ASTM D4812-99

(Test Method)Standard Test Method for Unnotched Cantilever Beam Impact Strength of Plastics

Standard Test Method for Unnotched Cantilever Beam Impact Strength of Plastics

SCOPE

1.1 This test method covers the determination of the resistance to breakage by flexural shock of plastics, as indicated by the energy extracted from standardized (Note 1) pendulum-type hammers, mounted in standardized machines, in breaking standard specimens with one pendulum swing. The result of this test is reported in terms of impact strength per unit of specimen width. Note 1-The machines with their pendulum-type hammers have been standardized in that they must comply with certain requirements, including a fixed height of hammer fall that results in a substantially fixed velocity of the hammer at the moment of impact. Hammers of different initial energies (produced by varying their effective weights) are recommended for use with specimens of different impact strengths. Moreover, manufacturers of the equipment are permitted to use different lengths and constructions of pendulums (with resulting possible differences in pendulum rigidities (see Section 4), and other differences in machine design).

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4812–99

Standard Test Method for

Unnotched Cantilever Beam Impact Resistance of Plastics

This standard is issued under the fixed designation D4812; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers the determination of the resis-

tance of plastics to breakage by flexural shock, as indicated by

3. Terminology

the energy extracted from standardized pendulum-type ham-

3.1 Definitions—Definitions used in this test method are in

mers, mounted in standardized machines, in breaking standard

accordance with Terminology D883.

specimens with one pendulum swing. The result of this test

method is reported as energy absorbed per unit of specimen

4. Summary of Test Method

width.

4.1 This test method differs from others of similar character

NOTE 1—The pendulum-type test instruments have been standardized

in that unnotched test specimens are used (see Test Methods

in that they must comply with certain requirements, including a fixed

D256 for procedures using notched test specimens). The lack

height of hammer fall that results in a substantially fixed velocity of the

of a notch makes this test method especially useful for

hammer at the moment of impact. Pendulums of different initial energies

reinforced materials where a notch may mask the effects of

(produced by varying their effective weights) are recommended for use

orientation. It may also be used with other filled or unrein-

with specimens of different impact strengths. Moreover, manufacturers of

the equipment are permitted to use different lengths and constructions of forced materials where a stress-concentrating notch is not

pendulums (with resulting possible differences in pendulum rigidities (see

desired. It is not valid for materials that twist when subjected

Section 5), and other differences in machine design).

to this test.

1.2 The values stated in SI units are to be regarded as the

5. Significance and Use

standard. The values given in parentheses are for information

5.1 The excess-energy pendulum-impact test indicates the

only.

energy to break standard test specimens of specified size under

1.3 This standard does not purport to address all of the

stipulated conditions of specimen mounting and pendulum

safety concerns, if any, associated with its use. It is the

velocity at impact.

responsibility of the user of this standard to establish appro-

5.2 The energy lost by the pendulum during the breakage of

priate safety and health practices and determine the applica-

thespecimenisthesumoftheenergiesrequiredtoproducethe

bility of regulatory limitations prior to use.

following results:

NOTE 2—ThisstandardandISO180,Method1U,aresimilarincontent

5.2.1 To initiate fracture of the specimen,

but are not technically equivalent.

5.2.2 To propagate the fracture across the specimen,

2. Referenced Documents 5.2.3 To throw the free end (or pieces) of the broken

2 specimen (toss correction),

2.1 ASTM Standards:

5.2.4 To bend the specimen,

D256 Test Methods for Impact Resistance of Plastics and

5.2.5 To produce vibration in the pendulum arm,

Electrical Insulating Materials

5.2.6 To produce vibration or horizontal movement of the

D618 Practice for Conditioning Plastics for Testing

machine frame or base,

D883 Terminology Relating to Plastics

5.2.7 To overcome friction in the pendulum bearing and in

D5947 Test Methods for Physical Dimensions of Solid

the excess-energy-indicating mechanism, and to overcome

Plastic Specimens

windage (pendulum air drag),

5.2.8 To indent or deform plastically the specimen at the

This test method is under the jurisdiction ofASTM Committee D20 on Plastics line of impact, and

