ASTM F1979-10(2014)

(Specification)Standard Specification for Paintballs Used in the Sport of Paintball

Standard Specification for Paintballs Used in the Sport of Paintball

ABSTRACT

This specification establishes testing procedures and critical characteristics of 0.68 caliber paintballs which help define whether a paintball is suitable for use in the sport of paintball. Furthermore, the specification establishes minimum warning and package labeling to help ensure that the paintballs are used in a safe manner and that the risk of injury is reduced. Tests shall be performed to conform with the requirements specified in accordance with the following test methods: paintball compatibility with polycarbonate and paintball impact breakage test.

SCOPE

1.1 This specification establishes testing procedures and critical characteristics of common calibers of paintball which help define whether a paintball is suitable for use in the sport of paintball. Furthermore, the specification establishes minimum warning and package labeling to help ensure that the paintballs are used in a safe manner and that the risk of injury is reduced.

1.2 This specification does not cover non-recreational paintballs, for example, those used by law enforcement, scientific, military, or theatrical entities.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This specification does not purport to address all of the safety issues associated with the sport of paintball. It is the responsibility of the user of this specification to establish appropriate safety and health practices and to comply with all applicable laws and regulations.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1979 −10 (Reapproved 2014) An American National Standard

Standard Specification for

Paintballs Used in the Sport of Paintball

This standard is issued under the fixed designation F1979; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This specification sets forth a set of guidelines and testing procedures for the manufacturing of

common calibers of paintball. The goal is to provide paintball manufacturers with a specification that

promotes safety in the sport of paintball.

1. Scope 3.1.1 caliber, n—the term used to refer to the size of a

paintball projectile. Related to the measurement of the diam-

1.1 This specification establishes testing procedures and

eter of the paintball.

critical characteristics of common calibers of paintball which

help define whether a paintball is suitable for use in the sport 3.1.2 cubic centimeter, n—commonly used unit of volume

of paintball. Furthermore, the specification establishes mini- extendingthederivedSI-unitcubicmeterandcorrespondingto

mum warning and package labeling to help ensure that the the volume of a cube measuring1×1×1cm.

paintballs are used in a safe manner and that the risk of injury

3.1.2.1 Discussion—The mass of one cubic centimeter of

is reduced.

water is approximately equal to 1 g.

1.2 This specification does not cover non-recreational

3.1.3 fill material, n—liquid inside of a paintball.

paintballs, for example, those used by law enforcement,

3.1.4 paintball, n—spherical ball, with a diameter and

scientific, military, or theatrical entities.

weightasdefinedinTable1,comprisedofashellandafill,and

1.3 The values stated in SI units are to be regarded as the

designed to be expelled from a paintball marker.

standard. The values given in parentheses are for information

3.1.5 paintball marker, n—device specifically designed to

only.

discharge paintballs which conforms to Specification F2272.

1.4 This specification does not purport to address all of the

3.1.6 shell—rigid to semirigid material (generally of gela-

safety issues associated with the sport of paintball. It is the

tin) that encapsulates the fill of a paintball.

responsibility of the user of this specification to establish

appropriate safety and health practices and to comply with all

4. General Requirements

applicable laws and regulations.

4.1 pH of Fill Material—The pH of the fill material used in

2. Referenced Documents

the paintball shall measure between 4.0 and 8.0 as measured

using a 10% solution of the fill in distilled water. Measure-

2.1 ASTM Standards:

ments shall be made using a properly calibrated pH meter. See

F2272Specification for Paintball Markers

Fig. 1 for the pH scale and pH levels for some common items.

3. Terminology

4.2 Paintball Fill Compatibility With Polycarbonate—

WhentestedinaccordancewithSection5,nomorethanoneof

3.1 Definitions of Terms Specific to This Standard:

the three polycarbonate tensile bars exposed to the fill material

shall develop a visible crack that is greater than 6.5 mm (0.256

in.) in length.

