ASTM D1465-10

(Test Method)Standard Test Method for Blocking and Picking Points of Petroleum Wax

Standard Test Method for Blocking and Picking Points of Petroleum Wax

SIGNIFICANCE AND USE

Blocking of waxed paper, because of the relatively low temperatures at which it may occur, can be a major problem to the paper-coating industry. For example, when the waxed surfaces in a roll of waxed paper stick together, upon separation the surface films are marred and the glossy finish is destroyed. The wax picking point and the wax blocking point indicate an approximate temperature range at or above which waxed surfaces in contact with each other are likely to cause surface film injury.

SCOPE

1.1 This test method covers the determination of the blocking point and picking point of petroleum wax.

1.2 WARNINGMercury has been designated by many regulatory agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s websitehttp://www.epa.gov/mercury/faq.htmfor additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are provided for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1465 − 10 TechnicalAssociation of Pulp and Paper Industry

Suggested Method T 652

Standard Test Method for

1

Blocking and Picking Points of Petroleum Wax

This standard is issued under the fixed designation D1465; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E1Specification for ASTM Liquid-in-Glass Thermometers

1.1 This test method covers the determination of the block-

3. Terminology

ing point and picking point of petroleum wax.

3.1 Definitions:

1.2 WARNING—Mercury has been designated by many

3.1.1 wax blocking point—the lowest temperature at which

regulatory agencies as a hazardous material that can cause

film disruption occurs across 50% of the waxed paper surface

central nervous system, kidney and liver damage. Mercury, or

when the test strips are separated.

its vapor, may be hazardous to health and corrosive to

3.1.2 wax picking point—the temperature at which the first

materials.Cautionshouldbetakenwhenhandlingmercuryand

film disruption occurs on the waxed paper when test strips are

mercury containing products. See the applicable product Ma-

separated.

terial Safety Data Sheet (MSDS) for details and EPA’s

website—http://www.epa.gov/mercury/faq.htm—for addi-

4. Summary of Test Method

tional information. Users should be aware that selling mercury

4.1 Paper test specimens are coated with the wax sample,

and/or mercury containing products into your state or country

folded with the waxed surfaces together, and placed on a

may be prohibited by law.

blocking plate.The plate is heated at one end and cooled at the

1.3 The values stated in SI units are to be regarded as

other end to impose a measured temperature gradient along its

standard. The values given in parentheses are provided for

length.After a conditioning period on the plate, the specimens

information only.

areremoved,unfolded,andexamined.Thepointsofinitialfilm

1.4 This standard does not purport to address all of the

disruption (picking point) and where 50% of the specimen

safety concerns, if any, associated with its use. It is the

width is disrupted (50% blocking point) are noted. The

responsibility of the user of this standard to establish appro-

temperatures of corresponding points on the blocking plate are

priate safety and health practices and determine the applica-

reported as the picking point and blocking point or blocking

bility of regulatory limitations prior to use.

range.

2. Referenced Documents

5. Significance and Use

2

2.1 ASTM Standards:

5.1 Blocking of waxed paper, because of the relatively low

D87Test Method for Melting Point of Petroleum Wax

temperatures at which it may occur, can be a major problem to

(Cooling Curve)

the paper-coating industry. For example, when the waxed

D938Test Method for Congealing Point of Petroleum

surfaces in a roll of waxed paper stick together, upon separa-

Waxes, Including Petrolatum

tion the surface films are marred and the glossy finish is

D2423Test Method for Surface Wax on Waxed Paper or

destroyed. The wax picking point and the wax blocking point

Paperboard

indicate an approximate temperature range at or above which

waxed surfaces in contact with each other are likely to cause

surface film injury.

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricantsand is the direct responsibility of

Subcommittee D02.10.0A on Physical/Chemical Properties. This test method was 6. Apparatus

preparedjointlybytheTechnicalAssociationofthePulpandPaperIndustryandthe

6.1 Wax Coating Device—Any manual- or machine-driven

American Society for Testing and Materials.

Current edition approved May 1, 2010. Published June 2010. Originally waxer that gives uniform coatings of the desired weights to a

approved in 1957. Last previous edition approved in 2004 as D1465–04. DOI:

strip of paper not less than 51 mm (2 in.) wide.

