ASTM D4061-94(2006)

(Test Method)Standard Test Method for Retroreflectance of Horizontal Coatings

Standard Test Method for Retroreflectance of Horizontal Coatings

SIGNIFICANCE AND USE

The quantity coefficient of retroreflected luminance is a measure of the reflected luminance in the direction of the observer. This is the light returned by the retroreflective surface to the observer from the source, which in practice is the vehicle headlamp.

This test method may be used as a measure of the nighttime performance of horizontally applied surfacing materials used on highway surfaces for lane markings and other traffic control purposes.

Since this test method is a laboratory procedure, test specimens must be prepared so that they can be mounted on the specimen holder. Specimens measured by this laboratory method may be used as transfer standards for the calibration of portable instrumentation.

Specimen selection and preparation may significantly influence the results of this test method.

SCOPE

1.1 This test method describes the instrumental measurement of the retroreflective properties of horizontal surfacing materials, such as traffic stripe paint systems, traffic tapes, and traffic surface symbols.

1.2 Specimen preparation, size, and shape must be determined and specified by the user of this test method. Likewise, the user must specify the observation and entrance angles to be used (see ).

1.3 The geometric requirements of this test method are based on materials for which the relative retroreflectance changes less than approximately 50 % over the observation angle range from 0.2 to 0.5. This is illustrated in .

1.4 This test method is a laboratory test and requires a facility that can be darkened sufficiently so that stray light does not affect the test results. This facility must be capable of housing the required 15-m test distance.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4061 −94(Reapproved2006)

Standard Test Method for

Retroreflectance of Horizontal Coatings

This standard is issued under the fixed designation D4061; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E809Practice for Measuring Photometric Characteristics of

Retroreflectors

1.1 This test method describes the instrumental measure-

ment of the retroreflective properties of horizontal surfacing 2.2 CIE Publication:

materials, such as traffic stripe paint systems, traffic tapes, and No. 54Retroreflection Definition and Measurement

traffic surface symbols.

3. Terminology

1.2 Specimen preparation, size, and shape must be deter-

mined and specified by the user of this test method. Likewise, 3.1 The terms and definitions inTerminology E284 apply to

theusermustspecifytheobservationandentranceanglestobe this test method.

used (see Fig. 1).

3.2 Definitions:

1.3 The geometric requirements of this test method are 3.2.1 coeffıcient of retroreflected luminance, R ,n—ratio of

L

based on materials for which the relative retroreflectance the luminance, L, of a projected surface to the normal

changes less than approximately 50% over the observation illuminance, E , at the surface on a plane normal to the

'

incident light, expressed in candelas per square metre per lux

angle range from 0.2 to 0.5°. This is illustrated in Fig. 2.

−2

−1

(cd·m ·lx ).

1.4 This test method is a laboratory test and requires a

R 5 L/E (1)

facilitythatcanbedarkenedsufficientlysothatstraylightdoes ~ !

L '

not affect the test results. This facility must be capable of

3.2.2 datum mark, n—in retroreflection,anindicationonthe

housing the required 15-m test distance.

retroreflector that is used to define the orientation of the

retroreflector with respect to rotation about the retroreflector

1.5 The values stated in SI units are to be regarded as the

axis.

standard. The values given in parentheses are for information

3.2.2.1 Discussion—The datum mark must not lie on the

only.

retroreflector axis.

1.6 This standard does not purport to address all of the

3.2.3 entrance angle,β, n—in retroreflection,anglebetween

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- the illumination axis and the retroreflector axis.

3.2.3.1 Discussion—For plane retroreflective surfaces, the

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. entrance angle is no larger than 90°.

3.2.3.2 Discussion—Theentranceanglemaybedividedinto

2. Referenced Documents components β and β . This is described in Practice E808.In

1 2

2 this test method only the component β is used. Therefore,

2.1 ASTM Standards:

where only the entrance angle β is specified the convention

E284Terminology of Appearance

used is β =0 and β = β.

