ASTM D4222-03(2008)

(Test Method)Standard Test Method for Determination of Nitrogen Adsorption and Desorption Isotherms of Catalysts and Catalyst Carriers by Static Volumetric Measurements

Standard Test Method for Determination of Nitrogen Adsorption and Desorption Isotherms of Catalysts and Catalyst Carriers by Static Volumetric Measurements

SIGNIFICANCE AND USE

The test method has two main functions: first, it provides data useful for establishing the pore size distribution of catalyst materials, which in turn may influence their performance; and second, it serves as a laboratory test which may be used to study porosity changes that may occur during the manufacture and evaluation of catalysts.

SCOPE

1.1 This test method covers the determination of nitrogen adsorption and desorption isotherms of catalysts and catalyst carriers at the boiling point of liquid nitrogen. A static volumetric measuring system is used to obtain sufficient equilibrium adsorption points on each branch of the isotherm to adequately define the adsorption and desorption branches of the isotherm. Thirty points evenly spread over the isotherm is considered to be the minimum number of points that will adequately define the isotherm.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4222 − 03(Reapproved 2008)

Standard Test Method for

Determination of Nitrogen Adsorption and Desorption

Isotherms of Catalysts and Catalyst Carriers by Static

Volumetric Measurements

This standard is issued under the fixed designation D4222; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the determination of nitrogen 3.1 Definitions—See Terminology D3766.

adsorption and desorption isotherms of catalysts and catalyst

3.2 Symbols:

carriers at the boiling point of liquid nitrogen. A static

volumetric measuring system is used to obtain sufficient

equilibriumadsorptionpointsoneachbranchoftheisothermto

PH = initial helium pressure, torr.

adequately define the adsorption and desorption branches of PH = helium pressure after equilibration, torr.

TH = temperature of manifold at initial helium pressure,

the isotherm. Thirty points evenly spread over the isotherm is

°C.

considered to be the minimum number of points that will

TH = temperature of manifold after equilibration, °C.

adequately define the isotherm.

P = initial N pressure, torr.

1 2

1.2 The values stated in SI units are to be regarded as the

T = manifold temperature at initial N pressure, K.

1 2

standard. The values given in parentheses are for information

T' = manifold temperature at initial N pressure, °C.

1 2

only.

P = pressure after equilibration, torr.

T = manifold temperature after equilibrrium, K.

1.3 This standard does not purport to address all of the

T' = manifold temperature after equilibrium, °C.

safety concerns, if any, associated with its use. It is the 2

P = initial N pressure during desorption, torr.

responsibility of the user of this standard to establish appro- 3 2

T = manifold temperature at initial N pressure, K.

3 2

priate safety and health practices and determine the applica-

T' = manifold temperature at initial N pressure, °C.

3 2

bility of regulatory limitations prior to use.

P = pressure after equilibration during desorption, torr.

T = manifold temperature after equilibration, K.

2. Referenced Documents

T' = manifold temperature after equilibration, °C.

2.1 ASTM Standards: P = liquid nitrogen vapor pressure, torr.

D3663Test Method for Surface Area of Catalysts and T = liquid nitrogen temperature, K.

s

X = relative pressure, P /P .

Catalyst Carriers

2(4) 0

V = volume of manifold, cm .

D3766Terminology Relating to Catalysts and Catalysis d

V = the dead-space volume factor, cm (STP)/torr.

s

E177Practice for Use of the Terms Precision and Bias in

W = mass of sample, g.

s

ASTM Test Methods

W = tare of sample tube, g.

E456Terminology Relating to Quality and Statistics

W' = sample mass + tare of tube after degassing, g.

E691Practice for Conducting an Interlaboratory Study to

W = sample mass + tare of tube after adsorption, g.

Determine the Precision of a Test Method 3

V = volume of nitrogen in the dead-space, cm (STP).

ds

V = see 12.4.3.

V = see 12.4.4.

