ASTM D923-97

(Practice)Standard Practices for Sampling Electrical Insulating Liquids (Withdrawn 2006)

Standard Practices for Sampling Electrical Insulating Liquids (Withdrawn 2006)

SCOPE

1.1 These practices cover sampling of new electrical insulating liquids including oils, askarels, silicones, and synthetic liquids as well as such liquids in service or subsequent to service in cables, transformers, circuit breakers, and other electrical apparatus. This test method shall apply to liquids having a viscosity of less than 3000 SUS (Saybolt Universal s) (647.3 cSt) and 100°F (37.8°C).

1.2 The values stated in inch-pound units are to be regarded as the standard.

1.3 Sampling procedures using syringe-type devices, tin plated steel cans with flexible sides and stainless steel cylinders are described in Methods D3613. This method describes preferred techniques to use when sampling for dissolved gas analysis and water content in insulating fluid.

1.4 The procedures appear in the following order: Procedure Section/Paragraph Dip-Type Device 6.2, 13, and X1.1 Pressure-Type Device 6.3, 14, and X1.2 Tank Car-Type Device 6.4, 15, and X1.3 Manifold-Type Device 6.5, 20, and X1.4 Electric Equipment Sample Outlet 6.6 and 18

1.5 Handle askarels as outlined in ANSI C107.1 to avoid environmental contamination. For methods of testing askarels see Methods D901.

1.6 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.> Specific precautionary statements are given in 12.7, 14.2, Section 17, 19.2, and 21.2.3.

WITHDRAWN RATIONALE

These practices cover sampling of new electrical insulating liquids including oils, askarels, silicones, and synthetic liquids as well as such liquids in service or subsequent to service in cables, transformers, circuit breakers, and other electrical apparatus. These practices apply to liquids having a viscosity of less than 6.476 104 m 2/s (540 cSt) at 40C (100F).

Formerly under the jurisdiction of Committee D27 on Electrical Insulating Liquids and Gases, these Practices were withdrawn in August 2006 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D 923–97

Standard Practices for

1

Sampling Electrical Insulating Liquids

This standard is issued under the fixed designation D 923; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope bility of regulatory limitations prior to use. Specific precau-

tionary statements are given in 1.5, 1.7, 14.2, Section 17, 19.2,

1.1 These practices cover sampling of new electrical insu-

and 21.2.3.

lating liquids including oils, askarels, silicones, and synthetic

liquids as well as such liquids in service or subsequent to

2. Referenced Documents

service in cables, transformers, circuit breakers, and other

2.1 ASTM Standards:

electrical apparatus. These practices apply to liquids having a

2

-4 2 D901 Methods of Testing Askarels

viscosity of less than 6.476 3 10 m /s (540 cSt) at 40°C

D 1933 Specification for Nitrogen Gas as an Electrical

(100°F).

2

Insulating Material

1.2 ThevaluesstatedinSIunitsareregardedasthestandard

D 3613 Test Methods of Sampling Electrical Insulating Oils

where applicable. Inch pound units are used where there is no

2

for Gas Analysis and Determination of Water Content

SI equivalent.

D 4057 Practice for Manual Sampling of Petroleum and

1.3 Sampling procedures using syringe-type devices, tin

3

Petroleum Products

platedsteelcanswithflexiblesidesandstainlesssteelcylinders

2.2 IEEE Standards:

are described in Test Methods D 3613. This method describes

799-1992 Guide for Handling and Disposal of Transformer

preferred techniques to use when sampling for dissolved gas

4

Grade Insulating Fluids Containing PCBs

analysis and water content in insulating fluid.

