ASTM D2323-93(1997)e1

(Specification)Standard Specification for Refined Pyridine (1 Degree) (Withdrawn 2003)

Standard Specification for Refined Pyridine (1 Degree) (Withdrawn 2003)

SCOPE

1.1 This specification covers refined pyridine.

1.2 Consult current OSHA regulations and supplier's Material Safety Data Sheets for all materials used in this specification.

1.3 The following applies to all specified limits in this standard: for purposes of determining conformance with this standard, an observed value or a calculated value shall be rounded off "to the nearest unit" in the last right-hand digit used in expressing the specification limit, in accordance with the rounding-off method of Practice E29.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: D 2323 – 93 (Reapproved 1997)

Standard Specification for

Refined Pyridine (1 Degree)

This standard is issued under the fixed designation D 2323; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editoral changes were made in the Scope Section in December l997.

1. Scope E 29 Practice for Using Significant Digits in Test Data to

Determine Conformance With Specifications

1.1 This specification covers refined pyridine.

2.2 Other Document:

1.2 The following applies to all specified limits in this

OSHA Regulations, 29 CFR, paragraphs 1910.1000 and

standard: for purposes of determining conformance with this

1910.1200

standard, an observed value or a calculated value shall be

rounded off “to the nearest unit” in the last right-hand digit

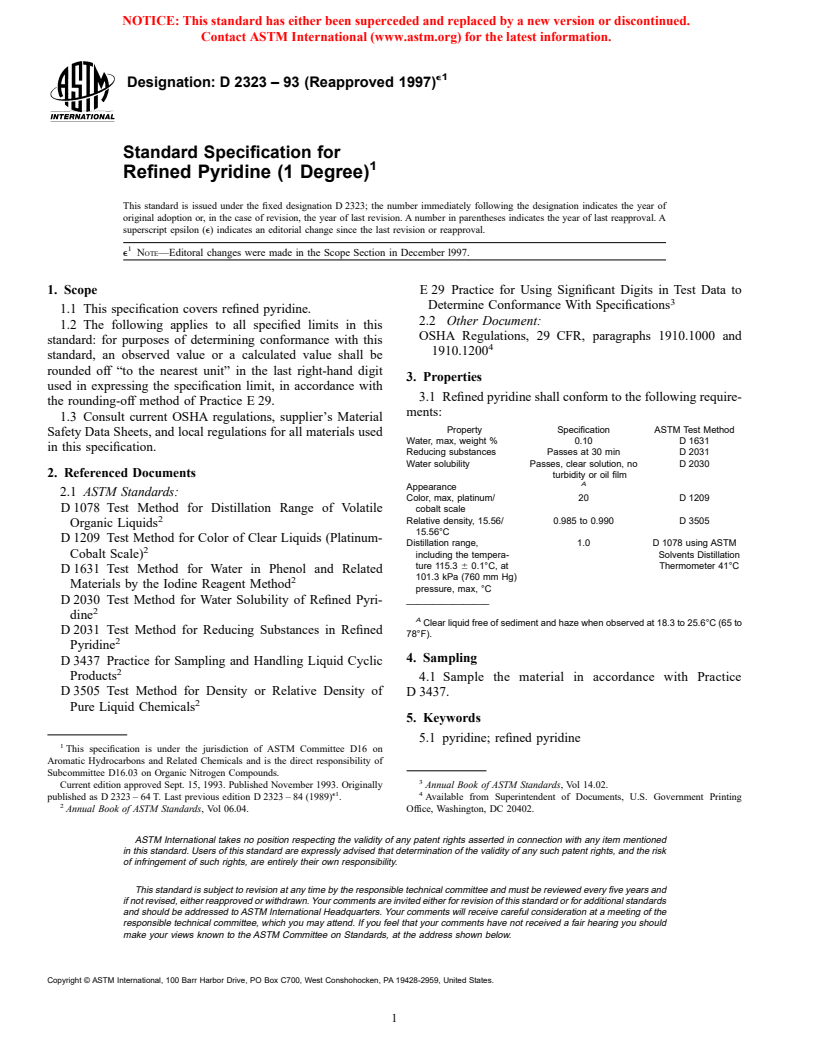

3. Properties

used in expressing the specification limit, in accordance with

3.1 Refined pyridine shall conform to the following require-

the rounding-off method of Practice E 29.

ments:

1.3 Consult current OSHA regulations, supplier’s Material

Property Specification ASTM Test Method

Safety Data Sheets, and local regulations for all materials used

Water, max, weight % 0.10 D 1631

in this specification.

