ASTM C829-81(2022)

(Practice)Standard Practices for Measurement of Liquidus Temperature of Glass by the Gradient Furnace Method

Standard Practices for Measurement of Liquidus Temperature of Glass by the Gradient Furnace Method

SIGNIFICANCE AND USE

3.1 These practices are useful for determining the maximum temperature at which crystallization will form in a glass, and a minimum temperature at which a glass can be held, for extended periods of time, without crystal formation and growth.

SCOPE

1.1 These practices cover procedures for determining the liquidus temperature (Note 1) of a glass (Note 1) by establishing the boundary temperature for the first crystalline compound, when the glass specimen is held at a specified temperature gradient over its entire length for a period of time necessary to obtain thermal equilibrium between the crystalline and glassy phases.

Note 1: These terms are defined in Terminology C162.

1.2 Two methods are included, differing in the type of sample, apparatus, procedure for positioning the sample, and measurement of temperature gradient in the furnace. Both methods have comparable precision. Method B is preferred for very fluid glasses because it minimizes thermal and mechanical mixing effects.

1.2.1 Method A employs a trough-type platinum container (tray) in which finely screened glass particles are fused into a thin lath configuration defined by the trough.

1.2.2 Method B employs a perforated platinum tray on which larger screened particles are positioned one per hole on the plate and are therefore melted separately from each other.2

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C829 − 81 (Reapproved 2022)

Standard Practices for

Measurement of Liquidus Temperature of Glass by the

Gradient Furnace Method

This standard is issued under the fixed designation C829; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 These practices cover procedures for determining the 2.1 ASTM Standards:

liquidus temperature (Note 1) of a glass (Note 1) by establish- C162Terminology of Glass and Glass Products

ing the boundary temperature for the first crystalline

2.2 Other Document:

compound, when the glass specimen is held at a specified NIST Certificate for Liquidus Temperature, SRM 773

temperature gradient over its entire length for a period of time

3. Significance and Use

necessarytoobtainthermalequilibriumbetweenthecrystalline

and glassy phases.

3.1 Thesepracticesareusefulfordeterminingthemaximum

temperature at which crystallization will form in a glass, and a

NOTE 1—These terms are defined in Terminology C162.

minimum temperature at which a glass can be held, for

1.2 Two methods are included, differing in the type of

extended periods of time, without crystal formation and

sample, apparatus, procedure for positioning the sample, and

growth.

measurement of temperature gradient in the furnace. Both

methodshavecomparableprecision.MethodBispreferredfor

4. Apparatus

veryfluidglassesbecauseitminimizesthermalandmechanical

4.1 The apparatus for determining the liquidus temperature

mixing effects.

shall consist essentially of an electrically heated gradient

1.2.1 Method A employs a trough-type platinum container

furnace, a device for controlling the furnace temperature,

(tray) in which finely screened glass particles are fused into a

temperature measuring equipment, and other items listed.

thin lath configuration defined by the trough.

4.1.1 Furnace:

1.2.2 Method B employs a perforated platinum tray on

4.1.1.1 Method A—Horizontal temperature gradient, electri-

which larger screened particles are positioned one per hole on

cally heated furnace, tube type, as illustrated in Figs. 1-3 and

the plate and are therefore melted separately from each other.

described in A1.1.

1.3 This standard does not purport to address all of the

4.1.1.2 Method B—An alternative furnace detail employing

safety concerns, if any, associated with its use. It is the

pregrooved Al O cores and dual windings, as illustrated in

2 3

responsibility of the user of this standard to establish appro-

Figs. 4 and 5, and described in A1.2.

priate safety, health, and environmental practices and deter-

4.1.1.3 Equivalenttemperaturegradientconditionsmayalso

mine the applicability of regulatory limitations prior to use.

be obtained with furnaces having multiple windings equipped

1.4 This international standard was developed in accor-

with separate power and control, or a tapped winding shunted

dance with internationally recognized principles on standard-

with suitable resistances. For high precision, temperature

ization established in the Decision on Principles for the

gradients in excess of 10 °C ⁄cm should be avoided.

