ASTM B114-07(2013)

(Test Method)Standard Test Method for Temperature-Resistance Constants of Sheet Materials for Shunts and Precision Resistors

Standard Test Method for Temperature-Resistance Constants of Sheet Materials for Shunts and Precision Resistors

SIGNIFICANCE AND USE

3.1 This test method covers the determination of the change of resistance with temperature for precision resistors and shunts made from sheet materials.

3.2 Materials normally used in the temperature range from 0 to 80°C may be tested using this test method.

SCOPE

1.1 This test method covers the determination of the change of resistance with temperature of sheet materials used for shunts and precision resistors for electrical apparatus. It is applicable to materials normally used in the temperature range of from 0 to 80°C.

1.2 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units may be approximate.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B114 − 07 (Reapproved 2013)

Standard Test Method for

Temperature-Resistance Constants of Sheet Materials for

Shunts and Precision Resistors

This standard is issued under the fixed designation B114; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Test Specimen

1.1 Thistestmethodcoversthedeterminationofthechange 4.1 The test specimen shall be of such dimensions that its

of resistance with temperature of sheet materials used for electrical resistance can be measured to the required accuracy.

shunts and precision resistors for electrical apparatus. It is

NOTE 1—Measurements are simplified if the specimen has a resistance

applicable to materials normally used in the temperature range

of 0.01 Ω or more. The specimen may be bent in the form of a “U” to

of from 0 to 80°C.

facilitate handling.

1.2 The values stated in inch-pound units are to be regarded

5. Terminals

as the standard. The metric equivalents of inch-pound units

may be approximate. 5.1 A current terminal shall be attached to each end of the

specimen. These terminals shall be either soldered or clamped

1.3 This standard does not purport to address all of the

in such a manner that there will be no change of current

safety concerns, if any, associated with its use. It is the

distribution in the specimen during the test.

responsibility of the user of this standard to become familiar

with all hazards including those identified in the appropriate

5.2 Potential terminals, one at each end, shall be located at

Material Safety Data Sheet (MSDS) for this product/material

a distance not less than two times the width of the specimen

as provided by the manufacturer, to establish appropriate

fromthecurrentterminals.Theseterminalsshallbeattachedat

safety and health practices, and determine the applicability of

the center of the width of the specimen either by soldering to

regulatory limitations prior to use.