Reducing substances Passes at 30 min D 2031

Water solubility Passes, clear solution, no D 2030

2. Referenced Documents

turbidity or oil film

A

Appearance

2.1 ASTM Standards:

Color, max, platinum/ 20 D 1209

D 1078 Test Method for Distillation Range of Volatile

cobalt scale

Relative density, 15.56/ 0.985 to 0.990 D 3505

Organic Liquids

15.56°C

D 1209 Test Method for Color of Clear Liquids (Platinum-

Distillation range, 1.0 D 1078 using ASTM

Cobalt Scale) including the tempera- Solvents Distillation

ture 115.3 6 0.1°C, at Thermometer 41°C

D 1631 Test Method for Water in Phenol and Related

101.3 kPa (760 mm Hg)

Materials by the Iodine Reagent Method

pressure, max, °C

D 2030 Test Method for Water Solubility of Refined Pyri- ________________

dine

A

Clear liquid free of sediment and haze when observed at 18.3 to 25.6°C (65 to

D 2031 Test Method for Reducing Substances in Refined

78°F).

Pyridine

4. Sampling

D 3437 Pract

...

This May Also Interest You

SIGNIFICANCE AND USE

5.1 The pyridine base content of cresylic acids is important in certain applications. This test method may be used as a tool for quality control and specification purposes by producers and users.

SCOPE

1.1 This test method covers the determination of pyridine and other basic nitrogen impurities in crude and refined cresylic acids streams, including mixtures.

1.2 This test method is applicable for pyridine base levels of 0.001 % to 0.5 %.

1.3 In determining the conformance of the test results using this method to applicable specifications, results shall be rounded off in accordance with the rounding-off method of Practice E29.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 8.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

- Standard4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 N-methylcarbamates and n-methylcarbomoyloximes are used in agriculture as insecticides and herbicides. They are sometimes found in both surface and ground waters and can be toxic to animals and plants at moderate to high concentrations. The manufacturing precursors and degradation products may be equally as hazardous to the environment.

SCOPE

1.1 This is a high-performance liquid chromatographic (HPLC) test method applicable to the determination of certain n-methylcarbamoyloximes and n-methylcarbamates in ground water and finished drinking water (1).2 This test method is applicable to any carbamate analyte that can be hydrolyzed to a primary amine. The following compounds have been validated using this test method:

Analyte

Chemical Abstract Services

Registry Number A

Aldicarb

116-06-3

Aldicarb sulfone

1646-88-4

Aldicarb sulfoxide

1646-87-3

Baygon

114-26-1

Carbaryl

63-25-2

Carbofuran

1563-66-2

3-Hydroxycarbofuran

16655-82-6

Methiocarb

2032-65-7

Methomyl

16752-77-5

Oxamyl

23135-22-0

1.2 This test method has been validated in a collaborative round-robin study (2) and estimated detection limits (EDLs) have been determined for the analytes listed in 1.1 (Table 1). Observed detection limits may vary between ground waters, depending on the nature of interferences in the sample matrix and the specific instrumentation used.

1.3 This test method is restricted to use by, or under the supervision of, analysts experienced in both the use of liquid chromatography and the interpretation of liquid chromatograms. Each analyst should demonstrate an ability to generate acceptable results with this test method using the procedure described in 12.3.

1.4 When this test method is used to analyze unfamiliar samples for any or all of the analytes listed in 1.1, analyte identifications should be confirmed by at least one additional qualitative technique.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Additional guidance on laboratory safety is available and suitable references for the information are provided (3-5).

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard16 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 When determining the limiting detectable concentration of a fluorescent substance, it is usually necessary to increase the readout scale of a photoelectric instrument to a point where noise (that is, random fluctuations of the system) becomes apparent. This noise will be superimposed upon the signal from the sample.

4.2 In molecular fluorescence spectroscopy, the limit of detection for the sample will be determined by the limiting signal-to-noise ratio, S/N, where the signal, S, is the difference between readings obtained with the sample and blank solutions, and N is the total root-mean-square (rms) noise. The limit of detection for the sample will be given by the instrument readings that give a signal equal to three times the rms value of the noise.

Note 2: Factors other than noise affecting the sample concentration corresponding to the limit of detection include: the spectral bandwidths of the excitation and emission monochromators, the intensity of the exciting light that can be concentrated on the sample, the fraction of the fluorescence collected by the detection system, the response time of the detection system, and the purity of the solvent. The size and arrangement of the sample container with respect to the light beams are also important, as they affect both the desired signal and the extraneous signal that only contributes noise.

Note 3: The value of rms noise (N) can be obtained by calculating the standard deviation of a series of readings of the signal from the sample at the peak emission wavelength at approximately 450 nm as follows:

where:

= mean of the series of readings, x = value of the individual reading, and n = number of readings. Alternatively, rms noise may be estimated by noting the extreme differences between the members of a series of readings (peak-to-peak noise) and dividing by a factor that is usually taken to be 5.6, 7

SCOPE

1.1 This test method employs the signal-to-noise ratio to determine the sensitivity of a fluorescence measuring system in testing for the limit of detection (LOD) of quinine sulfate dihydrate in solution. The results obtained with quinine sulfate dihydrate in solution are suitable for specifying instrument performance on samples having excitation and fluorescence bands wider than 10 nm at or near room temperature.