Development of International Standards, Guides and Recom-

4.1.2 Furnace Temperature Control:

mendations issued by the World Trade Organization Technical

4.1.2.1 Method A—A suitable temperature controller shall

Barriers to Trade (TBT) Committee.

be provided to maintain a fixed axial temperature distribution

over the length of the furnace.

4.1.2.2 Method B—Arheostatshallbeusedtosupplypower

totheouterwinding.Aseparaterheostatandcontrollershallbe

These practices are under the jurisdiction of ASTM Committee C14 on Glass

and Glass Productsand are the direct responsibility of Subcommittee C14.04 on

Physical and Mechanical Properties.

Current edition approved Feb. 1, 2022. Published March 2022. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 1976. Last previous edition approved in 2015 as C829–81(2015). contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

DOI: 10.1520/C0829-81R22. Standards volume information, refer to the standard’s Document Summary page on

From NBS Research Paper RP2096,Vol44,May1950,byO.H.GrauerandE. the ASTM website.

H. Hamilton, with modification and improvement by K. J. Gajewski, Ford Motor Available from National Institute of Standards and Technology (NIST), 100

Co., Glass Research and Development Office (work unpublished). Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C829 − 81 (2022)

NOTE 1—See A1.1 for further description.

1. Outer shell (stainless steel) 7. Outer protection tube

4 5

2. End plate (Transite) 8. Sil-O-Cel insulation

3. End plate (quartz) 9. Control thermocouple (platinum/rhodium)

4. Stand 10. Heating element wire

5. Inner protection tube 11. Specimen tray

6. Heating element tube

FIG. 1 Liquidus Furnace (Method A)

Material: 26-gauge stainless steel

FIG. 2 Liquidus Furnace Shell (Method A)

Millimetres

No. of Turns

A: 6 turns—4.8 mm spacing

B: 13 turns—9.5 mm spacing

C: 5 turns—6.4 mm spacing

D: 24 turns—4.8 mm spacing

FIG. 3 Recommended Liquidus Furnace Winding (Method A)

usedfortheinnercorewinding.Thebasicfurnacetemperature within 0.5°C. In addition to control thermocouples, MethodA

level is achieved by controlling power to both inner and outer requires an unshielded supported thermocouple for insertion

core windings. The slope of the gradient is achieved by into the furnace chamber to determine temperature gradients,

adjusting power input to the outer core winding only. The and Method B requires five thermocouples mounted in the

establishedtemperaturegradientisthenmaintainedbycontrol- specimen support fixture as shown in Fig. 6. An alternative

ling power to the inner core winding only. method is to attach (spot weld) the thermocouples to a fixed

4.1.3 Temperature-Measuring Equipment— Furnace tem- platinum or platinum alloy plate which supports the tray or

peratures shall be measured with calibrated Type R or S perforated plate. A solid-state digital thermometer capable of

thermocouples in conjunction with a calibrated potentiometer, the measurement accuracy specified may be used for tempera-

orothercomparableinstrumentation,capableofmeasurements ture measurement.

C829 − 81 (2022)