2 1

E308PracticeforComputingtheColorsofObjectsbyUsing

3.2.4 illumination axis, n— in retroreflection,alinefromthe

the CIE System

effective center of the source aperture to the retroreflector

E808Practice for Describing Retroreflection

center.

3.2.5 normal illuminance, E —theilluminanceonaretrore-

'

This test method is under the jurisdiction of ASTM Committee E12 on Color

flective surface measured in the plane that passes through the

and Appearance and is the direct responsibility of Subcommittee E12.10 on

retroreflector center and is perpendicular to the illumination

Retroreflection.

−2

axis; measured in lux (lumens·m ).

CurrenteditionapprovedJuly1,2006.PublishedJuly2006.Originallyapproved

in 1989. Last previous edition approved in 2000 as D4061–94(2000). DOI:

10.1520/D4061-94R06.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromU.S.NationalCommitteeoftheCIE(InternationalCommission

Standards volume information, refer to the standard’s Document Summary page on on Illumination), C/o Thomas M. Lemons, TLA-Lighting Consultants, Inc., 7 Pond

the ASTM website. St., Salem, MA 01970.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4061−94(2006)

illumination;forexample,thedirectionoftheroadonwhichor

with respect to which the retroreflector is intended to be

positioned. In testing horizontal road markings the retroreflec-

tor axis is usually the normal to the test surface.

3.2.11 rotation angle, ϵ,n—angle indicating the orientation

ofthespecimenwhenitisrotatedaboutaselectedaxisfixedin

it (for plane specimens, usually the specimen normal); in

retroreflection, the dihedral angle from the half-plane originat-

ingontheretroreflectoraxisandcontainingthepositivepartof

the second axis to the half-plane originating on the retroreflec-

tor axis and containing the datum mark.