1.1.1 This test method is not intended to be used as (1) a rigorous test of performance of instrumentation, or (2), to intercompare the quantitative performance of instruments of different design. Intercomparison of the LOD between instruments is commonly expressed as the ratio of the water Raman peak intensity to the root-mean-square (rms) noise as measured on a fluorometer using an excitation wavelength of 350 nm This test method uses the excitation and emission peak wavelengths for quinine sulfate dihydrate in solution, which are approximately 350 nm and 450 nm, respectively.

1.2 This test method has been applied to fluorescence-measuring systems utilizing non-laser, low-energy excitation sources. There is no assurance that extremely intense illumination will not cause photodecomposition2 of the compound suggested in this test method. For this reason, it is recommended that this test method not be indiscriminately employed with high intensity light sources. This test method is not intended to determine minimum detectable amounts of other materials. If this test method is extended to employ other chemical substances, the user should be aware of the possibility that these other substances may undergo decomposition or adsorption onto containers.

1.3 A typical LOD for conventional fluorometers using this test method is 1 ng of quinine sulfate per mL.

1.4 The suggested shelf life of a 1 mg/mL stock solution of quinine sulfate dihydrate is three months, when stored in the dark in a stoppered glass bottle.

1.5 The values stated in SI units are to be regarded as standard. No o...

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 The pyridine base content of cresylic acids is important in certain applications. This test method may be used as a tool for quality control and specification purposes by producers and users.

SCOPE

1.1 This test method covers the determination of pyridine and other basic nitrogen impurities in crude and refined cresylic acids streams, including mixtures.

1.2 This test method is applicable for pyridine base levels of 0.001 % to 0.5 %.

1.3 In determining the conformance of the test results using this method to applicable specifications, results shall be rounded off in accordance with the rounding-off method of Practice E29.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 8.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

- Standard4 pagesEnglish languagesale 15% off

ABSTRACT

These alternative test methods cover the indicator procedure for determining the total, primary, secondary, and tertiary amine values of fatty amines. These procedures are not applicable to fatty amidoamines and fatty diamines. The apparatus includes Erlenmeyer flasks and magnetic stirrer. Reagent grade chemicals shall be used in all tests and includes the following: water, bromphenol blue indicator solution, bromcresol green indicator solution, chloroform, hydrochloric acid standard solution, isopropyl alcohol, phenyl isothiocyanate, and salicylaldehyde. The procedure of determining the total amine values are detailed and the formula of calculating the total amine values is given.

SCOPE

1.1 These alternative test methods cover the indicator procedure for determining the total, primary, secondary, and tertiary amine values of fatty amines. These procedures are not applicable to fatty amidoamines and fatty diamines.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This test method can be used for research or for quality control to characterize isocyanates used in polyurethane products.

5.2 For toluene diisocyanate, results from this test method can relate to reactivity or performance in polyurethane systems.

SCOPE

1.1 This test method measures the color of clear liquids. It is applicable only to materials whose color-producing bodies have light-absorption characteristics similar to those of the platinum cobalt color standards used.2 (See Test Method D1209 and Note 1.) Suitable isocyanates include toluene diisocyanate, and pure or modified monomeric methylene di(phenylisocyanate).

1.2 The values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: This standard and ISO 6271-1 address the same subject matter, but differ in technical content.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 This procedure measures the amount of hydrogen gas generation potential of aluminized emulsion roof coating. There is the possibility of water reacting with aluminum pigment to generate hydrogen gas. This situation is to be avoided, so this test was designed to evaluate coating formulations and assess the propensity to gassing.

SCOPE

1.1 This test method covers a hydrogen gas and stability test for aluminum emulsified asphalt coatings.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers the physical requirements and testing of three types of lap cement for use with asphalt roll roofing. Type I is a brushing consistency lap cement intended for use in the exposed-nailing method of roll roofing application, and contains no mineral or other stabilizers. This type is further divided into two grades, as follows: Grade 1, which is made with an air-blown asphalt; and Grade 2, which is made with a vacuum-reduced or steam-refined asphalt. Both Types II and III, on the other hand, are heavy brushing or light troweling consistency lap cement intended for use in the concealed-nailing method of roll roofing application, only that Type II cement contains a quantity of short-fibered asbestos, while Type III cement contains a quantity of mineral or other stabilizers, or both, but contains no asbestos. The lap cements shall be sampled for testing, and shall adhere to specified values of the following properties: water content; distillation (total distillate at given temperatures); softening point of residue; solubility in trichloroethylene; and strength at indicated age.