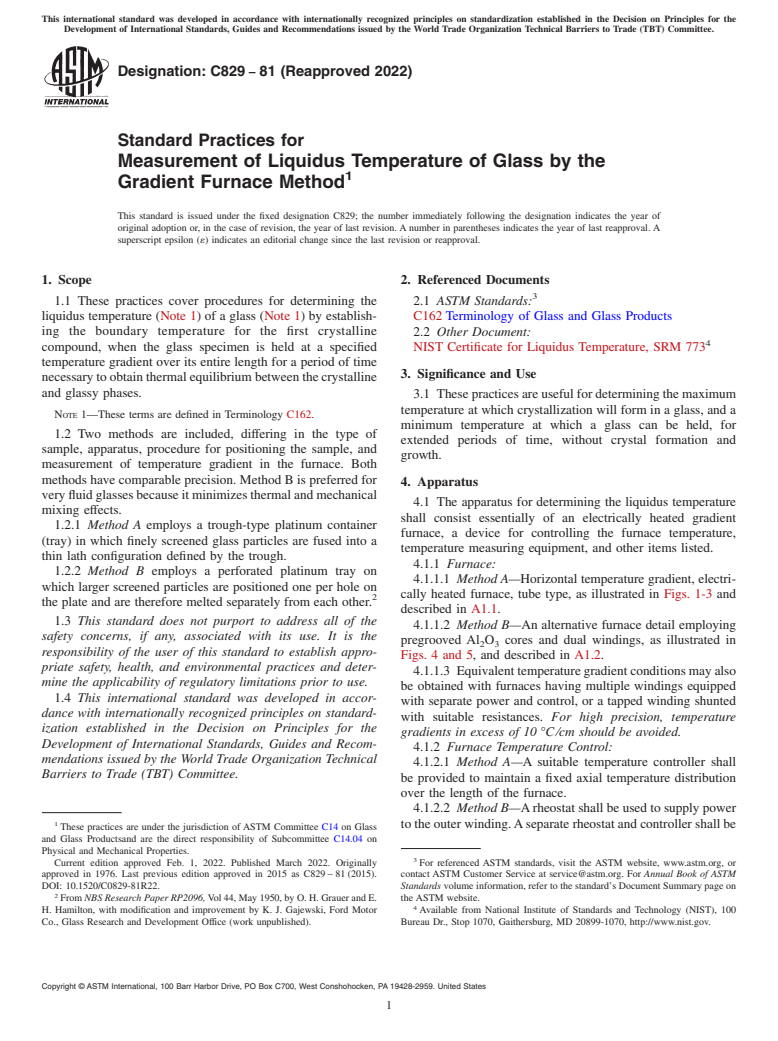

NOTE 1—See A1.2 for further description.

1. Stainless steel shell 7. Inner heating element tube

2. End plates (Transite ) 8. Perforated platinum tray

3. End seals (Fiberfrax ) 9. Mullite tube of riding device

4. Insulating cover (Fiberfrax ) 10. Alumina spacers

5. Refractory or Sil-O-Cel insulation 11. Controlling thermocouple

6. Outer heating element tube

FIG. 4 Liquidus Furnace (Method B)

