ASTM D7403-09

(Test Method)Standard Test Method for Determination of Residue of Emulsified Asphalt by Low Temperature Vacuum Distillation

Standard Test Method for Determination of Residue of Emulsified Asphalt by Low Temperature Vacuum Distillation

SIGNIFICANCE AND USE

This test method can be used for quantitative determination of residue in emulsified asphalts at a temperature of 135°C (275°F) with a 60 minute distillation test using current distillation apparatus. This method is suitable to obtain residues for service evaluation, quality control, and research. This distillation method is not intended to produce residues equivalent to the Test Method D 6997 260°C (500°F) distillation procedure.

SCOPE

1.1 This method covers the quantitative determination of residue in emulsified asphalts composed principally of a semisolid or liquid asphaltic base, water, and an emulsifying agent. The emulsified asphalts will generally contain polymeric materials. It is especially suitable for emulsified asphalt residue properties that may be altered at the high temperature 260°C (500°F) distillation. Since there is currently not a precision statement for this procedure, it is recommended to the user that this procedure not be used for buy/sell purposes at the present time.

1.2 The values stated in SI units are to be regarded as the standard. Values in parentheses in inch-pound units are provided for informational purposes only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7403 −09

Standard Test Method for

Determination of Residue of Emulsified Asphalt by Low

Temperature Vacuum Distillation

This standard is issued under the fixed designation D7403; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope distillation method is not intended to produce residues equiva-

lent to the Test Method D6997 260°C (500°F) distillation

1.1 This method covers the quantitative determination of

procedure.

residue in emulsified asphalts composed principally of a

semisolid or liquid asphaltic base, water, and an emulsifying

4. Apparatus

agent.Theemulsifiedasphaltswillgenerallycontainpolymeric

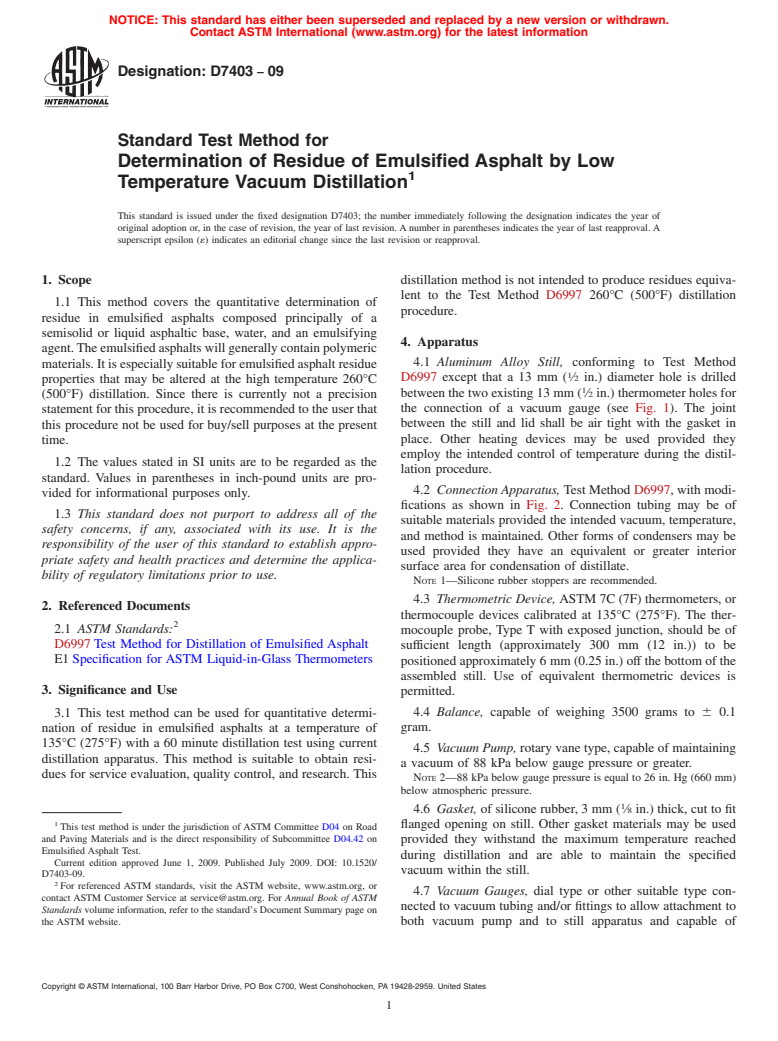

4.1 Aluminum Alloy Still, conforming to Test Method

materials.Itisespeciallysuitableforemulsifiedasphaltresidue

D6997 except that a 13 mm ( ⁄2 in.) diameter hole is drilled

properties that may be altered at the high temperature 260°C

between the two existing 13 mm ( ⁄2 in.) thermometer holes for

(500°F) distillation. Since there is currently not a precision

the connection of a vacuum gauge (see Fig. 1). The joint

statement for this procedure, it is recommended to the user that

between the still and lid shall be air tight with the gasket in

this procedure not be used for buy/sell purposes at the present

place. Other heating devices may be used provided they

time.

employ the intended control of temperature during the distil-

1.2 The values stated in SI units are to be regarded as the

lation procedure.