V = see 12.4.5.

ThistestisunderthejurisdictionofASTMCommitteeD32onCatalystsandis

t

the direct responsibility of Subcommittee D32.01 on Physical-Chemical Properties. V = see 12.4.7.

ad

Current edition approved April 1, 2008. Published April 2008. Originally

V = see 12.5.

de

approved in 1983. Last previous edition approved in 2003 as D4222–03. DOI:

10.1520/D4222-03R08.

4. Summary of Test Method

Adamson,A. W., Physical Chemistry of Surfaces, 3rd ed., John Wiley & Sons,

New York, NY, 1976, p. 532.

4.1 Thesampleisheatedandevacuatedtoremoveadsorbed

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

vapors from the surface.The nitrogen adsorption branch of the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

isotherm is determined by evacuating the sample, cooling the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. sample to the boiling point of liquid nitrogen (;77.3 K), and

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4222 − 03 (2008)

6.1.3 Pressure Sensing Devices or Pressure Transducers,

capable of measurements with a sensitivity of at least 0.1 torr,

in the range from 0 to 1000 torr (1 torr = 133.3 Pa).

6.1.4 Value (H), from the helium supply to the distribution

manifold.

6.1.5 Valve (N), from the nitrogen supply to the distribution

manifold.

6.1.6 The connection between the sample tube and the S

valve can be a standard-taper glass joint, a glass-to-glass seal,

or a compression fitting.

FIG. 1 Schematic Diagram of Adsorption Apparatus

3 3

6.2 Sample Tubes, with volumes from 5 cm to 100 cm

depending on the application.

subsequently adding stepwise, known amounts of nitrogen gas

to the sample in such amounts that the form of the adsorption

6.3 Heating Mantles or Small Furnaces.

isotherm is adequately defined and the saturation pressure of

6.4 Dewar Flasks.

nitrogen is reached. Each additional dose of nitrogen is

10−7

6.5 Laboratory Balance, with 0.1-mg ( kg) sensitivity.

introduced to the sample only after the foregoing dose of

nitrogen has reached adsorption equilibrium with the sample.

6.6 Thermometer or Thermocouple, for measuring the tem-

By definition, equilibrium is reached if the change in gas

perature of the distribution manifold [T' (i)or T' (i)] in °C.

1 2

pressure is no greater than 0.1 torr/5 min interval. The

6.6.1 The manifold may be thermostated at a particular

desorption isotherm is determined by desorbing nitrogen from

temperature, a few degrees above ambient, to obviate the

the saturated sample in a stepwise mode with the same

necessity of recording this temperature at each reading.

precautions taken to ensure desorption equilibration as applied

6.7 Thermometer, for measuring the temperature of the

under adsorption conditions. It is essential that the experimen-

liquidnitrogenbath(T (i))inKelvin.Preferably,thisthermom-

s

tal points be distributed over the isotherm in such a manner as

eter will be a nitrogen vapor-pressure-thermometer, often

tocorrectlyidentifyanddefinetheisotherm.Iftheadditionsor

referred to in a commercial instrument as a pressure saturation

withdrawals of nitrogen are too large, the temporarily too-high

tube, that gives P directly and has greater precision, or a

nitrogengaspressureduringadsorptionortoo-lowgaspressure

resistance thermometer from which P values may be derived.

during desorption, may result in so-called scanning effects

within the hysteresis loop of the adsorption-desorption

NOTE1—Apressuretransducermaybeplacedbetweenthesampletube

and the manifold to monitor equilibrium pressure, but this is not a

branches of the isotherm. The occurrence of scanning may

requirement of the system.

result in too-high equilibrium values for the adsorption iso-

therm and too-low values for the desorption isotherm.

