ASTM E2556/E2556M-09

(Specification)Standard Specification for Vapor Permeable Flexible Sheet Water-Resistive Barriers Intended for Mechanical Attachment

Standard Specification for Vapor Permeable Flexible Sheet Water-Resistive Barriers Intended for Mechanical Attachment

SCOPE

1.1 This specification is limited to vapor permeable flexible sheet materials which are intended to be mechanically attached and are generally installed behind the cladding system in exterior walls.

1.2 This specification is limited to the evaluation of materials and does not address installed performance. Although the fastening practices (type of fastener, fastening schedule, etc.) may affect the installed function of these materials, they are not included in this specification.

1.3 This specification does not address integration of the water-resistive barrier with other wall elements. The topic is addressed in more detail in Practice E2112 and Guide E2266.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2556/E2556M – 09

Standard Specification for

Vapor Permeable Flexible Sheet Water-Resistive Barriers

Intended for Mechanical Attachment

ThisstandardisissuedunderthefixeddesignationE2556/E2556M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope board, and Other Sheet Materials by the Dry Indicator

Method

1.1 This specification is limited to vapor permeable flexible

D828 Test Method for Tensile Properties of Paper and

sheet materials which are intended to be mechanically attached

Paperboard Using Constant-Rate-of-Elongation Appara-

and are generally installed behind the cladding system in

tus

exterior walls.

D882 Test Method for Tensile Properties of Thin Plastic

1.2 This specification is limited to the evaluation of mate-

Sheeting

rials and does not address installed performance.Although the

D4869 SpecificationforAsphalt-SaturatedOrganicFeltUn-

fastening practices (type of fastener, fastening schedule, etc.)

derlayment Used in Steep Slope Roofing

mayaffecttheinstalledfunctionofthesematerials,theyarenot

D5034 Test Method for Breaking Strength and Elongation

included in this specification.

of Textile Fabrics (Grab Test)

1.3 This specification does not address integration of the

E96/E96M Test Methods for Water Vapor Transmission of

water-resistive barrier with other wall elements. The topic is

Materials

addressed in more detail in Practice E2112 and Guide E2266.

E631 Terminology of Building Constructions

1.4 The values stated in either SI units or inch-pound units

E1677 Specification for an Air Barrier (AB) Material or

are to be regarded separately as standard. The values stated in

System for Low-Rise Framed Building Walls

each system may not be exact equivalents; therefore, each

E2112 Practice for Installation of Exterior Windows, Doors

system shall be used independently of the other. Combining

and Skylights

values from the two systems may result in non-conformance

E2128 Guide for Evaluating Water Leakage of Building

with the standard.

Walls

1.5 This standard does not purport to address all of the

E2136 GuideforSpecifyingandEvaluatingPerformanceof

safety concerns, if any, associated with its use. It is the

Single Family Attached and Detached Dwellings—

responsibility of the user of this standard to establish appro-

Durability

priate safety and health practices and determine the applica-

E2266 Guide for Design and Construction of Low-Rise

bility of regulatory limitations prior to use.

Frame Building Wall Systems to Resist Water Intrusion

2. Referenced Documents

G154 Practice for Operating Fluorescent Light Apparatus

for UV Exposure of Nonmetallic Materials

2.1 ASTM Standards:

2.2 Other Standards:

D226 SpecificationforAsphalt-SaturatedOrganicFeltUsed

AATCC Test Method 127 Water Resistance: Hydrostatic

in Roofing and Waterproofing

Pressure Test

D779 Test Method for Water Resistance of Paper, Paper-

CGSB CAN2-51.32.M77 Sheathing Membrane, Breather

Type

This specification is under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.55

on Exterior Building Wall Systems. Withdrawn. The last approved version of this historical standard is referenced

Current edition approved Nov. 1, 2009. Published March 2010. DOI: 10.1520/ on www.astm.org.

E2556_A2556M-09. Available from American Association of Textile Chemists and Colorists

For referenced ASTM standards, visit the ASTM website, www.astm.org, or (AATCC), P.O. Box 12215, Research Triangle Park, NC 27709, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.aatcc.org.

