ASTM F901-01(2017)

(Specification)Standard Specification for Aluminum Transmission Tower Bolts and Nuts

Standard Specification for Aluminum Transmission Tower Bolts and Nuts

ABSTRACT

This specification covers aluminum transmission tower bolts and nuts. Bolts shall be manufactured from alloy 2024 and nuts from alloy 6061 or 6262, and shall be cold formed, hot formed, or machined formed. Alloy materials for bolts and nuts shall conform to the chemical requirements of this specification. Bolts and nuts shall conform to the required tensile strength, dimensions, workmanship, finish, appearance, marking, packaging, and shipping. Test methods shall include chemical analysis, wedge tension test, shear test, and proof-stress test.

SCOPE

1.1 This specification covers aluminum structural bolts and nuts for use in the construction of aluminum transmission towers, substations, and similar aluminum structures.

1.2 Diameters of bolts and nuts furnished to this specification are 5/8 , 3/4 , and 7/8 in.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F901 −01 (Reapproved 2017)

Standard Specification for

Aluminum Transmission Tower Bolts and Nuts

ThisstandardisissuedunderthefixeddesignationF901;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E227 Test Method for Optical Emission Spectrometric

Analysis of Aluminum and Aluminum Alloys by the

1.1 This specification covers aluminum structural bolts and

Point-to-Plane Technique (Withdrawn 2002)

nuts for use in the construction of aluminum transmission

F606/F606M Test Methods for Determining the Mechanical

towers, substations, and similar aluminum structures.

Properties of Externally and Internally Threaded

1.2 Diameters of bolts and nuts furnished to this specifica-

Fasteners, Washers, Direct Tension Indicators, and Rivets

5 3 7

tion are ⁄8, ⁄4, and ⁄8 in.

F1470 Practice for Fastener Sampling for Specified Me-

chanical Properties and Performance Inspection

1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

2.2 ASME Standards:

conversions to SI units that are provided for information only

B1.1 Unified Inch Screw Threads (UN and UNR Thread

and are not considered standard.

Form)

B18.2.1 Square and Hex Bolts and Screws (Inch Series)

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard- Addenda A

B18.2.2 Square and Hex Nuts

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

2.3 Military Standard:

mendations issued by the World Trade Organization Technical

MIL-STD-A-8625 Anodic Coatings for Aluminum and

Barriers to Trade (TBT) Committee.

Aluminum Alloys

2. Referenced Documents

3. Ordering Information

2.1 ASTM Standards:

3.1 Orders for bolts and nuts under this specification shall

B565 Test Method for Shear Testing of Aluminum and

include the following:

Aluminum-Alloy Rivets and Cold-Heading Wire and

3.1.1 Quantity (number of pieces of each item and size);

Rods

3.1.2 Name of item;

D3951 Practice for Commercial Packaging

3.1.3 Size (diameter, threads per inch, length);

E29 Practice for Using Significant Digits in Test Data to

3.1.4 Alloy number;

Determine Conformance with Specifications

3.1.5 Shipment lot testing, as required (see Supplementary

E34 Test Methods for Chemical Analysis of Aluminum and

Requirements S1);

Aluminum-Base Alloys (Withdrawn 2017)

3.1.6 Source inspection, if required (see Section 14);

E55 Practice for Sampling Wrought Nonferrous Metals and

3.1.7 Certificate of compliance or test report, if required

Alloys for Determination of Chemical Composition

(see Section 16);

E101 TestMethodforSpectrographicAnalysisofAluminum

3.1.8 Additional requirements, if any, to be specified on the

and Aluminum Alloys by the Point-to-Plane Technique

purchase order (see 4.2.1, 4.2.3, 8.2.1, 8.2.2, 9.2, 12.1, and

(Withdrawn 1996)

13.1);

3.1.9 Supplementary requirements, if any; and

This specification is under the jurisdiction of ASTM Committee F16 on

3.1.10 ASTM specification and year of issue.

Fasteners and is the direct responsibility of Subcommittee F16.04 on Nonferrous

Fasteners. NOTE 1—Example: 10 000 piecesAluminum Transmission Tower Bolt,

Current edition approved Dec. 1, 2017. Published December 2017. Originally 0.750-10 by 2.00 in., Alloy 2024-T4, Furnish Certificate of Compliance,

approvedin1984.Lastpreviouseditionapprovedin2012asF901 – 01(2012).DOI:

Supplementary Requirement S2, ASTM F901–XX.

