ASTM A604/A604M-07

(Test Method)Standard Practice for Macroetch Testing of Consumable Electrode Remelted Steel Bars and Billets

Standard Practice for Macroetch Testing of Consumable Electrode Remelted Steel Bars and Billets

SIGNIFICANCE AND USE

Macroetch testing, as described herein, is a method for examining and rating transverse sections of bars and billets to describe certain conditions of macro segregation which are often characteristic of consumable electrode remelted materials.

This practice is not intended to define major defects such as those described by Method E 381.

SCOPE

1.1 This practice covers testing and inspection and is applicable to bars, billets, and blooms of carbon, alloy, and stainless steel which have been consumable electrode remelted.

1.2 For the purpose of this practice, the consumable electrode remelting process is defined as a steel refining method wherein single or multiple electrodes are remelted into a crucible producing an ingot which is superior to the original electrode by virtue of improved cleanliness or lower gas content or reduced chemical or nonmetallic segregation. See and for descriptions of applicable remelting processes.

1.3 This practice and the accompanying comparison macrographs are generally applicable to steel bar and billet sizes up to 225 in.2 [1450 cm2] in transverse cross section.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A604/A604M–07

Standard Practice for

Macroetch Testing of Consumable Electrode Remelted Steel

1

Bars and Billets

This standard is issued under the fixed designationA604/A604M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 2. Referenced Documents

2 4

1.1 This practice covers testing and inspection and is 2.1 ASTM Standards:

applicable to bars, billets, and blooms of carbon, alloy, and E381 Method of Macroetch Testing Steel Bars, Billets,

stainlesssteelwhichhavebeenconsumableelectroderemelted. Blooms, and Forgings

1.2 For the purpose of this practice, the consumable elec- 2.2 ASTM Adjuncts:

trode remelting process is defined as a steel refining method Adjunct to A604/A604MPractice for Macroetch Testing of

3

wherein single or multiple electrodes are remelted into a Consumable Electrode Remelted Steel Bars and Billets

crucible producing an ingot which is superior to the original

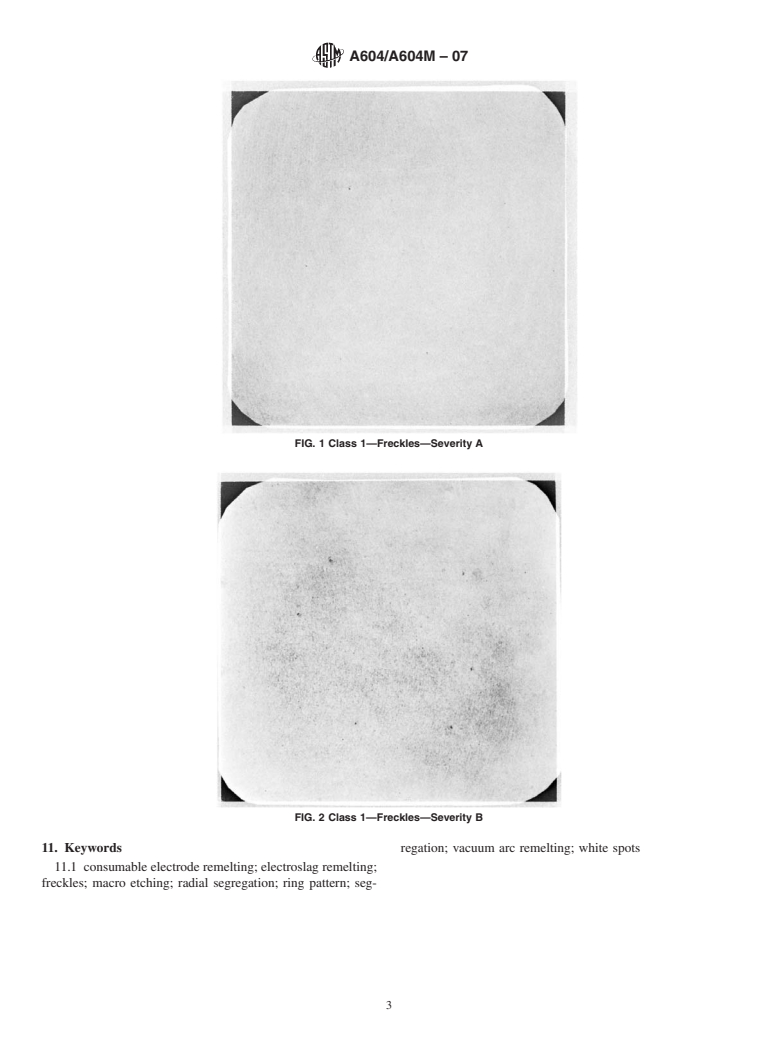

3. Description of Macroetch Testing

electrode by virtue of improved cleanliness or lower gas

content or reduced chemical or nonmetallic segregation. See 3.1 This practice employs the action of an acid or other

corrosive agent to develop the characteristics of a suitably

Appendix X1 and Appendix X2 for descriptions of applicable

remelting processes. prepared specimen. After etching, the sections are compared

visually, or at a very low magnification, if necessary for

1.3 This practice and the accompanying comparison mac-

3

rographs are generally applicable to steel bar and billet sizes clarification of conditions, to standard plates describing the

2 2

various conditions which may be found. Materials react differ-

up to 225 in. [1450 cm ] in transverse cross section.

1.4 The values stated in either SI units or inch-pound units ently to etching reagents because of variations in chemical

composition,methodofmanufacture,heattreatment,andmany

are to be regarded separately as standard. The values stated in

each system may not be exact equivalents; therefore, each other variables.

system shall be used independently of the other. Combining

4. Significance and Use

values from the two systems may result in non-conformance

4.1 Macroetch testing, as described herein, is a method for

with the standard.

examining and rating transverse sections of bars and billets to

1.5 This standard does not purport to address all of the

describe certain conditions of macro segregation which are

safety concerns, if any, associated with its use. It is the

often characteristic of consumable electrode remelted materi-

responsibility of the user of this standard to establish appro-

als.

priate safety and health practices and determine the applica-

4.2 This practice is not intended to define major defects

bility of regulatory limitations prior to use.

such as those described by Method E381.

5. Application

5.1 When material is furnished subject to macroetch testing

1 and inspection under this practice, the manufacturer and

This practice is under the jurisdiction of ASTM Committee A01 on Steel,

purchaser should be in agreement concerning the following:

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.06 on Steel Forgings and Billets.

5.1.1 The stage of manufacture at which the test shall be

Current edition approved May 1, 2007. Published June 2007. Originally

conducted,

approved in 1970. Last previous edition approved in 2003 as A604 – 93 (2003).

5.1.2 The number and location of the sections to be tested,

DOI: 10.1520/A0604_A0604M-07.

2

ASTM CommitteeA01 gratefully acknowledges the help of theAISI Commit-

tee on General Metallurgy in preparing the appendix, assembling the macroetch

4

photographs, and assisting with the text of this practice. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

A complete set of the 20 macrographs on glossy paper available from ASTM contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

International Headquarters. Order Adjunct No. ADJA0604. Original adjunct pro- Standards volume information, refer to the standard’s Document Summary page on

duced in 1985. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A604/A604M–07

5.1.3 The condition and preparation of the surface to be 7.2.4 Nitric Acid—This etchant consists of 5 % HNO

3

macroetched, solution in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.