7. Reagents

5. Significance and Use

7.1 Helium Gas—A cylinder of helium gas at least 99 %

5.1 The test method has two main functions: first, it pro-

pure.

vides data useful for establishing the pore size distribution of

7.2 Liquid Nitrogen , of such purity that P is not more than

catalyst materials, which in turn may influence their perfor-

20 torr above barometric pressure. A fresh daily supply is

mance; and second, it serves as a laboratory test which may be

recommended.

used to study porosity changes that may occur during the

7.3 Nitrogen Gas—A cylinder of nitrogen gas at least

manufacture and evaluation of catalysts.

99.999 % pure.

6. Apparatus

8. Procedure-Sample Preparation and Degassing

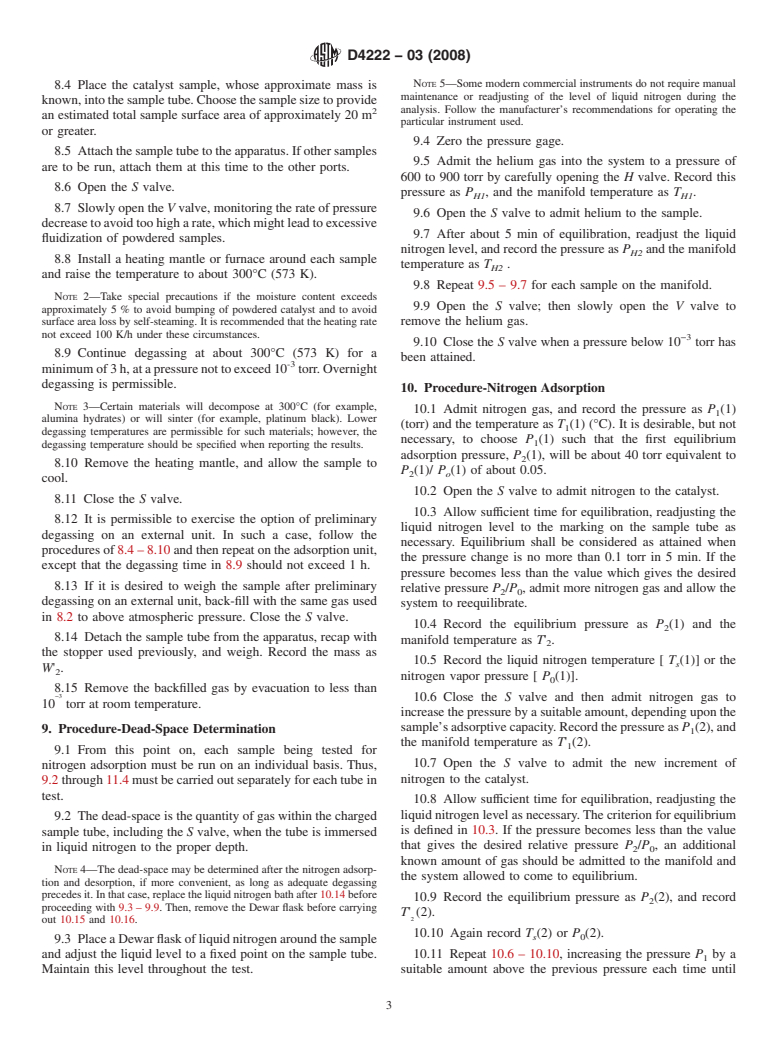

6.1 Ageneric schematic diagram of the minimum apparatus

requirement is shown in Fig. 1.Acommercial instrument may

8.1 Selectasampletubeofthedesiredsize.Tominimizethe

be used and may be constructed of glass or of metal. The

dead-space, a 5-cm sample tube is preferred for samples not

specific commercial apparatus chosen may have a different

exceeding about 1 g. However, to avoid boiling when degas-

configuration than that shown in Fig. 1 and may require

sing is started, a 25-cm sample tube may be preferred for

modification of the sequence of valve operation and of the

finely powdered catalysts. A small glass-wool plug or fritted

calculations and equations used. It should have the following

disk placed in the neck of the sample tube above the liquid

features as a minimum:

nitrogen level, will eliminate the possibility of any small

6.1.1 Distribution Manifold, having a (V ), known to the

d catalyst particles entering the vacuum system.

nearest 0.05 cm . This volume is defined as the volume

8.2 Fill the sample tube with nitrogen or helium at atmo-

between the stopcocks or valves and includes the pressure

sphericpressure,afterremovingairbyevacuation.Thismaybe

gage.

done on the adsorption unit or on a separate piece of equip-

6.1.2 Vacuum System, capable of attaining pressures below

-4

ment.

