ASTM C336-71(2010)

(Test Method)Standard Test Method for Annealing Point and Strain Point of Glass by Fiber Elongation

Standard Test Method for Annealing Point and Strain Point of Glass by Fiber Elongation

SIGNIFICANCE AND USE

This test method provides data useful for (1) estimating stress release, (2) the development of proper annealing schedules, and (3) estimating setting points for seals. Accordingly, its usage is widespread throughout manufacturing, research, and development. It can be utilized for specification acceptance.

SCOPE

1.1 This test method covers the determination of the annealing point and the strain point of a glass by measuring the viscous elongation rate of a fiber of the glass under prescribed condition.

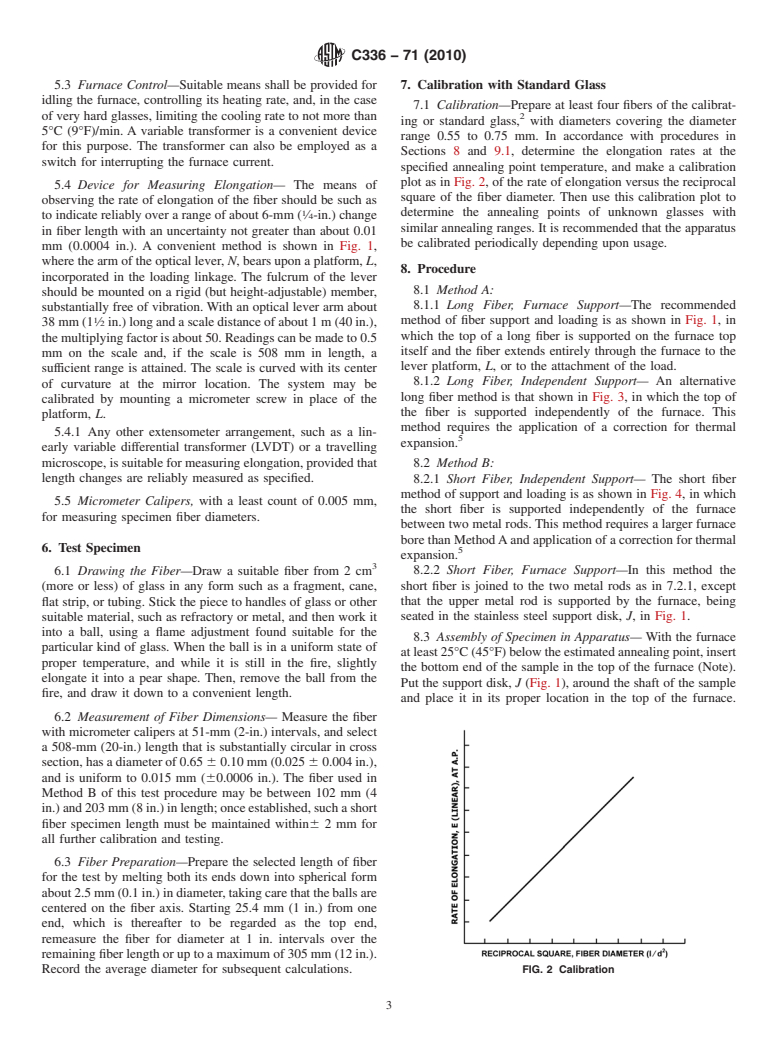

1.2 The annealing and strain points shall be obtained by following the specified procedure after calibration of the apparatus using fibers of standard glasses having known annealing and strain points, such as those specified and certified by the National Institute of Standards and Technology (NIST) (see Appendix X1).

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C336 − 71(Reapproved 2010)

Standard Test Method for

Annealing Point and Strain Point of Glass by Fiber

1

Elongation

This standard is issued under the fixed designation C336; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3. Definitions

3.1 annealing point—that temperature at which internal

1.1 This test method covers the determination of the anneal-

stresses in a glass are substantially relieved in a matter of

ing point and the strain point of a glass by measuring the

4

,5 ,6

minutes. During a test in accordance with the requirements

viscous elongation rate of a fiber of the glass under prescribed

of this method, the viscous elongation rate is measured by a

condition.

suitable extensometer while the specimen fiber is cooling at a

1.2 The annealing and strain points shall be obtained by

rate of 4 6 1°C/min.The elongation rate at the annealing point

following the specified procedure after calibration of the

is approximately 0.14 mm/min for a fiber of 0.65-mm diam-

apparatus using fibers of standard glasses having known

6

eter.

annealing and strain points, such as those specified and

3.2 annealing range—the range of glass temperature in

certified by the National Institute of Standards and Technology

2

which stresses in glass articles can be relieved at a commer-

(NIST) (see Appendix X1).

cially desirable rate. For purposes of comparing glasses, the

1.3 This standard does not purport to address all of the

annealing range is assumed to correspond with the tempera-

safety concerns, if any, associated with its use. It is the

tures between the annealing point (AP) and the strain point

responsibility of the user of this standard to establish appro-

(StP).

priate safety and health practices and determine the applica-

3.3 strain point—that temperature at which the internal

bility of regulatory limitations prior to use.

stresses in a glass are substantially relieved in a matter of

hours. The strain point is determined by extrapolation of the

2. Referenced Documents

annealing point data and is the temperature at which the

3

2.1 ASTM Standards:

viscous elongation rate is 0.0316 times that observed at the

C338 Test Method for Softening Point of Glass

annealing point.

C598 Test Method for Annealing Point and Strain Point of

Glass by Beam Bending

4. Significance and Use

4.1 This test method provides data useful for (1) estimating

stress release, (2) the development of proper annealing

1

This test method is under the jurisdiction of ASTM Committee C14 on Glass

schedules, and (3) estimating setting points for seals.

and Glass Products and is the direct responsibility of Subcommittee C14.04 on

Physical and Mechanical Properties.

4

Current edition approved April 1, 2010 Published May 2010. Originally Littleton, J. T., and Roberts, E. H., “A Method for Determining the Annealing

approved in 1954. Last previous edition approved in 2005 as C336 – 71 (2005). Temperature of Glass,” Journal of the Optical Society of America, Vol 4, 1920, p.

DOI: 10.1520/C0336-71R10. 224.

2 5

Available from National Institute of Standards and Technology (NIST), 100 Lillie, H. R., “Viscosity of Glass Between the Strain Point and Melting

Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov. Publi- Temperature,” Journal of American Ceramic Society, Vol 14, 1931, p. 502;

cation 260. “Re-Evaluation of Glass Viscosities at Annealing and Strain Points,” Journal of

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or American Ceramic Society, Vol 37, 1954, p. 111.

6

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM McGraw, D. A. and Babcock, C. L., “Effect of Viscosity and Stress Level on

Standards volume information, refer to the standard’s Document Summary page on Rate of Stress Release in Soda-Lime, Potash-Barium and Borosilicate Glasses,”

the ASTM website. Journal of the American Ceramic Society, Vol 42, 1959, p. 330.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C336 − 71 (2010)

Accordingly, its usage is widespread throughout of the couple. The cold junction of the thermocouple shall be

manufacturing, research, and development. It can be utilized maintained in an ice bath during tests.

for specification acceptance.

5.2.1 The temperature-indicating instrument, preferably a

potentiometer, shall be of such quality and sensitivity as to

5. Apparatus

permitreadi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.