ASTM E1822-02

(Test Method)Standard Test Method for Fire Testing of Stacked Chairs

Standard Test Method for Fire Testing of Stacked Chairs

SCOPE

1.1 This is a fire-test-response standard.

1.2 This test method provides a means of determining the burning behavior of stacking chairs used in public occupancies by measuring specific fire-test responses when a stack of chairs is subjected to a specified flaming ignition source under well ventilated conditions.

1.3 This test method is limited to stacked chairs.

1.4 Test data are obtained describing the burning behavior following application of a specific ignition source, from ignition until all burning has ceased, a period of 1 h has elapsed, or flashover under test conditions appears inevitable.

1.5 This test method does not provide information on the fire performance of stacked chairs under fire conditions other than those conditions specified in this test method. In particular, this test method does not apply to smoldering ignition by cigarettes. See 5.11 for further information.

1.6 The rate of heat release of the burning test specimen is measured by an oxygen consumption method. See 5.11.4 for further information.

1.7 Other measurements are the production of light-obscuring smoke and the concentrations of certain toxic gas species in the combustion gases. See 5.11.5 for further information.

1.8 The burning behavior is documented visually by photographic or video recordings.

1.9 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products or assemblies under actual fire conditions.

1.10 Fire testing of products and materials is inherently hazardous, and adequate safeguards for personnel and property shall be employed in conducting these tests. This test method may involve hazardous materials, operations, and equipment.

1.11 Use the SI system of units in referee decisions; see Practice E 380. The units given in parentheses are for information only.

1.12 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: E 1822 – 02

Standard Test Method for

Fire Testing of Stacked Chairs

This standard is issued under the fixed designation E 1822; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.12 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This is a fire-test-response standard.

responsibility of the user of this standard to establish appro-

1.2 This test method provides a means of determining the

priate safety and health practices and determine the applica-

burning behavior of stacking chairs used in public occupancies

bility of regulatory limitations prior to use.

by measuring specific fire-test responses when a stack of chairs

is subjected to a specified flaming ignition source under well

2. Referenced Documents

ventilated conditions.

2.1 ASTM Standards:

1.3 This test method is limited to stacked chairs.

D 123 Terminology Relating to Textiles

1.4 Test data are obtained describing the burning behavior

E 84 Test Method for Surface Burning Characteristics of

following application of a specific ignition source, from

Building Materials

ignition until all burning has ceased, a period of1hhas

E 176 Terminology of Fire Standards

elapsed, or flashover under test conditions appears inevitable.

E 380 Practice for Use of the International System of Units

1.5 This test method does not provide information on the

(SI) (the Modernized Metric System)

fire performance of stacked chairs under fire conditions other

E 800 Guide for Measurement of Gases Present or Gener-

than those conditions specified in this test method. In particu-

ated During Fires

lar, this test method does not apply to smoldering ignition by

E 1354 Test Method for Heat and Visible Smoke Release

cigarettes. See 5.11 for further information.

Rates for Materials and Products Using an Oxygen Con-

1.6 The rate of heat release of the burning test specimen is

sumption Calorimeter

measured by an oxygen consumption method. See 5.11.4 for

E 1474 Test Method for Determining the Heat Release Rate

further information.

of Upholstered Furniture and Mattress Components or

1.7 Other measurements are the production of light-

Composites Using a Bench Scale Oxygen Consumption

obscuring smoke and the concentrations of certain toxic gas

Calorimeter

species in the combustion gases. See 5.11.5 for further infor-

E 1537 Test Method for Fire Testing of Real Scale Uphol-

mation.

stered Furniture Items

1.8 The burning behavior is documented visually by photo-

E 1590 Test Method for Fire Testing of Real Scale Mat-

graphic or video recordings.

tresses

1.9 This standard is used to measure and describe the

2.2 ISO Standards:

response of materials, products, or assemblies to heat and

ISO 3261 Fire Tests—Vocabulary

flame under controlled conditions, but does not by itself

ISO 4880 Burning Behaviour of Textiles and Textile

incorporate all factors required for fire hazard or fire risk

Products—Vocabulary

assessment of the materials, products or assemblies under

ISO 9705 Fire Tests—Full Scale Room Test for Surface

actual fire conditions.

Products

1.10 Fire testing of products and materials is inherently

2.3 UL Standards:

hazardous, and adequate safeguards for personnel and property

UL 1056 Fire Test of Upholstered Furniture

shall be employed in conducting these tests. This test method

UL 1895 Fire Test of Mattresses

may involve hazardous materials, operations, and equipment.