10 torr (1 torr = 133.3 Pa). This will include a vacuum gage

(not shown in Fig. 1). Access to the distribution manifold is 8.3 Remove the sample tube from the system, cap, and

through the valve V. weigh. Record the mass as W .

D4222 − 03 (2008)

NOTE 5—Some modern commercial instruments do not require manual

8.4 Place the catalyst sample, whose approximate mass is

maintenance or readjusting of the level of liquid nitrogen during the

known,intothesampletube.Choosethesamplesizetoprovide

analysis. Follow the manufacturer’s recommendations for operating the

an estimated total sample surface area of approximately 20 m

particular instrument used.

or greater.

9.4 Zero the pressure gage.

8.5 Attachthesampletubetotheapparatus.Ifothersamples

9.5 Admit the helium gas into the system to a pressure of

are to be run, attach them at this time to the other ports.

600 to 900 torr by carefully opening the H valve. Record this

8.6 Open the S valve.

pressure as P , and the manifold temperature as T .

H1 H1

8.7 Slowlyopenthe Vvalve,monitoringtherateofpressure

9.6 Open the S valve to admit helium to the sample.

decreasetoavoidtoohigharate,whichmightleadtoexcessive

9.7 After about 5 min of equilibration, readjust the liquid

fluidization of powdered samples.

nitrogenlevel,andrecordthepressureas P andthemanifold

H2

8.8 Install a heating mantle or furnace around each sample

temperature as T .

H2

and raise the temperature to about 300°C (573 K).

9.8 Repeat 9.5 – 9.7 for each sample on the manifold.

NOTE 2—Take special precautions if the moisture content exceeds

9.9 Open the S valve; then slowly open the V valve to

approximately5%to avoid bumping of powdered catalyst and to avoid

surfacearealossbyself-steaming.Itisrecommendedthattheheatingrate remove the helium gas.

not exceed 100 K/h under these circumstances.

−3

9.10 Close the S valve when a pressure below 10 torr has

8.9 Continue degassing at about 300°C (573 K) for a

been attained.

-3

minimumof3h,atapressurenottoexceed10 torr.Overnight

degassing is permissible.

10. Procedure-Nitrogen Adsorption

NOTE 3—Certain materials will decompose at 300°C (for example,

10.1 Admit nitrogen gas, and record the pressure as P (1)

alumina hydrates) or will sinter (for example, platinum black). Lower

(torr) and the temperature as T (1) (°C). It is desirable, but not

degassing temperatures are permissible for such materials; however, the

necessary, to choose P (1) such that the first equilibrium

degassing temperature should be specified when reporting the results.

adsorption pressure, P (1), will be about 40 torr equivalent to

8.10 Remove the heating mantle, and allow the sample to

P (1)/ P (1) of about 0.05.

2 o

cool.

10.2 Open the S valve to admit nitrogen to the catalyst.

8.11 Close the S valve.

10.3 Allow sufficient time for equilibration, readjusting the

8.12 It is permissible to exercise the option of preliminary

liquid nitrogen level to the marking on the sample tube as

degassing on an external unit. In such a case, follow the

necessary. Equilibrium shall be considered as attained when

proceduresof8.4–8.10andthenrepeatontheadsorptionunit,

the pressure change is no more than 0.1 torr in 5 min. If the

except that the degassing time in 8.9 should not exceed 1 h.

pressure becomes less than the value which gives the desired

8.13 If it is desired to weigh the sample after preliminary

relative pressure P /P , admit more nitrogen gas and allow the

2 0

degassing on an external unit, back-fill with the same gas used

system to reequilibrate.

in 8.2 to above atmospheric pressure. Close the S valve.