10.1520/F0901-01R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from IHS, 15 Inverness Way East, Englewood, CO 80112, http://

the ASTM website. www.global.ihs.com.

3 5

The last approved version of this historical standard is referenced on Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

www.astm.org. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F901 − 01 (2017)

4. Materials and Manufacture may be tested in full size as specified in 13.2.2. Bolts subjected

to tension tests shall meet the tensile strength requirements

4.1 Materials—Bolts shall be manufactured from Alloy

specified in Table 1. Bolts of less than 3 diameters in length or

2024 and nuts from Alloy 6061 or 6262. The materials

for other reasons cannot be tested full size in tension, shall be

chemical composition shall be capable of developing the

subject to a shear test to be performed in accordance with

mechanicalpropertiesrequiredbyTable1,wheninthefinished

12.2.1. The test results shall conform to the following mini-

condition.

mum shear-strength requirements: 37 ksi (255 MPa) for

4.2 Manufacture:

2024-T4.

4.2.1 Forming—Unless otherwise specified, the bolts and

6.2 Nuts—Nuts shall be tested in accordance with the

nuts shall be cold formed, hot formed, or machined from

mechanical requirements for the applicable type and shall meet

suitable material at the option of the manufacturer.

the minimum proof-load requirements in Table 1.

4.2.2 Condition—The fasteners shall be furnished in the

following conditions:

7. Significance of Numerical Limits

Alloy Fastener Condition

7.1 For purposes of determining compliance with the speci-

2024-T4 bolts solution treated and naturally aged

fied limits for requirements of the properties listed in this

6061-T6 nuts solution treated and artificially aged

specification, an observed value or calculated value shall be

6262-T9 nuts solution treated, artificially aged, and

cold worked

rounded in accordance with Practice E29.

4.2.3 Threads—Unless otherwise specified, the threads shall

be rolled or cut at the option of the manufacturer. 8. Dimensions

8.1 Bolts and Nuts:

5. Chemical Composition

8.1.1 Bolts—Bolts shall be full-size body in accordance

5.1 Chemical Composition Limits—The bolts and nuts shall

with the requirements of AMSE B18.2.1, except the full-body

conform to the requirements as to chemical composition

length listed in Table 4 shall be the basis of manufacture and

prescribed in Table 2.

inspection. Unless otherwise specified, hex bolts shall be

furnished. The ends of the bolts need not be chamfered or

5.2 Manufacturer’s Analysis—When test reports are re-

quired on the inquiry or purchase order (see 3.1.7), the pointed.

8.1.2 Nuts—The dimensions of the nuts shall be in accor-

manufacturer shall furnish a certificate of conformance certi-

fying compliance with the chemical limits specified in Table 2. dance with the requirements of ASME B 18.2.2. Unless

otherwise specified, nuts are to be either the regular hex series

5.3 Product Analysis:

or a recessed hex series that allows penetration of the bolt

5.3.1 Product analyses may be made by the purchaser from

threads into the nut recess area.

finished products representing each lot. The chemical compo-

sition thus determined shall conform to the requirements in 8.2 Threads:

8.2.1 Bolts—Unless otherwise specified, the bolts shall be

Table 2.

5.3.2 In the event of disagreement, a referee chemical Class 2A threads in accordance with ASME B1.1.

8.2.2 Nuts—Unless otherwise specified, the nuts shall be

analysis shall be performed if agreed upon by both parties. A

sample as required by Table 3 shall be selected for each lot. Class 2B threads in accordance with ASME B1.1.

