ASTM D4371/D4371M-06(2019)e1

(Test Method)Standard Test Method for Determining the Washability Characteristics of Coal

Standard Test Method for Determining the Washability Characteristics of Coal

SIGNIFICANCE AND USE

5.1 Although the determination of the washability characteristics of coal is not an exact science, this washability test method can be used to investigate the cleaning characteristics of coarse- and fine-coal fractions. However, especially with the fine-coal fractions, this test method may not be applicable for low-rank coals for reasons explained in 1.2.

5.2 The usefulness of this test procedure and the usefulness of the results derived from washability testing are directly related to the care exercised in developing and following the sampling regime while taking into consideration the desired degree of precision. For more exacting work, it will be necessary to know the general washability characteristics of the material in question. This can be done only through pilot testing as described in 9.6 and Annex A3.

5.3 This test method, in conjunction with the advice of experts and with knowledge of the particle size analysis (see Test Method D4749), is used for the engineering design of coal preparation facilities.

5.4 This test method is also used to assist in process control and to determine the efficiency of operating preparation plants.

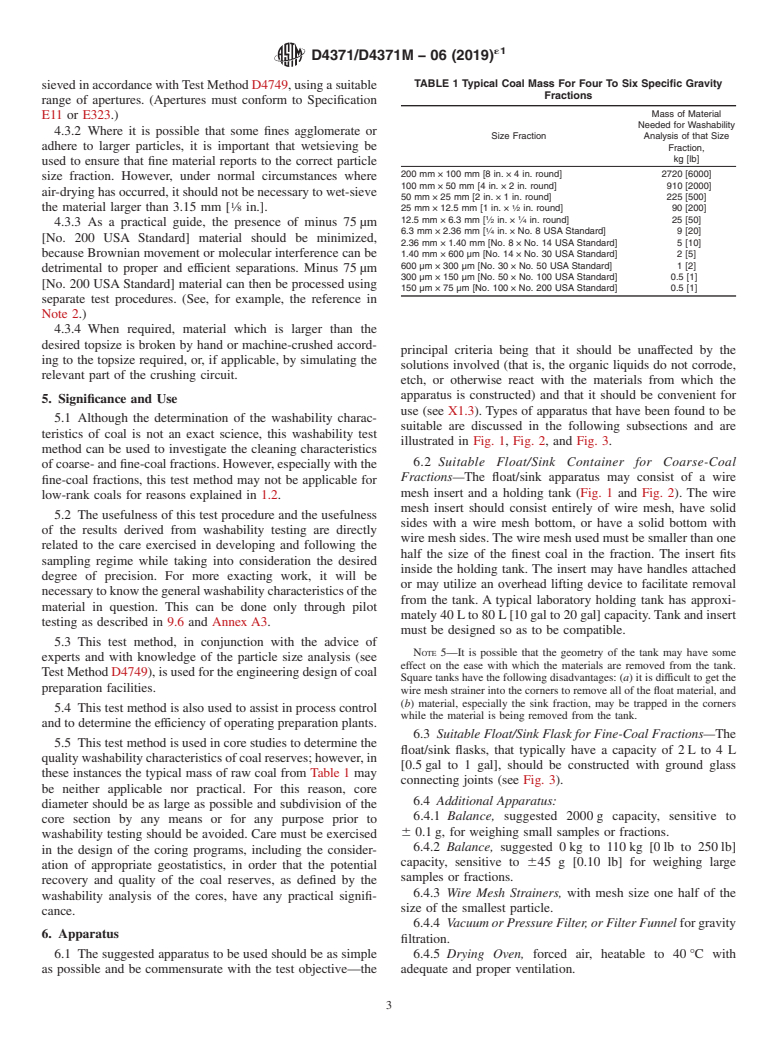

5.5 This test method is used in core studies to determine the quality washability characteristics of coal reserves; however, in these instances the typical mass of raw coal from Table 1 may be neither applicable nor practical. For this reason, core diameter should be as large as possible and subdivision of the core section by any means or for any purpose prior to washability testing should be avoided. Care must be exercised in the design of the coring programs, including the consideration of appropriate geostatistics, in order that the potential recovery and quality of the coal reserves, as defined by the washability analysis of the cores, have any practical significance.

SCOPE

1.1 This test method describes procedures for determining the washability characteristics of coarse-coal fractions and fine-coal fractions. Each sample being tested can have more than one coarse-coal size fraction and more than one fine-coal size fraction (see Annex A1). Each such size fraction has an upper size limit and a lower size limit, neither of which overlaps with the next larger nor smaller size fraction. (See Test Method D4749.)