10.1520/D1465-10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6.2 Trimming Board,orotherdeviceforcuttingpaperstrips.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.3 Paper Scales, sensitive to 0.002 g, or suitable balance

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. for measuring basis weights of unwaxed and waxed paper.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1465 − 10

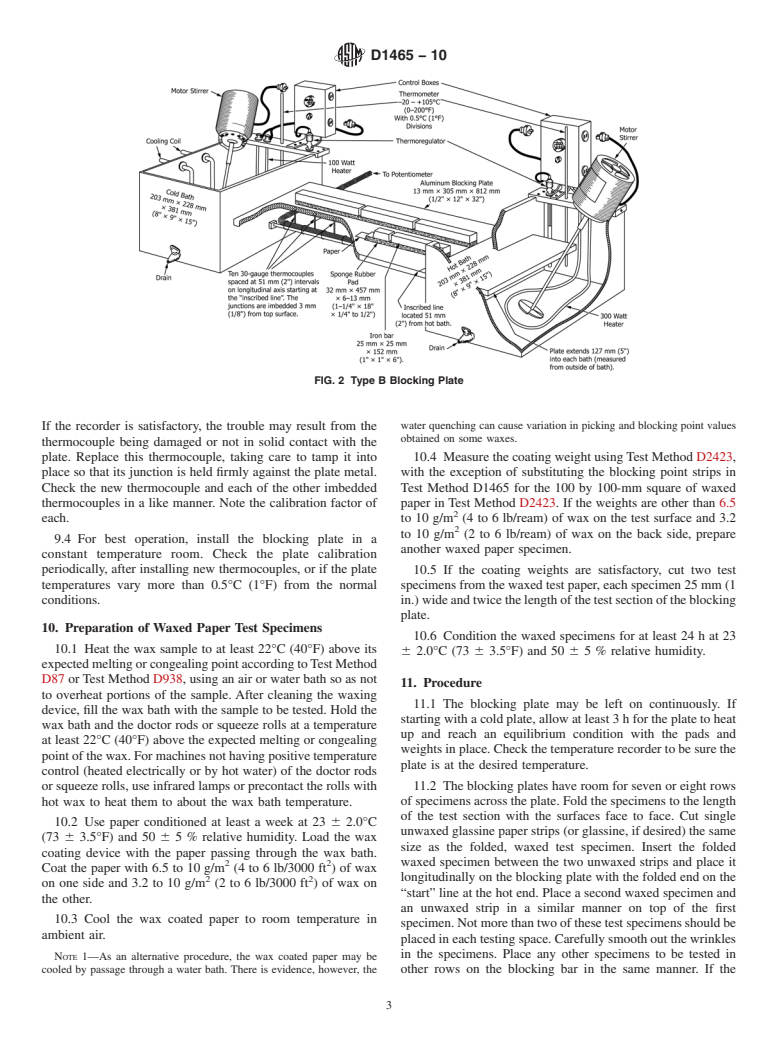

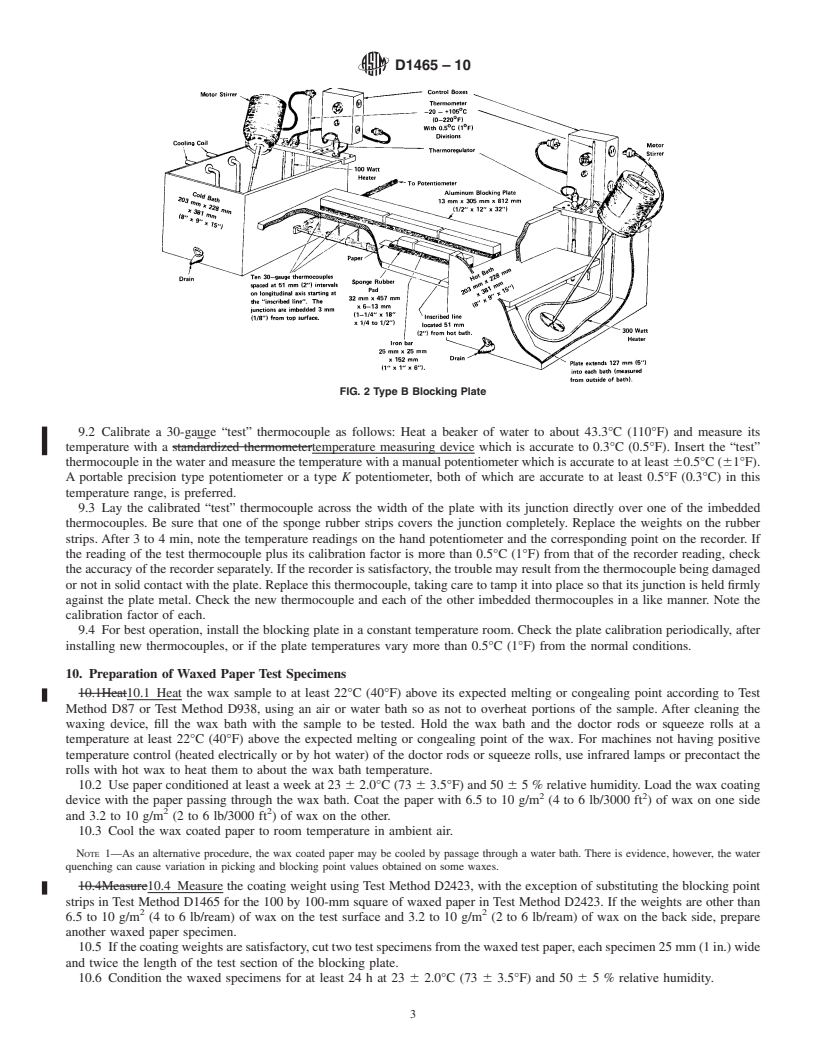

6.4 Blocking PlateAssembly,consistingofametalplate305

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Technical Association of Pulp and Paper Industry

Designation:D1465–04 Designation:D1465–10 Suggested Method T 652

Standard Test Method for

1

Blocking and Picking Points of Petroleum Wax

This standard is issued under the fixed designation D1465; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of the blocking point and picking point of petroleum wax.

1.2

1.2 WARNING—Mercury has been designated by many regulatory agencies as a hazardous material that can cause central

nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution

should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet

(MSDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware

that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are provided for information

only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D87 Test Method for Melting Point of Petroleum Wax (Cooling Curve)

D938 Test Method for Congealing Point of Petroleum Waxes, Including Petrolatum

D2423 Test Method for Surface Wax on Waxed Paper or Paperboard

E1 Specification for ASTM Liquid-in-Glass Thermometers

3. Terminology

3.1 Definitions:

3.1.1 wax blocking point—thelowesttemperatureatwhichfilmdisruptionoccursacross50%ofthewaxedpapersurfacewhen

the test strips are separated.