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

5.2.9 To overcome the friction caused by the rubbing of the

Current edition approved March 10, 1999. Published June 1999. Originally

striking nose (or other part of the pendulum) over the face of

published as D4812–88. Last previous edition D4812–93.

the bent specimen.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4812–99

5.3 For relatively brittle materials for which fracture propa- relationship will exist under another set of test conditions. The

gationenergyissmallincomparisonwiththefractureinitiation ranking of materials may even be changed under different

energy, the indicated impact energy absorbed is, for all testing conditions.

practical purposes, the sum of items given in 5.2.1 and 5.2.3. 5.8 Before proceeding with this test method, reference

The toss correction (5.2.3) may represent a very large fraction shouldbemadetothespecificationofthematerialbeingtested.

of the total energy absorbed when testing relatively dense and Any test specimen preparation, conditioning, dimensions, or

brittle materials. testing parameters, or combination thereof, covered in the

5.4 For materials for which the fracture propagation energy material specification shall take precedence over those men-

(5.2.2) may be large compared to the fracture initiation energy tionedinthistestmethodexceptincaseswheretodosowould

(5.2.1), factors (5.2.2, 5.2.5, and 5.2.9) can become quite conflict with the purpose for conducting testing. If there are no

significant, even when the specimen is accurately machined material specifications, then the default conditions apply.

and positioned and the machine is in good condition with

6. Apparatus

adequate capacity (Note 3). Bending (5.2.4) and indentation

6.1 Impact Machine, consisting of a massive base on which

losses (5.2.8) may be appreciable when testing soft materials.

is mounted a vise for holding the specimen and to which is

NOTE 3—Although the frame and base of the machine should be

connected, through a rigid frame and antifriction bearings, one

sufficiently rigid and massive to handle the energies of tough specimens

of a number of pendulum-type hammers (or one basic hammer

without motion or excessive vibration, the pendulum arm cannot be made

to which extra weights may be attached) having an initial

very massive because the greater part of its mass must be concentrated

nearitscenterofpercussionatthestrikingnose.Locatingthestrikingnose

energy suitable for use with the particular specimen to be

precisely at the center of percussion reduces vibration of the pendulum

tested, plus a pendulum holding and releasing mechanism and

arm when used with brittle specimens. However, some losses due to

a pointer and dial mechanism for indicating the excess energy

pendulum-arm vibration, the amount varying with the design of the

remaining in the pendulum after breaking the specimen. A jig

pendulum, will occur with tough specimens even when the striking nose

for positioning the specimen in the vise and graphs or tables to

is properly positioned.

aid in the calculation of the correction for frictionandwindage

5.5 In a well-designed machine of sufficient rigidity and

should be included. See Fig. 1 for one type of machine that

massthelossesduetotheitemsgivenin5.2.6and5.2.7should

may be used. The type of machine that is depicted can also be

be very small. Vibrational losses (5.2.6) can be quite large

used for the testing of notched specimens using Test Methods

when specimens of tough materials are tested in machines of

D256. Detailed requirements are given in 6.2-6.5. SeeAppen-

insufficient mass which are not securely fastened to a heavy

dix X1 for general methods for checking and calibrating the

base.

machine. Additional instructions for adjusting a particular

5.6 Thistestmethodrequiresthatthetypeoffailureforeach

machine should be supplied by the manufacturer.

specimen be recorded as one of the three coded categories

6.2 Pendulum,consistingofasingleormultimemberedarm

defined as follows:

with a bearing on one end and a head, containing the striking

5.6.1 C (Complete Break)—Abreak in which the specimen

nose, on the other.Although a large proportion of the mass of

is separated into two or more pieces.

5.6.2 P (Partial Break)—An incomplete break that has

fractured at least 90% of the depth of the specimen.

5.6.3 NB (Non-Break)—An incomplete break where the

fracture extends less than 90% of the depth of the specimen.

5.6.3.1 For tough materials the pendulum may not have the

energy necessary to completely break the extreme outermost

fibers and toss the broken piece or pieces. Results obtained

from “non-break” specimens shall be considered a departure

from standard and shall be reported as “NB” only and a

numerical value shall not be reported. Impact values cannot be

directly compared for any two materials that experience

different types of failure as defined by this code.

