ASTM E1208-21

(Practice)Standard Practice for Fluorescent Liquid Penetrant Testing Using the Lipophilic Post-Emulsification Process

Standard Practice for Fluorescent Liquid Penetrant Testing Using the Lipophilic Post-Emulsification Process

SIGNIFICANCE AND USE

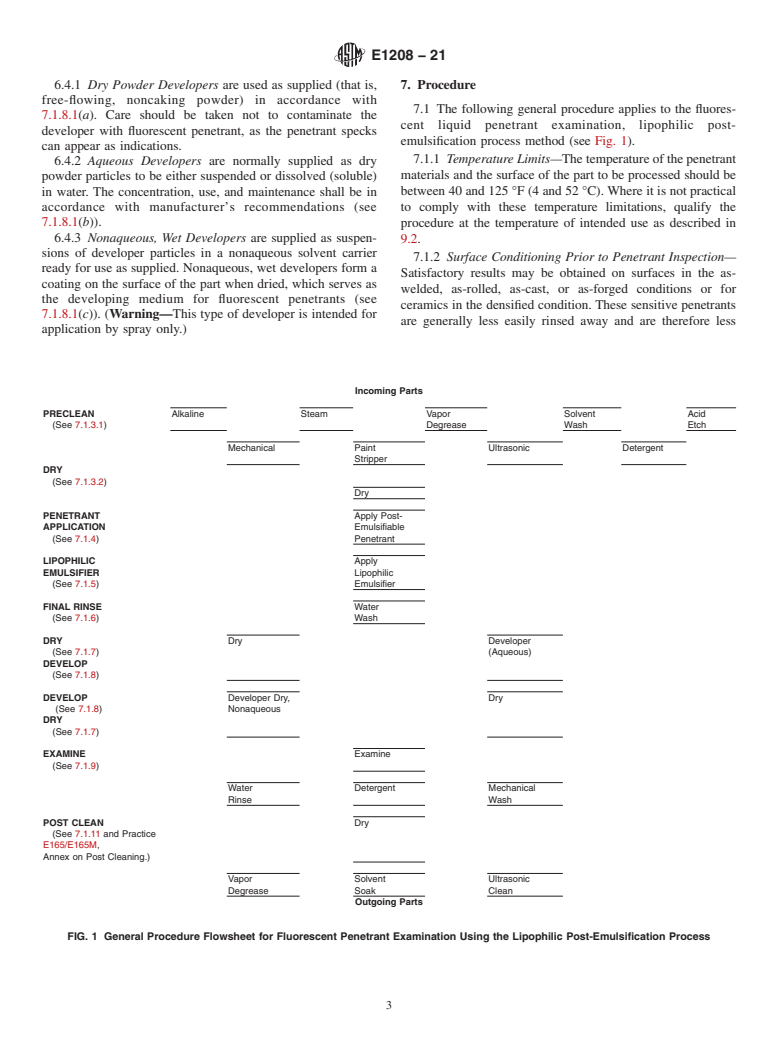

5.1 Liquid penetrant examination methods indicate the presence, location, and, to a limited extent, the nature and magnitude of the detected discontinuities. This practice is normally used for production examination of critical components or structures when (a) removal of excessive amounts of penetrant from discontinuities using a water-washable process can be a problem and (b) the use of a hydrophilic remover is impractical.

SCOPE

1.1 This practice covers procedures for fluorescent liquid penetrant examination utilizing the lipophilic post-emulsification process. It is a nondestructive testing method for detecting discontinuities that are open to the surface such as cracks, seams, laps, cold shuts, laminations, through leaks, or lack of fusion and is applicable to in-process, final, and maintenance examination. It can be effectively used in the examination of nonporous, metallic materials, both ferrous and of nonmetallic materials such as glazed or fully densified ceramics and certain nonporous plastics and glass.

1.2 This practice also provides a reference:

1.2.1 By which a fluorescent liquid penetrant examination, lipophilic post-emulsification process recommended or required by individual organizations can be reviewed to ascertain its applicability and completeness.

1.2.2 For use in the preparation of process specifications dealing with the fluorescent penetrant examination of materials and parts using the lipophilic post-emulsification process. Agreement by the purchaser and the manufacturer regarding specific techniques is strongly recommended.

1.2.3 For use in the organization of the facilities and personnel concerned with the liquid penetrant examination.

1.3 This practice does not indicate or suggest standards for evaluation of the indications obtained. It should be pointed out, however, that indications must be interpreted or classified and then evaluated. For this purpose there must be a separate code or specification or a specific agreement to define the type, size, location, and direction of indications considered acceptable, and those considered unacceptable.

1.3.1 The user is encouraged to use materials and processing parameters necessary to detect conditions of a type or severity which could affect the evaluation of the product.

1.4 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 All areas of this document may be open to agreement between the cognizant engineering organization and the supplier, or specific direction from the cognizant engineering organization.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:E1208 −21

Standard Practice for

Fluorescent Liquid Penetrant Testing Using the Lipophilic

1

Post-Emulsification Process

This standard is issued under the fixed designation E1208; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mathematical conversions to SI units that are provided for

information only and are not considered standard.

