ASTM F384-06(2011)

(Specification)Standard Specifications and Test Methods for Metallic Angled Orthopedic Fracture Fixation Devices

Standard Specifications and Test Methods for Metallic Angled Orthopedic Fracture Fixation Devices

SIGNIFICANCE AND USE

A2.5.1 The test method establishes a uniform cantilever bending fatigue test to characterize and compare the fatigue performance of different angled device designs. This test method may be used to determine an angled device's fatigue life at either a specific or over a range of maximum bending moment conditions. Additionally, this test method may be alternatively used to estimate an angled device's fatigue strength for a specified number of fatigue cycles.

A2.5.2 The test method utilizes a simplified angled device cantilever bending load model that may not be exactly representative of the in-situ loading configuration. The user should note that the test results generated by this test method can not be used to directly predict the in-vivo performance of the angled device being tested. The data generated from this test method can be used to conduct relative comparisons of different angled device designs.

A2.5.3 This test method may not be appropriate for all types of implant applications. The user is cautioned to consider the appropriateness of the method in view of the devices being tested and their potential application.

A2.5.4 This test method assumes that the angled device is manufactured from a material that exhibits linear-elastic material behavior; therefore, this test method is not applicable for testing angled devices made from materials that exhibit nonlinear elastic behavior.

A2.5.5 This test method is restricted to the testing of angled devices within the material's linear-elastic range; therefore, this test method is not applicable for testing angled devices under conditions that would approach or exceed the bending strength of the angled device being tested.

SCOPE

1.1 These specifications and test methods provide a comprehensive reference for angled devices used in the surgical internal fixation of the skeletal system. This standard establishes consistent methods to classify and define the geometric and performance characteristics of angled devices. This standard also presents a catalog of standard specifications that specify material, labeling, and handling requirements, and standard test methods for measuring performance related mechanical characteristics determined to be important to the in vivo performance of angled devices.

1.2 It is not the intention of this standard to define levels of performance of case-specific clinical performance for angled devices, as insufficient knowledge is available to predict the consequences of their use in individual patients for specific activities of daily living. Futhermore, this standard does not describe or specify specific designs for angled devices used in the surgical internal fixation of the skeletal system.

1.3 This standard may not be appropriate for all types of angled devices. The user is cautioned to consider the appropriateness of this standard in view of a particular angled device and its potential application.

Note 1—This standard is not intended to address intramedullary hip screw nails or other angled devices without a sideplate.

1.4 This standard includes the following test methods used in determining the following angled device mechanical performance characteristics:

1.4.1 Standard test method for single cycle compression bend testing of metallic angled orthopedic fracture fixation devices (see Annex A1).

1.4.2 Standard test method for determining the bending fatigue properties of metallic angled orthopedic fracture fixation devices (see Annex A2).

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

Note 2—There is currently no ISO standard that is either similar to equivalent to this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation: F384 – 06 (Reapproved 2011)

Standard Specifications and Test Methods for

Metallic Angled Orthopedic Fracture Fixation Devices

ThisstandardisissuedunderthefixeddesignationF384;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

equivalent to this standard.

1. Scope

1.1 These specifications and test methods provide a com-

2. Referenced Documents

prehensive reference for angled devices used in the surgical

2.1 ASTM Standards:

internal fixation of the skeletal system. This standard estab-

E4 Practices for Force Verification of Testing Machines

lishes consistent methods to classify and define the geometric

E8 Test Methods for Tension Testing of Metallic Materials

and performance characteristics of angled devices. This stan-

E122 Practice for Calculating Sample Size to Estimate,

dard also presents a catalog of standard specifications that

With Specified Precision, the Average for a Characteristic

specify material, labeling, and handling requirements, and

of a Lot or Process

standard test methods for measuring performance related

F67 Specification for Unalloyed Titanium, for Surgical

mechanicalcharacteristicsdeterminedtobeimportanttothe in

Implant Applications (UNS R50250, UNS R50400, UNS

vivo performance of angled devices.

R50550, UNS R50700)

1.2 It is not the intention of this standard to define levels of

F75 Specification for Cobalt-28 Chromium-6 Molybdenum

performance of case-specific clinical performance for angled

Alloy Castings and Casting Alloy for Surgical Implants

devices, as insufficient knowledge is available to predict the

(UNS R30075)

consequences of their use in individual patients for specific

F90 Specification for Wrought Cobalt-20Chromium-

activities of daily living. Futhermore, this standard does not

15Tungsten-10Nickel Alloy for Surgical Implant Applica-

describe or specify specific designs for angled devices used in

tions (UNS R30605)

the surgical internal fixation of the skeletal system.