standard. Values in parentheses in inch-pound units are pro-

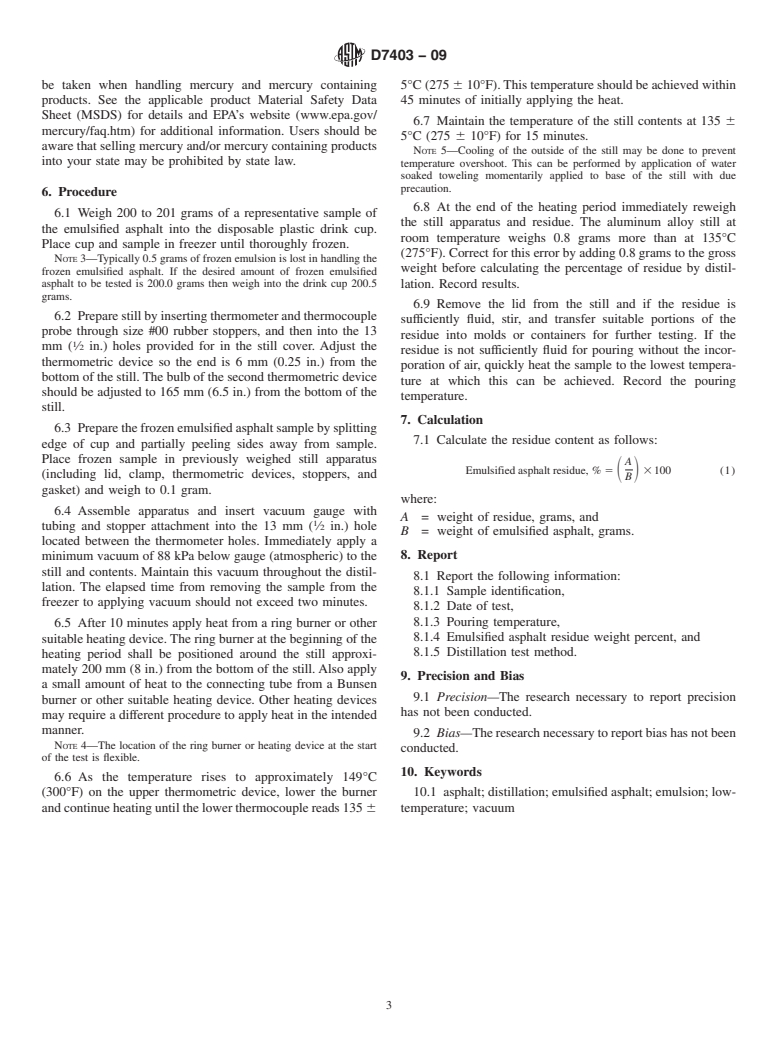

4.2 ConnectionApparatus, Test Method D6997, with modi-

vided for informational purposes only.

fications as shown in Fig. 2. Connection tubing may be of

1.3 This standard does not purport to address all of the

suitable materials provided the intended vacuum, temperature,

safety concerns, if any, associated with its use. It is the

and method is maintained. Other forms of condensers may be

responsibility of the user of this standard to establish appro-

used provided they have an equivalent or greater interior

priate safety and health practices and determine the applica-

surface area for condensation of distillate.

bility of regulatory limitations prior to use.

NOTE 1—Silicone rubber stoppers are recommended.

4.3 Thermometric Device, ASTM 7C (7F) thermometers, or

2. Referenced Documents

thermocouple devices calibrated at 135°C (275°F). The ther-

2.1 ASTM Standards:

mocouple probe, Type T with exposed junction, should be of

D6997 Test Method for Distillation of Emulsified Asphalt

sufficient length (approximately 300 mm (12 in.)) to be

E1 Specification for ASTM Liquid-in-Glass Thermometers

positioned approximately 6 mm (0.25 in.) off the bottom of the

assembled still. Use of equivalent thermometric devices is

3. Significance and Use

permitted.

4.4 Balance, capable of weighing 3500 grams to 6 0.1

3.1 This test method can be used for quantitative determi-

gram.

nation of residue in emulsified asphalts at a temperature of

135°C (275°F) with a 60 minute distillation test using current

4.5 Vacuum Pump, rotary vane type, capable of maintaining

distillation apparatus. This method is suitable to obtain resi-

a vacuum of 88 kPa below gauge pressure or greater.

dues for service evaluation, quality control, and research. This

NOTE 2—88 kPa below gauge pressure is equal to 26 in. Hg (660 mm)

below atmospheric pressure.

4.6 Gasket, of silicone rubber, 3 mm ( ⁄8 in.) thick, cut to fit

flanged opening on still. Other gasket materials may be used

This test method is under the jurisdiction of ASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.42 on

provided they withstand the maximum temperature reached

Emulsified Asphalt Test.

during distillation and are able to maintain the specified

Current edition approved June 1, 2009. Published July 2009. DOI: 10.1520/

vacuum within the still.

D7403-09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.7 Vacuum Gauges, dial type or other suitable type con-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

nected to vacuum tubing and/or fittings to allow attachment to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. both vacuum pump and to still apparatus and capable of

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7403−09

FIG. 1Aluminum Alloy Still Lid Showing Location of the Hole for Vacuum Gauge Connection

FIG. 2Connection Apparatus Schematic

reading a minimum vacuum of 88 kPa below gauge pressure 5. Hazards

(660 mm or 26 in. Hg below atmospheric pressure).

5.1 Warning—Mercury has been designated by the United

4.8 Freezer, maintained at approximately –10°C.

States Environmental ProtectionAgency (EPA) and many state

agencies as a hazardous material that can cause central nervous

4.9 Disposable Plastic Drink Cups, of convenient size and

system,kidneyandliverdamage.Mercury,oritsvapor,maybe

make to serve as a container during freezing of emulsified

asphalt. hazardous to health and corrosive to materials. Caution should

D7403−09

be taken when handling mercury and mercury containing 5°C (275 6 10°F).This temperature should be achieved with

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.