This specification is under the jurisdiction ofASTM Committee F08 on Sports

Equipment, Playing Surfaces, and Facilities and is the direct responsibility of

4.3 Maximum Weight—The paintballs shall not weigh more

Subcommittee F08.24 on Paintball and Equipment.

than as defined in Table 1 based on the caliber of the paintball.

Current edition approved May 1, 2014. Published September 2014. Originally

approved in 1999. Last previous edition approved in 2010 as F1979–10. DOI:

4.4 Fill Color Limitations—The paintballs shall not contain

10.1520/F1979-10R14.

fill material with a color mimicking that of human blood.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.5 Diameter of Paintball—The diameter of the paintball as

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. measured both polar and at the seam shall measure within the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1979−10 (2014)

TABLE 1 Common Calibers of Paintballs with Minimum and Maximum Diameter and Maximum Weight

68 Caliber 43 Caliber 50 Caliber 55 Caliber 62 Caliber

18 mm 11 mm 13 mm 14 mm 16 mm

Min (mm) Diameter 16.500 10.430 12.130 13.340 15.000

Max (mm) Diameter 18.000 11.390 13.240 14.560 16.420

Min (in) Diameter 0.650 0.410 0.470 0.520 0.590

Max (in.) Diameter 0.709 0.448 0.521 0.573 0.646

Weight (g) Maximum 3.500 0.900 1.400 1.700 2.500

Weight (oz) Maximum 0.123 0.032 0.049 0.060 0.088

FIG. 1The pH Scale

minimum and maximum range as defined in Table 1 based on how these tensile bars react to the fill. A control test is also

the caliber of the paintball. conductedusingtapwaterinplaceofthepaintballfillmaterial.

4.6 Impact Breakage—The impact breakage of the paintball 5.3 Significance and Use—This test method provides a

shall be tested in accordance with Section 6. All ten of the means to help determine the suitability of specific paintball fill

paintballs that impact the target shall break upon impact. material for use in the sport of paintball. This test method

provides a relative indicator of the reaction that a polycarbon-

4.7 Environmental Safety—Paintballs shall not contain en-

ate lens would have to the paintball fill material being tested.

vironmentally hazardous or toxic substances as defined in

CERCLA Regulations 40CFR302.4; SARA Toxic Chemical

4 5

List Section 313; Clean Air Act , Section 112B; and RCRA

Regulations 40FRR261.24 through 40CFR261.33.

TEST METHODS

5. Paintball Compatibility with Polycarbonate

5.1 Scope—This test method is intended to determine the

compatibility of the paintball fill with polycarbonate, the

plastic material currently universally used for protective eye-

wear lenses in paintball.