1.2 While, in general, this test method has useful application in determining the washability characteristics of low-rank coals, in the strictest sense, it is not necessarily the most technically correct test method to determine washability characteristics of low-rank coals because of problems relative to the loss of moisture through drying during sample preparation and analysis. Methods that are directly applicable to low-rank coals are to be developed.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.4 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 8 and Appendix X1.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D4371/D4371M − 06 (Reapproved 2019)

Standard Test Method for

Determining the Washability Characteristics of Coal

This standard is issued under the fixed designation D4371/D4371M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—The designation was editorially updated to dual and other editorial changes were made throughout in December

2019.

INTRODUCTION

TheAmerican Society for Testing and Materials has recognized the need for a standard procedure

to conduct washability analyses that will serve as an aid to technical communication among

individuals and organizations that supply, purchase, and utilize coal. This test method standardizes

procedures utilized for performing washability analyses, the data from which can be used for

interpretingpreparationplantefficiency,fordeterminingpreparationplantdesign,andfordetermining

the potential recovery and quality of coal reserves.

1. Scope of the user of this standard to establish appropriate safety,

health, and environmental practices and determine the appli-

1.1 This test method describes procedures for determining

cability of regulatory limitations prior to use. For specific

the washability characteristics of coarse-coal fractions and

hazard statements, see Section 8 and Appendix X1.

fine-coal fractions. Each sample being tested can have more

1.5 This international standard was developed in accor-

than one coarse-coal size fraction and more than one fine-coal

dance with internationally recognized principles on standard-

size fraction (see Annex A1). Each such size fraction has an

ization established in the Decision on Principles for the

upper size limit and a lower size limit, neither of which

Development of International Standards, Guides and Recom-

overlaps with the next larger nor smaller size fraction. (See

mendations issued by the World Trade Organization Technical

Test Method D4749.)

Barriers to Trade (TBT) Committee.

1.2 While,ingeneral,thistestmethodhasusefulapplication

in determining the washability characteristics of low-rank

2. Referenced Documents

coals, in the strictest sense, it is not necessarily the most

2.1 ASTM Standards:

technically correct test method to determine washability char-

D2013Practice for Preparing Coal Samples for Analysis

acteristicsoflow-rankcoalsbecauseofproblemsrelativetothe

D2234/D2234MPractice for Collection of a Gross Sample

loss of moisture through drying during sample preparation and

of Coal

analysis.Methodsthataredirectlyapplicabletolow-rankcoals

D4749Test Method for Performing the Sieve Analysis of

are to be developed.

Coal and Designating Coal Size

1.3 The values stated in either SI units or inch-pound units

D6883Practice for Manual Sampling of Stationary Coal

are to be regarded separately as standard. The values stated in

from Railroad Cars, Barges, Trucks, or Stockpiles

each system are not necessarily exact equivalents; therefore, to

E11Specification forWovenWireTest Sieve Cloth andTest

ensure conformance with the standard, each system shall be

Sieves

used independently of the other, and values from the two

E100Specification for ASTM Hydrometers

systems shall not be combined.

E126Test Method for Inspection, Calibration, and Verifica-

1.4 This standard does not purport to address the safety

tion of ASTM Hydrometers

concerns, if any, associated with its use. It is the responsibility

E323Specification for Perforated-Plate Sieves for Testing

Purposes

This test method is under the jurisdiction of ASTM Committee D05 on Coal

and Coke and is the direct responsibility of Subcommittee D05.07 on Physical

Characteristics of Coal. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2019. Published December 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1984. Last previous edition approved in 2012 as D4371–06(2012). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D4371_D4371M-06R19E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D4371/D4371M − 06 (2019)

3. Terminology specific gravity fraction that sinks in a certain solution of

specific gravity liquids.

3.1 Definitions:

3.1.1 coal washability—the determination of the theoretical

4. Summary of Test Method

limits for the removal of mineral impurities from coal by

4.1 Procedure A—Describes a washability procedure for

beneficiation processes that rely on specific gravity separa-

tions. coalfractionscomposedofparticlesofcoalthatarelargerthan

a specified, predetermined size, generally between 2.36 mm

3.2 Definitions of Terms Specific to This Standard:

[No. 8 USAStandard Sieve Series] and 9.5 mm [ ⁄8 in.] round

3.2.1 washability analysis of coal—the analysis of the

in diameter. These coal fractions will be referred to as

specific gravity distribution of chemical and physical charac-

coarse-coal fractions.

teristics of coal.

