ASTM E693-12e1

(Practice)Standard Practice for Characterizing Neutron Exposures in Iron and Low Alloy Steels in Terms of Displacements Per Atom (DPA)

Standard Practice for Characterizing Neutron Exposures in Iron and Low Alloy Steels in Terms of Displacements Per Atom (DPA)

SIGNIFICANCE AND USE

4.1 A pressure vessel surveillance program requires a methodology for relating radiation-induced changes in materials exposed in accelerated surveillance locations to the condition of the pressure vessel (see Practice E853). An important consideration is that the irradiation exposures be expressed in a unit that is physically related to the damage mechanisms.

4.2 A major source of neutron radiation damage in metals is the displacement of atoms from their normal lattice sites. Hence, an appropriate damage exposure index is the number of times, on the average, that an atom has been displaced during an irradiation. This can be expressed as the total number of displaced atoms per unit volume, per unit mass, or per atom of the material. Displacements per atom is the most common way of expressing this quantity. The number of dpa associated with a particular irradiation depends on the amount of energy deposited in the material by the neutrons, and hence, depends on the neutron spectrum. (For a more extended discussion, see Practice E521.)

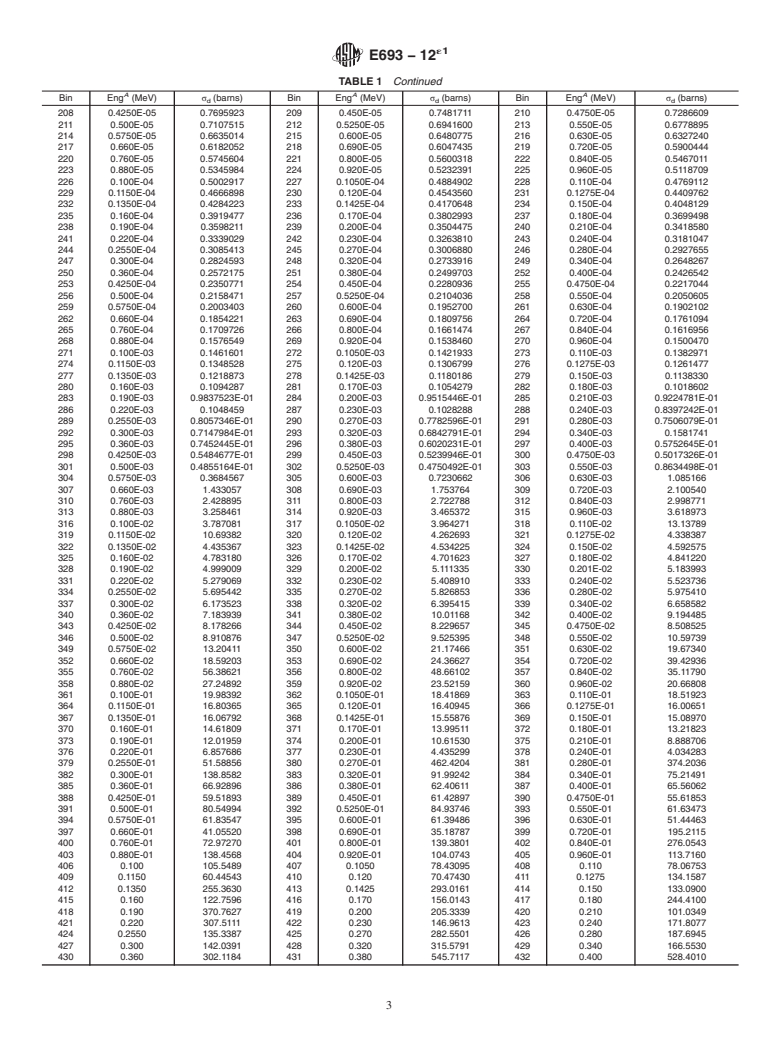

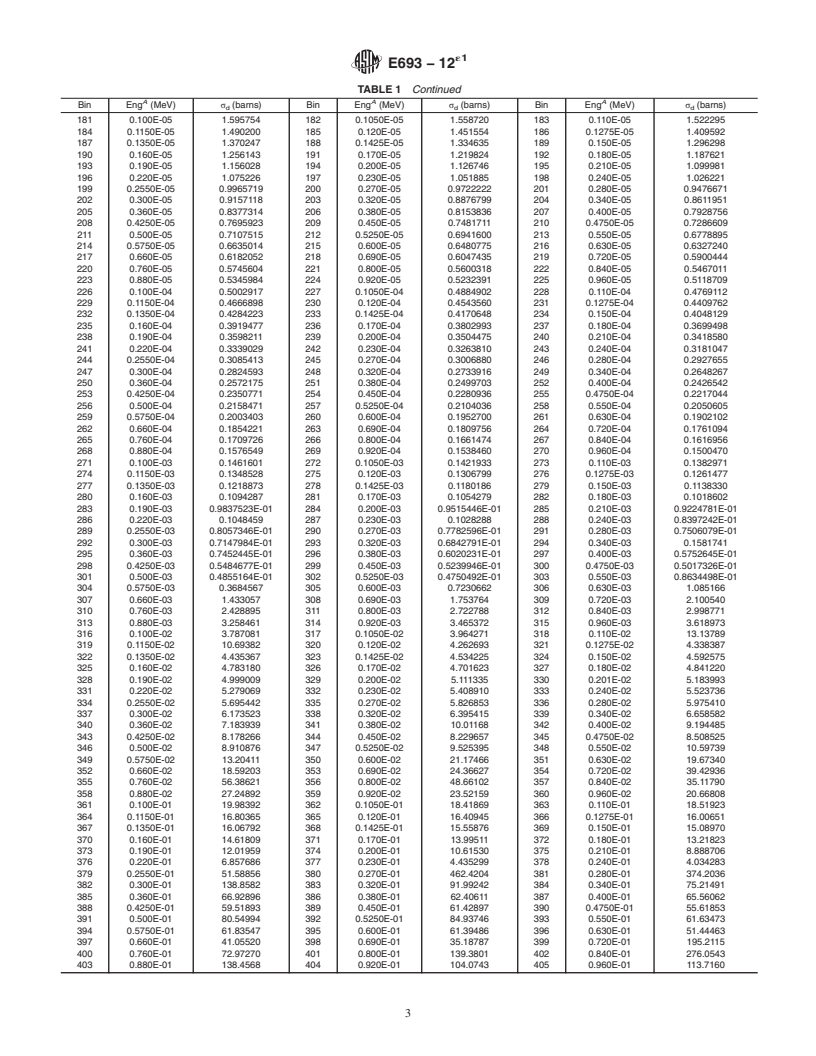

4.3 No simple correspondence exists in general between dpa and a particular change in a material property. A reasonable starting point, however, for relative correlations of property changes produced in different neutron spectra is the dpa value associated with each environment. That is, the dpa values themselves provide a spectrum-sensitive index that may be a useful correlation parameter, or some function of the dpa values may affect correlation. (A) Energies represent the lower bin boundary. The upper bin limit is 20.0 MeV

4.4 Since dpa is a construct that depends on a model of the neutron interaction processes in the material lattice, as well as the cross section (probability) for each of these processes, the value of dpa would be different if improved models or cross sections are used. The calculated dpa cross section for ferritic iron, as given in this practice, is determined by the procedure given in 6.3. The currently re...

SCOPE

1.1 This practice describes a standard procedure for characterizing neutron irradiations of iron (and low alloy steels) in terms of the exposure index displacements per atom (dpa) for iron.