2.4 CA Standards:

1.11 Use the SI system of units in referee decisions; see

CA TB 129, Flammability Test Procedure for Mattresses for

Practice E 380. The units given in parentheses are for infor-

mation only.

Annual Book of ASTM Standards, Vol 07.01.

Annual Book of ASTM Standards, Vol 04.07.

1 4

This test method is under the jurisdiction of ASTM Committee E05 on Fire Annual Book of ASTM Standards, Vol 14.02.

Standards and is the direct responsibility of Subcommittee E05.15 on Furnishings Available from International Standardization Organization, P.O. Box 56,

and Contents. CH-1211, Geneva 20, Switzerland.

Current edition approved Jan. 10, 2002. Published April 2002. Originally Available from Underwriters Laboratories, Inc., 333 Pfingsten Road, North-

published as E 1822–96. Last previous edition E 1822–99. brook, IL 60062.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 1822

Use in Public Buildings 4.3 In Test Configuration C, the test specimen is placed on

CA TB 133, Flammability Test Procedure for Seating Fur- a weighing platform located directly under a hood.

niture for Use in Public Occupancies

4.4 Heat, smoke, and combustion gas release instrumenta-

2.5 Other Document:

tion is placed in the duct.

Nordtest Method NT Fire 032, Upholstered Furniture:

4.5 Additional (optional) instrumentation placed in the test

Burning Behavior—Full Scale Test

room is also described.

3. Terminology

5. Significance and Use

3.1 Definitions—For definitions of terms used in this test

5.1 This test method provides a means of measuring a

method and associated with fire issues, refer to Terminology

variety of fire-test-response characteristics resulting from burn-

E 176 and ISO 3261. In case of conflict, the definitions in

ing a stack of five stacking chairs. After ignition using a

Terminology E 176 shall prevail. For definitions of terms used

in this test method and associated with textile issues refer to propane gas burner, the test specimen is permitted to burn

freely under well-ventilated conditions. The most important

Terminology D 123 and ISO 4880. In case of conflict, the

definitions in Terminology D 123 shall prevail. fire-test-response characteristic measured in this test method is

3.2 Definitions of Terms Specific to This Standard: the rate of heat release, which quantifies the intensity of the fire

3.2.1 stacking chair, n—chair that is intended to be stacked

generated.

when not in use.

5.2 The rate of heat release is measured by the principle of

3.2.2 test specimen, n—stack of five identical stacking

oxygen consumption. Annex A3 discusses the assumptions and

chairs.

limitations.

3.2.3 upholstered, adj—covered with material (as fabric or

5.3 This test method also provides measures of other fire-

padding) to provide a soft surface.

test-response characteristics, including smoke obscuration (as

3.2.4 upholstered seating furniture, n—a unit of interior

the rate of smoke release, total smoke released or optical

furnishing that (1) contains any surface that is covered, in

density of smoke), combustion gas release (as concentrations

whole or in part, with a fabric or other upholstery cover

of combustion gases), and mass loss, that are important to

material, (2) contains upholstery material, and (3) is intended

making decisions on fire safety.

or promoted for sitting upon.

5.4 In the majority of fires, the most important gaseous

3.2.5 upholstery cover material, n—the outermost layer of

components of smoke are the carbon oxides present in all fires.

fabric or related material used to enclose the main support

They are indicators of the toxicity of the atmosphere and of the

system, or upholstery materials, or both, used in the furniture

completeness of combustion. Measurement of concentrations

unit.

of carbon oxides are useful for two purposes: as part of fire

3.2.6 upholstery material, n—the padding, stuffing, or fill-

hazard assessment calculations and to improve the accuracy of

ing material used in a furniture item, which may be either loose

or attached, enclosed by an upholstery cover material, or heat-release measurements. Other toxic combustion gases,

located between the upholstery cover material and support which are specific to certain materials, are also indicators of the

system, if present.

toxicity of the atmospheres, but are less crucial for determining

3.2.6.1 Discussion—This includes, but is not limited to, combustion completeness and are optional measures; however

material such as foams, cotton batting, polyester fiberfill,

fire hazard assessment often requires their measurement.

bonded cellulose, or down.

5.5 The type of ignition chosen (flaming source) is common

in both accidental and intentional fires in public occupancies.