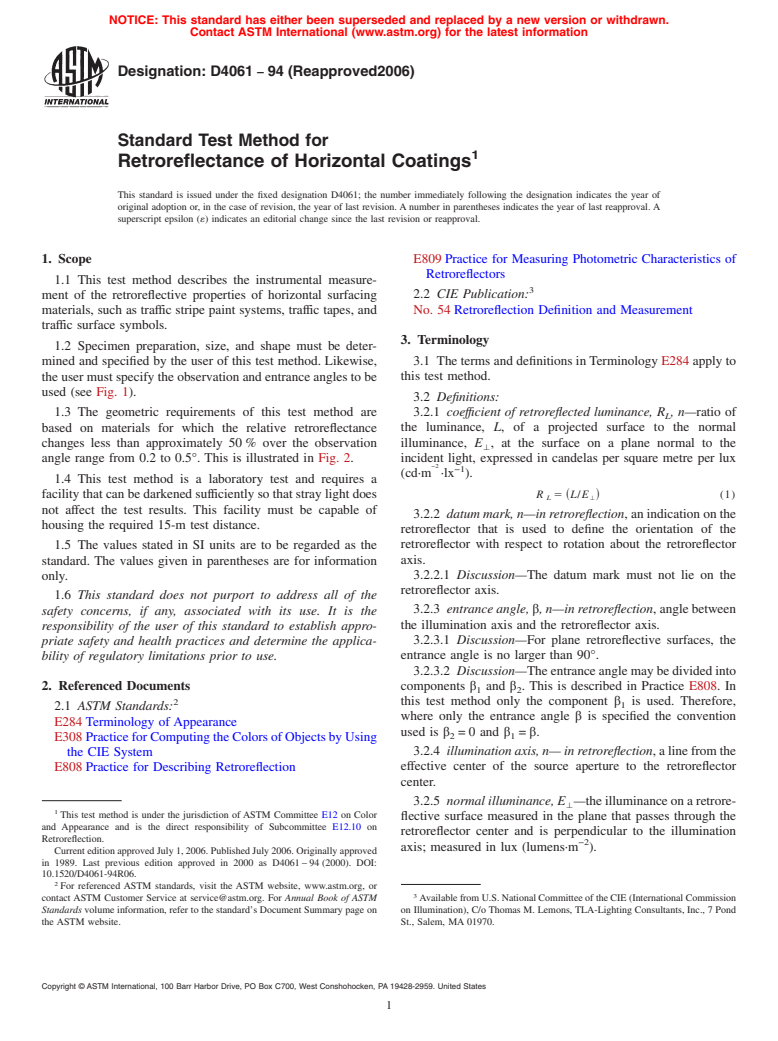

NOTE1—Includesobservationangleα,entranceangleβ,viewingangle

3.2.11.1 Discussion—The rotation angle shown in Fig. 3,

ν , co-viewing angle ν , and co-entrance angle β . The retroreflector axis,

a c c

with the datum mark oriented away from the source, is 0°.

illumination axis, and observation axis all lie in the same plane.

3.2.12 source, n—an object that produces light or other

FIG. 1Diagram Illustrating Geometry for Measurement of Hori-

zontal Coatings Specimens

radiant flux.

3.2.13 specific luminance—see coefficient of retroreflected

luminance.

3.2.14 viewing angle, ν—the angle between the observation

axis and the retroreflector axis.

3.2.14.1 Discussion—In testing road markings specimens,

the retroreflector axis is usually the normal to the test surface

(see definition of retroreflector axis).

3.3 Definitions of Terms Specific to This Standard:

3.3.1 co-entrance angle, β,n—the complement of the

c

entrance angle (90°− β).

3.3.1.1 Discussion—On a typical test specimen, this is the

angle from the plane surface of the material to the observation

axis.

FIG. 2 Illustration of Typical Rate of Change of Retroreflectance

Versus Observation Angle for Horizontal Retroreflective Material

3.3.2 co-viewing angle, ν,n—the complement of the view-

c

Measured at 86° Entrance Angle

ing angle (90°− η).

4. Summary of Test Method

3.2.6 observation angle, n—angle between the axes of the

4.1 This test method involves the use of a light-projector

incident beam and the observed (reflected) beam, ( in retrore-

source, a photoreceptor, a specimen holder, and a receptor-

flection, α, between the illumination axis and the observation

source support, all arranged with approximately 15-m separa-

axis).

tion between the specimen holder and receptor-source support

3.2.6.1 Discussion—The observation angle is always posi-

in a suitable darkened area. The observation angle is generally

tive and in the context of retroreflection is restricted to small

small (0.2 to 2.0°) and the entrance angle approaches 90° (the

acute angles.

light is near the grazing angle).

3.2.7 observation axis, n—in retroreflection, a line from the

effective center of the receiver aperture to the retroreflector 4.2 The general procedure is to determine the ratio of the

center. retroreflected light from the test surface to the incident light on

the test surface. From these measurements, the photometric

3.2.8 receiver, n—the portion of a photometric instrument

quantity, specific luminance is calculated.

that receives the viewing beam from the specimen, including a

collector such as an integrating sphere, if used, often the

5. Significance and Use

monochromator or spectral filters, the detector, and associated

5.1 The quantity coefficient of retroreflected luminance is a

optics and electronics.

measure of the reflected luminance in the direction of the

3.2.9 retroreflection, n—reflection in which the reflected

observer.Thisisthelightreturnedbytheretroreflectivesurface

rays are preferentially returned in directions close to the

totheobserverfromthesource,whichinpracticeisthevehicle

opposite of the direction of the incident rays, this property

headlamp.

being maintained over wide variations of the direction of the

B

5.2 This test method may be used as a measure of the

incident rays. [CIE]

nighttime performance of horizontally applied surfacing mate-

3.2.10 retroreflector axis, n—a designated line segment

rials used on highway surfaces for lane markings and other

from the retroreflector center that is used to describe the

traffic control purposes.

angular position of the retroreflector.