Chemical analysis shall be performed to the requirements of

13.1 and the result shall conform to Table 2. 9. Workmanship, Finish, and Appearance

9.1 Workmanship—Bolts and nuts shall have a workmanlike

6. Mechanical Properties

finish free of injurious burrs, seams, laps, irregular surfaces,

6.1 Bolts—Bolts having a length three times the diameter or

and other imperfections affecting serviceability.

longer shall be tested full size as specified in 13.2.2. At the

9.2 Finish:

manufacturer’s option, bolts of less than 3 diameters in length

9.2.1 Bolts—Unless otherwise specified, bolts shall be fur-

nished anodized per MIL-STD-A-8625, Type II, Class 2 and

TABLE 1 Tensile Strength of 2024-T4 Bolts and Proof Loads for

color coded for length as indicated in Table 4.

A

6061-T6 and 6262-T9 Nuts

9.2.2 Nuts—Unless otherwise specified, nuts shall be fur-

Bolt Size, in. Tensile Strength, min, lbf (kN)

nished waxed.

⁄8 12 400 (55)

⁄4 18 400 (82)

⁄8 25 400 (113)

10. Sampling

A

Based on a tensile unit stress of 55 000 psi (380 MPa) and the thread stress

10.1 Alot,forthepurposesofselectingtestspecimens,shall

area calculated as follows:

consist of no more than 100 000 pieces offered for inspection

A 5 0.7854 fD2 s0.9743/ndg

s

at one time having the following common characteristics:

where:

10.1.1 One type of item (that is, bolts or nuts),

A = stress area,

s

10.1.2 Same alloy and temper,

D = nominal diameter, and

10.1.3 One nominal diameter and thread series, and

n = threads/in.

10.1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F901 − 01 (Reapproved 2012) F901 − 01 (Reapproved 2017)

Standard Specification for

Aluminum Transmission Tower Bolts and Nuts

This standard is issued under the fixed designation F901; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers aluminum structural bolts and nuts for use in the construction of aluminum transmission towers,

substations, and similar aluminum structures.

5 3 7

1.2 Diameters of bolts and nuts furnished to this specification are ⁄8, ⁄4, and ⁄8 in.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

B565 Test Method for Shear Testing of Aluminum and Aluminum-Alloy Rivets and Cold-Heading Wire and Rods

D3951 Practice for Commercial Packaging

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E34 Test Methods for Chemical Analysis of Aluminum and Aluminum-Base Alloys (Withdrawn 2017)

E55 Practice for Sampling Wrought Nonferrous Metals and Alloys for Determination of Chemical Composition

E101 Test Method for Spectrographic Analysis of Aluminum and Aluminum Alloys by the Point-to-Plane Technique (Withdrawn

1996)

E227 Test Method for Optical Emission Spectrometric Analysis of Aluminum and Aluminum Alloys by the Point-to-Plane

Technique (Withdrawn 2002)

F606F606/F606M Test Methods for Determining the Mechanical Properties of Externally and Internally Threaded Fasteners,

Washers, and Rivets (Metric) F0606_F0606M Direct Tension Indicators, and Rivets

F1470 Practice for Fastener Sampling for Specified Mechanical Properties and Performance Inspection

2.2 ASME Standards:

B1.1 Unified Inch Screw Threads (UN and UNR Thread Form)

B18.2.1 Square and Hex Bolts and Screws (Inch Series) Addenda A

B18.2.2 Square and Hex Nuts

2.3 Military Standard:

MIL-STD-A-8625 Anodic Coatings for Aluminum and Aluminum Alloys

3. Ordering Information

3.1 Orders for bolts and nuts under this specification shall include the following:

3.1.1 Quantity (number of pieces of each item and size);

3.1.2 Name of item;

This specification is under the jurisdiction of ASTM Committee F16 on Fasteners and is the direct responsibility of Subcommittee F16.04 on Nonferrous Fasteners.

