ASTM D7308-17

(Practice)Standard Practice for Sample Preparation of Thermoplastic Pavement Marking Materials

Standard Practice for Sample Preparation of Thermoplastic Pavement Marking Materials

SIGNIFICANCE AND USE

5.1 This practice provides a standard procedure for the preparation of thermoplastic pavement marking material test specimens prior to testing for various properties as called for in the governing specification. Specimens that are prepared using this standard methodology yield test results that are consistent with the material from which it was sampled. Test results from specimens can be used to determine compliance of the thermoplastic pavement marking material to the specification. This practice can also be used by manufacturers of these materials to prepare specimens for testing to determine the uniformity of thermoplastic pavement marking materials from batch to batch.

5.2 This practice does not address any issues related to specific testing of the thermoplastic pavement marking materials for any physical or chemical property.

SCOPE

1.1 This practice covers the proper preparation of test specimens of thermoplastic pavement marking materials obtained to ensure test results are representative of the material being tested.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7308 − 17

Standard Practice for

Sample Preparation of Thermoplastic Pavement Marking

1

Materials

This standard is issued under the fixed designation D7308; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Practice

1.1 This practice covers the proper preparation of test

4.1 The thermoplastic pavement marking material is pre-

specimens of thermoplastic pavement marking materials ob-

pared for the testing of various physical and chemical proper-

tained to ensure test results are representative of the material

ties as outlined in the governing specification by melting a

being tested.

sample of the traffic marking material to its application

temperature under continuous agitation. Depending upon the

1.2 The values stated in SI units are to be regarded as the

requirements of the governing specification the sample can

standard. The values given in parentheses are for information

then be exposed to the required heating time and conditions

only.

prior to the preparation of the test specimens or the test

1.3 This standard does not purport to address all of the

specimens may be prepared immediately after the material has

safety concerns, if any, associated with its use. It is the

reached application temperature.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4.2 If required by the governing specification that the

bility of regulatory limitations prior to use.

sample be subjected to an extended period of heating prior to

1.4 This international standard was developed in accor-

the preparation of the test specimen in order to determine the

dance with internationally recognized principles on standard-

effect of heat history upon various physical or chemical

ization established in the Decision on Principles for the

properties, the sample must be melted down in the prescribed

Development of International Standards, Guides and Recom-

manneroutlinedinthispracticepriortobeingsubjectedtosuch

mendations issued by the World Trade Organization Technical

conditions.

Barriers to Trade (TBT) Committee.

5. Significance and Use

2. Referenced Documents

2 5.1 This practice provides a standard procedure for the

2.1 ASTM Standards:

preparation of thermoplastic pavement marking material test

D7307 Practice for Sampling ofThermoplasticTraffic Mark-

specimens prior to testing for various properties as called for in

ing Materials

the governing specification. Specimens that are prepared using

this standard methodology yield test results that are consistent

3. Terminology

with the material from which it was sampled. Test results from

3.1 Definitions of Terms Specific to This Standard:

specimens can be used to determine compliance of the ther-

3.1.1 thermoplastic pavement marking material, n—a

moplastic pavement marking material to the specification. This

highly filled 100 % total solids highway marking material that

practice can also be used by manufacturers of these materials

when heated to a molten state can be extruded or sprayed onto

to prepare specimens for testing to determine the uniformity of

a road surface and when cooled forms a solid, durable

thermoplasticpavementmarkingmaterialsfrombatchtobatch.

delineator.

5.2 This practice does not address any issues related to

specific testing of the thermoplastic pavement marking mate-

1

This practice is under the jurisdiction of ASTM Committee D01 on Paint and

rials for any physical or chemical property.

Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.44 on Traffic Coatings.

Current edition approved June 1, 2017. Published June 2017. Originally 6. Apparatus

approved in 2007. Last previous edition approved in 2012 as D7308 – 07 (2012).