3.2.10.1 Discussion—Thedirectionoftheretroreflectoraxis 5.3 Since this test method is a laboratory procedure, test

is usually chosen centrally among the intended directions of specimensmustbepreparedsothattheycanbemountedonthe

D4061−94(2006)

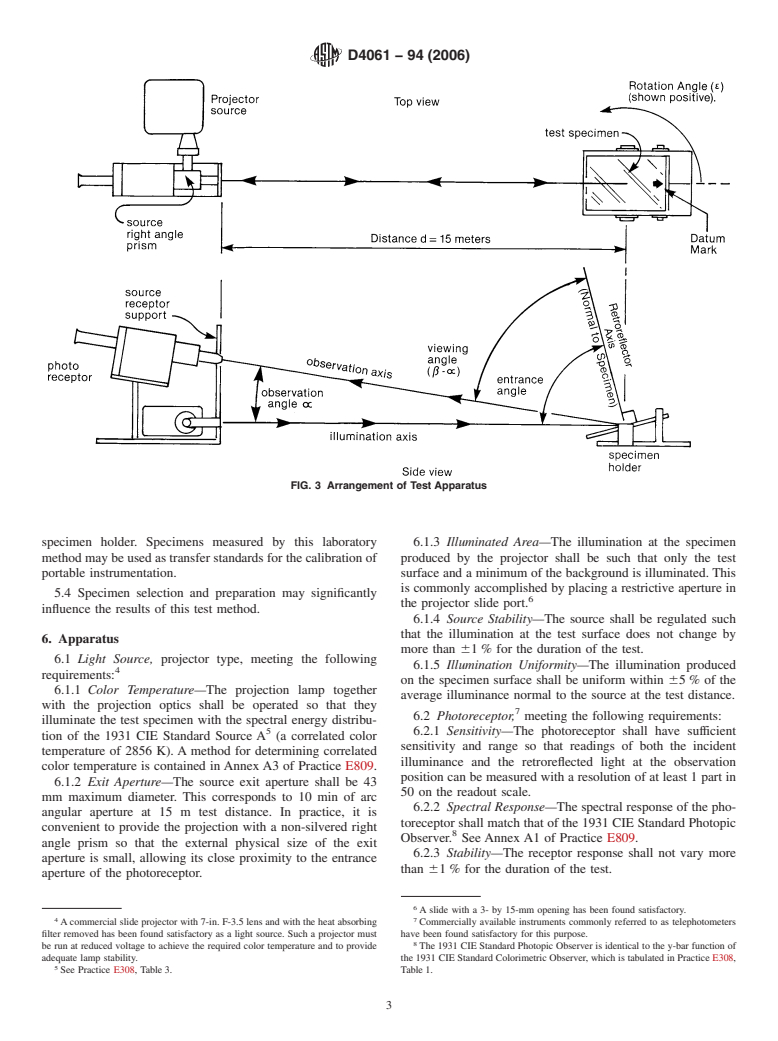

FIG. 3 Arrangement of Test Apparatus

specimen holder. Specimens measured by this laboratory 6.1.3 Illuminated Area—The illumination at the specimen

method may be used as transfer standards for the calibration of produced by the projector shall be such that only the test

portable instrumentation. surface and a minimum of the background is illuminated. This

is commonly accomplished by placing a restrictive aperture in

5.4 Specimen selection and preparation may significantly

the projector slide port.

influence the results of this test method.

6.1.4 Source Stability—The source shall be regulated such

that the illumination at the test surface does not change by

6. Apparatus

more than 61% for the duration of the test.

6.1 Light Source, projector type, meeting the following

6.1.5 Illumination Uniformity—The illumination produced

requirements:

on the specimen surface shall be uniform within 65% of the

6.1.1 Color Temperature—The projection lamp together

average illuminance normal to the source at the test distance.

with the projection optics shall be operated so that they

6.2 Photoreceptor, meeting the following requirements:

illuminate the test specimen with the spectral energy distribu-

5 6.2.1 Sensitivity—The photoreceptor shall have sufficient

tion of the 1931 CIE Standard Source A (a correlated color

sensitivity and range so that readings of both the incident

temperature of 2856 K). A method for determining correlated

illuminance and the retroreflected light at the observation

color temperature is contained in Annex A3 of Practice E809.