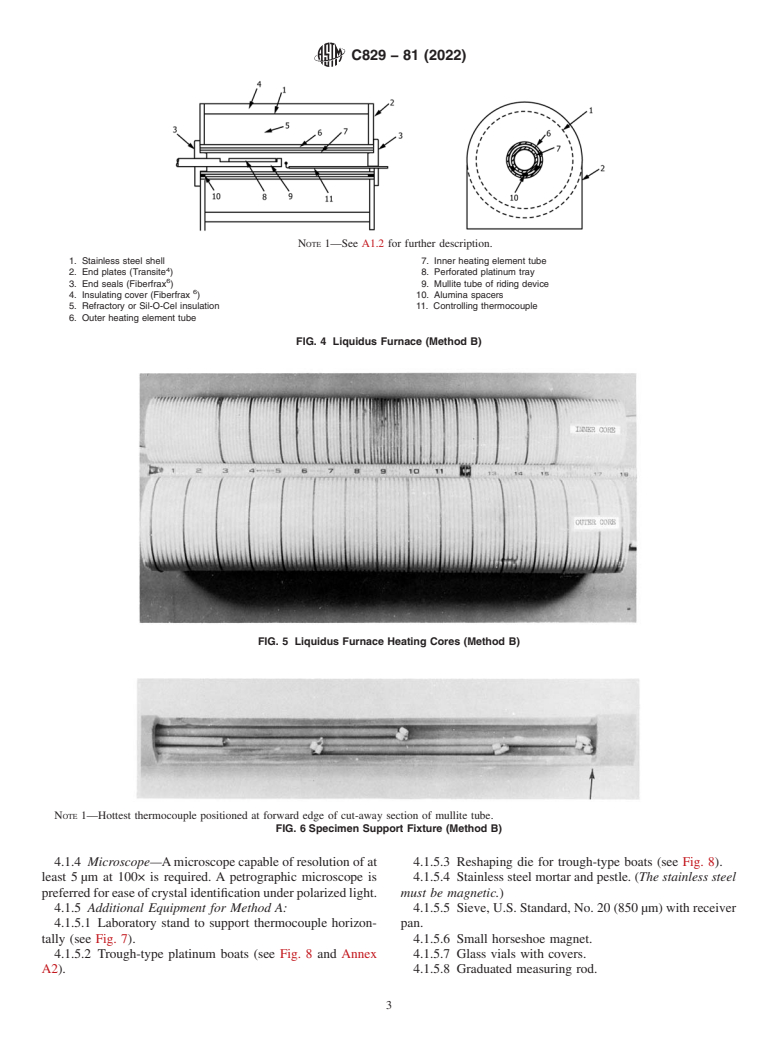

FIG. 5 Liquidus Furnace Heating Cores (Method B)

NOTE 1—Hottest thermocouple positioned at forward edge of cut-away section of mullite tube.

FIG. 6 Specimen Support Fixture (Method B)

4.1.4 Microscope—Amicroscopecapableofresolutionofat 4.1.5.3 Reshaping die for trough-type boats (see Fig. 8).

least 5µm at 100× is required. A petrographic microscope is 4.1.5.4 Stainlesssteelmortarandpestle.(The stainless steel

preferredforeaseofcrystalidentificationunderpolarizedlight. must be magnetic.)

4.1.5 Additional Equipment for Method A: 4.1.5.5 Sieve,U.S.Standard,No.20(850µm)withreceiver

4.1.5.1 Laboratory stand to support thermocouple horizon- pan.

tally (see Fig. 7). 4.1.5.6 Small horseshoe magnet.

4.1.5.2 Trough-type platinum boats (see Fig. 8 and Annex 4.1.5.7 Glass vials with covers.

A2). 4.1.5.8 Graduated measuring rod.

C829 − 81 (2022)

6. Procedure

6.1 Method A—Fill to one-half to three-quarters full two

specimen trays that are free of cracks, pits, or adhering glass

with the crushed glass specimen. Distribute evenly over the

length of each tray. Place the filled trays in the furnace, one on

either side of the maximum temperature point, and locate so

thattheircentersareatthepredeterminedgradienttemperature

level corresponding to the liquidus temperature, if known.

Record the location of the trays in the furnace. Either the

single- or the double-core furnace may be used. Modify the

FIG. 7 Thermocouple and Support (Method A)

double-core furnace design to accommodate two samples by

providingtworidingdevicesandmeansforinsertionfromboth

ends of the furnace.

4.1.5.9 Stainless steel tongs.

4.1.5.10 Other minor items as described in the text. 6.2 Method B—Use one or two perforated specimen trays

4.1.6 Additional Equipment for Method B: that are free of cracks, pits, or adhering glass. Using the

4.1.6.1 Riding device for simultaneously holding and posi- pointed stainless steel tongs or tweezers, select chips of the

tioning multiple thermocouples and a perforated platinum tray. samplefromtheNo.12(1.70mm)sieveandplaceoneineach

This device is provided with leveling screws, a means for of the drilled holes in each tray. Position a tray in the cut-away

lateraladjustment,andapositivestopforpreciselylocatingthe sectionofthemullitetubeontheridingdevicewiththedouble

boat and thermocouples within the furnace. The device shown rowofholesforward(towardthehotend),andtheforwardend

in Fig. 9 meets these requirements. of the tray indexed precisely over the most forward of the five

4.1.6.2 Perforated platinum trays (see Fig. 10 and Annex thermocouples against the forward edge of the cut-away

A2). section, as shown in Fig. 4. An alternative method is to move

4.1.6.3 Stainless steel mortar and pestle. thefurnaceintopositionaroundafixedtray.Onesampleinone

4.1.6.4 Sieves, U.S. Standard, No. 8 (2.36mm) and No. 12 tray supported by one riding device may be tested in the

(1.70mm) with receiver pan. double-core furnace. Two samples may be tested simultane-

4.1.6.5 Glass vials with covers. ously by modifying the furnace design to provide for insertion

4.1.6.6 Stainless steel pointed tongs. frombothends.Carefullyfeedtheridingdevicecontainingthe

4.1.6.7 Other minor items as shown in illustrations and tray into the furnace until the prepositioned stop plate is

described in the text. contacted. Close the end opening of the furnace around the

riding device with suitable insulation.