1.4 The procedures appear in the following order:

3. Terminology

Procedure Section/Paragraph

3.1 Definition:

Dip-Type Device (drum thief) 6.2, 13, and A1.1

3.1.1 sampling—the obtaining of that amount of a material

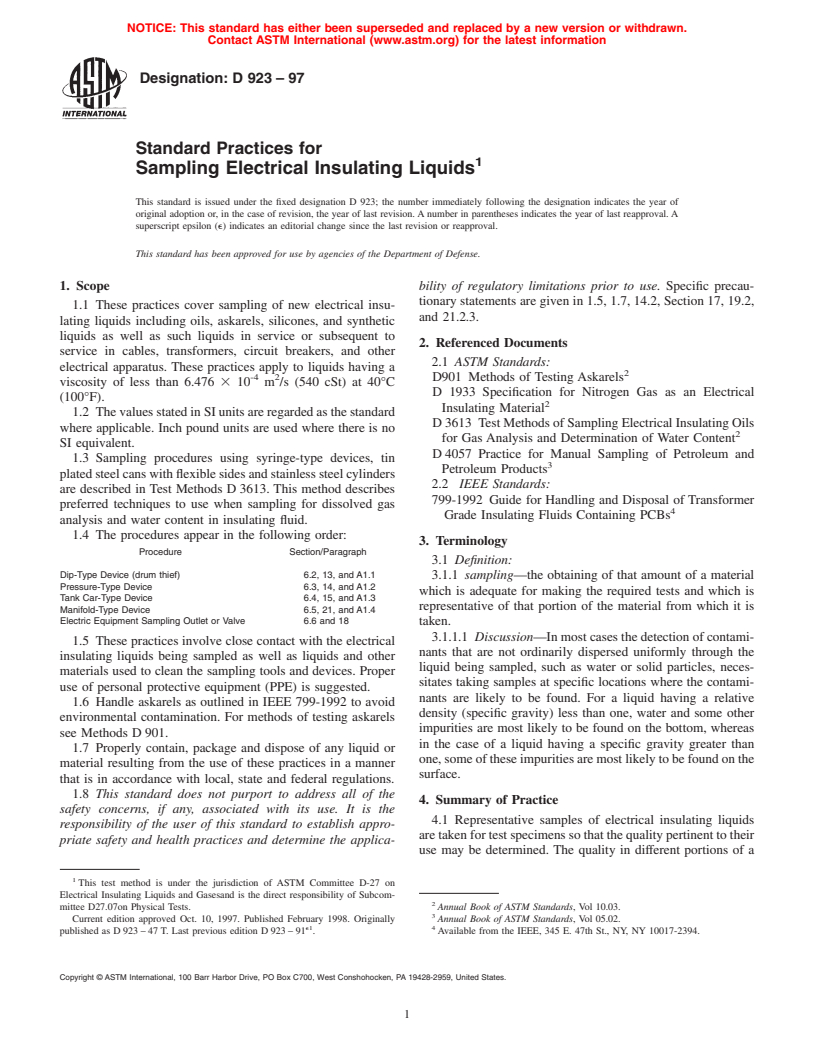

Pressure-Type Device 6.3, 14, and A1.2

which is adequate for making the required tests and which is

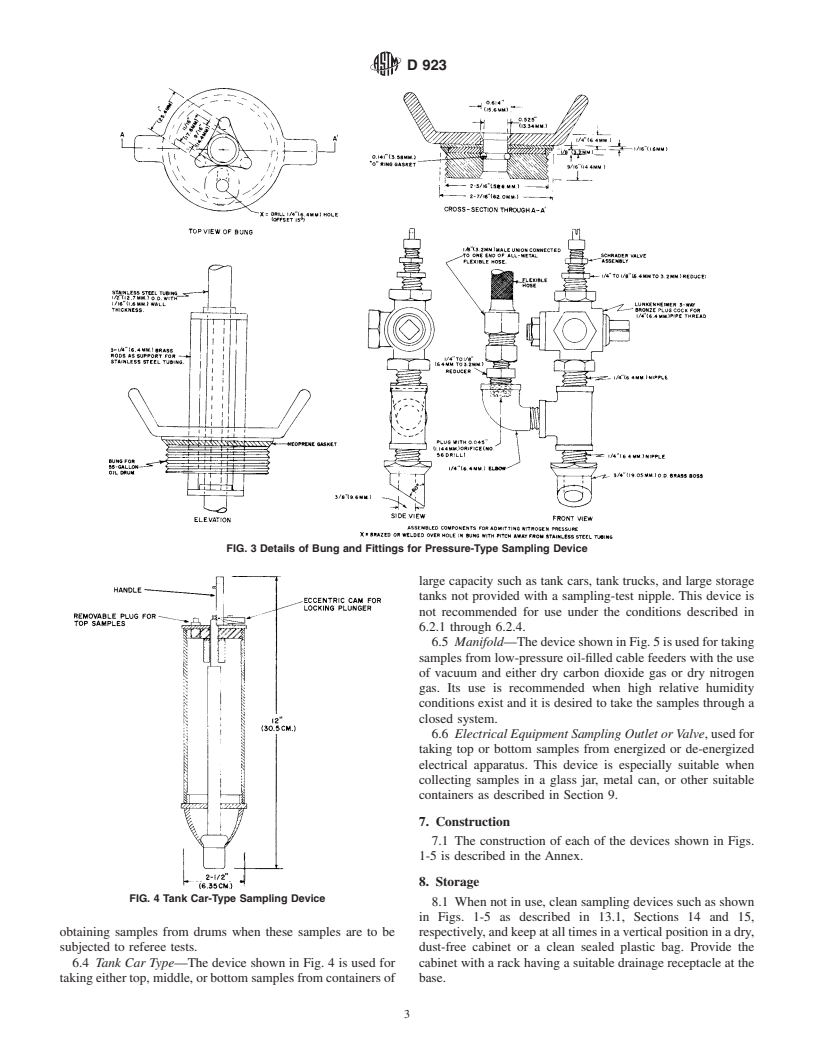

Tank Car-Type Device 6.4, 15, and A1.3

representative of that portion of the material from which it is

Manifold-Type Device 6.5, 21, and A1.4

Electric Equipment Sampling Outlet or Valve 6.6 and 18

taken.

3.1.1.1 Discussion—In most cases the detection of contami-

1.5 These practices involve close contact with the electrical

nants that are not ordinarily dispersed uniformly through the

insulating liquids being sampled as well as liquids and other

liquid being sampled, such as water or solid particles, neces-

materials used to clean the sampling tools and devices. Proper

sitates taking samples at specific locations where the contami-

use of personal protective equipment (PPE) is suggested.

nants are likely to be found. For a liquid having a relative

1.6 Handle askarels as outlined in IEEE 799-1992 to avoid

density (specific gravity) less than one, water and some other

environmental contamination. For methods of testing askarels

impurities are most likely to be found on the bottom, whereas

see Methods D 901.

in the case of a liquid having a specific gravity greater than

1.7 Properly contain, package and dispose of any liquid or

one,someoftheseimpuritiesaremostlikelytobefoundonthe

material resulting from the use of these practices in a manner

surface.

that is in accordance with local, state and federal regulations.

1.8 This standard does not purport to address all of the

4. Summary of Practice

safety concerns, if any, associated with its use. It is the

4.1 Representative samples of electrical insulating liquids

responsibility of the user of this standard to establish appro-

aretakenfortestspecimenssothatthequalitypertinenttotheir

priate safety and health practices and determine the applica-

use may be determined. The quality in different portions of a

1

This test method is under the jurisdiction of ASTM Committee D-27 on

Electrical Insulating Liquids and Gasesand is the direct responsibility of Subcom-

2

mittee D27.07on Physical Tests. Annual Book of ASTM Standards, Vol 10.03.

3

Current edition approved Oct. 10, 1997. Published February 1998. Originally Annual Book of ASTM Standards, Vol 05.02.

e1 4

published as D 923 – 47 T. Last previous edition D 923 – 91 . Available from the IEEE, 345 E. 47th St., NY, NY 10017-2394.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 923

given container, or the average quality of the whole bulk may

be ascertained if desired.

5. Significance and Use

5.1 Accurate sampling, whether of the complete

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.