Current edition approved April 1, 2012Dec. 1, 2017. Published May 2012December 2017. Originally approved in 1984. Last previous edition approved in 20072012 as

F901 – 01(2007).(2012). DOI: 10.1520/F0901-01R12.10.1520/F0901-01R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Available from IHS, 15 Inverness Way East, Englewood, CO 80112, http://www.global.ihs.com.

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, DLA Document Services, Building 4/D, 700 Robbins Ave., Philadelphia, PA

19111-5098, http://dodssp.daps.dla.mil.19111-5094, http://quicksearch.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F901 − 01 (2017)

3.1.3 Size (diameter, threads per inch, length);

3.1.4 Alloy number;

3.1.5 Shipment lot testing, as required (see Supplementary Requirements S1);

3.1.6 Source inspection, if required (see Section 14);

3.1.7 Certificate of compliance or test report, if required (see Section 16);

3.1.8 Additional requirements, if any, to be specified on the purchase order (see 4.2.1, 4.2.3, 8.2.1, 8.2.2, 9.2, 12.1, and 13.1);

3.1.9 Supplementary requirements, if any; and

3.1.10 ASTM specification and year of issue.

NOTE 1—Example: 10 000 pieces Aluminum Transmission Tower Bolt, 0.750-10 by 2.00 in., Alloy 2024-T4, Furnish Certificate of Compliance,

Supplementary Requirement S2, ASTM F901–XX.

4. Materials and Manufacture

4.1 Materials—Bolts shall be manufactured from Alloy 2024 and nuts from Alloy 6061 or 6262. The materials chemical

composition shall be capable of developing the mechanical properties required by Table 1, when in the finished condition.

4.2 Manufacture:

4.2.1 Forming—Unless otherwise specified, the bolts and nuts shall be cold formed, hot formed, or machined from suitable

material at the option of the manufacturer.

4.2.2 Condition—The fasteners shall be furnished in the following conditions:

Alloy Fastener Condition

2024-T4 bolts solution treated and naturally aged

6061-T6 nuts solution treated and artificially aged

6262-T9 nuts solution treated, artificially aged, and

cold worked

4.2.3 Threads—Unless otherwise specified, the threads shall be rolled or cut at the option of the manufacturer.

5. Chemical Composition

5.1 Chemical Composition Limits—The bolts and nuts shall conform to the requirements as to chemical composition prescribed

in Table 2.

5.2 Manufacturer’s Analysis—When test reports are required on the inquiry or purchase order (see 3.1.7), the manufacturer shall

furnish a certificate of conformance certifying compliance with the chemical limits specified in Table 2.

5.3 Product Analysis:

5.3.1 Product analyses may be made by the purchaser from finished products representing each lot. The chemical composition

thus determined shall conform to the requirements in Table 2.

5.3.2 In the event of disagreement, a referee chemical analysis shall be performed if agreed upon by both parties. A sample as

required by Table 3 shall be selected for each lot. Chemical analysis shall be performed to the requirements of 13.1 and the result

shall conform to Table 2.

6. Mechanical Properties

6.1 Bolts—Bolts having a length three times the diameter or longer shall be tested full size as specified in 13.2.2. At the

manufacturer’s option, bolts of less than 3 diameters in length may be tested in full size as specified in 13.2.2. Bolts subjected to

tension tests shall meet the tensile strength requirements specified in Table 1. Bolts of less than 3 diameters in length or for other

reasons cannot be tested full size in tension, shall be subject to a shear test to be performed in accordance with 12.2.1. The test

results shall conform to the following minimum shear-strength requirements: 37 ksi (255 MPa) for 2024-T4.

