ASTM F384-06e1

(Specification)Standard Specifications and Test Methods for Metallic Angled Orthopedic Fracture Fixation Devices

Standard Specifications and Test Methods for Metallic Angled Orthopedic Fracture Fixation Devices

SIGNIFICANCE AND USE

A2.5.1 The test method establishes a uniform cantilever bending fatigue test to characterize and compare the fatigue performance of different angled device designs. This test method may be used to determine an angled device's fatigue life at either a specific or over a range of maximum bending moment conditions. Additionally, this test method may be alternatively used to estimate an angled device's fatigue strength for a specified number of fatigue cycles.

A2.5.2 The test method utilizes a simplified angled device cantilever bending load model that may not be exactly representative of the in-situ loading configuration. The user should note that the test results generated by this test method can not be used to directly predict the in-vivo performance of the angled device being tested. The data generated from this test method can be used to conduct relative comparisons of different angled device designs.

A2.5.3 This test method may not be appropriate for all types of implant applications. The user is cautioned to consider the appropriateness of the method in view of the devices being tested and their potential application.

A2.5.4 This test method assumes that the angled device is manufactured from a material that exhibits linear-elastic material behavior; therefore, this test method is not applicable for testing angled devices made from materials that exhibit nonlinear elastic behavior.

A2.5.5 This test method is restricted to the testing of angled devices within the material's linear-elastic range; therefore, this test method is not applicable for testing angled devices under conditions that would approach or exceed the bending strength of the angled device being tested.

SCOPE

1.1 These specifications and test methods provide a comprehensive reference for angled devices used in the surgical internal fixation of the skeletal system. This standard establishes consistent methods to classify and define the geometric and performance characteristics of angled devices. This standard also presents a catalog of standard specifications that specify material, labeling, and handling requirements, and standard test methods for measuring performance related mechanical characteristics determined to be important to the in vivo performance of angled devices.

1.2 It is not the intention of this standard to define levels of performance of case-specific clinical performance for angled devices, as insufficient knowledge is available to predict the consequences of their use in individual patients for specific activities of daily living. Futhermore, this standard does not describe or specify specific designs for angled devices used in the surgical internal fixation of the skeletal system.

1.3 This standard may not be appropriate for all types of angled devices. The user is cautioned to consider the appropriateness of this standard in view of a particular angled device and its potential application.

Note 1—This standard is not intended to address intramedullary hip screw nails or other angled devices without a sideplate.

1.4 This standard includes the following test methods used in determining the following angled device mechanical performance characteristics:

1.4.1 Standard test method for single cycle compression bend testing of metallic angled orthopedic fracture fixation devices (see Annex A1).

1.4.2 Standard test method for determining the bending fatigue properties of metallic angled orthopedic fracture fixation devices (see Annex A2).

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

Note 2—There is currently no ISO standard that is either similar to equivalent to this standard.

A2.1.1 This test method describes methods for bending fatigue testing in order to determine intrinsic structural properties of metallic angled devices. The test method may be used to determine the fatigue life at a specific or o...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F384 – 06

Standard Specifications and Test Methods for

1

Metallic Angled Orthopedic Fracture Fixation Devices

ThisstandardisissuedunderthefixeddesignationF384;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Units information was editorially corrected in August 2009.

NOTE 2—There is currently no ISO standard that is either similar to

1. Scope

equivalent to this standard.

1.1 These specifications and test methods provide a com-

prehensive reference for angled devices used in the surgical

2. Referenced Documents

internal fixation of the skeletal system. This standard estab-

2

2.1 ASTM Standards:

lishes consistent methods to classify and define the geometric

E4 Practices for Force Verification of Testing Machines

and performance characteristics of angled devices. This stan-

E8 Test Methods for Tension Testing of Metallic Materials

dard also presents a catalog of standard specifications that

E122 Practice for Calculating Sample Size to Estimate,

specify material, labeling, and handling requirements, and

With Specified Precision, the Average for a Characteristic

standard test methods for measuring performance related

of a Lot or Process

mechanicalcharacteristicsdeterminedtobeimportanttothe in

F67 Specification for Unalloyed Titanium, for Surgical

vivo performance of angled devices.

