ASTM D5824-98(2003)

(Test Method)Standard Test Method for Determining Resistance to Delamination of Adhesive Bonds in Overlay-Wood Core Laminates Exposed to Heat and Water

Standard Test Method for Determining Resistance to Delamination of Adhesive Bonds in Overlay-Wood Core Laminates Exposed to Heat and Water

SIGNIFICANCE AND USE

This test method measures quantitatively the effects of water soaking and drying, and their associated swelling and shrinking stresses on adhesive bonds in overlay-laminated assemblies.

Adhesive bond performance is based on the ability of the adhesive and adhesive bonds to resist delamination during accelerated exposure to water and heat.

Resistance to delamination when subjected to environmental factors is critical to the performance of the laminated assembly in service.

This test method is to be used to determine the quality of adhesive bonds in overlay-wood core laminates after the adhesive has been certified by a specification appropriate for the product, class, and end use.

SCOPE

1.1 This test method provides a procedure to determine the quality of bond between an overlay and a wood core in an adhesively bonded laminate. The quality of bond is determined by measuring the resistance to delamination of the adhesively bonded laminate when tested under specific conditions of preparation, conditioning, and testing. Such products include, but are not limited to, window and door components, such as stiles and rails, and other overlaid panels. Typical wood-based cores are finger-jointed lumber, particleboard, oriented strand board, and hardboard. Typical overlays would be veneer, high-pressure laminate, high-density polyethylene, and fiberglass-reinforced plastic.

1.2 Adhesive bond performance as measured by resistance to delamination in this test method is suitable for use in adhesive product development, manufacturing quality control, and monitoring bonding processes.

1.3 This test method does not provide guidance for determining bond line performance for plywood products.

1.4 The values stated in inch-pound units are to be regarded as standard.

1.5 sponsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5824–98(Reapproved2003)

Standard Test Method for

Determining Resistance to Delamination of Adhesive Bonds

in Overlay-Wood Core Laminates Exposed to Heat and

Water

This standard is issued under the fixed designation D5824; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method provides a procedure to determine the 2.1 ASTM Standards:

quality of bond between an overlay and a wood core in an D907 Terminology of Adhesives

adhesively bonded laminate.The quality of bond is determined D4442 Test Methods for Direct Moisture Content Measure-

by measuring the resistance to delamination of the adhesively ment of Wood and Wood-Base Materials

bonded laminate when tested under specific conditions of D5266 Practice for Estimating the Percentage of Wood

preparation, conditioning, and testing. Such products include, Failure in Adhesive Bonded Joints

but are not limited to, window and door components, such as E6 TerminologyRelatingtoMethodsofMechanicalTesting

stiles and rails, and other overlaid panels. Typical wood-based E41 Terminology Relating To Conditioning

cores are finger-jointed lumber, particleboard, oriented strand E177 Practice for Use of the Terms Precision and Bias in

board, and hardboard. Typical overlays would be veneer, ASTM Test Methods

high-pressure laminate, high-density polyethylene, and E691 Practice for Conducting an Interlaboratory Study to

fiberglass-reinforced plastic. Determine the Precision of a Test Method

1.2 Adhesive bond performance as measured by resistance

3. Terminology

to delamination in this test method is suitable for use in

adhesive product development, manufacturing quality control, 3.1 Definitions—Certain terms in this test method are de-

fined in Terminologies D907, E6, and E41.

and monitoring bonding processes.

1.3 This test method does not provide guidance for deter- 3.1.1 delamination, n—the separation of layers in a lami-

mining bond line performance for plywood products. nate because of failure of the adhesive, either in the adhesive

itselforattheinterfacebetweentheadhesiveandtheadherend.

1.4 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical (See Terminology D907.)

3.1.2 overlay, n—a uniform layer of material, usually in the

conversions to SI units that are provided for information only

and are not considered standard. form of a sheet, adhesively bonded to an adherend with the

purpose of improving the appearance or physical properties of

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the the laminate.

3.2 Definitions of Terms Specific to This Standard:

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 3.2.1 edge, n—in an adhesively bonded laminate, the di-

mension along its length [and parallel to the grain] where the

bility of regulatory limitations prior to use.

overlay is bonded to the core.

3.2.2 end, n—in an adhesively bonded laminate, the dimen-

sion which is perpendicular to the length of the laminate where

the overlay is bonded to the core.

This test method is under the jurisdiction of ASTM Committee D14 on

Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood

Adhesives For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 10, 2003. Published April 2003. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1995. Last previous edition approved in 1998 as D5824 – 98. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D5824-98R03. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5824–98 (2003)

4. Significance and Use nominalwidthofthepanelisused,theedgesaretobeprepared

as the product would exist in service.