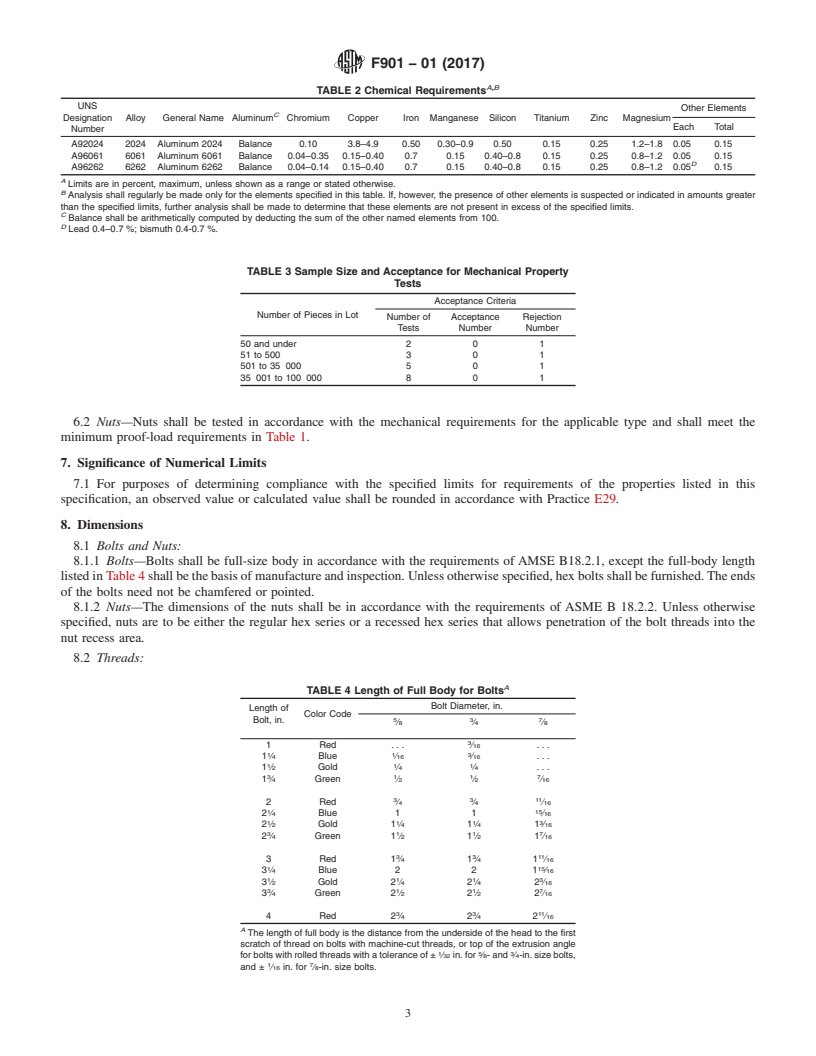

TABLE 1 Tensile Strength of 2024-T4 Bolts and Proof Loads for

A

6061-T6 and 6262-T9 Nuts

Bolt Size, in. Tensile Strength, min, lbf (kN)

⁄8 12 400 (55)

⁄4 18 400 (82)

⁄8 25 400 (113)

A

Based on a tensile unit stress of 55 000 psi (380 MPa) and the thread stress

area calculated as follows:

A 50.7854 fD 2 0.9743/n g

s d

s

where:

A = stress area,

s

D = nominal diameter, and

n = threads/in.

F901 − 01 (2017)