5.6.4 Averages reported must likewise be derived from

specimens contained within a single failure category. This

letter code will be included with the reported impact identify-

ing the types of failure associated with the reported value. If

morethanonetypeoffailureisobservedforasamplematerial,

then the report will indicate the average impact value for each

typeoffailure,followedbythepercentofthespecimensfailing

in that manner and identified by the letter code.

5.7 The value of this impact test method lies mainly in the

areas of quality control and materials specification. The fact

that a material shows twice the energy absorption of another

under these conditions of test does not indicate that this same FIG. 1 Cantilever Beam Impact Test Equipment

D4812–99

thependulumshouldbeconcentratedinthehead,thearmmust energy of the next lighter one will be found convenient. Each

be sufficiently rigid to maintain the proper clearances and pendulum shall have an energy within 60.5% of its nominal

geometric relationships between the machine parts and the capacity.

specimen and to minimize vibrational losses which are always 6.2.5 When the pendulum is free-hanging, the striking

surface shall come within 0.5% of scale of touching the front

included in the measured impact value.

face of a standard specimen. During an actual swing this

6.2.1 Striking Nose (of the Pendulum),ofhardenedsteeland

element shall make initial contact with the specimen on a line

cylindrical surface having a radius of curvature of 0.80 6 0.20

22.00 6 0.05 mm (0.866 6 0.002 in.) above the top surface of

mm (0.031 6 0.008 in.) with its axis horizontal and perpen-

the vise.

dicular to the plane of swing of the pendulum.

6.2.6 Means shall be provided for determining energy re-

6.2.1.1 The line of contact of the striking nose shall be

maining in the pendulum after breaking the specimen. This

located at the center of percussion of the pendulum within

may consist of a pointer and dial mechanism or it may consist

62.54 mm (0.100 in.) (Note 4). Those portions of the pendu-

of an electronic determination provided with a digital display.

lum adjacent to the cylindrical striking edge shall be recessed

The device will indicate the height of rise of the pendulum

orinclinedatasuitableanglesothattherewillbenochancefor

beyond the point of impact in terms of energy removed from

other than this cylindrical surface coming into contact with the

thespecificpendulum.Theindicatedremainingenergymustbe

specimen during the break.

corrected for friction and pendulum windage. Instructions for

6.2.2 Pendulum Holding and Releasing Mechanism,ina

makingthesecorrectionsareincludedin9.3andAppendixX2.

