ASTM C1728-13

(Specification)Standard Specification for Flexible Aerogel Insulation

Standard Specification for Flexible Aerogel Insulation

SCOPE

1.1 This specification covers the classification and performance of flexible aerogel thermal insulation. This will cover the range of continuous exposure operating temperatures from -321°F (-196°C) up to 1200° F (649°C).

1.2 For satisfactory performance, properly installed protective vapor retarders or barriers shall be used on below ambient temperature applications to reduce movement of moisture through or around the insulation to the colder surface. Failure to use a vapor retarder or barrier could lead to insulation and system non-performance.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The following safety hazards caveat pertains only to the test methods described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1728 −13

Standard Specification for

1

Flexible Aerogel Insulation

This standard is issued under the fixed designation C1728; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C177 Test Method for Steady-State Heat Flux Measure-

ments and Thermal Transmission Properties by Means of

1.1 This specification covers the classification and perfor-

the Guarded-Hot-Plate Apparatus

mance of flexible aerogel thermal insulation. This will cover

C303 Test Method for Dimensions and Density of Pre-

the range of continuous exposure operating temperatures from

formed Block and Board–Type Thermal Insulation

-321°F (-196°C) up to 1200° F (649°C).

C335 Test Method for Steady-State Heat Transfer Properties

1.2 For satisfactory performance, properly installed protec-

of Pipe Insulation

tive vapor retarders or barriers shall be used on below ambient

C356 Test Method for Linear Shrinkage of Preformed High-

temperature applications to reduce movement of moisture

Temperature Thermal Insulation Subjected to Soaking

through or around the insulation to the colder surface. Failure

Heat

to use a vapor retarder or barrier could lead to insulation and

C390 Practice for Sampling and Acceptance of Thermal

system non-performance.

Insulation Lots

1.3 The values stated in inch-pound units are to be regarded C411 Test Method for Hot-Surface Performance of High-

Temperature Thermal Insulation

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only C447 Practice for Estimating the Maximum Use Tempera-

ture of Thermal Insulations

and are not considered standard.

C518 Test Method for Steady-State Thermal Transmission

1.4 The following safety hazards caveat pertains only to the

Properties by Means of the Heat Flow Meter Apparatus

test methods described in this specification. This standard does

C795 Specification for Thermal Insulation for Use in Con-

not purport to address all of the safety concerns, if any,

tact with Austenitic Stainless Steel

associated with its use. It is the responsibility of the user of this

C1045 Practice for Calculating Thermal Transmission Prop-

standard to establish appropriate safety and health practices

erties Under Steady-State Conditions

and determine the applicability of regulatory limitations prior

C1058 Practice for Selecting Temperatures for Evaluating

to use.

and Reporting Thermal Properties of Thermal Insulation

C1101/C1101M Test Methods for Classifying the Flexibility

2. Referenced Documents

or Rigidity of Mineral Fiber Blanket and Board Insulation

2

2.1 ASTM Standards:

C1104/C1104M Test Method for Determining the Water

C165 Test Method for Measuring Compressive Properties of

Vapor Sorption of Unfaced Mineral Fiber Insulation

Thermal Insulations

C1114 Test Method for Steady-State Thermal Transmission

C167 Test Methods for Thickness and Density of Blanket or

Properties by Means of the Thin-Heater Apparatus

Batt Thermal Insulations

C1338 Test Method for Determining Fungi Resistance of

C168 Terminology Relating to Thermal Insulation

Insulation Materials and Facings

C1511 Test Method for Determining the Water Retention

1

This specification is under the jurisdiction of ASTM Committee C16 on

(Repellency) Characteristics of Fibrous Glass Insulation

Thermal Insulation and is the direct responsibility of Subcommittee C16.23 on

(Aircraft Type)

Blanket and Loose Fill Insulation.

C1617 Practice for Quantitative Accelerated Laboratory

Current edition approved May 1, 2013. Published May 2013. Originally

Evaluation of Extraction Solutions Containing Ions

approved in 2012. Last previous edition approved in 2012 as C1728–12. DOI:

10.1520/C1728-13.