4.1 This test method measures quantitatively the effects of

6.3 Test ten specimens, representing at least four different

water soaking and drying, and their associated swelling and

panels.

shrinking stresses on adhesive bonds in overlay-laminated

assemblies.

7. Preparation and Conditioning of Laboratory Test

4.2 Adhesive bond performance is based on the ability of

Panels

the adhesive and adhesive bonds to resist delamination during

7.1 Select veneer, either rotary cut or sliced, 0.063 in. (1.6

accelerated exposure to water and heat.

mm) in thickness, and wood-based core, a minimum of 0.5 in.

4.3 Resistance to delamination when subjected to environ-

(13 mm) in thickness, so that they are free from defects such as

mental factors is critical to the performance of the laminated

knots, cracks, rough surfaces, or any unusual amount of

assembly in service.

discoloration. The species and type of veneer and composition

4.4 Thistestmethodistobeusedtodeterminethequalityof

of the wood core are to be agreed upon between the purchaser

adhesive bonds in overlay-wood core laminates after the

and the manufacturer of the adhesive. As an alternative to

adhesive has been certified by a specification appropriate for

veneer, specific overlays can be used as agreed upon between

the product, class, and end use.

the purchaser and the adhesive manufacturer. Surface the core

5. Apparatus

to a thickness tolerance of 60.005 in. (0.13 mm) (see Table 1).

Iffinger-jointed/edge-bondedcorestockisused,itmustremain

5.1 Oven(s)—Forced-air oven capable of maintaining 170

intact without delamination during the test cycle. Both the

6 5°F (77 6 3°C), with sufficient air circulation to ensure that

veneer and the wood-based core are to be 61 % of the

the prescribed drying temperature is uniformly maintained

moisture content recommended by the manufacture of the

when the oven is fully loaded and the air flow is parallel to the

adhesive. In the absence of such a recommendation, the

faces of the specimens. A mechanism is to be provided for

moisture content is to be from 10 to 12 %, based on oven-dry

moisture to be removed from the chamber during drying of the

weight as determined on representative samples in accordance

specimens.

with Method A of Test Methods D4442. Cut the veneer and

5.1.1 Use an oven to accommodate a sufficient number of

wood core to a suitable size and grain orientation in order to

test specimens and to provide for at least 3-in. (76-mm)

build a panel with the grain of the veneer parallel to the grain

separation between the test specimens so that the drying

of the wood core. A size that has been found to be convenient

temperature is uniformly maintained.

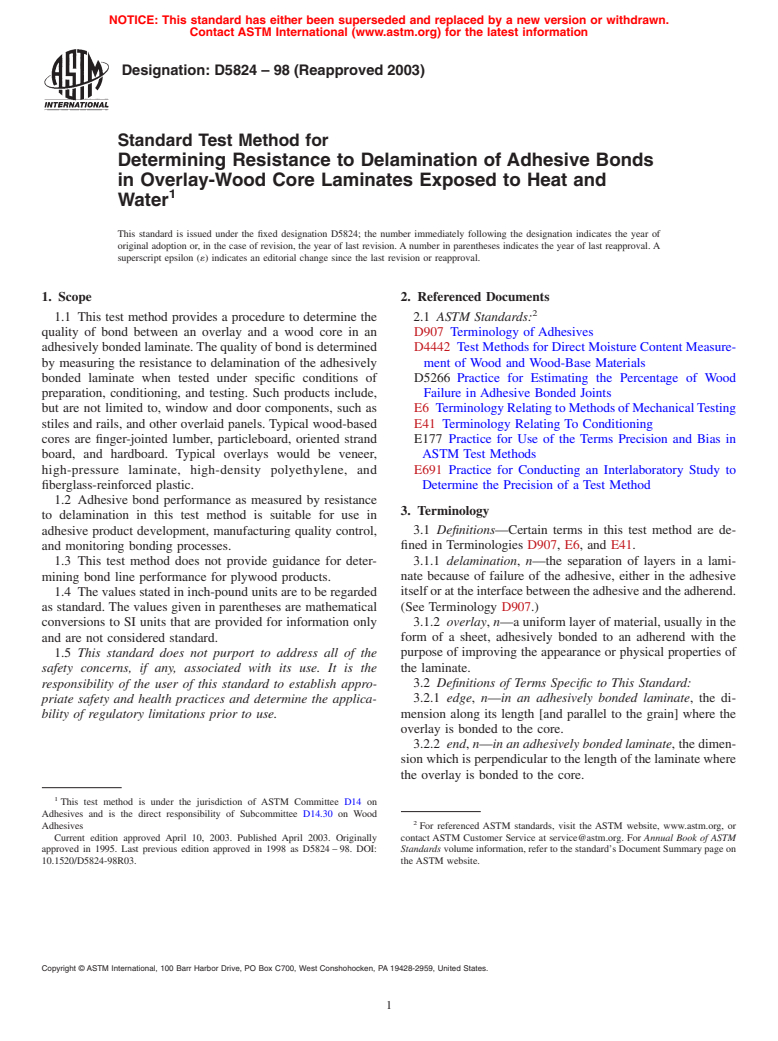

is shown in Fig. 1.