5.2 Summary of Test Method—This test method involves

bending polycarbonate tensile bars in a test fixture while these

bars are exposed to the paintball fill material and observing

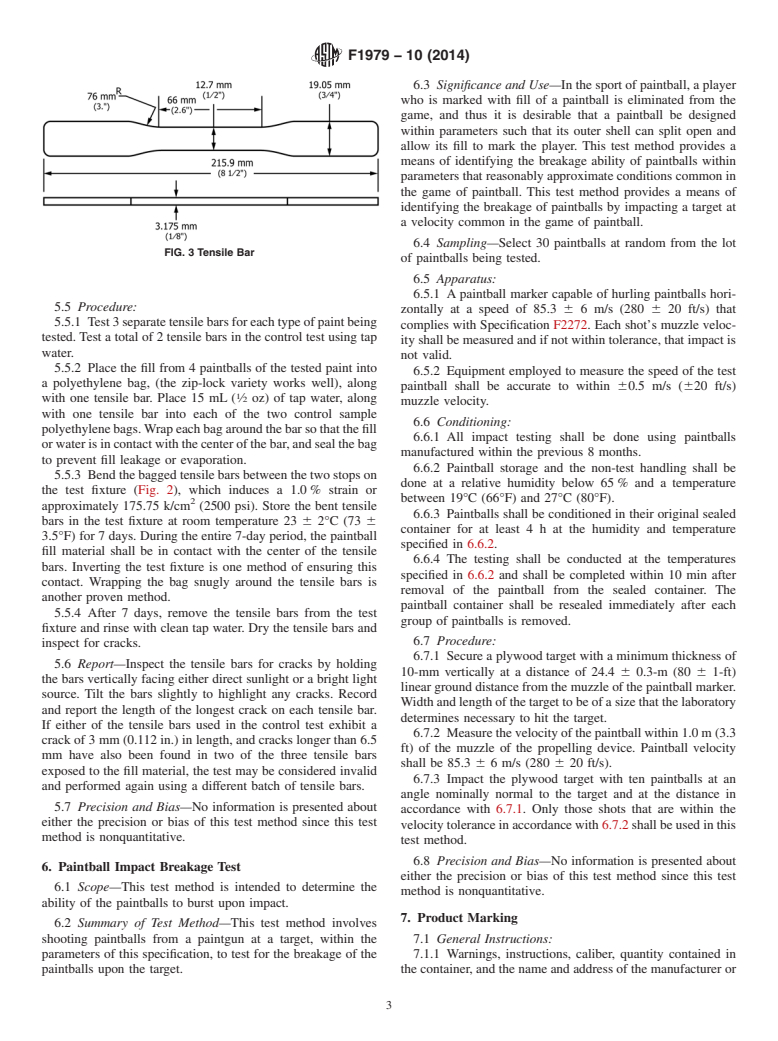

FIG. 2Tensile Bar Shown Without Wrapping

U.S. Environmental ProtectionAgency, “Designation of Hazardous Substances

5.4 Apparatus:

List of Hazardous Substances and Reportable Quantities,” Comprehensive Environ-

mental Response Compensation and Liabilities Act, Bureau of Federal Affairs,

This test method shall be conducted using a test fixture as

40CFR302.4, April 4, 1985.