SCOPE

1.1 This specification covers lap cement consisting of asphalt dissolved in a volatile petroleum solvent with or without mineral or other stabilizers, or both, for use with roll roofing. The fibered version of these cements excludes the use of asbestos fibers.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 The following precautionary caveat applies only to the test method portion, Section 6, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Coefficients of linear thermal expansion are used, for example, for design purposes and to determine if failure by thermal stress may occur when a solid body composed of two different materials is subjected to temperature variations.

5.2 This test method is comparable to Test Method D3386 for testing electrical insulation materials, but it covers a more general group of solid materials and it defines test conditions more specifically. This test method uses a smaller specimen and substantially different apparatus than Test Methods E228 and D696.

5.3 This test method may be used in research, specification acceptance, regulatory compliance, and quality assurance.

SCOPE

1.1 This test method determines the technical coefficient of linear thermal expansion of solid materials using thermomechanical analysis techniques.

1.2 This test method is applicable to solid materials that exhibit sufficient rigidity over the test temperature range such that the sensing probe does not produce indentation of the specimen.

1.3 The recommended lower limit of coefficient of linear thermal expansion measured with this test method is 5 μm/(m·°C). The test method may be used at lower (or negative) expansion levels with decreased accuracy and precision (see Section 12).

1.4 This test method is applicable to the temperature range from −120 °C to 900 °C. The temperature range may be extended depending upon the instrumentation and calibration materials used.

1.5 SI units are the standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard5 pagesEnglish languagesale 15% off

- Standard5 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Research O.N. correlates with commercial automotive spark-ignition engine antiknock performance under mild conditions of operation.

5.2 Research O.N. is used by engine manufacturers, petroleum refiners and marketers, and in commerce as a primary specification measurement related to the matching of fuels and engines.

5.2.1 Empirical correlations that permit calculation of automotive antiknock performance are based on the general equation:

Values of k1, k2, and k3 vary with vehicles and vehicle populations and are based on road-O.N. determinations.

5.2.2 Research O.N., in conjunction with Motor O.N., defines the antiknock index of automotive spark-ignition engine fuels, in accordance with Specification D4814. The antiknock index of a fuel approximates the Road octane ratings for many vehicles, is posted on retail dispensing pumps in the U.S., and is referred to in vehicle manuals.

This is more commonly presented as:

5.2.3 Research O.N. is also used either alone or in conjunction with other factors to define the Road O.N. capabilities of spark-ignition engine fuels for vehicles operating in areas of the world other than the United States.

5.3 Research O.N. is used for measuring the antiknock performance of spark-ignition engine fuels that contain oxygenates.

5.4 Research O.N. is important in relation to the specifications for spark-ignition engine fuels used in stationary and other nonautomotive engine applications.

SCOPE

1.1 This laboratory test method covers the quantitative determination of the knock rating of liquid spark-ignition engine fuel in terms of Research O.N., including fuels that contain up to 25 % v/v of ethanol. However, this test method may not be applicable to fuel and fuel components that are primarily oxygenates.2 The sample fuel is tested using a standardized single cylinder, four-stroke cycle, variable compression ratio, carbureted, CFR engine run in accordance with a defined set of operating conditions. The O.N. scale is defined by the volumetric composition of PRF blends. The sample fuel knock intensity is compared to that of one or more PRF blends. The O.N. of the PRF blend that matches the K.I. of the sample fuel establishes the Research O.N.

1.2 The O.N. scale covers the range from 0 to 120 octane number but this test method has a working range from 40 to 120 Research O.N. Typical commercial fuels produced for spark-ignition engines rate in the 88 to 101 Research O.N. range. Testing of gasoline blend stocks or other process stream materials can produce ratings at various levels throughout the Research O.N. range.

1.3 The values of operating conditions are stated in SI units and are considered standard. The values in parentheses are the historical inch-pound units. The standardized CFR engine measurements continue to be in inch-pound units only because of the extensive and expensive tooling that has been created for this equipment.

1.4 For purposes of determining conformance with all specified limits in this standard, an observed value or a calculated value shall be rounded “to the nearest unit” in the last right-hand digit used in expressing the specified limit, in accordance with the rounding method of Practice E29.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see Section 8, 14.4.1, 15.5.1, 16.6.1, Annex A1, A2.2.3.1, A2.2.3.3 (6) and (9), A2.3.5, X3.3.7, X4.2.3.1, X4.3.4.1, X4.3.9.3, X4.3.11.4, and X4.5.1.8.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Gu...

- Standard48 pagesEnglish languagesale 15% off

- Standard48 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.