5. Preparation of Test Specimens

6.3 Treatment Time—Leave the specimens in the furnace

5.1 Select a mass of glass of approximately 70g. Break the

until equilibrium between the crystal and glassy phases is

sample into pieces of a size that will fit into the mortar. Clean

established. The time required is a function of the glass

the sample with acetone, rinse with distilled water, and dry.

composition. Twenty-four hours is sufficient for many glasses,

Clean the mortar and pestle, sieve, and magnet in the same

butsomeglassesmaytakedaystoreachequilibrium.Complete

manner (Note 2). Crush the sample, using the mortar and

crystallization of the specimen indicates insufficient tempera-

pestle, by using a hammer or other suitable means.

ture in heat treatment. Total lack of crystallization indicates

insufficient time or excess temperature.

NOTE2—Fromthispointon,contactwithbarehandsorothersourceof

contamination must be avoided.

6.4 Temperature Gradient—Determine the temperature gra-

5.2 Method A—Pour the crushed sample onto a No. 20

dients over the lengths of the specimens at the end of the

(850µm) sieve. Retain the material not passing the sieve and

heating period just prior to removal from the furnace.

repeat the crushing procedure until all the glass has been

6.4.1 Single-Core Furnace—Establish a temperature profile

reducedtoasizetopassthroughthesieveintothereceiverpan.

over the length of each tray by using a traveling unshielded

With the test specimen still in the pan, move the magnet

Type R or S thermocouple supported horizontally as near the

throughout the specimen to remove magnetic fragments that

top of the trays as practical and centered over their widths.

may have been introduced during crushing. If not to be tested

Start the probe at the hotter end of each tray, toward the center

immediately, place the specimen in a covered glass vial or

of the furnace, and make successive temperature readings

other suitable container.

along the tray length at ⁄2-in. (12.7 mm) intervals. Allow the

thermocouple temperature to stabilize in each position as

5.3 Method B—Pour the crushed sample onto a No. 8

indicated by constancy of temperature over a period of time.

(2.36mm) sieve fitted over a No. 12 (1.70 mm) sieve and

Record the temperature of each thermocouple position to the

receiver pan. Retain only that part of the sample not passing

nearest 1°C as related to tray position, and plot as in Fig. 11.

throughtheNo.12sieve.ThatglassretainedontheNo.8sieve

may be recrushed if necessary to increase the No. 12 sieve 6.4.2 Double-Core Furnace—Obtainthetemperatureprofile

sample size. Discard the fines passing through to the receiver as related to tray position from readings of the five Type R or

pan. If not to be tested immediately, place the specimen in a S thermocouples mounted in fixed positions in the riding

covered glass vial or other suitable container. device.

C829 − 81 (2022)

FIG. 8 Platinum Tray and Reforming Die (Method A)

NOTE 1—See A1.2 and Fig. 4 for legend.

FIG. 9 Riding Device (Method B)

6.5 Method A: double-core furnace has been used, retract the riding device

6.5.1 Removethespecimensfromthefurnace,freefromthe from the furnace, remove the tray, and place it on the

trays, cool, and examine under a microscope for evidence of heat-resistant flat surface. Immediately upon removal and

crystallization. If the single-core furnace has been used for the before the glass specimen hardens, bend the sidewalls of the

heat treatment, grasp the trays with smooth-faced forceps and tray slightly inward at 1-in. (25.4 mm) intervals along its

dragoutsidethefurnaceontoaheat-resistantflatsurface.Ifthe length.After the specimen has solidified, but is still quite hot,

C829 − 81 (2022)

FIG. 10 Platinum Tray for Holding Glass (Method B)

FIG. 11 Liquidus Furnace Temperature Gradient

bend the sidewalls outward to separate the specimen from the Cool the specimen to room temperature and mark to identify

tray. Repeat the inward and outward bend

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.