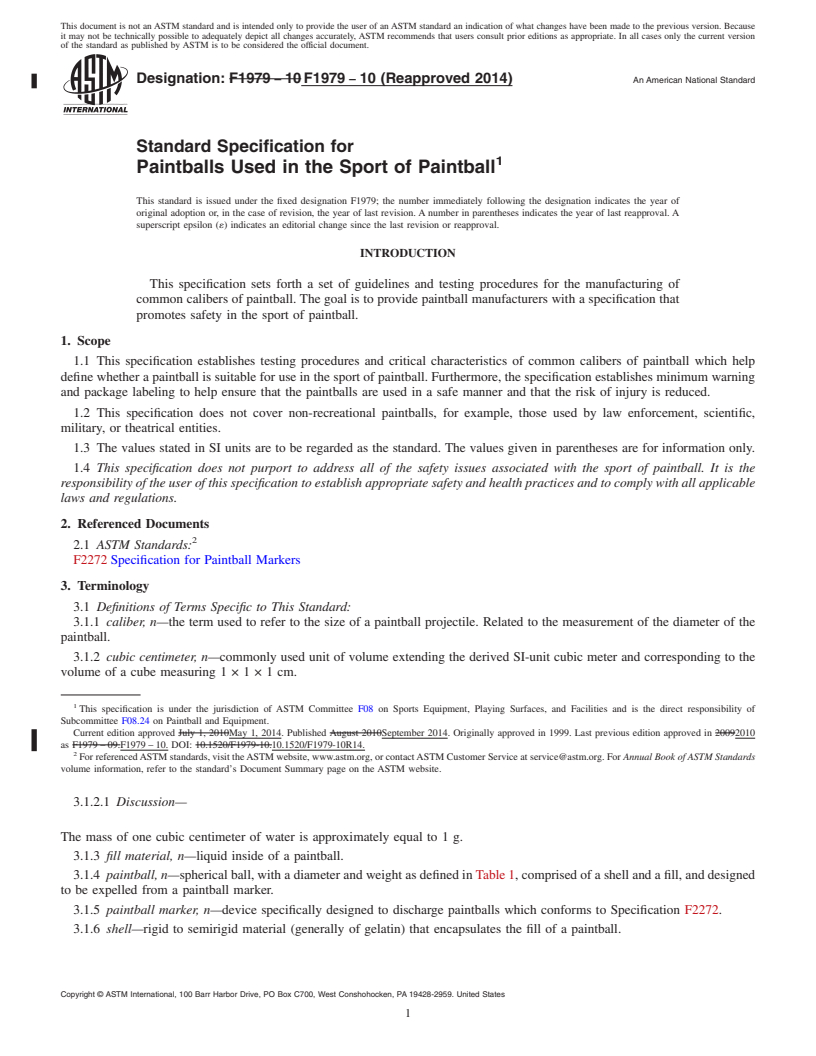

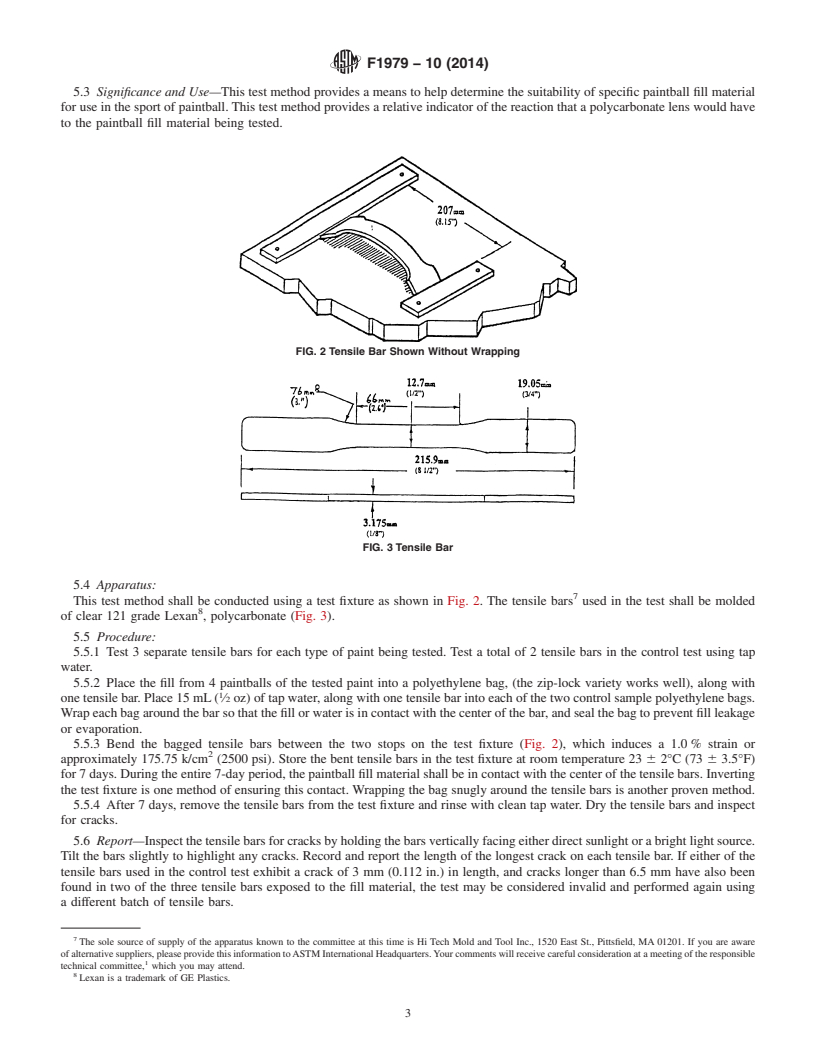

shown in Fig. 2. The tensile bars used in the test shall be

U.S. Environmental ProtectionAgency, “SuperfundAmendment and Reautho-

molded of clear 121 grade Lexan , polycarbonate (Fig. 3).

rization Act,” Environmental Protection Agency Regulation, Bureau of Federal

Affairs, Title III, 1986.