10.4 Record the equilibrium pressure as P (1) and the

8.14 Detach the sample tube from the apparatus, recap with

manifold temperature as T' .

the stopper used previously, and weigh. Record the mass as

10.5 Record the liquid nitrogen temperature [ T (1)] or the

s

W' .

nitrogen vapor pressure [ P (1)].

8.15 Remove the backfilled gas by evacuation to less than

−3

10.6 Close the S valve and then admit nitrogen gas to

10 torr at room temperature.

increasethepressurebyasuitableamount,dependinguponthe

sample’sadsorptivecapacity.Recordthepressureas P (2),and

9. Procedure-Dead-Space Determination

the manifold temperature as T' (2).

9.1 From this point on, each sample being tested for

10.7 Open the S valve to admit the new increment of

nitrogen adsorption must be run on an individual basis. Thus,

nitrogen to the catalyst.

9.2through11.4mustbecarriedoutseparatelyforeachtubein

test.

10.8 Allow sufficient time for equilibration, readjusting the

liquidnitrogenlevelasnecessary.Thecriterionforequilibrium

9.2 Thedead-spaceisthequantityofgaswithinthecharged

is defined in 10.3. If the pressure becomes less than the value

sample tube, including the S valve, when the tube is immersed

that gives the desired relative pressure P /P , an additional

in liquid nitrogen to the proper depth.

2 0

known amount of gas should be admitted to the manifold and

NOTE 4—The dead-space may be determined after the nitrogen adsorp-

the system allowed to come to equilibrium.

tion and desorption, if more convenient, as long as adequate degassing

precedesit.Inthatcase,replacetheliquidnitrogenbathafter10.14before

10.9 Record the equilibrium pressure as P (2), and record

proceeding with 9.3 – 9.9. Then, remove the Dewar flask before carrying

T' (2).

out 10.15 and 10.16.

10.10 Again record T (2) or P (2).

s 0

9.3 PlaceaDewarflaskofliquidnitrogenaroundthesample

and adjust the liquid level to a fixed point on the sample tube. 10.11 Repeat 10.6 – 10.10, increasing the pressure P by a

Maintain this level throughout the test. suit

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4222–98 Designation: D 4222 – 03 (Reapproved 2008)

Standard Test Method for

Determination of Nitrogen Adsorption and Desorption

Isotherms of Catalysts Byand Catalyst Carriers by Static

Volumetric Measurements

This standard is issued under the fixed designation D4222; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of nitrogen adsorption and desorption isotherms of catalysts and catalyst carriers

at the boiling point of liquid nitrogen. A static volumetric measuring system is used to obtain sufficient equilibrium adsorption

points on each branch of the isotherm to adequately define the adsorption and desorption branches of the isotherm. Thirty points

evenly spread over the isotherm is considered to be the minimum number of points that will adequately define the isotherm.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D3663 Test Method for Surface Area of Catalysts and Catalyst Carriers

D3766 Terminology Relating to Catalysts and Catalysis

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions— Consult Terminology D 3766— See Terminology D3766.

3.2 Symbols:

PH = initial helium pressure, torr.

PH = helium pressure after equilibration, torr.

TH = temperature of manifold at initial helium pressure, °C.

TH = temperature of manifold after equilibration, °C.

P = initial N pressure, torr.

1 2

T = manifold temperature at initial N pressure, K.

1 2

T8 = manifold temperature at initial N pressure, °C.

1 2

P = pressure after equilibration, torr.

T = manifold temperature after equilibrrium, K.

T8 = manifold temperature after equilibrium, °C.