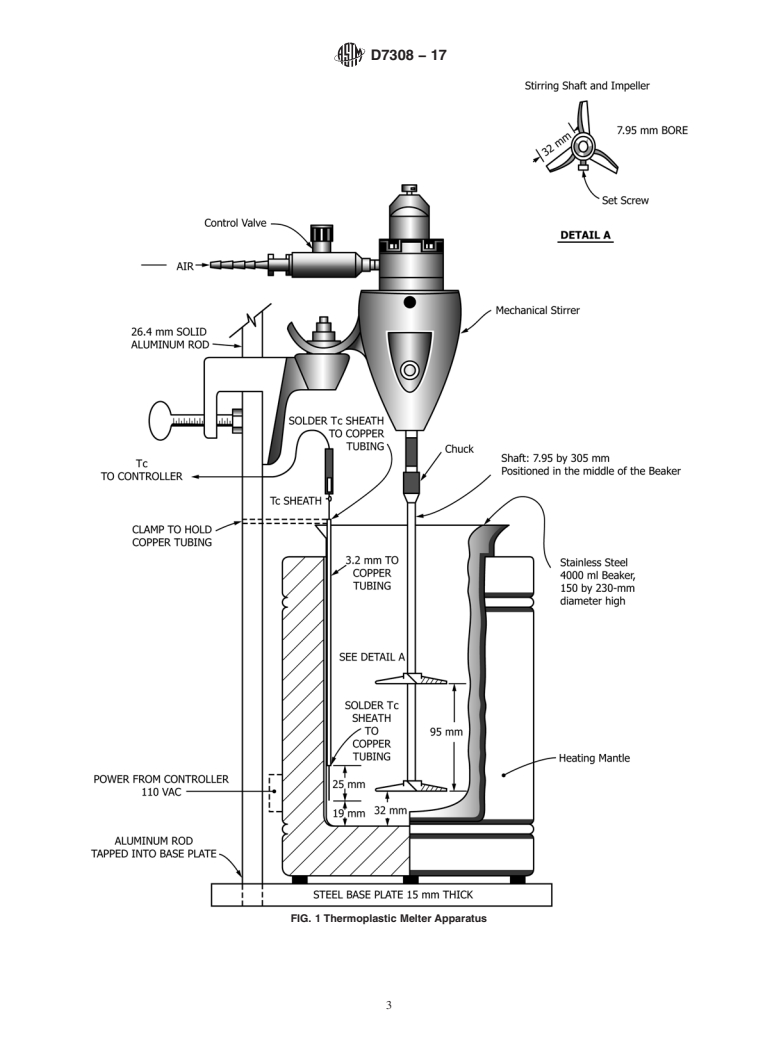

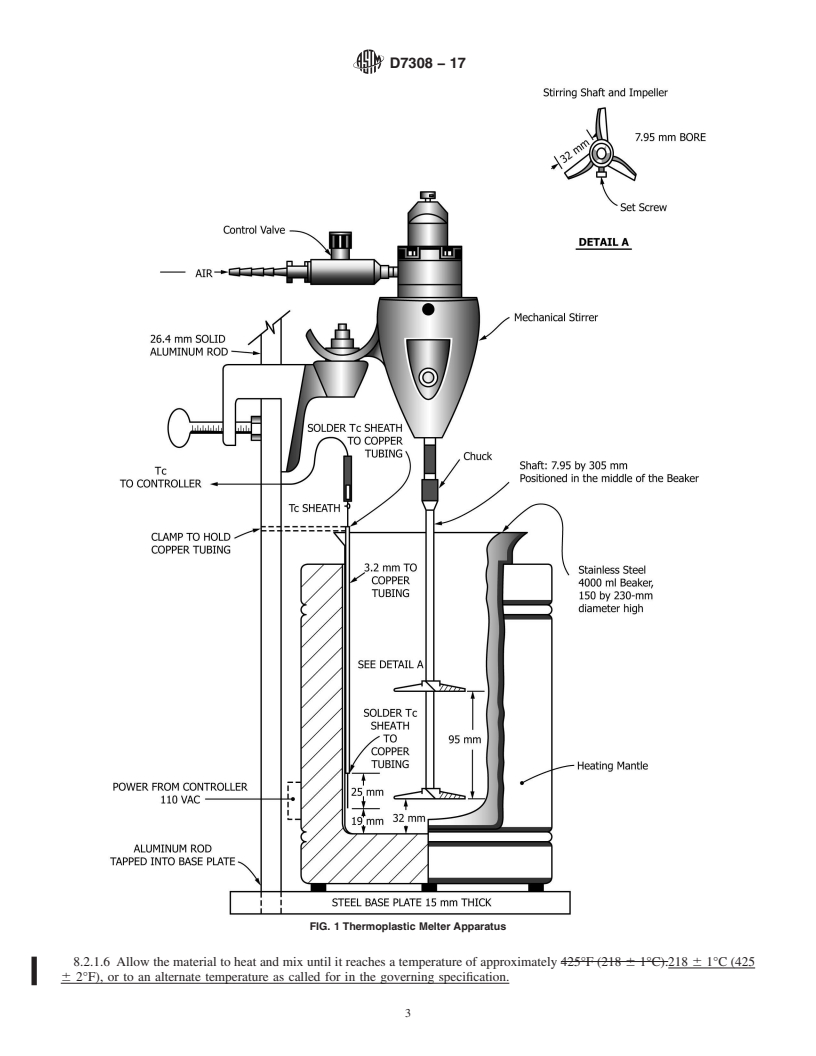

DOI: 10.1520/D7308-17. 6.1 Procedure A (Preferred):

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1.1 Stainless Steel 4000 ml Beaker, 150 by 230-mm

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

diameter high. Alternatively an unlined 0.95 L (1 qt) or 3.48 L

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. (1 gal) can may be used depending on the sample size.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7308 − 17

6.1.2 Heating Mantle of sufficient size. Note that aluminum troller in accordance with the manufactures instructions.

foil may be used to serve as somewhat of

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7308 − 07 (Reapproved 2012) D7308 − 17

Standard Practice for

Sample Preparation of Thermoplastic TrafficPavement

1

Marking Materials

This standard is issued under the fixed designation D7308; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the proper preparation of test specimens of thermoplastic trafficpavement marking materials obtained

to ensure test results are representative of the material being tested.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D7307 Practice for Sampling of Thermoplastic Traffic Marking Materials

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 thermoplastic traffıcpavement marking material, n—a highly filled 100 % total solids highway marking material that when

heated to a molten state can be extruded or sprayed onto a road surface and when cooled forms a solid, durable delineator.

4. Summary of Practice

4.1 The thermoplastic trafficpavement marking material is prepared for the testing of various physical and chemical properties

as outlined in the governing specification by melting a sample of the traffic marking material to its application temperature under

