ASTM D5503-94(1999)

(Practice)Standard Practice for Natural Gas Sample-Handling and Conditioning Systems for Pipeline Instrumentation

Standard Practice for Natural Gas Sample-Handling and Conditioning Systems for Pipeline Instrumentation

SCOPE

1.1 This practice covers sample-handling and conditioning systems for typical pipeline monitoring instrumentation (gas chromatographs, moisture analyzers, etc.). The selection of the sample-handling and conditioning system depends upon the operating conditions and stream composition.

1.2 This practice is intended for single phase mixtures that vary in composition. A representative sample cannot be obtained from a two phase stream.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The values stated in SI units are to be regarded as standard. The values stated in English units are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5503 – 94 (Reapproved 1999)

Standard Practice for

Natural Gas Sample-Handling and Conditioning Systems for

Pipeline Instrumentation

This standard is issued under the fixed designation D 5503; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 density—mass per unit volume of the substance being

considered.

1.1 This practice covers sample-handling and conditioning

3.1.3 dew point—the temperature and pressure at which the

systems for typical pipeline monitoring instrumentation (gas

first droplet of liquid forms from a vapor.

chromatographs, moisture analyzers, and so forth). The selec-

3.1.4 lag time—time required to transport the sample to the

tion of the sample-handling and conditioning system depends

analyzer.

upon the operating conditions and stream composition.

3.1.5 natural gas—mixture of low molecular weight hydro-

1.2 This practice is intended for single-phase mixtures that

carbons obtained from petroleum-bearing regions.

vary in composition. A representative sample cannot be ob-

3.1.6 sample probe—device to extract a representative

tained from a two-phase stream.

sample from the pipeline.

1.3 This standard does not purport to address all of the

3.1.7 system turnaround time—the time required to trans-

safety concerns, if any, associated with its use. It is the

port the sample to the analyzer and to measure the desired

responsibility of the user of this standard to establish appro-

components.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Significance and Use

1.4 The values stated in SI units are to be regarded as

4.1 A well-designed sample-handling and conditioning sys-

standard. The values stated in English units are for information

tem is essential to the accuracy and reliability of pipeline

only.

instruments. Approximately 70 % of the problems encountered

2. Referenced Documents are associated with the sampling system.

2.1 ASTM Standards:

5. Selection of Sample-Handling and Conditioning

D 1142 Test Method for Water Vapor Content of Gaseous

System

Fuels by Measurement of Dew-Point Temperature

5.1 The sample-handling and conditioning system must

D 3764 Practice for Validation of Process Stream Analyz-

3 extract a representative sample from a flowing pipeline, trans-

ers

port the sample to the analyzer, condition the sample to be

2.2 Other Documents:

4 compatible with the analyzer, switch sample streams and

ANSI/API 2530 (AGA Report Number 3)

5 calibration gases, transport excess sample to recovery (or

AGA Report Number 8

6 disposal), and resist corrosion by the sample.

NACE Standard MR-01-75

5.2 The sample probe should be located in a flowing

3. Terminology pipeline where the flow is fully developed (little turbulence)

and where the composition is representative. In areas of high

3.1 Definitions:

turbulence, the contaminates that normally flow along the

3.1.1 compressed natural gas—natural gas compressed to

bottom or the wall of the pipeline will form aerosols.

approximately 3600 psi.

5.3 The purpose of the sample probe is to extract a repre-

sentative sample by obtaining it near the center of the pipeline

This practice is under the jurisdiction of ASTM Committee D-3 on Gaseous

where changes in stream composition can be quickly detected.

Fuels and is the direct responsibility of Subcommittee D03.01 on Collection and

5.3.1 The tip in the sample probe should be positioned in the

Measurement of Gaseous Samples.

Current edition approved Feb. 15, 1994. Published April 1994.

center one third of the pipeline away from the pipeline wall

Annual Book of ASTM Standards, Vol 05.06.

where large particles accumulate.

Annual Book of ASTM Standards, Vol 05.02.

4 5.3.2 The probe should be a minimum of five pipe diameters

Available from American National Standards Institute, 11 W. 42nd St., 13th

Floor, New York, NY 10036. from any device that could produce aerosols or significant

Available from American Gas Association, 1515 Wilson Blvd., Arlington, VA

pressure drop.

22209.