4. Summary of Test Method

This test method is thus applicable to stacked chairs in public

4.1 This fire-test-response test method determines a number

occupancies. Such facilities include, but are not limited to,

of fire-test-response characteristics associated with a stack of

health-care facilities, old-age convalescent and board and care

five stacking chairs, ignited with a propane gas burner. Mea-

homes, college dormitories and residence halls, and hotels and

surements to be made include the rate of heat and smoke

motels.

release, total amount of heat released, rates and concentrations

5.6 One of the following three configurations is to be used

of carbon oxides released, and rates and amounts of mass of

in this test method:

test specimen lost. Other optional measurements are also

5.6.1 Test Configuration A—A test room with the following

described.

dimensions: 3.66 by 2.44 by 2.44 m high (12 by 8 by 8 ft).

4.2 In Test Configurations A and B, the test specimen is

5.6.2 Test Configuration B—A test room with the following

placed on a weighing platform located in a test room. An

exhaust hood, connected to a duct, is located at the doorway of dimensions: 3.66 by 3.05 by 2.44 m high (12 by 10 by 8 ft).

the room.

5.6.3 Test Configuration C—An open calorimeter (or furni-

ture calorimeter).

5.7 Rooms of other dimensions are acceptable where it has

Available from California Bureau of Home Furnishings and Thermal Insula-

been shown that equivalent test results are obtained.

tion, State of California, Department of Consumer Affairs, 3485 Orange Grove Ave.,

5.8 Measurements in the three test configurations listed in

North Highlands, CA 95660-5595.

Available from Nordtest, P.O. Box 22, SF-00341, Helsingfors, Finland. 5.6 have been shown to give similar results for heat release in

E 1822

the duct and mass loss up to a rate of heat release of 600 kW

(1).

5.9 Measurements of temperatures, gas concentrations, and

smoke obscuration in the room are dependent on room size.

5.10 Studies on the flammability performance of furniture

indicate that bench-scale fire tests are useful for preliminary

evaluations of component materials for substitution purposes

(see Appendix X2).

5.11 Limitations:

5.11.1 This test method is not applicable to ignition by

cigarettes or by any other smoldering source.

5.11.2 The ignition source in this test method is a flaming

source. Moreover, this particular ignition source has been

shown to be able to provide a distinction among different kinds

of stacked chairs. However, the fraction of actual flaming

stacked chair fires occurring with ignitions more or less intense

than that used here is not known.

5.11.3 It is not known whether the results of this test method

will be equally valid when stacking chairs are burned under

conditions different from those specified. In particular, it is

unclear whether the use of a different ignition source, the same

ignition source but having a different duration of flame

exposure, or a different gas-flow rate will change the results.

5.11.4 The value of rate of heat release corresponding to the

critical limit between propagating fires and nonpropagating

fires is not known.

5.11.5 As yet, there is not a known direct correlation

between smoke obscuration or smoke toxicity measurements in

the exhaust duct and overall fire hazard.