Implant Applications (UNS R50250, UNS R50400, UNS

1.2 It is not the intention of this standard to define levels of

R50550, UNS R50700)

performance of case-specific clinical performance for angled

F75 Specification for Cobalt-28 Chromium-6 Molybdenum

devices, as insufficient knowledge is available to predict the

Alloy Castings and Casting Alloy for Surgical Implants

consequences of their use in individual patients for specific

(UNS R30075)

activities of daily living. Futhermore, this standard does not

F90 Specification for Wrought Cobalt-20Chromium-

describe or specify specific designs for angled devices used in

15Tungsten-10Nickel Alloy for Surgical Implant Applica-

the surgical internal fixation of the skeletal system.

tions (UNS R30605)

1.3 This standard may not be appropriate for all types of

F136 Specification for Wrought Titanium-6Aluminum-

angled devices. The user is cautioned to consider the appro-

4Vanadium ELI (Extra Low Interstitial)Alloy for Surgical

priatenessofthisstandardinviewofaparticularangleddevice

Implant Applications (UNS R56401)

and its potential application.

F138 Specification for Wrought 18Chromium-14Nickel-

NOTE 1—This standard is not intended to address intramedullary hip 2.5Molybdenum Stainless Steel Bar and Wire for Surgical

screw nails or other angled devices without a sideplate.

Implants (UNS S31673)

F139 Specification for Wrought 18Chromium-14Nickel-

1.4 This standard includes the following test methods used

2.5Molybdenum Stainless Steel Sheet and Strip for Surgi-

in determining the following angled device mechanical perfor-

cal Implants (UNS S31673)

mance characteristics:

F382 Specification and Test Method for Metallic Bone

1.4.1 Standard test method for single cycle compression

Plates

bend testing of metallic angled orthopedic fracture fixation

F543 Specification and Test Methods for Metallic Medical

devices (see Annex A1).

Bone Screws

1.4.2 Standard test method for determining the bending

F565 Practice for Care and Handling of Orthopedic Im-

fatigue properties of metallic angled orthopedic fracture fixa-

plants and Instruments

tion devices (see Annex A2).

F620 Specification for Alpha Plus Beta Titanium Alloy

1.5 The values stated in SI units are to be regarded as

Forgings for Surgical Implants

standard. No other units of measurement are included in this

F621 Specification for Stainless Steel Forgings for Surgical

standard.

Implants

1

These specifications and test methods are under the jurisdiction of ASTM

Committee F04 on Medical and Surgical Materials and Devices and are the direct

2

responsibility of Subcommittee F04.21 on Osteosynthesis.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Jan. 15, 2006. Published February 2006. Originally

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1973. Last previous edition approved in 2000 as F384–00. DOI:

Standards volume information, refer to the standard’s Document Summary page on

10.1520/F0384-06E01.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

F384 – 06

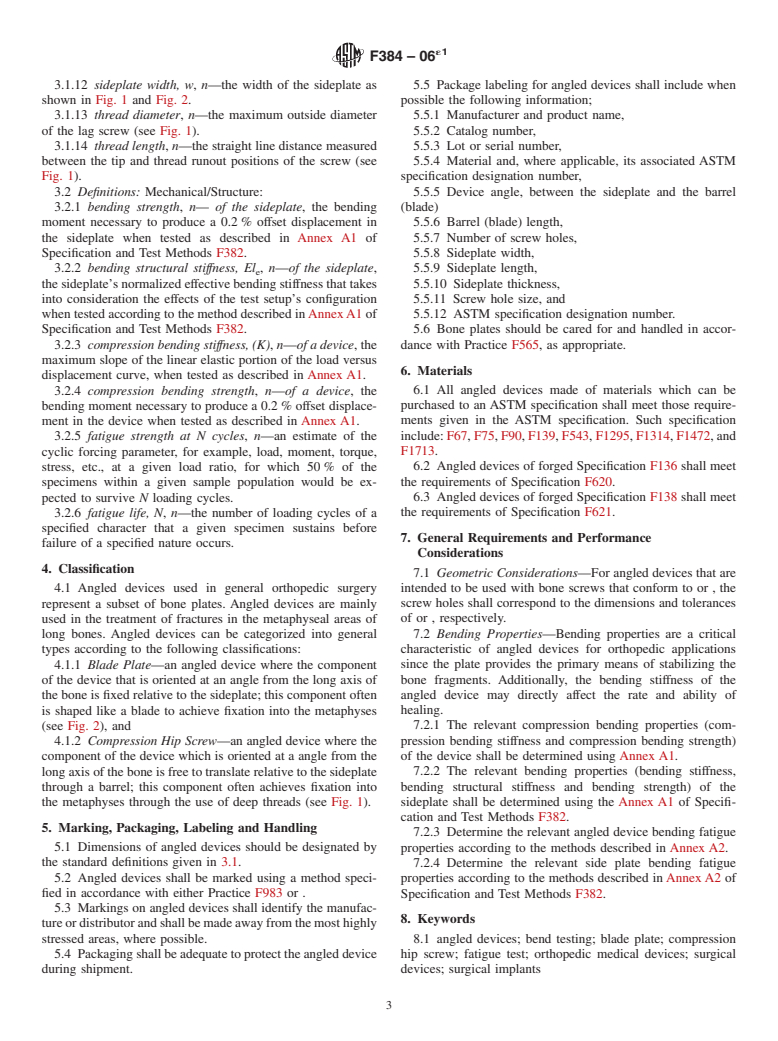

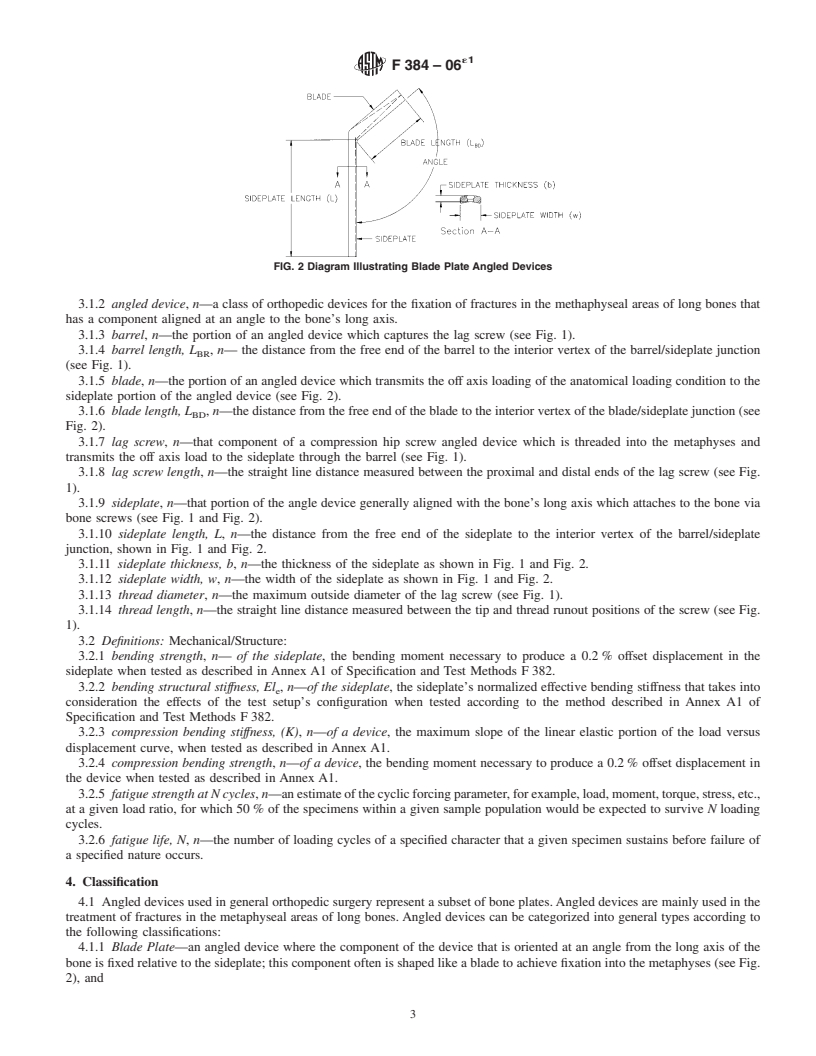

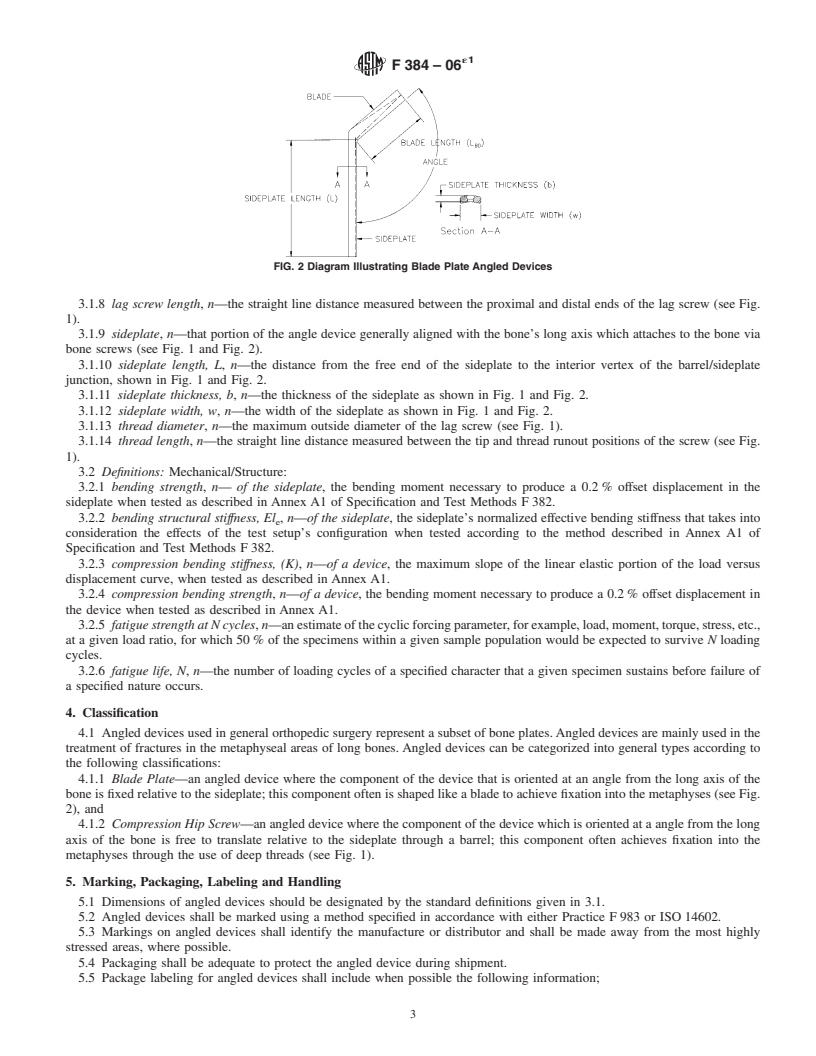

FIG. 1 Diagram Illustrating Compression Hip Screw Angled Devices

F983 Practice for Permanent M

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:F384–00 Designation: F 384 – 06

Standard Specifications and Test Methods for

1

Metallic Angled Orthopedic Fracture Fixation Devices

This standard is issued under the fixed designation F 384; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Units information was editorially corrected in August 2009.

1. Scope

1.1This standard is intended to1.1 These specifications and test methods provide a comprehensive reference for angled devices

used in the surgical internal fixation of the skeletal system. This standard establishes consistent methods to classify and define the

geometric and performance characteristics of angled devices. This standard also presents a catalog of standard specifications that

specify material and labelingmaterial, labeling, and handling requirements, and standard test methods for measuring performance

related mechanical characteristics determined to be important to the in vivo performance of angled devices.

1.2 It is not the intention of this standard to define levels of performance of case-specific clinical performance for angled

devices, as insufficient knowledge is available to predict the consequences of their use in individual patients for specific activities

of daily living. Futhermore, it is not the intention of this standard todoes not describe or specify specific designs for angled devices

used in the surgical internal fixation of the skeletal system.

1.3 This standard may not be appropriate for all types of angled devices. The user is cautioned to consider the appropriateness

of this standard in view of a particular angled device and its potential application.

NOTE 1—This standard is not intended to address intramedullary hip screw nails or other angled devices without a sideplate.

1.4 This standard includes the following test methods used in determining the following angled device mechanical performance

characteristics:

1.4.1 Standardtestmethodforsinglecyclecompressionbendtestingofmetallicangledorthopedicfracturefixationdevices(see

Annex A1).

1.4.2 Standardtestmethodfordeterminingthebendingfatiguepropertiesofmetallicangledorthopedicfracturefixationdevices

(see Annex A2).

1.5Unless otherwise indicated, the values stated in SI units shall be regarded as the standard.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

NOTE1—There 2—There is currently no ISO standard that is either similar to equivalent to this standard.