P = initial N pressure during desorption, torr.

3 2

T = manifold temperature at initial N pressure, K.

3 2

T8 = manifold temperature at initial N pressure, °C.

3 2

This test is under the jurisdiction of ASTM Committee D-32 on Catalysts and is the direct responsibility of Subcommittee D32.01 on Physical-Chemical Properties.

Current edition approved March 10, 1998. Published November 1998. Originally published as D 4222 - 83. Last previous edition D 4222 - 91.

This test is under the jurisdiction of ASTM Committee D32 on Catalysts and is the direct responsibility of Subcommittee D32.01 on Physical-Chemical Properties.

Current edition approved April 1, 2008. Published April 2008. Originally approved in 1983. Last previous edition approved in 2003 as D4222–03.

Annual Book of ASTM Standards, Vol 05.03.

Adamson, A. W., Physical Chemistry of Surfaces, 3rd ed., John Wiley & Sons, New York, NY, 1976, p. 532.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 14.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4222 – 03 (2008)

P = pressure after equilibration during desorption, torr.

T = manifold temperature after equilibration, K.

T8 = manifold temperature after equilibration, °C.

P = liquid nitrogen vapor pressure, torr.

T = liquid nitrogen temperature, K.

s

X = relative pressure, P 2(4)/P .

2(4) 0

V = volume of manifold, cm .

d

V = the dead-space volume factor, cm (STP)/torr.

s

W = weightmass of sample, g.

s

W = tare weight of sample tube, g.

W8 = sample mass + tare weight of tube after degassing, g.

W = sample mass + tare weight of tube after adsorption, g.

V = volume of nitrogen in the dead-space, cm (STP).

ds

V = see 12.4.5see 12.4.3.

V = see 12.4.7see 12.4.4.

V = see 12.4.8. see 12.4.5.

t

V V = see 12.4.10.see 12.4.7.

ad(de) ad

V = see 12.5.

de

4. Summary of Test Method

4.1 The sample is heaterheated and evacuated to remove adsorbed vapors from the surface. The nitrogen adsorption branch of

the isotherm is determined by evacuating the sample, cooling the sample to the boiling point of liquid nitrogen (;77.3 K), and

subsequently adding stepwise, known amounts of nitrogen gas to the sample in such amounts that the form of the adsorption

isotherm is adequately defined and the saturation pressure of nitrogen is reached. Each additional dose of nitrogen is introduced

to the sample only after the foregoing dose of nitrogen has reached adsorption equilibrium with the sample. By definition,

equilibriumisreachedifthechangeingaspressureisnogreaterthan0.1torr/5mininterval.Thedesorptionisothermisdetermined

by desorbing nitrogen from the saturated sample in a stepwise mode with the same precautions taken to ensure desorption

equilibration as applied under adsorption conditions. It is essential that the experimental points be distributed over the isotherm

in such a manner as to correctly identify and define the isotherm. If the additions or withdrawals of nitrogen are too large, the

temporarily too-high nitrogen gas pressure during adsorption or too-low gas pressure during desorption, may result in so-called

scanningeffectswithinthehysteresisloopoftheadsorption-desorptionbranchesoftheisotherm.Theoccurrenceofscanningmay

result in too-high equilibrium values for the adsorption isotherm and too-low values for the desorption isotherm.

5. Significance and Use

5.1 The test method has two main functions: first, it provides data useful for establishing the pore shape and pore size

distribution of catalyst materials, which in turn may influence their performance; and second, it serves as a laboratory test which

may be used to study porosity changes that may occur during the manufacture and evaluation of catalysts.

6. Apparatus

6.1 Ageneric schematic diagram of the minimum apparatus requirement is shown in Fig. 1.Acommercial instrument may be

used and may be constructed of glass or of metal. The specific commercial apparatus chosen may have a different configuration

than that shown in Fig. 1 and may require modification of the sequence of valve operation and of the calculations and equations

used. It should have the following features as a minimum:

6.1.1 Distribution Manifold, having a (V ), known to the nearest 0.05 cm . This volume is defined as the volume between the

d

stopcocks or valves and includes the pressure gage.