continuous agitation. Depending upon the requirements of the governing specification the sample can then be exposed to the

required heating time and conditions prior to the preparation of the test specimens or the test specimens may be prepared

immediately after the material has reached application temperatures.temperature.

4.2 If required by the governing specification that the sample be subjected to an extended periodsperiod of heating prior to the

preparation of the test specimen in order to determine the effect of heat history upon various physical or chemical properties, the

sample must be melted down in the prescribed manner outlined in this practice prior to being subjected to such conditions.

5. Significance and Use

5.1 This practice provides a standard procedure for the preparation of thermoplastic trafficpavement marking material test

specimens prior to testing for various properties as called for in the governing specification. Specimens that are prepared using this

standard methodology yield test results that are consistent with the material from which it was sampled. Test results from

specimens can be used to determine compliance of the thermoplastic trafficpavement marking material to the specification. This

1

This practice is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.44 on Traffic Coatings.

Current edition approved June 1, 2012June 1, 2017. Published August 2012June 2017. Originally approved in 2007. Last previous edition approved in 20072012 as D7308

– 07. 07 (2012). DOI: 10.1520/D7308-07R12.10.1520/D7308-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7308 − 17

sample preparation guide practice can also be used by manufacturers of these materials to prepare specimens for testing to

determine the uniformity of thermoplastic trafficpavement marking materials from batch to batch.

5.2 This practice does not address any issues related to specific testing of the t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.