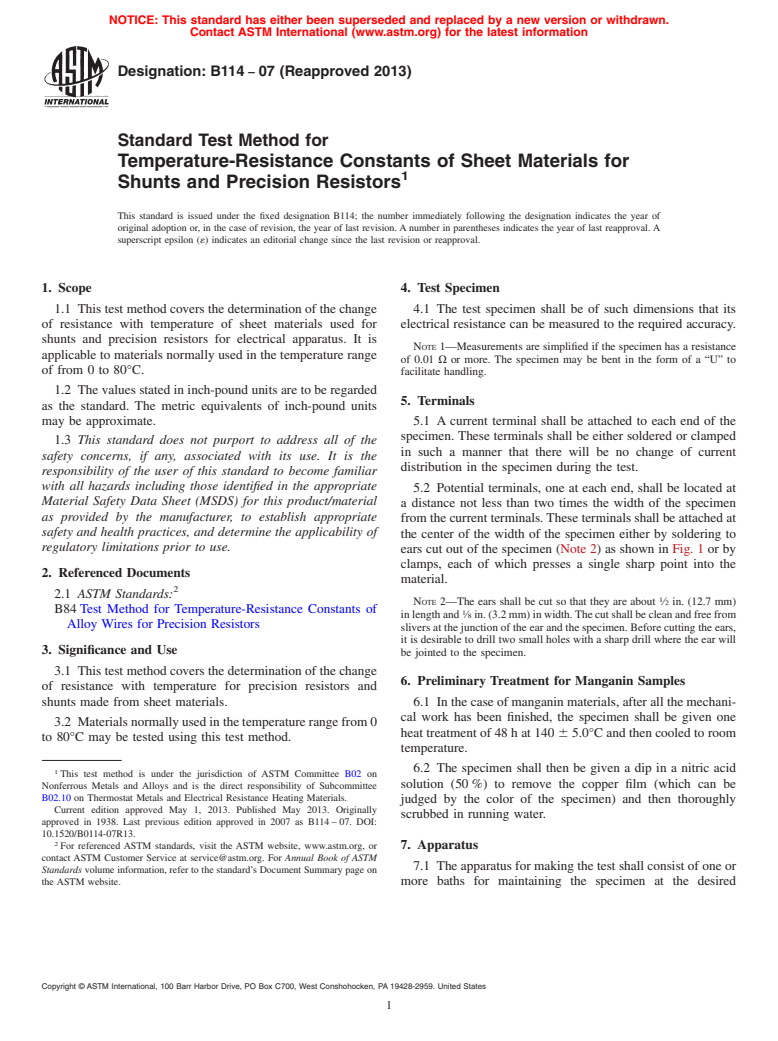

ears cut out of the specimen (Note 2) as shown in Fig. 1 or by

clamps, each of which presses a single sharp point into the

2. Referenced Documents

material.

2.1 ASTM Standards:

NOTE 2—The ears shall be cut so that they are about ⁄2 in. (12.7 mm)

B84Test Method for Temperature-Resistance Constants of

inlengthand ⁄8in.(3.2mm)inwidth.Thecutshallbecleanandfreefrom

Alloy Wires for Precision Resistors

sliversatthejunctionoftheearandthespecimen.Beforecuttingtheears,

it is desirable to drill two small holes with a sharp drill where the ear will

3. Significance and Use

be jointed to the specimen.

3.1 Thistestmethodcoversthedeterminationofthechange

6. Preliminary Treatment for Manganin Samples

of resistance with temperature for precision resistors and

shunts made from sheet materials.

6.1 Inthecaseofmanganinmaterials,afterallthemechani-

cal work has been finished, the specimen shall be given one

3.2 Materialsnormallyusedinthetemperaturerangefrom0

heattreatmentof48hat140 65.0°Candthencooledtoroom

to 80°C may be tested using this test method.

temperature.

6.2 The specimen shall then be given a dip in a nitric acid

This test method is under the jurisdiction of ASTM Committee B02 on

solution (50%) to remove the copper film (which can be

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.10 on Thermostat Metals and Electrical Resistance Heating Materials.

judged by the color of the specimen) and then thoroughly

Current edition approved May 1, 2013. Published May 2013. Originally

scrubbed in running water.

approved in 1938. Last previous edition approved in 2007 as B114–07. DOI:

10.1520/B0114-07R13.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 7. Apparatus

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7.1 Theapparatusformakingthetestshallconsistofoneor

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. more baths for maintaining the specimen at the desired

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B114 − 07 (2013)

appreciable errors in the results. With apparatus of good

quality, a change of 1°C in its temperature is allowable.

10.3 The test current shall not be of such a magnitude as to

produceanappreciablechangeinresistanceofthespecimenor

measuring apparatus due to the heating effect. The dimensions

of the specimen should be such that the power dissipated shall

2 2

not exceed 0.02 W/in. (0.003 W/cm ) of exposed surface. To

determine experimentally that the test current is not too large,

the specimen may be immersed in a bath having a temperature

at which it has been found that the sheet has a relatively large

changeinresistancewithtemperature.Thetestcurrentshallbe

appliedandmaintaineduntiltheresistanceofthespecimenhas

become constant. The current shall then be increased by 40%

and maintained at this value until the resistance has again

become constant. If the change in resistance is greater than

0.001%, the test current is too large and shall be reduced until

the foregoing limitation is reached.

10.4 Themeasurementsshallbemadeinsuchawaythatthe

effectsofthermoelectromotiveforcesandparasiticcurrentsare

avoided. When these effects are small, the resistance of the

specimen when measured by a Kelvin bridge may be obtained

byeitheroftwomethods.Inthefirstmethod,thegalvanometer

zero shall be obtained with the galvanometer key open. The

FIG. 1 Test Specimen Showing Terminal Connections

bridge shall be balanced both with the direct and reversed

connection of the battery, the average value of the two results

temperature, thermometers for measuring the temperatures of beingtheresistanceofthespecimen.Inthesecondmethod,the

the baths, and suitable means for measuring the resistance of

zero of the galvanometer shall be obtained with the galvanom-

the specimen. eter key closed and the battery key open. A single balance of

the bridge is then sufficient to obtain the resistance of the

8. Baths

specimen.