5.3.3 The sample probe should not be located within a

Available from National Association of Corrosion Engineers, 1440-T S. Creek

defined meter tube region (see ANSI/API 2530 AGA Report

Dr., Houston, TX 77084.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5503

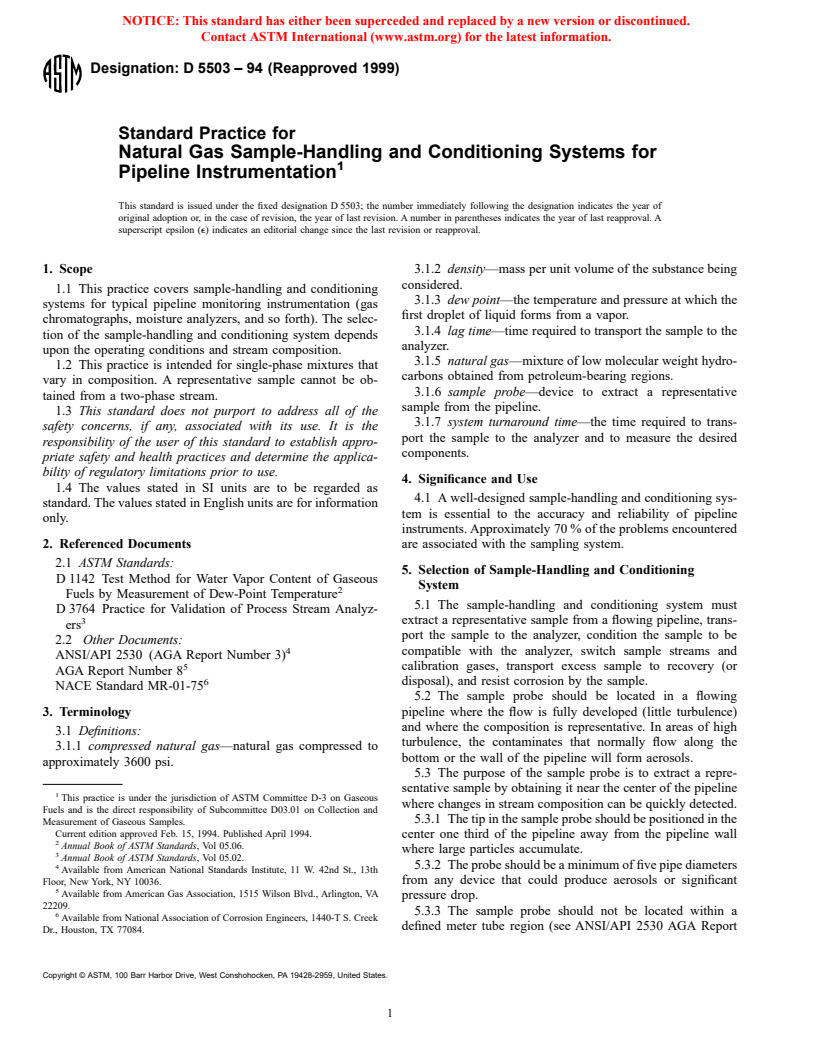

Number 3 and AGA Report Number 8 for more information). 6.1.2 Most pipeline samples require some filtering. Since all

5.3.4 The sample probe should be mounted vertically from filter elements eventually plug, they should be replaced on a

the top on horizontal pipelines. The sample probe should not be regular maintenance schedule. There are several types of filter

located on vertical pipelines. designs.

5.4 The sampling-handling system must transport the 6.1.2.1 In-Line Filter—All of the sample passes through an

sample to the analyzer and dispose of excess sample. Since the in-line filter. The active filter elements are available in Teflon

sampling point and the analyzer may be separated by some polypropylene, copolymer, or stainless steel. (See Fig. 1.)