4.1.1 Each coarse-coal size fraction is independently sepa-

3.2.1.1 Discussion—In this test method, the specific gravity

rated into two distinct specific gravity fractions by placing the

fractions are obtained by subjecting the material being studied

sample into a large tank of sufficient capacity, for example,

to a series of solutions, each with a discrete specific gravity,

40Lto80L[10galto20gal],containingascreenbasketinsert

thatcovertherangeofspecificgravitiesinquestion.Inthecase

and a solution of organic liquids adjusted to the required

ofthewashabilityanalysisofcoal,thesesolutionsareobtained

specific gravity. The suspension is stirred gently to assure that

bythemixingofvariousorganicliquidsthatarerelativelyinert

allparticlesareallowedtoeitherfloatorsink.Thematerialthat

toward the majority of coal types. The distribution, as deter-

floats on the solution is removed first, followed by the portion

mined by the analysis, is affected by the physical condition of

of sample that sinks.

the sample subjected to the washability analysis, for example,

4.2 Procedure B—Describes a washability procedure for

the moisture content and the size content of the material.

coal fractions composed of particles of coal that are smaller

3.2.2 coarse coal—that portion of a coal sample being

thanthespecified,predeterminedsizechosenin4.1.Thesecoal

subjected to a washability study that is larger than a specific

fractions will be referred to as fine-coal fractions.

predeterminedparticlesize,generallybetween2.36mm[No.8

4.2.1 Each fine-coal size fraction is separated into two

USA Standard Sieve Series] and 9.5 mm [ ⁄8 in.] round in

distinct specific gravity fractions by placing a portion of the

diameter.

fine-coalsampleintoafloat/sinkflaskofsufficientcapacity,for

3.2.2.1 Discussion—This same particle size breakpoint

example, 2L to 4 L [0.5gal to 1 gal], containing a solution of

should then be used in subsequent washability studies of the

organic liquids adjusted to the required specific gravity (Note

same material sampled from the same location for the same

1,Note2,Note3,andNote4).Extremecaremustbeexercised

application.Thisbreakpointisdeterminedbytheanalystorthe

to avoid overloading the float/sink flask. This suspension is

person designing the test procedure as the point that best suits

thenstirredtobecertainthateachindividualparticleisallowed

theapplication.Thiscoarse-coalfractionmaybefurthersieved

to float or sink. The material that floats is removed first by

(generally by dry-sieving) to produce additional size fractions,

carefully inserting a stopper into the neck of the flask and

each of which is processed through the desired specific gravity

pouring the organic solution and float material from the upper

solutions.

portion of the float/sink flask through a filtering medium that

traps the float material. The sink material is then removed and

3.2.3 fine coal—that portion of a coal sample being sub-

captured in a similar manner.

jected to a washability study that is smaller than the predeter-

mined particle size generally between 2.36 mm [No. 8 USA

NOTE 1—A limited number of laboratories are currently using separa-

Standard Sieve Series] and 9.5 mm [ ⁄8 in.] round in diameter,

toryfunnelsfortheseparationoffinecoalparticleshavingadiameterless

which is specified in 3.2.2. than one third the diameter of the stopcock port.

NOTE 2—Some laboratories use centrifugal methods of separating

3.2.3.1 Discussion—This same particle size breakpoint

fine-coal density fractions. Centrifugal methods are not a part of this test

should then be used in subsequent washability studies of the

method.Apossible source of information is the Bureau of Mines’ Report

same material sampled from the same location for the same

of Investigations 5741 (1), or the Department of Energy, Pittsburgh

application.Thisbreakpointisdeterminedbytheanalystorthe

Energy Technology Center, Coal Preparation Branch, P.O. Box 10940,

Pittsburgh, PA 15236.

person designing the test procedure as the point which best

NOTE3—Preparationandadjustmentoftheorganicsolutionsshouldbe

suits the application. This fine-coal fraction may be further

done in an unrestricted container to allow proper mixing of the reagents

sieved (generally by wet-sieving) to produce additional size

prior to their introduction into the float/sink flasks.

fractions, each of which is processed through the desired

NOTE 4—It is a general guide that the depth of the particles floating

specific gravity solutions.

should not exceed three to five times the mean diameter of the particles in

the sample. It is suggested to use 200 g, or less.