-4

6.1.2 Vacuum System, capable of attaining pressures below 10 torr (1 torr = 133.3 Pa). This will include a vacuum gage (not

shown in Fig. 1). Access to the distribution manifold is through the valve V.

6.1.3 Pressure Sensing Devices or Pressure Transducers, capable of measurements with a sensitivity of at least 0.1 torr, in the

range from 0 to 1000 torr (1 torr = 133.3 Pa).

FIG. 1 Schematic Diagram of Adsorption Apparatus

D 4222 – 03 (2008)

6.1.4 Value (H), from the helium supply to the distribution manifold.

6.1.5 Valve (N), from the nitrogen supply to the distribution manifold.

6.1.6 The connection between the sample tube and the S valve can be a standard-taper glass joint, a glass-to-glass seal, or a

compression fitting.

3 3

6.2 Sample Tubes, with volumes from 5 cm to 25100 cm depending on the application.

6.3 Heating Mantles or Small Furnaces .

6.4 Dewar Flasks.

10−7

6.5 Laboratory Balance, with 0.1-mg ( kg) sensitivity.

6.6 ThermometerThermometer or Thermocouple , for measuring the temperature of the distribution manifold [T8 (i)or T8 (i)]

1 2

in °C.

6.6.1 The manifold may be thermostated at a particular temperature, a few degrees above ambient, to obviate the necessity of

recording this temperature at each reading.

6.7 Thermometer,formeasuringthetemperatureoftheliquidnitrogenbath( T (i))inKelvin.Preferably,thisthermometerwill

s

beanitrogenvapor-pressure-thermometerthatgives (i))inKelvin.Preferably,thisthermometerwillbeanitrogenvapor-pressure-

thermometer, often referred to in a commercial instrument as a pressure saturation tube, that gives P directly and has greater

precision, or a resistance thermometer from which P values may be derived.

NOTE 1—Apressuretransducermaybeplacedbetweenthesampletubeandthemanifoldtomonitorequilibriumpressure,butthisisnotarequirement

of the system.

7. Reagents

7.1 Helium Gas—A cylinder of helium gas at least 99 % pure.

7.2 Liquid Nitrogen , of such purity that P is not more than 20 torr above barometric pressure. A fresh daily supply is

recommended.

7.3 Nitrogen Gas— A cylinder of nitrogen gas at least 99.999 % pure.

8. Procedure-Sample Preparation and Degassing

8.1 Select a sample tube of the desired size. To minimize the dead-space, a 5-cm sample tube is preferred for samples not

exceeding about 1 g. However, to avoid boiling when degassing is started, a 25-cm sample tube may be preferred for finely

powdered catalysts.Asmall glass-wool plug or fritted disk placed in the neck of the sample tube above the liquid nitrogen level,

will eliminate the possibility of any small catalyst particles entering the vacuum system.

8.2 Fill the sample tube with nitrogen or helium at atmospheric pressure, after removing air by evacuation. This may be done

on the adsorption unit or on a separate piece of equipment.

8.3 Remove the sample tube from the system, cap, and weigh. Record the weightmass as W .

8.4 Placethecatalystsample,whoseapproximateweightmassisknown,intothesampletube.Choosethesamplesizetoprovide

an estimated total sample surface area of approximately 20 m or greater.

8.5 Attach the sample tube to the apparatus. If other samples are to be run, attach them at this time to the other ports.

8.6 Open the S valve.

8.7 Slowly open the V valve, monitoring the rate of pressure decrease to avoid too high a rate, which might lead to excessive

fluidization of powdered samples.