2. Referenced Documents

2

2.1 ASTM Standards:

E4 Practices for Force Verification of Testing Machines

E8 Test Methods for Tension Testing of Metallic Materials

E 122 Practice for Choice of Sample Size to Estimate theAverage Quality of a Lot or Process Practice for Calculating Sample

Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or Process

F67 Specification for UnalloyedTitanium for Surgical ImplantApplications Specification for UnalloyedTitanium, for Surgical

Implant Applications (UNS R50250, UNS R50400, UNS R50550, UNS R50700)

F75 Specification for Cobalt-28 Chromium-6 Molybdenum Casting Alloy Castings and Cast ProductsCasting Alloy for

Surgical Implants (UNS R30075)

F90 Specification for Wrought Cobalt-20 Chromium-15 Tungsten-10 Nickel Alloy for Surgical Implant Applications

4

(R30605) Specification for Wrought Cobalt-20Chromium-15Tungsten-10Nickel Alloy for Surgical Implant Applications

(UNS R30605)

F 136 Specification for Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy (UNS R56401) for

1

ThesespecificationsandtestmethodsareunderthejurisdictionofASTMCommitteeF04onMedicalandSurgicalMaterialsandDevicesandarethedirectresponsibility

of Subcommittee F04.21 on Osteosynthesis .

Current edition approved Nov. 10, 2000. Published February 2001. Originally published as F384-73. Last previous edition F384-99.

Current edition approved Jan. 15, 2006. Published February 2006. Originally approved in 1973. Last previous edition approved in 2000 as F 384 – 00.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

. Vol 03.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:F384–06 Designation: F 384 – 06

Standard Specifications and Test Methods for

1

Metallic Angled Orthopedic Fracture Fixation Devices

This standard is issued under the fixed designation F 384; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Units information was editorially corrected in August 2009.

1. Scope

1.1 These specifications and test methods provide a comprehensive reference for angled devices used in the surgical internal

fixation of the skeletal system. This standard establishes consistent methods to classify and define the geometric and performance

characteristics of angled devices. This standard also presents a catalog of standard specifications that specify material, labeling,

and handling requirements, and standard test methods for measuring performance related mechanical characteristics determined

to be important to the in vivo performance of angled devices.

1.2 It is not the intention of this standard to define levels of performance of case-specific clinical performance for angled

devices, as insufficient knowledge is available to predict the consequences of their use in individual patients for specific activities

of daily living. Futhermore, this standard does not describe or specify specific designs for angled devices used in the surgical

internal fixation of the skeletal system.

1.3 This standard may not be appropriate for all types of angled devices. The user is cautioned to consider the appropriateness

of this standard in view of a particular angled device and its potential application.

NOTE 1—This standard is not intended to address intramedullary hip screw nails or other angled devices without a sideplate.

1.4 This standard includes the following test methods used in determining the following angled device mechanical performance

characteristics:

1.4.1 Standardtestmethodforsinglecyclecompressionbendtestingofmetallicangledorthopedicfracturefixationdevices(see

Annex A1).

1.4.2 Standardtestmethodfordeterminingthebendingfatiguepropertiesofmetallicangledorthopedicfracturefixationdevices

(see Annex A2).

1.5Unless otherwise indicated, the values stated in SI units shall be regarded as the standard.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

NOTE 2—There is currently no ISO standard that is either similar to equivalent to this standard.

2. Referenced Documents

2

2.1 ASTM Standards:

E4 Practices for Force Verification of Testing Machines

E8 Test Methods for Tension Testing of Metallic Materials

E 122 Practice for Calculating Sample Size to Estimate, With Specified Precision, theAverage for a Characteristic of a Lot or

Process

F67 SpecificationforUnalloyedTitanium,forSurgicalImplantApplications(UNSR50250,UNSR50400,UNSR50550,UNS

R50700)

F75 Specification for Cobalt-28 Chromium-6 Molybdenum Alloy Castings and Casting Alloy for Surgical Implants (UNS

R30075)

F90 Specification for Wrought Cobalt-20Chromium-15Tungsten-10Nickel Alloy for Surgical Implant Applications (UNS

R30605)

F 136 Specification for Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical Implant

Applications (UNS R56401)

1

ThesespecificationsandtestmethodsareunderthejurisdictionofASTMCommitteeF04onMedicalandSurgicalMaterialsandDevicesandarethedirectresponsibility

of Subcommittee F04.21 on Osteosynthesis .

Current edition approved Jan. 15, 2006. Published February 2006. Originally approved in 1973. Last previous edition approved in 2000 as F 384 – 00.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

F384–06

F 138 Specification for Wrought 18Chromium-14Nickel-2.5Molybdenum Stainless Steel Bar and Wire for Surgical Implants

(UNS S31673)

F 139 Specification for Wrought 18Chromium-14Nickel-2.5Molybdenum Stainless Steel Sheet and Strip for Surgical Implants

(UNS S31673)

F 382 Specification and Test Method for Metallic Bone Plates

F 543 Specification and Test Methods for Metallic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.