1.1 This practice covers procedures for fluorescent liquid

penetrant examination utilizing the lipophilic post- 1.5 All areas of this document may be open to agreement

emulsificationprocess.Itisanondestructivetestingmethodfor between the cognizant engineering organization and the

detecting discontinuities that are open to the surface such as supplier, or specific direction from the cognizant engineering

cracks, seams, laps, cold shuts, laminations, through leaks, or organization.

lack of fusion and is applicable to in-process, final, and

1.6 This standard does not purport to address all of the

maintenance examination. It can be effectively used in the

safety concerns, if any, associated with its use. It is the

examination of nonporous, metallic materials, both ferrous and

responsibility of the user of this standard to establish appro-

of nonmetallic materials such as glazed or fully densified

priate safety, health, and environmental practices and deter-

ceramics and certain nonporous plastics and glass.

mine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accor-

1.2 This practice also provides a reference:

dance with internationally recognized principles on standard-

1.2.1 By which a fluorescent liquid penetrant examination,

ization established in the Decision on Principles for the

lipophilic post-emulsification process recommended or re-

Development of International Standards, Guides and Recom-

quiredbyindividualorganizationscanbereviewedtoascertain

mendations issued by the World Trade Organization Technical

its applicability and completeness.

Barriers to Trade (TBT) Committee.

1.2.2 For use in the preparation of process specifications

dealing with the fluorescent penetrant examination of materials

2. Referenced Documents

and parts using the lipophilic post-emulsification process.

2

2.1 ASTM Standards:

Agreement by the purchaser and the manufacturer regarding

D129 Test Method for Sulfur in Petroleum Products (Gen-

specific techniques is strongly recommended.

eral High Pressure Decomposition Device Method)

1.2.3 For use in the organization of the facilities and

D516 Test Method for Sulfate Ion in Water

personnel concerned with the liquid penetrant examination.

D808 Test Method for Chlorine in New and Used Petroleum

1.3 This practice does not indicate or suggest standards for

Products (High Pressure Decomposition Device Method)

evaluationoftheindicationsobtained.Itshouldbepointedout,

D1552 Test Method for Sulfur in Petroleum Products by

however, that indications must be interpreted or classified and

High Temperature Combustion and Infrared (IR) Detec-

then evaluated. For this purpose there must be a separate code

tion or Thermal Conductivity Detection (TCD)

or specification or a specific agreement to define the type, size,

E165/E165M Practice for Liquid Penetrant Testing for Gen-

location, and direction of indications considered acceptable,

eral Industry

and those considered unacceptable.

E433 Reference Photographs for Liquid Penetrant Inspec-

1.3.1 Theuserisencouragedtousematerialsandprocessing

tion

parameters necessary to detect conditions of a type or severity

E543 Specification forAgencies Performing Nondestructive

which could affect the evaluation of the product.

Testing

1.4 Units—The values stated in inch-pound units are to be

E1316 Terminology for Nondestructive Examinations

regarded as standard. The values given in parentheses are

E2297 GuideforUseofUV-AandVisibleLightSourcesand

Meters used in the Liquid Penetrant and Magnetic Particle

Methods

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.03 on Liquid

2

Penetrant and Magnetic Particle Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2021. Published August 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1987. Last previous edition approved in 2016 as E1208 – 16. DOI: Standards volu

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1208 − 16 E1208 − 21

Standard Practice for

Fluorescent Liquid Penetrant Testing Using the Lipophilic

1

Post-Emulsification Process

This standard is issued under the fixed designation E1208; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers procedures for fluorescent liquid penetrant examination utilizing the lipophilic post-emulsification

process. It is a nondestructive testing method for detecting discontinuities that are open to the surface such as cracks, seams, laps,

cold shuts, laminations, through leaks, or lack of fusion and is applicable to in-process, final, and maintenance examination. It can

be effectively used in the examination of nonporous, metallic materials, both ferrous and of nonmetallic materials such as glazed

or fully densified ceramics and certain nonporous plastics and glass.

1.2 This practice also provides a reference:

1.2.1 By which a fluorescent liquid penetrant examination, lipophilic post-emulsification process recommended or required by

individual organizations can be reviewed to ascertain its applicability and completeness.

1.2.2 For use in the preparation of process specifications dealing with the fluorescent penetrant examination of materials and parts

using the lipophilic post-emulsification process. Agreement by the purchaser and the manufacturer regarding specific techniques

is strongly recommended.

1.2.3 For use in the organization of the facilities and personnel concerned with the liquid penetrant examination.

1.3 This practice does not indicate or suggest standards for evaluation of the indications obtained. It should be pointed out,

however, that indications must be interpreted or classified and then evaluated. For this purpose there must be a separate code or

specification or a specific agreement to define the type, size, location, and direction of indications considered acceptable, and those

considered unacceptable.

1.3.1 The user is encouraged to use materials and processing parameters necessary to detect conditions of a type or severity which

could affect the evaluation of the product.

1.4 Units—The values stated in inch-pound units are to be regarded as standard. SI unitsThe values given in parentheses are for

information only.mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 All areas of this document may be open to agreement between the cognizant engineering organization and the supplier, or

specific direction from the cognizant engineering organization.

1

This practice is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.03 on Liquid Penetrant

and Magnetic Particle Methods.

Current edition approved June 1, 2016July 1, 2021. Published June 2016August 2021. Originally approved in 1987. Last previous edition approved in 20102016 as

E1208 - 10.E1208 – 16. DOI: 10.1520/E1208-16.10.1520/E1208-21.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1208 − 21

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D129 Test Method for Sulfur in Petroleum Products (General High Pressure Decomposition Device Method)

D516 Test Method for Sulfate Ion in Water

D808 Test Method for Chlorine in New and Used Petroleum Products (High Pressure Decomposition Device Method)

D1552 Test Method for Sulfur in Petroleum Products by High Temperature Combustion and Infrared (IR) Detection or Thermal

Conductivity Detection (TCD)

E165/E165M Practice for Liquid Penetrant Testing for General Industry

E433 R

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.