8.1 Eachbathshallconsistofchemicallyneutraloil.Theoil

11. Procedure

shall be of such quantity and so well stirred that the tempera-

ture in the region occupied by the specimen and the thermom- 11.1 Connect the test specimen in the measuring circuit and

submerge entirely in the oil bath. For a check on the constancy

etershallbeuniformwithin0.2°Cforanytemperaturebetween

0 and 80°C. of the specimen, make an initial resistance measurement at

room temperature. Raise the temperature of the oil bath or

8.2 In an automatically controlled bath, the temperature of

transfer the specimen to a bath maintained constant at the

the bath at any time during the test at any temperature level

highest temperature at which measurements are to be made.

shall not differ from its mean temperature by more than 0.2°C.

When the test specimen has attained a constant resistance,

In a manually controlled bath, the rate of change of tempera-

recordthereadingofthemeasuringdeviceandthetemperature

ture shall not exceed 0.2°C/min.

of the bath.

9. Temperature Measurement

11.2 Decrease the temperature of the test specimen to the

next lower temperatures either by cooling the bath and main-

9.1 The temperature shall be measured by a calibrated

taining it constant at the next lower temperature, or by

temperature measuring device of suitable precision and accu-

removingthespecimentoanotherbathmaintainedatthelower

racy. The thermometer shall have sufficient sensitivity to

temperature. When the resistance of the specimen has become

indicate temperature changes of 0.1°C. It shall be sufficiently

constant, again make observations of resistance and tempera-

accurate to measure temperature differences to 0.2°C in the

ture.

range from 0 to 80°C.

11.3 In this manner make a series of determinations of the

10. Resistance Measurements

change of resistance with temperature for the desired descend-

10.1 The change of resistance of the specimen shall be ing temperature range.

measuredbyapparatuscapableofdeterminingsuchchangesto

11.4 Take measurements at a sufficient number of tempera-

0.001% of the resistance of the specimen. A Kelvin double

turestodeterminethecharacteristicsofthematerial.Inorderto

bridge, digital ohmmeter, or equivalent is suitable for this

calculate a resistance-temperature equation, tests at three

purpose (see Appendix X1).

temperatures are required. If an independent check is to be

10.2 The temperature of the measuring apparatus shall not made, make observations of at least five temperatures. For

change during the test by an amount sufficient to introduce plotting a curve, six or more observations are generally made.

B114 − 07 (2013)

11.5 Note the temperature of the measuring apparatus at resistance in ohms per ohm in going from 25°C to t , and∆R

1 2

frequent intervals during the test of each specimen. the similar change in going from 25°C to t . That is:

∆R 5 R 2 R /R (7)

~ !

1 1 25 25

12. Resistance-Temperature Equation

and

12.1 Express the results in terms of the constants in an

equation of the following form: ∆R 5 R 2 R /R (8)

~ !

2 2 25 25

R 5 R 11α t 2 25 1β t 2 25 (1)

@ ~ ! ~ ! #

t 25

Then

where:

α 5 ~∆R 2 K ∆R !/K~K11!∆t (9)

2 1

R = resistanceofthespecimeninohmsattemperature, 2

t

β 5 ~K∆R 1∆R !/K~K11!~∆t! (10)

1 2

°C, t,

If K =1, this simplifies to:

R = resistanceofthespecimeninohmsatthestandard

temperature of 25°C,

α 5 ∆R 2∆R /2∆t (11)

~ !

2 1

t = temperature of specimen, °C, and

β 5 ~∆R 1∆R !/1~∆t! (12)

1 2

α and β = temperature-resistance constants of the material.

NOTE 5—A useful alternative method of calculation is presented as

Temperature of maximum or minimum resistance

follows: The resistance-temperature equation is referred to 0°C, and

=25°C−(α⁄2β) relative resistance values are used. For example, over the useful range

from 15 to 35°C, the resistance-temperature curve of manganin is

NOTE 3—This equation will yield either a maximum or a minimum,

parabolic and of the form:

dependingonwhichexistsinthetemperaturerangeinquestion.However,

P 5 P 1At1Bt (13)

t 0

this equation is normally used for those alloys such as manganin, having

atemperature-resistancecurveapproximatingaparabolawithamaximum

where:

near room t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.