F136 Specification for Wrought Titanium-6Aluminum-

1.3 This standard may not be appropriate for all types of

4Vanadium ELI (Extra Low Interstitial)Alloy for Surgical

angled devices. The user is cautioned to consider the appro-

Implant Applications (UNS R56401)

priatenessofthisstandardinviewofaparticularangleddevice

F138 Specification for Wrought 18Chromium-14Nickel-

and its potential application.

2.5Molybdenum Stainless Steel Bar and Wire for Surgical

NOTE 1—This standard is not intended to address intramedullary hip

Implants (UNS S31673)

screw nails or other angled devices without a sideplate.

F139 Specification for Wrought 18Chromium-14Nickel-

2.5Molybdenum Stainless Steel Sheet and Strip for Surgi-

1.4 This standard includes the following test methods used

in determining the following angled device mechanical perfor- cal Implants (UNS S31673)

F382 Specification and Test Method for Metallic Bone

mance characteristics:

1.4.1 Standard test method for single cycle compression Plates

F543 Specification and Test Methods for Metallic Medical

bend testing of metallic angled orthopedic fracture fixation

Bone Screws

devices (see Annex A1).

1.4.2 Standard test method for determining the bending F565 Practice for Care and Handling of Orthopedic Im-

plants and Instruments

fatigue properties of metallic angled orthopedic fracture fixa-

tion devices (see Annex A2). F620 Specification for Alpha Plus Beta Titanium Alloy

Forgings for Surgical Implants

1.5 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this F621 Specification for Stainless Steel Forgings for Surgical

Implants

standard.

F983 Practice for Permanent Marking of Orthopaedic Im-

NOTE 2—There is currently no ISO standard that is either similar to

plant Components

These specifications and test methods are under the jurisdiction of ASTM

Committee F04 on Medical and Surgical Materials and Devices and are the direct

responsibility of Subcommittee F04.21 on Osteosynthesis. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedJune1,2011.PublishedJuly2011.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

´1

in 1973. Last previous edition approved in 2006 as F384–06 . DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

F0384-06R11. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

F384 – 06 (2011)

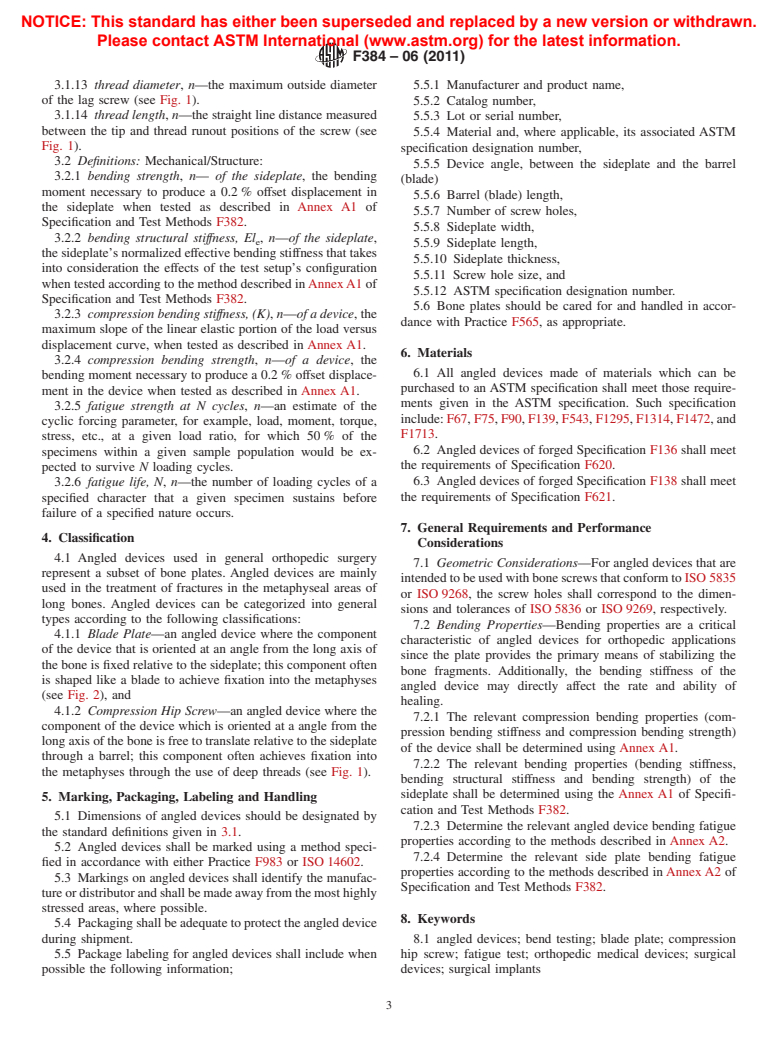

FIG. 1 Diagram Illustrating Compression Hip Screw Angled Devices

F1295 Specification for Wrought Titanium-6Aluminum-

7Niobium Alloy for Surgical Implant Applications (UNS

R56700)