position such that the vertical height of fall of the striking nose

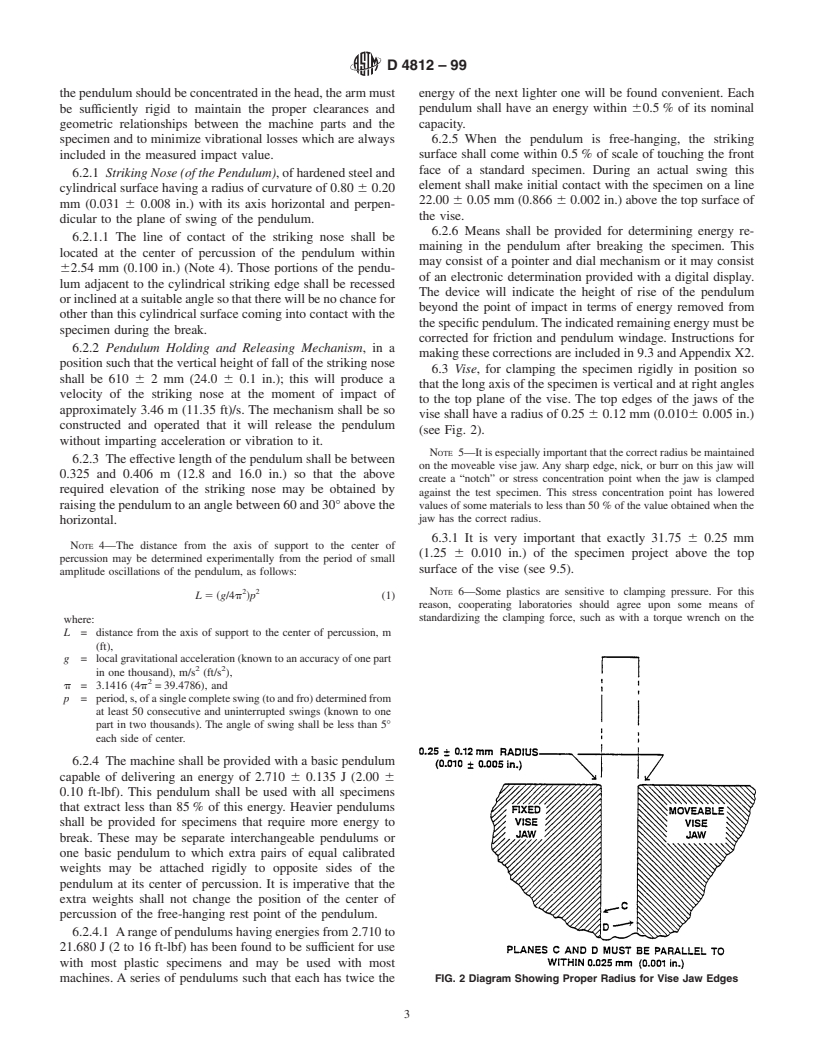

6.3 Vise, for clamping the specimen rigidly in position so

shall be 610 6 2 mm (24.0 6 0.1 in.); this will produce a

thatthelongaxisofthespecimenisverticalandatrightangles

velocity of the striking nose at the moment of impact of

to the top plane of the vise. The top edges of the jaws of the

approximately 3.46 m (11.35 ft)/s. The mechanism shall be so

vise shall have a radius of 0.25 6 0.12 mm (0.0106 0.005 in.)

constructed and operated that it will release the pendulum

(see Fig. 2).

without imparting acceleration or vibration to it.

NOTE 5—Itisespeciallyimportantthatthecorrectradiusbemaintained

6.2.3 The effective length of the pendulum shall be between

on the moveable vise jaw. Any sharp edge, nick, or burr on this jaw will

0.325 and 0.406 m (12.8 and 16.0 in.) so that the above

create a “notch” or stress concentration point when the jaw is clamped

required elevation of the striking nose may be obtained by

against the test specimen. This stress concentration point has lowered

raisingthependulumtoananglebetween60and30°abovethe values of some materials to less than 50% of the value obtained when the

jaw has the correct radius.

horizontal.

6.3.1 It is very important that exactly 31.75 6 0.25 mm

NOTE 4—The distance from the axis of support to the center of

(1.25 6 0.010 in.) of the specimen project above the top

percussion may be determined experimentally from the period of small

surface of the vise (see 9.5).

amplitude oscillations of the pendulum, as follows:

2 2

NOTE 6—Some plastics are sensitive to clamping pressure. For this

L 5 ~g/4p !p (1)

reason, cooperating laboratories should agree upon some means of

standardizing the clamping force, such as with a torque wrench on the

where:

L = distance from the axis of support to the center of percussion, m

(ft),

g = localgravitationalacceleration(knowntoanaccuracyofonepart

2 2

in one thousand), m/s (ft/s ),

p = 3.1416 (4p =39.4786), and

p = period,s,ofasinglecompleteswing(toandfro)determinedfrom

at least 50 consecutive and uninterrupted swings (known to one

part in two thousands). The angle of swing shall be less than 5°

each side of center.

6.2.4 The machine shall be provided with a basic pendulum

capable of delivering an energy of 2.710 6 0.135 J (2.00 6

0.10 ft-lbf). This pendulum shall be used with all specimens

that extract less than 85% of this energy. Heavier pendulums

shall be provided for specimens that require more energy to

break. These may be separate interchangeable pendulums or

one basic pendulum to which extra pairs of equal calibrated

weights may be attached rigidly to opposite sides of the

pendulum at its center of percussion. It is imperative that the

extra weights shall not change the position of the center of

percussion of the free-hang

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.