3.2.4 float/sink—a reference to the physical action that

4.3 Preparation of Test Sample, Sieving:

particles undergo when immersed in a liquid of a predeter-

mined specific gravity. 4.3.1 The bulk sample should be spread on an impervious

base, preferably under shelter.The sample should be dried and

3.2.4.1 Discussion—Aseriesoffloat/sinktestsisconsidered

as being synonymous with a washability analysis. A float

fraction or float material is the material or the specific gravity

fraction that floats in a certain solution of specific gravity

The boldface numbers in parentheses refer to the list of references appended to

liquids. A sink fraction or sink material is the material or the this standard.

´1

D4371/D4371M − 06 (2019)

TABLE 1 Typical Coal Mass For Four To Six Specific Gravity

sievedinaccordancewithTestMethodD4749,usingasuitable

Fractions

range of apertures. (Apertures must conform to Specification

Mass of Material

E11 or E323.)

Needed for Washability

4.3.2 Where it is possible that some fines agglomerate or

Size Fraction Analysis of that Size

adhere to larger particles, it is important that wetsieving be

Fraction,

kg [lb]

used to ensure that fine material reports to the correct particle

200 mm × 100 mm [8 in. × 4 in. round] 2720 [6000]

size fraction. However, under normal circumstances where

100 mm × 50 mm [4 in. × 2 in. round] 910 [2000]

air-dryinghasoccurred,itshouldnotbenecessarytowet-sieve

50 mm × 25 mm [2 in. × 1 in. round] 225 [500]

the material larger than 3.15 mm [ ⁄8 in.]. 25 mm × 12.5 mm [1 in. × ⁄2 in. round] 90 [200]

1 1

12.5 mm × 6.3 mm [ ⁄2 in. × ⁄4 in. round] 25 [50]

4.3.3 As a practical guide, the presence of minus 75µm

6.3mm×2.36mm[ ⁄4 in. × No. 8 USA Standard] 9 [20]

[No. 200 USA Standard] material should be minimized,

2.36 mm × 1.40 mm [No. 8 × No. 14 USA Standard] 5 [10]

because Brownian movement or molecular interference can be 1.40 mm × 600 µm [No. 14 × No. 30 USA Standard] 2 [5]

600 µm × 300 µm [No. 30 × No. 50 USA Standard] 1 [2]

detrimental to proper and efficient separations. Minus 75µm

300 µm × 150 µm [No. 50 × No. 100 USA Standard] 0.5 [1]

[No. 200 USAStandard] material can then be processed using

150 µm × 75 µm [No. 100 × No. 200 USA Standard] 0.5 [1]

separate test procedures. (See, for example, the reference in

Note 2.)

4.3.4 When required, material which is larger than the

desired topsize is broken by hand or machine-crushed accord-

principal criteria being that it should be unaffected by the

ing to the topsize required, or, if applicable, by simulating the

solutions involved (that is, the organic liquids do not corrode,

relevant part of the crushing circuit.

etch, or otherwise react with the materials from which the

apparatus is constructed) and that it should be convenient for

5. Significance and Use

use (see X1.3). Types of apparatus that have been found to be

5.1 Although the determination of the washability charac-

suitable are discussed in the following subsections and are

teristics of coal is not an exact science, this washability test

illustrated in Fig. 1, Fig. 2, and Fig. 3.

method can be used to investigate the cleaning characteristics

6.2 Suitable Float/Sink Container for Coarse-Coal

ofcoarse-andfine-coalfractions.However,especiallywiththe

Fractions—The float/sink apparatus may consist of a wire

fine-coal fractions, this test method may not be applicable for

mesh insert and a holding tank (Fig. 1 and Fig. 2). The wire

low-rank coals for reasons explained in 1.2.

mesh insert should consist entirely of wire mesh, have solid

5.2 The usefulness of this test procedure and the usefulness

sides with a wire mesh bottom, or have a solid bottom with

of the results derived from washability testing are directly

wiremeshsides.Thewiremeshusedmustbesmallerthanone

related to the care exercised in developing and following the

half the size of the finest coal in the fraction. The insert fits

sampling regime while taking into consideration the desired

inside the holding tank. The insert may have handles attached

degree of precision. For more exacting work, it will be

or may utilize an overhead lifting device to facilitate removal

necessarytoknowthegeneralwashabilitycharacteristicsofthe

from the tank. A typical laboratory holding tank has approxi-

material in question. This can be done only through pilot

mately40Lto80L[10galto20gal]capacity.Tankandinsert

testing as described in 9.6 and Annex A3.

must be designed so as to be compatible.

5.3 This test method, in conjunction with the advice of

NOTE 5—It is possible that the geometry of the tank may have some

experts and with knowledge of the particle size analysis (see

effect on the ease with which the materials are removed from the tank.

TestMethodD4749),isusedfortheengineeringdesignofc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.