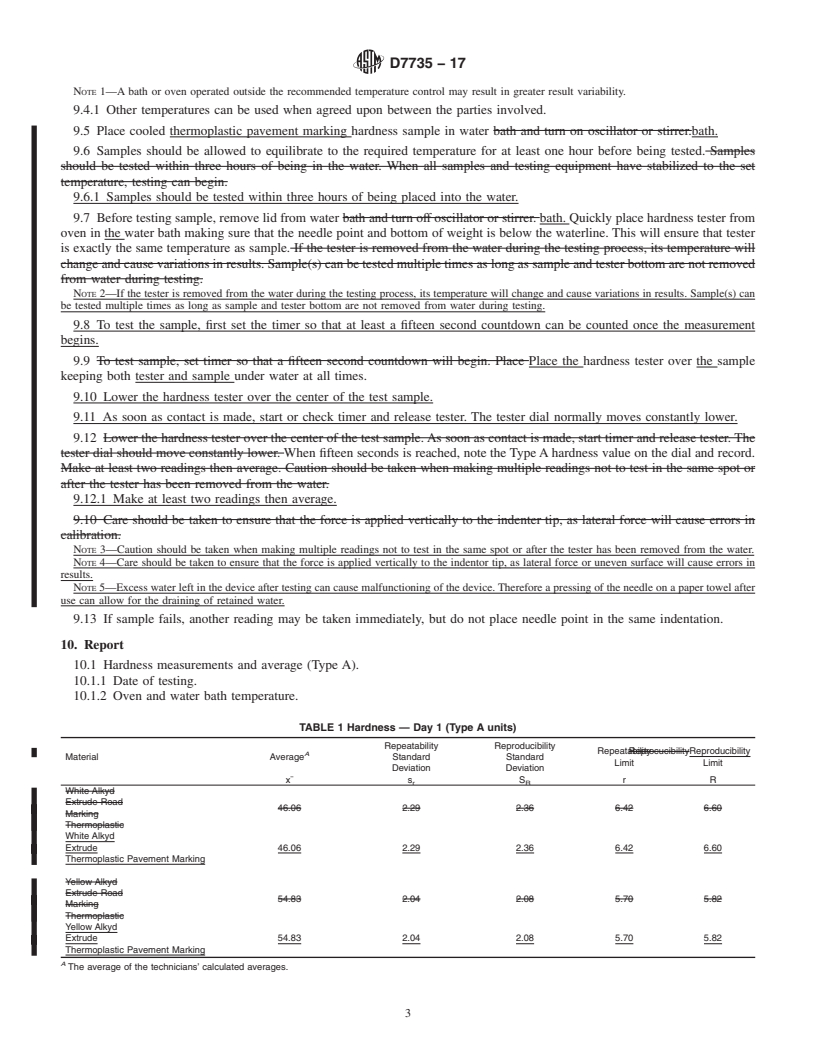

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7735 − 11 (Reapproved 2016) D7735 − 17

Standard Test Method for

Type A Durometer Hardness Testing of Road Marking

ThermoplasticThermoplastic Pavement Marking at Elevated

1

Temperatures

This standard is issued under the fixed designation D7735; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers Type A Durometer hardness of road marking thermoplasticthermoplastic pavement marking

material at elevated temperatures.

1.2 This test method is similar to Test Method D2240 for hardness with special attention given to keeping the temperature of

the test sample and instrument constant. Within the highway materials community, it is sometimes known as “indentation

resistance.”

1.3 All materials, instruments or equipment used for the determination of temperature, hardness and time shall be traceable to

National Institute of Standards and Technology or other internationally recognized organizations parallel in nature.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D16 Terminology for Paint, Related Coatings, Materials, and Applications

D2240 Test Method for Rubber Property—Durometer Hardness

D7307 Practice for Sampling of Thermoplastic Traffic Marking Materials

D7308 Practice for Sample Preparation of Thermoplastic Pavement Marking Materials

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions:

3.1.1 The terms and definitions in Terminology D16 apply to this method.

3.1.2 hardness, adv—the value of resistance of a small penetrating device. In the case of the Type A Durometer in accordance

with Test Method D2240, the presser foot/indentor (spherical to 0.79 6 0.03 mm or 0.03 6 0.001 in.) is connected to a spring

loaded to a total of 0.075 N/Durometer units at full deflection. For reading of Type A hardness the instruments scale reads from

0 to 100. Minimal deflection is 0 (softest) and maximum is 100 (hardest).

3.1.3 thermoplastic, n—trafficpavement marking (same as 3.1.4).

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.44 on Traffic Coatings.

Current edition approved April 1, 2016June 1, 2017. Published April 2016August 2017. Originally approved in 2011. Last previous edition approved in 20112016 as D7735

ɛ1

– 11 . (2016). DOI: 10.1520/7735-11R16.10.1520/7735-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7735 − 17

3.1.4 thermoplastic traffıcpavement marking—a highly filled 100 % total solids highway marking system that when heated to

a molten state can be extruded or sprayed onto a road surface and when cooled forms a solid durable delineator or road marking

thermoplasticthermoplastic pavement marking usually melted to 220°C (425°F).

4. Summary of Test Method

4.1 This method was developed to enable the testing of hardness or indentation resistance of road marking thermoplasticther-

moplastic pavement marking material at ambient roadway/highway temperatures. Due to the speed at which basic road marking

thermoplasticthermoplastic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.