8.8 Install a heating mantle or furnace around each sample and raise the temperature to about 300°C (573 K).

NOTE 2—Takespecialprecautionsifthemoisturecontentexceedsapproximately5%toavoidbumpingofpowderedcatalystandtoavoidsurfacearea

loss by self-steaming. It is recommended that the heating rate not exceed 100 K/h under these circumstances.

-3

8.9 Continuedegassingatabout300°C(573K)foraminimumof3h,atapressurenottoexceed10 torr.Overnightdegassing

is permissible.

NOTE 3—Certain materials will decompose at 300°C (for example, alumina hydrates) or will sinter (for example, platinum black). Lower degassing

temperatures are permissible for such materials; however, the degassing temperature should be specified when reporting the results.

8.10 Remove the heating mantle, and allow the sample to cool.

8.11 Close the S valve.

8.12 It is permissible to exercise the option of preliminary degassing on an external unit. In such a case, follow the procedures

of 8.4-8.10 and then repeat on the adsorption unit, except that the degassing time in 8.9 should not exceed 1 h.

8.13 If it is desired to weigh the sample after preliminary degassing on an external unit, back-fill with the same gas used in 8.2

to above atmospheric pressure. Close the S valve.

8.14 Detach the sample tube from the apparatus, recap with the stopper used previously, and weigh. Record the weightmass as

W8 .

−3

8.15 Remove the backfilled gas by evacuation to less than 10 torr at room temperature.

9. Procedure-Dead-Space Determination

9.1 From this point on, each sample being tested for nitrogen adsorption must be run on an individual basis.Thus, 9.2 through

D 4222 – 03 (2008)

11.4 must be carried out separately for each tube in test.

9.2 The dead-space is the quantity of gas within the charged sample tube, including the S valve, when the tube is immersed in

liquid nitrogen to the proper depth.

NOTE 4—The dead-space may be determined after the nitrogen adsorption and desorption, if more convenient, as long as adequate degassing precedes

it. In that case, replace the liquid nitrogen bath after 10.14 before proceeding with 9.3-9.9. Then, remove the Dewar flask before carrying out 10.15 and

10.16.

9.3 Place a Dewar flask of liquid nitrogen around the sample and adjust the liquid level to a fixed point on the sample tube.

Maintain this level throughout the test.

NOTE 5—Some modern commercial instruments do not require manual maintenance or readjusting of the level of liquid nitrogen during the analysis.

Follow the manufacturer’s recommendations for operating the particular instrument used.

9.4 Zero the pressure gage.

9.5 Admittheheliumgasintothesystemtoapressureof600to900torrbycarefullyopeningthe Hvalve.Recordthispressure

as P , and the manifold temperature as T .

H1 H1

9.6 Open the S valve to admit helium to the sample.

9.7 After about 5 min of equilibration, readjust the liquid nitrogen level, and record the pressure as P and the manifold

H2

temperature as T .

H2

9.8 Repeat 9.5-9.7 for each sample on the manifold.

9.9 Open the S valve; then slowly open the V valve to remove the helium gas.

−3

9.10 Close the S valve when a pressure below 10 torr has been attained.

10. Procedure-Nitrogen Adsorption

10.1 Admit nitrogen gas, and record the pressure as P (1) (torr) and the temperature as T (1) (°C). It is desirable, but not

1 1

necessary,tochoose P (1)suchthatthefirstequilibriumadsorptionpressure, P (1),willbeabout40torrequivalentto P (1)/ P (1)

1 2 2 o

of about 0.05.

10.2 Open the S valve to admit nitrogen to the catalyst.

10.3 Allowsufficienttimeforequilibration,readjustingtheliquidnitrogenleveltothemarkingonthesampletubeasnecessary.

Equilibrium shall be considered as attained when the pressure change is no more than 0.1 torr in 5 min. If the pressure becomes

less than the value which gives the desired relative pressure P /P , admit more nitrogen gas and allow the system to reequilibrate.

2 0

10.4 Record the equilibrium pressure as P (1)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.