Standards volume information, refer to the standard’s Document Summary page on Available from Canadian General Standards Board (CGSB), Gatineau, Quebec

the ASTM website. K1A 1G6, Canada, http://www.tpsgc-pwgsc.gc.ca/cgsb.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2556/E2556M – 09

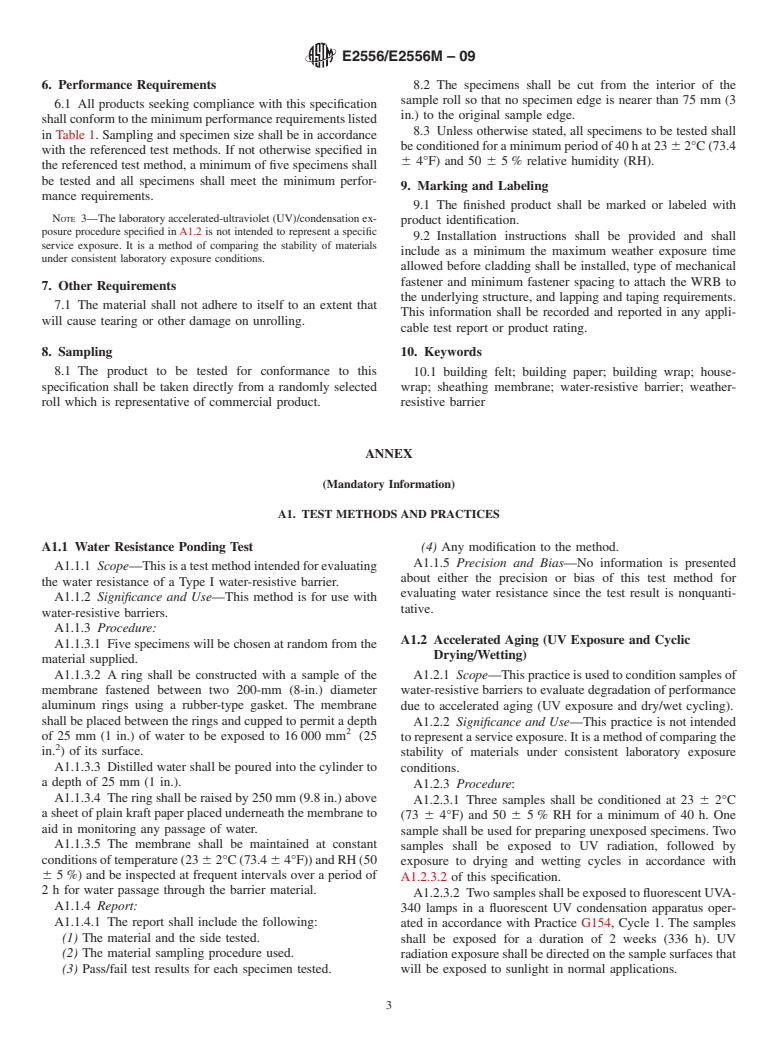

TABLE 1 Requirements for Water Resistive Barriers

Minimum Performance Requirements

Test Requirement Specimen Type Test Method

Type I Type II

Dry tensile (1) as Test Method D828 for paper 3500 N/m (20 lb/in.) minimum (machine and cross direction)

strength or dry manufactured and felt materials, or

breaking force and Test Methods D882 for 3500 N/m (20 lb/in.) minimum (machine and cross direction)

(choose 1) (2) aged in polymeric materials, or

accordance Test Method D5034 (Grab 178 N (40 lbf) minimum (machine direction)

with A1.2 Method)

156 N (35 lbf) minimum (cross direction)

Water resistance (1) as Test Method D779, or 10 min minimum 60 min minimum

test (choose 1) manufactured

and Water Resistance Ponding No water shall transmit through not applicable

(2) aged in Test (A1.1), or the membrane in 120 min

accordance

with A1.2 AATCC Test Method 127 not applicable No leakage is permitted to the underside

except that the specimens of any specimen in 300 min

shall be held at a

hydrostatic head of

55 cm (21.6 in.)

Water vapor as received Test Method E96/E96M 290 ng/(Pa · s · m ) (5 perms) minimum

transmission (Dessicant Method)

test

Pliability test as received see A1.3 The material shall not crack when bent over a 1.6 mm ( ⁄16-in.)

diameter mandrel at a temperature of 0°C (32°F)

Federal Specification UU-B-790a Federal Specification be perforated with small holes or may be non-perforated,

Building Paper, Vegetable Fiber (Kraft, Waterproofed, composed of films or non-woven materials.