F1314 Specification for Wrought Nitrogen Strengthened 22

Chromium−13Nickel−5Manganese−2.5Molybdenum

Stainless Steel Alloy Bar and Wire for Surgical Implants

(UNS S20910)

F1472 Specification for Wrought Titanium-6Aluminum-

4VanadiumAlloy for Surgical ImplantApplications (UNS

R56400)

F1713 Specification for Wrought Titanium-13Niobium-

13Zirconium Alloy for Surgical Implant Applications

FIG. 2 Diagram Illustrating Blade Plate Angled Devices

(UNS R58130)

2.2 ISO Standards:

ISO 5835 Implants for Surgery—Metal Bone Screws with

3.1.4 barrel length, L , n— the distance from the free end

BR

Hexagonal Drive Connection—Spherical Under Surface

of the barrel to the interior vertex of the barrel/sideplate

of Head, Asymmetrical Thread

junction (see Fig. 1).

ISO5836 ImplantsforSurgery—MetalBonePlates—Holes

3.1.5 blade, n—the portion of an angled device which

Corresponding to Screws with Asymmetrical Thread and

transmits the off axis loading of the anatomical loading

Spherical Under Surface

conditiontothesideplateportionoftheangleddevice(seeFig.

ISO 9268 Implants for Surgery—Metal Bone Screws with

2).

Conical Under-Surface of Head—Dimensions

3.1.6 blade length, L , n—the distance from the free end

BD

ISO9269 ImplantsforSurgery—MetalBonePlates—Holes

ofthebladetotheinteriorvertexoftheblade/sideplatejunction

and Slots Corresponding to Screws with Conical Under-

(see Fig. 2).

Surface

3.1.7 lag screw, n—that component of a compression hip

ISO 14602 Non-active Surgical Implants—Implants for

screwangleddevicewhichisthreadedintothemetaphysesand

Osteosynthesis—Particular Requirements

transmits the off axis load to the sideplate through the barrel

(see Fig. 1).

3. Terminology

3.1.8 lag screw length, n—the straight line distance mea-

3.1 Definitions: Geometric

sured between the proximal and distal ends of the lag screw

3.1.1 angle, n—defined at either the barrel/sideplate or

(see Fig. 1).

blade/sideplate junction (see Fig. 1 and Fig. 2).

3.1.9 sideplate, n—that portion of the angle device gener-

3.1.2 angled device, n—aclassoforthopedicdevicesforthe

ally aligned with the bone’s long axis which attaches to the

fixation of fractures in the methaphyseal areas of long bones

bone via bone screws (see Fig. 1 and Fig. 2).

that has a component aligned at an angle to the bone’s long

3.1.10 sideplate length, L, n—thedistancefromthefreeend

axis.

of the sideplate to the interior vertex of the barrel/sideplate

3.1.3 barrel, n—the portion of an angled device which

junction, shown in Fig. 1 and Fig. 2.

captures the lag screw (see Fig. 1).

3.1.11 sideplate thickness, b, n—the thickness of the side-

plate as shown in Fig. 1 and Fig. 2.

3.1.12 sideplate width, w, n—the width of the sideplate as

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. shown in Fig. 1 and Fig. 2.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

F384 – 06 (2011)

3.1.13 thread diameter, n—the maximum outside diameter 5.5.1 Manufacturer and product name,

of the lag screw (see Fig. 1). 5.5.2 Catalog number,

3.1.14 thread length, n—the straight line distance measured

5.5.3 Lot or serial number,

between the tip and thread runout positions of the screw (see

5.5.4 Material and, where applicable, its associated ASTM

Fig. 1).

specification designation number,

3.2 Definitions: Mechanical/Structure:

5.5.5 Device angle, between the sideplate and the barrel

3.2.1 bending strength, n— of the sideplate, the bending

(blade)

moment necessary to produce a 0.2% offset displacement in

5.5.6 Barrel (blade) length,

the sideplate when tested as described in Annex A1 of

5.5.7 Number of screw holes,

Specification and Test Methods F382.

5.5.8 Sideplate width,

3.2.2 bending structural stiffness, El , n—of the sideplate,

e

5.5.9 Sideplate length,

thesideplate’snormalizedeffectivebendingstiffnessthattakes

5.5.10 Sideplate thickness,

into consideration the effects of the test setup’s configuration

5.5.11 Screw hole size, and

whentestedaccordingtothemethoddescribedinAnnexA1of

5.5.12 ASTM specification designation number.

Specification and Test Methods F382.