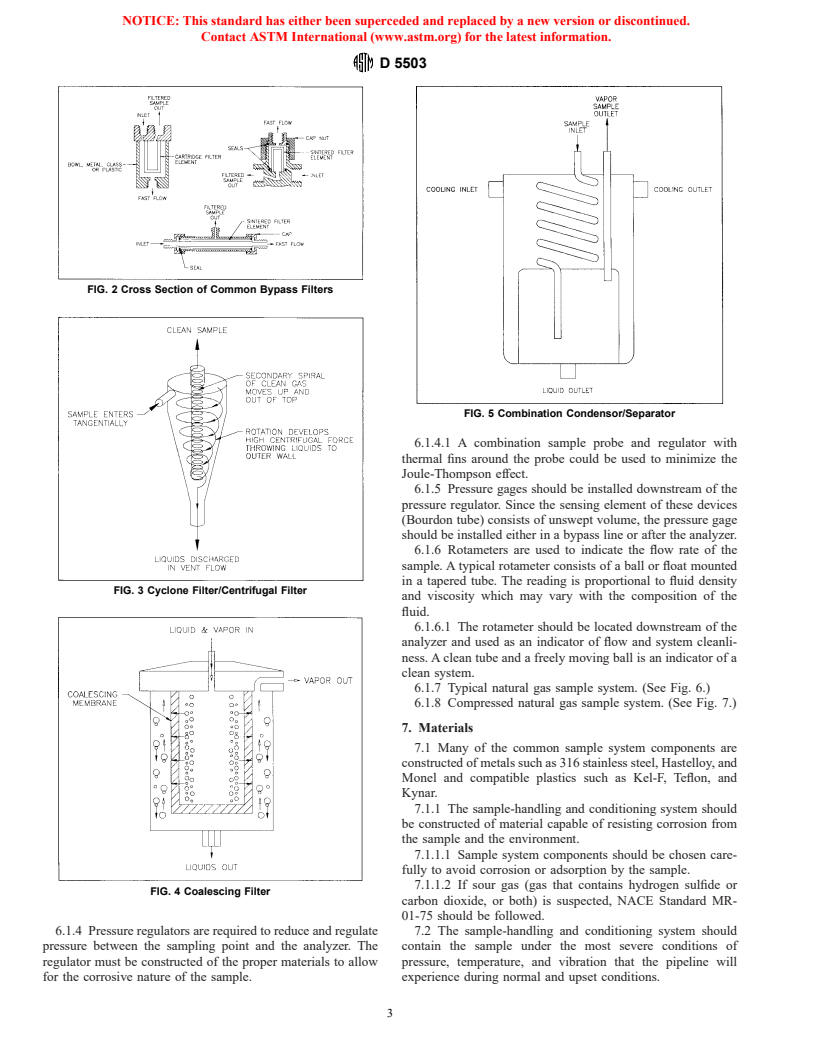

distance, the time required to transport the sample to the 6.1.2.2 Bypass Filter—Only a small portion of the sample

analyzer can contribute significantly to the system turnaround passes through a bypass filter, while a majority of the sample

time. passes across its surface keeping it clean. The active filter

5.4.1 The analyzer should be located as close to the sam- element is either a disposable cartridge or a reusable sintered

pling point as is practical to minimize the sample lag time. metal element. (See Fig. 2.)

5.4.2 The sample-handling system should be equipped with 6.1.2.3 Cyclone Filter—The cyclone filter is a centrifugal

a full open ball valve and a particular filter. cleanup device. The sample enters at high velocity tangentially

5.5 The sizing of the sample transport line will be influ- to the wall of a cylindrical-shaped vessel with a conical-shaped

enced by a number of factors: bottom. The centrifugal force developed by the spinning action

5.5.1 The sample point pressure and the location of the of the gas as it follows the shape of the vessel forces particles

pressure reduction regulator. and droplets to the wall where they are removed through the

5.5.2 The acceptable lag time between the sample point and vent flow. (See Fig. 3.)

the analyzer. 6.1.2.4 Coalescing Filter—Coalescers, also known as mem-

5.5.3 The requirements of the analyzer such as flow rate, brane separators, are used to force finely divided liquid

pressure, and temperature for the analysis. For multistream droplets to combine into larger droplets so they can be

systems, the sample line and associated manifold tubing should separated by gravity. The design of the coalescer body forces

be flushed with sufficient sample to assure a representative the heavier phase out the bottom and the lighter phase out the

sample of the selected stream. top. The flow rates out the top and the bottom are critical for

5.5.4 The presence of sample-conditioning elements will proper operation. (See Fig. 4.)

contribute to the lag time and must be considered in the (a) Since this process removes part of the sample, the impact

calculation of the minimum sample flow rate. on sample composition must be considered.

5.5.4.1 Each element could be considered as an equivalent (b) The coalescer should be located immediately upstream

length of sample line and added to the length of line from the from the analyzer.

sample point to the analyzer. 6.1.3 The combination condenser/separator is used to re-

5.5.4.2 The purge time of each element is calculated as the move condensable liquids from a vapor sample. The sample

time necessary for five volumes of sample to flow through the enters the separator and cools as it passes through the device.

element. The condensed liquid phase is separated by gravity and

5.5.5 A vapor sample must be kept at least 10°C above the removed from the bottom of the separator. (See Fig. 5.)

hydrocarbon dew point temperature to prevent condensation of 6.1.3.1 Since this process removes part of the sample, the

the sample. The sample line should be heat traced and insulated impact on sample composition must be considered.

when appropriate. 6.1.3.2 The condenser/separator should be located immedi-

5.5.5.1 For compressed natural gas (CNG), the pressure ately upstream from the analyzer.

must be reduced in two stages to avoid condensation of liquids

caused by the Joule-Thompson effect. In a heated zone at

approximately 50°C, the pressure should be dropped to ap-

proximately 10 MPa (1500 psig) and then to a suitable pressure

for the analyzer. Any conditioning of the sample must be

completed in the heated zone.

5.5.5.2 The sample line from the heated zone to the analyzer

must be heat traced to avoid par

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.