U.S. Environmental Protection Agency, “National Emission Standards for Air

Pollutants List of Hazardous Air Pollutants,” Clean Air Act, Bureau of Federal The sole source of supply of the apparatus known to the committee at this time

Affairs, Section 112B, 1967. isHiTechMoldandToolInc.,1520EastSt.,Pittsfield,MA01201.Ifyouareaware

U.S.EnvironmentalProtectionAgency,“DefinitionofCharacteristicandListed of alternative suppliers, please provide this information to ASTM International

Hazardous Waste, Identification and Listing of Hazardous Waste,” Resource Headquarters.Your comments will receive careful consideration at a meeting of the

Conservation and Recovery Act, Bureau of Federal Affairs, 40CFR261, May 19, responsible technical committee, which you may attend.

1980. Lexan is a trademark of GE Plastics.

F1979−10 (2014)

6.3 Significance and Use—In the sport of paintball, a player

who is marked with fill of a paintball is eliminated

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1979 − 10 F1979 − 10 (Reapproved 2014) An American National Standard

Standard Specification for

Paintballs Used in the Sport of Paintball

This standard is issued under the fixed designation F1979; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This specification sets forth a set of guidelines and testing procedures for the manufacturing of

common calibers of paintball. The goal is to provide paintball manufacturers with a specification that

promotes safety in the sport of paintball.

1. Scope

1.1 This specification establishes testing procedures and critical characteristics of common calibers of paintball which help

define whether a paintball is suitable for use in the sport of paintball. Furthermore, the specification establishes minimum warning

and package labeling to help ensure that the paintballs are used in a safe manner and that the risk of injury is reduced.

1.2 This specification does not cover non-recreational paintballs, for example, those used by law enforcement, scientific,

military, or theatrical entities.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This specification does not purport to address all of the safety issues associated with the sport of paintball. It is the

responsibility of the user of this specification to establish appropriate safety and health practices and to comply with all applicable

laws and regulations.

2. Referenced Documents

2.1 ASTM Standards:

F2272 Specification for Paintball Markers

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 caliber, n—the term used to refer to the size of a paintball projectile. Related to the measurement of the diameter of the

paintball.

3.1.2 cubic centimeter, n—commonly used unit of volume extending the derived SI-unit cubic meter and corresponding to the

volume of a cube measuring 1 × 1 × 1 cm.

This specification is under the jurisdiction of ASTM Committee F08 on Sports Equipment, Playing Surfaces, and Facilities and is the direct responsibility of

Subcommittee F08.24 on Paintball and Equipment.

Current edition approved July 1, 2010May 1, 2014. Published August 2010September 2014. Originally approved in 1999. Last previous edition approved in 20092010

as F1979 – 09.F1979 – 10. DOI: 10.1520/F1979-10.10.1520/F1979-10R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.1.2.1 Discussion—

The mass of one cubic centimeter of water is approximately equal to 1 g.

3.1.3 fill material, n—liquid inside of a paintball.

3.1.4 paintball, n—spherical ball, with a diameter and weight as defined in Table 1, comprised of a shell and a fill, and designed

to be expelled from a paintball marker.

3.1.5 paintball marker, n—device specifically designed to discharge paintballs which conforms to Specification F2272.

3.1.6 shell—rigid to semirigid material (generally of gelatin) that encapsulates the fill of a paintball.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1979 − 10 (2014)

TABLE 1 Common Calibers of Paintballs with Minimum and Maximum Diameter and Maximum Weight

68 Caliber 43 Caliber 50 Caliber 55 Caliber 62 Caliber

18 mm 11 mm 13 mm 14 mm 16 mm

Min (mm) Diameter 16.500 10.430 12.130 13.340 15.000

Max (mm) Diameter 18.000 11.390 13.240 14.560 16.420

Min (in) Diameter 0.650 0.410 0.470 0.520 0.590

Max (in.) Diameter 0.709 0.448 0.521 0.573 0.646

Weight (g) Maximum 3.500 0.900 1.400 1.700 2.500

Weight (oz) Maximum 0.123 0.032 0.049 0.060 0.088

4. General Requirements

4.1 pH of Fill Material—The pH of the fill material used in the paintball shall measure between 4.0 and 8.0 as measured using

a 10 % solution of the fill in distilled water. Measurements shall be made using a properly calibrated pH meter. See Fig. 1 for the

pH scale and pH levels for some common items.