5.6 Bone plates should be cared for and handled in accor-

3.2.3 compression bending stiffness, (K), n—of a device,the

dance with Practice F565, as appropriate.

maximum slope of the linear elastic portion of the load versus

displacement curve, when tested as described in Annex A1.

6. Materials

3.2.4 compression bending strength, n—of a device, the

6.1 All angled devices made of materials which can be

bending moment necessary to produce a 0.2% offset displace-

purchased to anASTM specification shall meet those require-

ment in the device when tested as described in Annex A1.

ments given in the ASTM specification. Such specification

3.2.5 fatigue strength at N cycles, n—an estimate of the

include:F67,F75,F90,F139,F543,F1295,F1314,F1472,and

cyclic forcing parameter, for example, load, moment, torque,

F1713.

stress, etc., at a given load ratio, for which 50% of the

6.2 Angled devices of forged Specification F136 shall meet

specimens within a given sample population would be ex-

the requirements of Specification F620.

pected to survive N loading cycles.

6.3 Angled devices of forged Specification F138 shall meet

3.2.6 fatigue life, N, n—the number of loading cycles of a

the requirements of Specification F621.

specified character that a given specimen sustains before

failure of a specified nature occurs.

7. General Requirements and Performance

4. Classification

Considerations

4.1 Angled devices used in general orthopedic surgery

7.1 Geometric Considerations—For angled devices that are

represent a subset of bone plates. Angled devices are mainly

intendedtobeusedwithbonescrewsthatconformtoISO5835

used in the treatment of fractures in the metaphyseal areas of

or ISO9268, the screw holes shall correspond to the dimen-

long bones. Angled devices can be categorized into general

sions and tolerances of ISO5836 or ISO9269, respectively.

types according to the following classifications:

7.2 Bending Properties—Bending properties are a critical

4.1.1 Blade Plate—an angled device where the component

characteristic of angled devices for orthopedic applications

of the device that is oriented at an angle from the long axis of

since the plate provides the primary means of stabilizing the

theboneisfixedrelativetothesideplate;thiscomponentoften

bone fragments. Additionally, the bending stiffness of the

is shaped like a blade to achieve fixation into the metaphyses

angled device may directly affect the rate and ability of

(see Fig. 2), and

healing.

4.1.2 Compression Hip Screw—an angled device where the

7.2.1 The relevant compression bending properties (com-

component of the device which is oriented at a angle from the

pression bending stiffness and compression bending strength)

longaxisoftheboneisfreetotranslaterelativetothesideplate

of the device shall be determined using Annex A1.

through a barrel; this component often achieves fixation into

7.2.2 The relevant bending properties (bending stiffness,

the metaphyses through the use of deep threads (see Fig. 1).

bending structural stiffness and bending strength) of the

sideplate shall be determined using the Annex A1 of Specifi-

5. Marking, Packaging, Labeling and Handling

cation and Test Methods F382.

5.1 Dimensions of angled devices should be designated by

7.2.3 Determine the relevant angled device bending fatigue

the standard definitions given in 3.1.

properties according to the methods described in Annex A2.

5.2 Angled devices shall be marked using a method speci-

7.2.4 Determine the relevant side plate bending fatigue

fied in accordance with either Practice F983 or ISO14602.

properties according to the methods described inAnnexA2 of

5.3 Markings on angled devices shall identify the manufac-

Specification and Test Methods F382.

tureordistributorandshallbemadeawayfromthemosthighly

stressed areas, where possible.

8. Keywords

5.4 Packagingshallbeadequatetoprotecttheangleddevice

during shipment. 8.1 angled devices; bend testing; blade plate; compression

5.5 Package labeling for angled devices shall include when hip screw; fatigue test; orthopedic medical devices; surgical

possible the following information; devices; surgical implants

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

F384 – 06 (2011)

ANNEXES

(Mandatory Information)

A1. STANDARD TEST METHOD FOR SINGLE CYCLE COMPRESSION BEND TESTING OF METALLIC ANGLED

ORTHOPEDIC FRACTURE FIXATION DEVICES

A1.1 Scope

A1.1.1 This test method describes methods for single cycle

bend testing for determining intrinsic, structural properties of

metallic angled orthopedic fracture fixation devices. The test

method measures the angled device’s compression bending

stiffness and compression bending strength.

A1.1.2 This test method is intended to provide a means to

mechanically characterize different angled device designs. It is

not the intention of this test method to define levels of

performance for angled devices, as these characteristics are

driven by patient-specific clinical requirements.

A1.1.3 This test method is designed to provide flexibility in

the testing configuration so that a range of clinical failure

modes for the angled fixation devices (for example, sideplate,

lag screw, and barrel fractures) can be evaluated.

A1.1.4 The values stated in SI units are to be regarded as

standard. No other units of measurement are incl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.