1.2 Although the methods of this practice apply to any material for which a displacement cross section σd(E) is known (see Practice E521), this practice is written specifically for iron.

1.3 It is assumed that the displacement cross section for iron is an adequate approximation for calculating displacements in steels that are mostly iron (95 to 100 %) in radiation fields for which secondary damage processes are not important.

1.4 Procedures analogous to this one can be formulated for calculating dpa in charged particle irradiations. (See Practice E521.)

1.5 The application of this practice requires knowledge of the total neutron fluence and flux spectrum. Refer to Practice E521 for determining these quantities.

1.6 The correlation of radiation effects data is beyond the scope of this practice.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: E693 − 12

Standard Practice for

Characterizing Neutron Exposures in Iron and Low Alloy

1

Steels in Terms of Displacements Per Atom (DPA)

This standard is issued under the fixed designation E693; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—The title of this practice was updated editorially in May 2017.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This practice describes a standard procedure for charac-

E170 Terminology Relating to Radiation Measurements and

terizing neutron irradiations of iron (and low alloy steels) in

Dosimetry

terms of the exposure index displacements per atom (dpa) for

E521 Practice for Investigating the Effects of Neutron Ra-

iron.

diation Damage Using Charged-Particle Irradiation

1.2 Although the methods of this practice apply to any

E821 Practice for Measurement of Mechanical Properties

material for which a displacement cross sectionσ (E) is known

d

During Charged-Particle Irradiation

(see Practice E521), this practice is written specifically for iron.

E853 Practice for Analysis and Interpretation of Light-Water

1.3 It is assumed that the displacement cross section for iron

Reactor Surveillance Results

is an adequate approximation for calculating displacements in

steels that are mostly iron (95 to 100 %) in radiation fields for

3. Terminology

which secondary damage processes are not important.

3.1 Definitions for terms used in this practice can be found

1.4 Procedures analogous to this one can be formulated for

in Terminology E170.

calculating dpa in charged particle irradiations. (See Practice

E521.)