4.2 Paintball Fill Compatibility With Polycarbonate—When tested in accordance with Section 5, no more than one of the three

polycarbonate tensile bars exposed to the fill material shall develop a visible crack that is greater than 6.5 mm (0.256 in.) in length.

4.3 Maximum Weight—The paintballs shall not weigh more than as defined in Table 1 based on the caliber of the paintball.

4.4 Fill Color Limitations—The paintballs shall not contain fill material with a color mimicking that of human blood.

4.5 Diameter of Paintball—The diameter of the paintball as measured both polar and at the seam shall measure within the

minimum and maximum range as defined in Table 1 based on the caliber of the paintball.

4.6 Impact Breakage—The impact breakage of the paintball shall be tested in accordance with Section 6. All ten of the paintballs

that impact the target shall break upon impact.

4.7 Environmental Safety—Paintballs shall not contain environmentally hazardous or toxic substances as defined in CERCLA

4 5 6

Regulations 40CFR302.4; SARA Toxic Chemical List Section 313; Clean Air Act , Section 112B; and RCRA Regulations

40FRR261.24 through 40CFR261.33.

TEST METHODS

5. Paintball Compatibility with Polycarbonate

5.1 Scope—This test method is intended to determine the compatibility of the paintball fill with polycarbonate, the plastic

material currently universally used for protective eyewear lenses in paintball.

5.2 Summary of Test Method—This test method involves bending polycarbonate tensile bars in a test fixture while these bars

are exposed to the paintball fill material and observing how these tensile bars react to the fill. A control test is also conducted using

tap water in place of the paintball fill material.

U.S. Environmental Protection Agency, “Designation of Hazardous Substances List of Hazardous Substances and Reportable Quantities,” Comprehensive Environmental

Response Compensation and Liabilities Act, Bureau of Federal Affairs, 40CFR302.4, April 4, 1985.

U.S. Environmental Protection Agency, “Superfund Amendment and Reauthorization Act,” Environmental Protection Agency Regulation, Bureau of Federal Affairs, Title

III, 1986.

U.S. Environmental Protection Agency, “National Emission Standards for Air Pollutants List of Hazardous Air Pollutants,” Clean Air Act, Bureau of Federal Affairs,

Section 112B, 1967.

U.S. Environmental Protection Agency, “Definition of Characteristic and Listed Hazardous Waste, Identification and Listing of Hazardous Waste,” Resource Conservation

and Recovery Act, Bureau of Federal Affairs, 40CFR261, May 19, 1980.

FIG. 1 The pH Scale

F1979 − 10 (2014)

5.3 Significance and Use—This test method provides a means to help determine the suitability of specific paintball fill material

for use in the sport of paintball. This test method provides a relative indicator of the reaction that a polycarbonate lens would have

to the paintball fill material being tested.

FIG. 2 Tensile Bar Shown Without Wrapping

FIG. 3 Tensile Bar

5.4 Apparatus:

This test method shall be conducted using a test fixture as shown in Fig. 2. The tensile bars used in the test shall be molded

of clear 121 grade Lexan , polycarbonate (Fig. 3).

5.5 Procedure:

5.5.1 Test 3 separate tensile bars for each type of paint being tested. Test a total of 2 tensile bars in the control test using tap

water.

5.5.2 Place the fill from 4 paintballs of the tested paint into a polyethylene bag, (the zip-lock variety works well), along with

one tensile bar. Place 15 mL ( ⁄2 oz) of tap water, along with one tensile bar into each of the two control sample polyethylene bags.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.