Leached from Thermal Insulation on Aqueous Corrosion

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

of Metals

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

E84 Test Method for Surface Burning Characteristics of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Building Materials

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1728−13

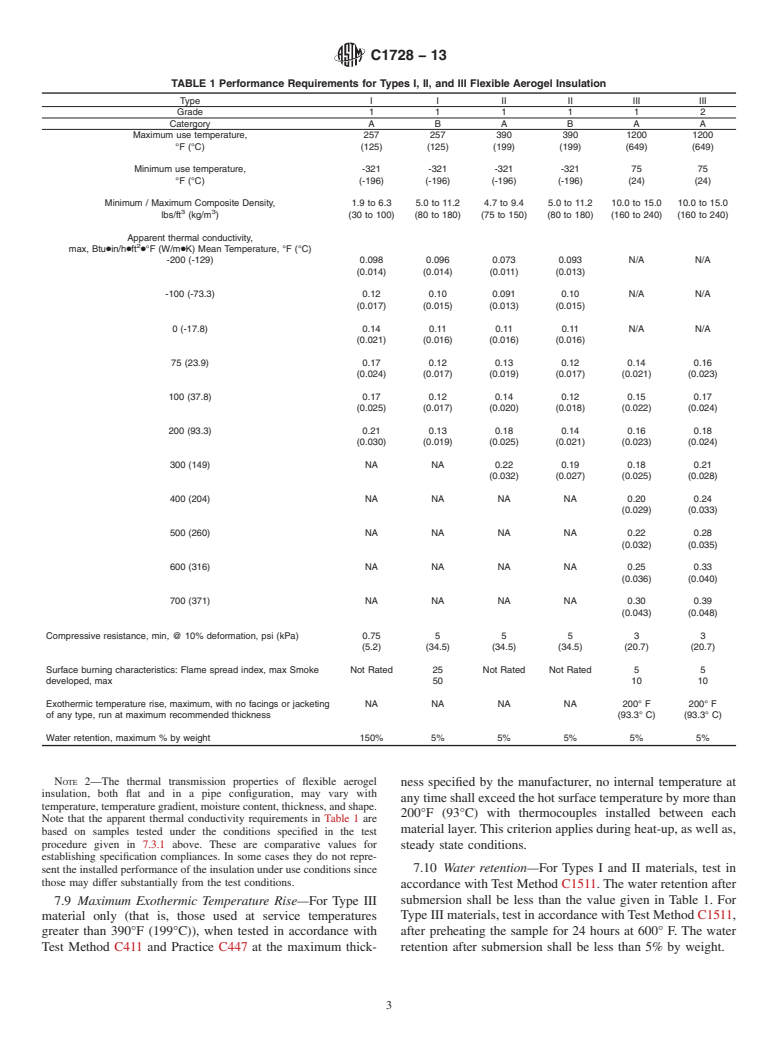

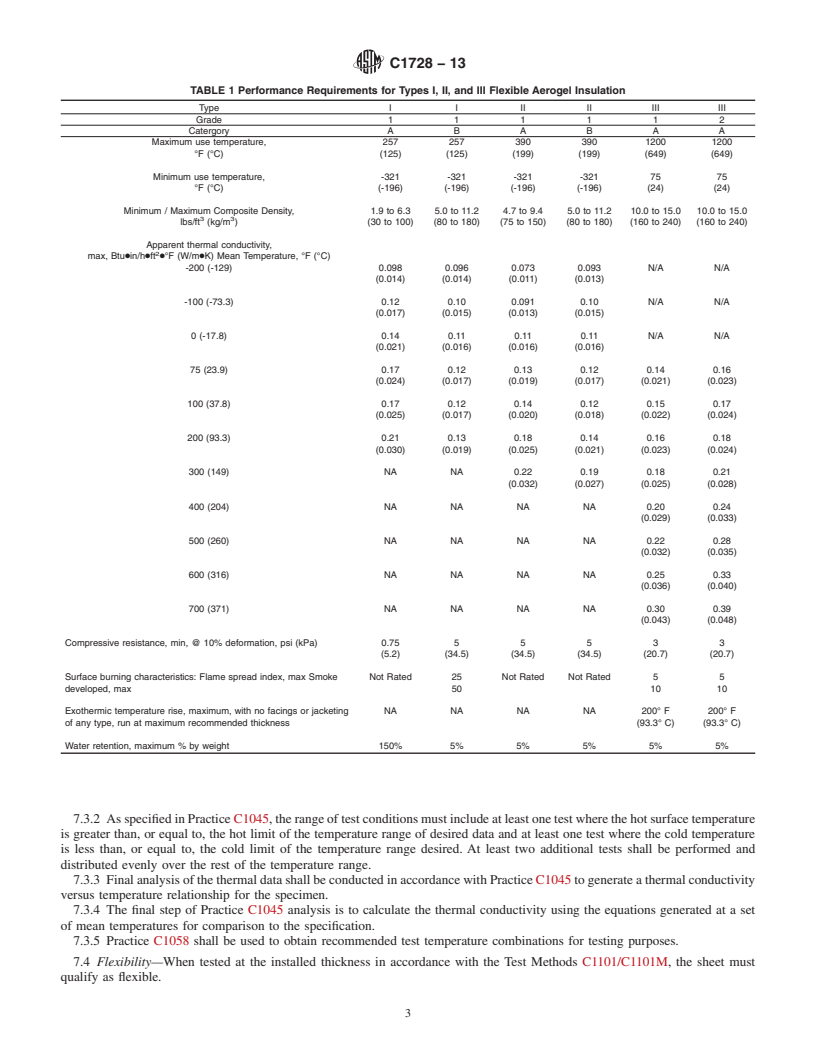

E2231 Practice for Specimen Preparation and Mounting of 7.1 Maximum Use Temperature—When tested in accor-

Pipe and Duct Insulation Materials to Assess Surface dancewithTestMethodC411inaflatconfigurationandthehot

Burning Characteristics surface performance of Practice C447 in a flat configuration at

3

the insulation’s maximum use temperature at a

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1728 − 12 C1728 − 13

Standard Specification for

1

Flexible Aerogel Insulation

This standard is issued under the fixed designation C1728; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the classification and performance of flexible aerogel thermal insulation. This will cover the range

of continuous exposure operating temperatures from -321°F (-196°C) up to 1200° F (649°C).

1.2 For satisfactory performance, properly installed protective vapor retarders or barriers shall be used on below ambient

temperature applications to reduce movement of moisture through or around the insulation to the colder surface. Failure to use a

vapor retarder or barrier could lead to insulation and system non-performance.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 The following safety hazards caveat pertains only to the test methods described in this specification. This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C165 Test Method for Measuring Compressive Properties of Thermal Insulations

C167 Test Methods for Thickness and Density of Blanket or Batt Thermal Insulations

C168 Terminology Relating to Thermal Insulation

C177 Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the

Guarded-Hot-Plate Apparatus