5.2 Vacuum-Pressure Vessel—Autoclave or similar vessel

7.2 Follow the adhesive manufacturer’s instructions for

capable of withstanding 80-psi (562-kPa) pressure, equipped

conditions and procedures for preparing the adhesive and

with a pump or similar device capable of drawing a vacuum of

applying it to the wood core, as well as for assembling,

25 in. Hg (84.4 kPa). Provide a system so that pressure is

pressing, and curing the panel.

maintained at 75 psi (517 kPa).

7.3 After assembly, condition the panels for a period of

5.2.1 Use a vessel so that all the specimens are at least 2 in.

seven days (or until the panels reach equilibrium) at a relative

(51 mm) below the water level during the complete cycle.

humidity of 50 6 2 % and a temperature of 73.4 6 2°F (23 6

6. Test Specimens

1°C), or condition them in accordance with a specific recom-

mendation by the adhesive manufacturer.

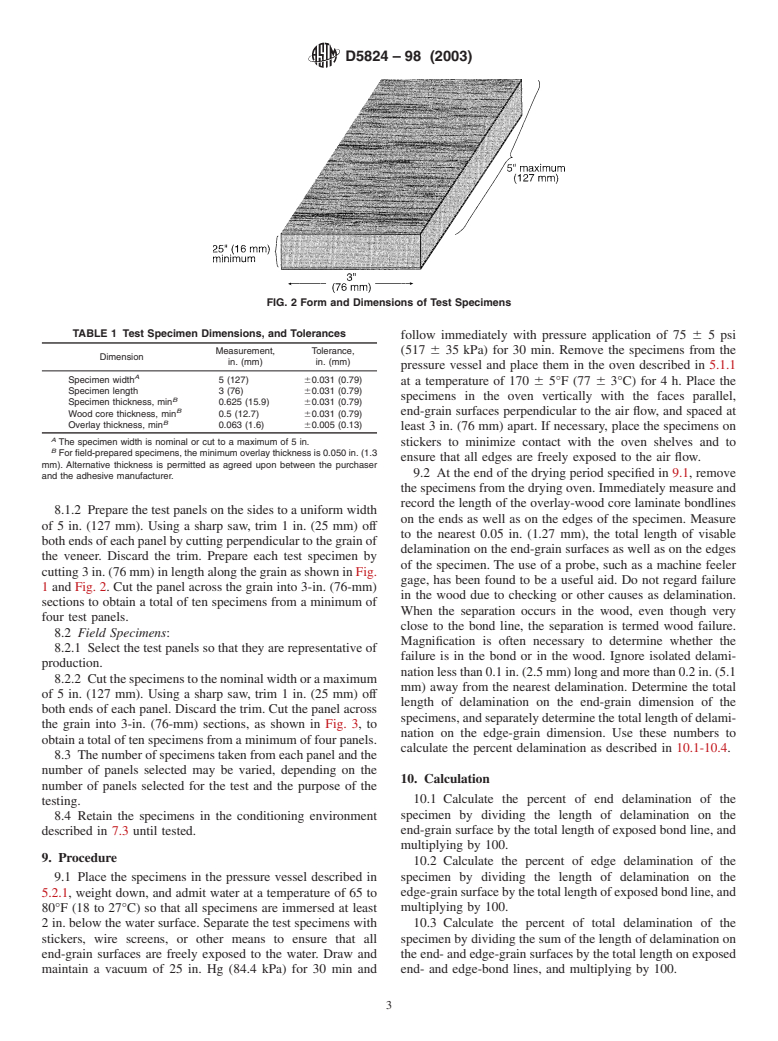

6.1 Cut laboratory specimens from prepared test panels (see

Fig. 1) as described in Sections 7 and 8 to the form and

8. Preparation of Specimens

dimensions shown in Fig. 2 and Table 1.

6.2 Cut field specimens from test panels (see Fig. 3)tothe 8.1 Laboratory Specimens:

form and dimensions shown in Fig. 2 and Table 1. When the 8.1.1 Prepare the test panels as described in Section 7.

FIG. 1 Laboratory Test Panel

D5824–98 (2003)

FIG. 2 Form and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.