position can be measured with a resolution of at least 1 part in

6.1.2 Exit Aperture—The source exit aperture shall be 43

50 on the readout scale.

mm maximum diameter. This corresponds to 10 min of arc

6.2.2 Spectral Response—The spectral response of the pho-

angular aperture at 15 m test distance. In practice, it is

toreceptor shall match that of the 1931 CIE Standard Photopic

convenient to provide the projection with a non-silvered right

Observer. See Annex A1 of Practice E809.

angle prism so that the external physical size of the exit

6.2.3 Stability—The receptor response shall not vary more

aperture is small, allowing its close proximity to the entrance

than 61% for the duration of the test.

aperture of the photoreceptor.

A slide with a 3- by 15-mm opening has been found satisfactory.

4 7

Acommercial slide projector with 7-in. F-3.5 lens and with the heat absorbing Commercially available instruments commonly referred to as telephotometers

filter removed has been found satisfactory as a light source. Such a projector must have been found satisfactory for this purpose.

be run at reduced voltage to achieve the required color temperature and to provide The 1931 CIE Standard Photopic Observer is identical to the y-bar function of

adequate lamp stability. the 1931 CIE Standard Colorimetric Observer, which is tabulated in Practice E308,

See Practice E308, Table3. Table1.

D4061−94(2006)

6.2.4 Linearity—The linearity of the photometric scale over 6.3.3 Leading Edge Reflections—The specimen holder must

the range of readings to be taken shall be within 61%. be provided with a means of eliminating reflections from the

Correction factors may be used to ensure linear response. A leading edge of the specimen, and the holder itself must be

methodfordetermininglinearityiscontainedinPracticeE809, non-reflective.

Annex A2. 6.3.4 Incident Light Measurement Provision—It is desirable

6.2.5 Field of View—The field of view shall be limited by that the specimen holder be such that the photoreceptor can

use of light baffles or a field aperture on the instrument so that easily be substituted for the specimen, which is required when

the entire test specimen is fully within the field of view yet as incident light measurements are taken.

much stray light is rejected as is practical.Abackground light

6.4 Receptor-Source Support—A device that adequately

levellessthan5%ofsmallest m reading(see8.6)isdesirable.

supportsandseparatesthephotoreceptorfromthesourceatthe

Whenbackgroundlevelsaregreaterthan5%,carefulattention

observation position. The required accuracy of separation of

must be given to noise levels.

the source exit aperture from the photoreceptor entrance

6.2.5.1 In this test, the receptor’s field of view must always

aperture is dependent on the properties of the test specimen.

be larger than the projected area of the test specimen.

For most horizontal surfacing materials, the divergence pat-

6.2.6 Entrance Aperture—The photoreceptor shall be pro-

terns are gradual and a positioning accuracy of 61mm(or

vided with an entrance aperture of 43 mm maximum diameter.

60.5% of the resolution) at 15 m test distance is adequate.A

This is equivalent to 10 min angular aperture at 15 m. The

common method of fixing this distance is to provide a bar with

physical size of the entrance aperture must be small so that the

holesmachinedinitatseparationscorrespondingtothedesired

photoreceptor may be positioned physically close to the source

observation angles. In this method, the minimum practical

exit aperture.

observation angle is about 0.2°.

6.3 Specimen Holder—The specimen holder, commonly

6.5 Photometric Site—Sufficient space is required so that

custom built to fit the desired specimen size and shape, must

the projector source and test surface can be separated by about

meet the following requirements (see Fig. 4 and Fig. 5).

15 m. This facility must be such that stray light does not

6.3.1 Angular Accuracy—The test surface must be position-

appreciably affect the test results. Flat black paint, black

ablesothattheentranceangleisaccuratetowithin0.5%ofits

curtains,blacktape,andothermeansshallbeusedtoeliminate

complement (that is, for 86° entrance angle, the angle must be

unwanted light and stray reflections.

accurateto0.005×4°=0.02°).Thi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.