C303 Test Method for Dimensions and Density of Preformed Block and Board–Type Thermal Insulation

C335 Test Method for Steady-State Heat Transfer Properties of Pipe Insulation

C356 Test Method for Linear Shrinkage of Preformed High-Temperature Thermal Insulation Subjected to Soaking Heat

C390 Practice for Sampling and Acceptance of Thermal Insulation Lots

C411 Test Method for Hot-Surface Performance of High-Temperature Thermal Insulation

C447 Practice for Estimating the Maximum Use Temperature of Thermal Insulations

C518 Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus

C665 Specification for Mineral-Fiber Blanket Thermal Insulation for Light Frame Construction and Manufactured Housing

C795 Specification for Thermal Insulation for Use in Contact with Austenitic Stainless Steel

C1045 Practice for Calculating Thermal Transmission Properties Under Steady-State Conditions

C1058 Practice for Selecting Temperatures for Evaluating and Reporting Thermal Properties of Thermal Insulation

C1101/C1101M Test Methods for Classifying the Flexibility or Rigidity of Mineral Fiber Blanket and Board Insulation

C1104/C1104M Test Method for Determining the Water Vapor Sorption of Unfaced Mineral Fiber Insulation

C1114 Test Method for Steady-State Thermal Transmission Properties by Means of the Thin-Heater Apparatus

C1338 Test Method for Determining Fungi Resistance of Insulation Materials and Facings

C1511 Test Method for Determining the Water Retention (Repellency) Characteristics of Fibrous Glass Insulation (Aircraft

Type)

1

This specification is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.23 on Blanket and Loose

Fill Insulation.

Current edition approved Jan. 15, 2012May 1, 2013. Published January 2012May 2013. Originally approved in 2012. Last previous edition approved in 2012 as C1728–12.

DOI: 10.1520/C1728-12.10.1520/C1728-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1728 − 13

C1617 Practice for Quantitative Accelerated Laboratory Evaluation of Extraction Solutions Containing Ions Leached from

Thermal Insulation on Aqueous

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.