3.1.2 wax picking point—the temperature at which the first film disruption occurs on the waxed paper when test strips are

separated.

4. Summary of Test Method

4.1 Paper test specimens are coated with the wax sample, folded with the waxed surfaces together, and placed on a blocking

plate.The plate is heated at one end and cooled at the other end to impose a measured temperature gradient along its length.After

a conditioning period on the plate, the specimens are removed, unfolded, and examined. The points of initial film disruption

(picking point) and where 50% of the specimen width is disrupted (50% blocking point) are noted. The temperatures of

corresponding points on the blocking plate are reported as the picking point and blocking point or blocking range.

5. Significance and Use

5.1 Blocking of waxed paper, because of the relatively low temperatures at which it may occur, can be a major problem to the

paper-coating industry. For example, when the waxed surfaces in a roll of waxed paper stick together, upon separation the surface

films are marred and the glossy finish is destroyed. The wax picking point and the wax blocking point indicate an approximate

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.10.0A

on Properties of Petroleum Wax. Physical/Chemical Properties. This test method was prepared jointly by the Technical Association of the Pulp and Paper Industry and the

American Society for Testing and Materials.

Current edition approved Nov.May 1, 2004.2010. Published November 2004.June 2010. Originally approved in 1957. Last previous edition approved in 20002004 as

D1465–90(2000).D1465–04. DOI: 10.1520/D1465-104.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1465–10

temperature range at or above which waxed surfaces in contact with each other are likely to cause surface film injury.

6. Apparatus

6.1 Wax Coating Device—Any manual- or mac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.