4. Significance and Use

1.5 The application of this practice requires knowledge of 4.1 A pressure vessel surveillance program requires a meth-

the total neutron fluence and flux spectrum. Refer to Practice

odology for relating radiation-induced changes in materials

E521 for determining these quantities. exposed in accelerated surveillance locations to the condition

of the pressure vessel (see Practice E853). An important

1.6 The correlation of radiation effects data is beyond the

consideration is that the irradiation exposures be expressed in

scope of this practice.

a unit that is physically related to the damage mechanisms.

1.7 This standard does not purport to address all of the

4.2 A major source of neutron radiation damage in metals is

safety concerns, if any, associated with its use. It is the

the displacement of atoms from their normal lattice sites.

responsibility of the user of this standard to establish appro-

Hence, an appropriate damage exposure index is the number of

priate safety and health practices and determine the applica-

times, on the average, that an atom has been displaced during

bility of regulatory limitations prior to use.

an irradiation. This can be expressed as the total number of

1.8 This international standard was developed in accor-

displaced atoms per unit volume, per unit mass, or per atom of

dance with internationally recognized principles on standard-

the material. Displacements per atom is the most common way

ization established in the Decision on Principles for the

of expressing this quantity. The number of dpa associated with

Development of International Standards, Guides and Recom-

a particular irradiation depends on the amount of energy

mendations issued by the World Trade Organization Technical

deposited in the material by the neutrons, and hence, depends

Barriers to Trade (TBT) Committee.

on the neutron spectrum. (For a more extended discussion, see

Practice E521.)

1

This practice is under the jurisdiction of ASTM Committee E10 on Nuclear

Technology and Applicationsand is the direct responsibility of Subcommittee

2

E10.05 on Nuclear Radiation Metrology. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved June 1, 2012. Published June 2012. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1979. Last previous edition approved in 2007 as E693 – 01(2007). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E0693-12E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

E693 − 12

4.3 No simple correspondence exists in general between dpa associated with each environment. That is, the dpa values

and a particular change in a material property. A reasonable themselves provide a spectrum-sensitive index that may be a

starting point, howev

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E693 − 12 E693 − 12

Standard Practice for

Characterizing Neutron Exposures in Iron and Low Alloy

Steels in Terms of Displacements Per Atom (DPA),

1

E 706(ID)(DPA)

This standard is issued under the fixed designation E693; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—The title of this practice was updated editorially in May 2017.

1. Scope

1.1 This practice describes a standard procedure for characterizing neutron irradiations of iron (and low alloy steels) in terms

of the exposure index displacements per atom (dpa) for iron.

1.2 Although the methods of this practice apply to any material for which a displacement cross section σ (E) is known (see

d

Practice E521), this practice is written specifically for iron.

1.3 It is assumed that the displacement cross section for iron is an adequate approximation for calculating displacements in

steels that are mostly iron (95 to 100 %) in radiation fields for which secondary damage processes are not important.

1.4 Procedures analogous to this one can be formulated for calculating dpa in charged particle irradiations. (See Practice E521.)

1.5 The application of this practice requires knowledge of the total neutron fluence and flux spectrum. Refer to Practice E521

for determining these quantities.

1.6 The correlation of radiation effects data is beyond the scope of this practice.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E170 Terminology Relating to Radiation Measurements and Dosimetry

E521 Practice for Investigating the Effects of Neutron Radiation Damage Using Charged-Particle Irradiation

E821 Practice for Measurement of Mechanical Properties During Charged-Particle Irradiation

E853 Practice for Analysis and Interpretation of Light-Water Reactor Surveillance Results

3. Terminology

3.1 Definitions for terms used in this practice can be found in Terminology E170.

4. Significance and Use

4.1 A pressure vessel surveillance program requires a methodology for relating radiation-induced changes in materials exposed

in accelerated surveillance locations to the condition of the pressure vessel (see Practice E853). An important consideration is that

the irradiation exposures be expressed in a unit that is physically related to the damage mechanisms.

1

This practice is under the jurisdiction of ASTM Committee E10 on Nuclear Technology and Applicationsand is the direct responsibility of Subcommittee E10.05 on

Nuclear Radiation Metrology.

Current edition approved June 1, 2012. Published June 2012. Originally approved in 1979. Last previous edition approved in 2007 as E693 – 01(2007). DOI:

10.1520/E0693-12.10.1520/E0693-12E01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

E693 − 12

4.2 A major source of neutron radiation damage in metals is the displacement of atoms from their normal lattice sites. Hence,

an appropriate damage exposure index is the number of times, on the average, that an atom has been displaced during an

irradiation. This can be expressed as the total number of displaced atoms per unit volume, per unit mass, or per atom of the

material. Displacements per atom is the most common way of expressing this quantity. The number of dpa associated with a

particular irradiation depends on the amount of energy deposited in the material by the neutrons, and hence, depends on the neutron

spectrum. (For

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.