Water Repellant and Fire Resistant)

3.2.4 Type I WRB—water-resistive barrier with base-level

TAPPI T-410 Test Method for Grammage of Paper and

water resistance (see Table 1).

Paperboard (Weight Per Unit Area)

3.2.5 Type II WRB—water-resistive barrier with enhanced

UBC Standard 14-1 Kraft Waterproof Building Paper

water resistance (see Table 1).

UBC Standard 32-1 Asphalt Saturated Rag Felt

3.2.6 Water-Resistive Barrier (WRB)—a material that is

ICC-ESAcceptance CriteriaAC38 for Water-Resistive Bar-

intended to resist liquid water that has penetrated the cladding

riers

system.

3. Terminology

NOTE 1—Wall assemblies often include two lines of defense against

3.1 Definitions—For definitions of general terms related to rain water ingress. The cladding serves as the first line of defense and the

water-resistive barrier as the second line of defense

building construction used in this specification, refer to Termi-

NOTE 2—Water-resistive barriers are sometimes referred to as weather

nology E631.

resistant barriers or sheathing membranes.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 felt-based barrier—asphalt-saturatedorganicfeltsthat

4. Classification

comply with Specification D226 and are intended for use as

water-resistive barriers.

4.1 This specification covers vapor permeable flexible sheet

3.2.2 paper-based barrier—building papers composed pre-

materials that are classified as Type I and Type II, which are

dominantly of sulfate pulp fibers that comply with Federal

determined by the degree of water resistance. The water-

Specification UU-B-790a and that are intended for use as

resistive barrier material composition shall determine the

water-resistive barriers.

specific test method used to measure physical and mechanical

3.2.3 polymer-basedbarrier—plasticsheetmaterialsforuse

properties (see Table 1). Appendix X1 provides explanatory

as water-resistive barriers. These materials are generally re-

information on the physical and mechanical property test

ferred to as a housewrap or building wrap. These materials can

methods.

5. Materials and Manufacture

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

5.1 Description of the material composition and structure

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

dodssp.daps.dla.mil.

shall be made available upon request.

Available from TechnicalAssociation of the Pulp and Paper Industry (TAPPI),

5.1.1 Descriptions of the materials shall include roll weight

15 Technology Parkway South, Norcross, GA 30092, http://www.tappi.org.

and dimensions.

Uniform Building Code (UBC) information is available from International

Code Council (ICC), 500 New Jersey Ave., NW, 6th Floor, Washington, DC

5.1.2 Descriptions of the material composition shall include

20001-2070, http://www.iccsafe.org.

linear density (basis weight). Basis weight shall be measured

Available from the ICC Evaluation Service (ICC-ES), 5360 Workman Mill

Road, Whittier, CA 90601, http://www.icc-es.org. using TAPPI T-410.

E2556/E2556M – 09

6. Performance Requirements 8.2 The specimens shall be cut from the interior of the

sample roll so that no specimen edge is nearer than 75 mm (3

6.1 All products seeking compliance with this specification

in.) to the original sample edge.

shallconformtotheminimumperformancerequirementslisted

8.3 Unless otherwise stated, all specimens to be tested shall

in Table 1. Sampling and specimen size shall be in accordance

beconditionedforaminimumperiodof40hat23 62°C(73.4

with the referenced test methods. If not otherwise specified in

6 4°F) and 50 6 5 % relative humidity (RH).

the referenced test method, a minimum of five specimens shall

be tested and all specimens shall meet the minimum perfor-

9. Marking and Labeling

mance requirements.

9.1 The finished product shall be marked or labeled with

NOTE 3—The laboratory accelerated-ultraviolet (UV)/condensation ex-

product identification.

posure procedure specified in A1.2 is not intended to represent a specific

9.2 Installation instructions shall be provided and shall

service exposure. It is a method of comparing the stability of materials

include as a minimum the maximum weather exposure time

under consistent laboratory exposure conditions.

allowed before cladding shall be installed, type of mechanical

fastener and minimum fastener spacing to attach the WRB to

7. Other Requirements

the underlying structure, and lapping and taping requirements.

7.1 The material shall not adhere to itself to an extent that

This information shall be recorded and reported in any appli-

will cause tearing or other damage on unrolling.

cable test report or product rating.