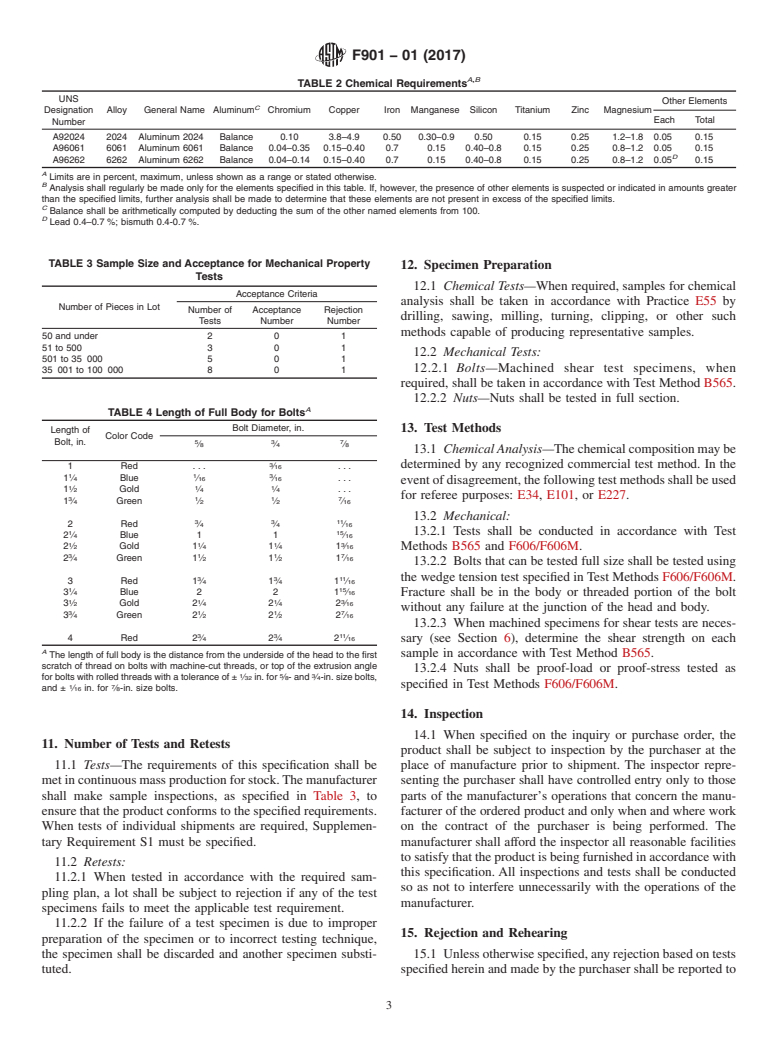

A,B

TABLE 2 Chemical Requirements

UNS

Other Elements

C

Designation Alloy General Name Aluminum Chromium Copper Iron Manganese Silicon Titanium Zinc Magnesium

Each Total

Number

A92024 2024 Aluminum 2024 Balance 0.10 3.8–4.9 0.50 0.30–0.9 0.50 0.15 0.25 1.2–1.8 0.05 0.15

A96061 6061 Aluminum 6061 Balance 0.04–0.35 0.15–0.40 0.7 0.15 0.40–0.8 0.15 0.25 0.8–1.2 0.05 0.15

D

A96262 6262 Aluminum 6262 Balance 0.04–0.14 0.15–0.40 0.7 0.15 0.40–0.8 0.15 0.25 0.8–1.2 0.05 0.15

A

Limits are in percent, maximum, unless shown as a range or stated otherwise.

B

Analysis shall regularly be made only for the elements specified in this table. If, however, the presence of other elements is suspected or indicated in amounts greater

than the specified limits, further analysis shall be made to determine that these elements are not present in excess of the specified limits.

C

Balance shall be arithmetically computed by deducting the sum of the other named elements from 100.

D

Lead 0.4–0.7 %; bismuth 0.4-0.7 %.

TABLE 3 Sample Size and Acceptance for Mechanical Property

Tests

Acceptance Criteria

Number of Pieces in Lot

Number of Acceptance Rejection

Tests Number Number

50 and under 2 0 1

51 to 500 3 0 1

501 to 35 000 5 0 1

35 001 to 100 000 8 0 1

6.2 Nuts—Nuts shall be tested in accordance with the mechanical requirements for the applicable type and shall meet the

minimum proof-load requirements in Table 1.

7. Significance of Numerical Limits

7.1 For purposes of determining compliance with the specified limits for requirements of the properties listed in this

specification, an observed value or calculated value shall be rounded in accordance with Practice E29.

8. Dimensions

8.1 Bolts and Nuts:

8.1.1 Bolts—Bolts shall be full-size body in accordance with the requirements of AMSE B18.2.1, ex

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.