6. Apparatus

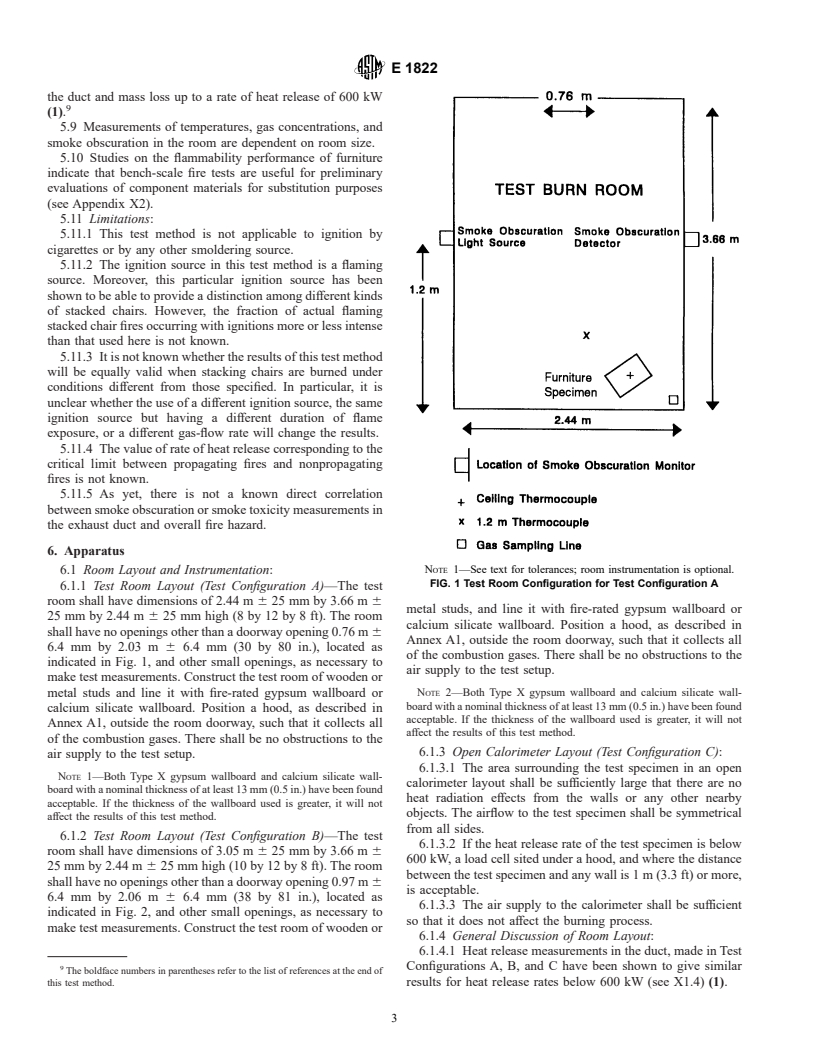

6.1 Room Layout and Instrumentation: NOTE 1—See text for tolerances; room instrumentation is optional.

FIG. 1 Test Room Configuration for Test Configuration A

6.1.1 Test Room Layout (Test Configuration A)—The test

room shall have dimensions of 2.44 m 6 25 mm by 3.66 m 6

metal studs, and line it with fire-rated gypsum wallboard or

25 mm by 2.44 m 6 25 mm high (8 by 12 by 8 ft). The room

calcium silicate wallboard. Position a hood, as described in

shall have no openings other than a doorway opening 0.76 m 6

Annex A1, outside the room doorway, such that it collects all

6.4 mm by 2.03 m 6 6.4 mm (30 by 80 in.), located as

of the combustion gases. There shall be no obstructions to the

indicated in Fig. 1, and other small openings, as necessary to

air supply to the test setup.

make test measurements. Construct the test room of wooden or

metal studs and line it with fire-rated gypsum wallboard or NOTE 2—Both Type X gypsum wallboard and calcium silicate wall-

board with a nominal thickness of at least 13 mm (0.5 in.) have been found

calcium silicate wallboard. Position a hood, as described in

acceptable. If the thickness of the wallboard used is greater, it will not

Annex A1, outside the room doorway, such that it collects all

affect the results of this test method.

of the combustion gases. There shall be no obstructions to the

6.1.3 Open Calorimeter Layout (Test Configuration C):

air supply to the test setup.

6.1.3.1 The area surrounding the test specimen in an open

NOTE 1—Both Type X gypsum wallboard and calcium silicate wall-

calorimeter layout shall be sufficiently large that there are no

board with a nominal thickness of at least 13 mm (0.5 in.) have been found

heat radiation effects from the walls or any other nearby

acceptable. If the thickness of the wallboard used is greater, it will not

objects. The airflow to the test specimen shall be symmetrical

affect the results of this test method.

from all sides.

6.1.2 Test Room Layout (Test Configuration B)—The test

6.1.3.2 If the heat release rate of the test specimen is below

room shall have dimensions of 3.05 m 6 25 mm by 3.66 m 6

600 kW, a load cell sited under a hood, and where the distance

25 mm by 2.44 m 6 25 mm high (10 by 12 by 8 ft). The room

between the test specimen and any wall is 1 m (3.3 ft) or more,

shall have no openings other than a doorway opening 0.97 m 6

is acceptable.

6.4 mm by 2.06 m 6 6.4 mm (38 by 81 in.), located as

6.1.3.3 The air supply to the calorimeter shall be sufficient

indicated in Fig. 2, and other small openings, as necessary to

so that it does not affect the burning process.

make test measurements. Construct the test room of wooden or

6.1.4 General Discussion of Room Layout:

6.1.4.1 Heat release measurements in the duct, made in Test

9 Configurations A, B, and C have been shown to give similar

The boldface numbers in parentheses refer to the list of references at the end o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.