8. Sampling 10. Keywords

8.1 The product to be tested for conformance to this

10.1 building felt; building paper; building wrap; house-

specification shall be taken directly from a randomly selected wrap; sheathing membrane; water-resistive barrier; weather-

roll which is representative of commercial product.

resistive barrier

ANNEX

(Mandatory Information)

A1. TEST METHODS AND PRACTICES

A1.1 Water Resistance Ponding Test (4) Any modification to the method.

A1.1.5 Precision and Bias—No information is presented

A1.1.1 Scope—Thisisatestmethodintendedforevaluating

about either the precision or bias of this test method for

the water resistance of a Type I water-resistive barrier.

evaluating water resistance since the test result is nonquanti-

A1.1.2 Significance and Use—This method is for use with

tative.

water-resistive barriers.

A1.1.3 Procedure:

A1.2 Accelerated Aging (UV Exposure and Cyclic

A1.1.3.1 Five specimens will be chosen at random from the

Drying/Wetting)

material supplied.

A1.1.3.2 A ring shall be constructed with a sample of the A1.2.1 Scope—Thispracticeisusedtoconditionsamplesof

membrane fastened between two 200-mm (8-in.) diameter water-resistive barriers to evaluate degradation of performance

aluminum rings using a rubber-type gasket. The membrane due to accelerated aging (UV exposure and dry/wet cycling).

shall be placed between the rings and cupped to permit a depth A1.2.2 Significance and Use—This practice is not intended

of 25 mm (1 in.) of water to be exposed to 16 000 mm (25

torepresentaserviceexposure.Itisamethodofcomparingthe

in. ) of its surface. stability of materials under consistent laboratory exposure

A1.1.3.3 Distilled water shall be poured into the cylinder to

conditions.

a depth of 25 mm (1 in.).

A1.2.3 Procedure:

A1.1.3.4 The ring shall be raised by 250 mm (9.8 in.) above

A1.2.3.1 Three samples shall be conditioned at 23 6 2°C

a sheet of plain kraft paper placed underneath the membrane to

(73 6 4°F) and 50 6 5 % RH for a minimum of 40 h. One

aid in monitoring any passage of water.

sample shall be used for preparing unexposed specimens. Two

A1.1.3.5 The membrane shall be maintained at constant

samples shall be exposed to UV radiation, followed by

conditionsoftemperature(23 62°C(73.4 64°F))andRH(50

exposure to drying and wetting cycles in accordance with

6 5 %) and be inspected at frequent intervals over a period of

A1.2.3.2 of this specification.

2 h for water passage through the barrier material.

A1.2.3.2 TwosamplesshallbeexposedtofluorescentUVA-

A1.1.4 Report:

340 lamps in a fluorescent UV condensation apparatus oper-

A1.1.4.1 The report shall include the following:

ated in accordance with Practice G154, Cycle 1. The samples

(1) The material and the side tested.

shall be exposed for a duration of 2 weeks (336 h). UV

(2) The material sampling procedure used.

radiationexposureshallbedirectedonthesamplesurfacesthat

(3) Pass/fail test results for each specimen tested. will be exposed to sunlight in normal applications.

E2556/E2556M – 09

A1.2.3.3 Three specimens shall be cut from the samples A1.3.3 Procedure:

That have been exposed to UV radiation and subjected to A1.3.3.1 Five specimens will be chosen at random from the

further accelerated aging consisting of 25 cycles of drying and material supplied.

soaking as follows: A1.3.3.2 Each specimen is bent 180 6 5° over a 1.6 mm

(1) Oven drying at 49°C (120°F) for 3 h, with all surfaces ( ⁄16 in.) mandrel in 2 61s.

exposed. A1.3.3.3 The specimen and mandrel shall be maintained at

(2)Immersioninroom-temperature(23 62°C(73 64°F)) constantconditionsoftemperature(0 62°C(32 64°F)during

water for 3 h, with all surfaces submerged. the test procedure.

(3) After removal from the water, specimens shall be A1.3.4 Report:

blotted dry, then air-dried for 18 h at a 23.8 6 2.8°C (75 6 A1.3.4.1 The report shall include the following:

5°F) room temperature, with all surfaces exposed. (1) The material tested.

(2) The material sampling procedure used.

A1.3 Pliability

(3) Observations of any visual cracking.

A1.3.1 Scope—This is the test method intended for evalu- (4) Any modification to the method.

ating the pliability of a water-resistive barrier A1.3.5 Precision and Bias—No information is presented

A1.3.2 Significance and Use—This method is for use with about either the precision or bi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.