ASTM E2322-03

(Test Method)Standard Test Method for Conducting Traverse and Concentrated Load Tests on Panels used in Floor and Roof Construction

Standard Test Method for Conducting Traverse and Concentrated Load Tests on Panels used in Floor and Roof Construction

SIGNIFICANCE AND USE

Transverse Load—The procedures outlined will serve to evaluate the performance of floor and roof segments for deflection, permanent set and ultimate capacity. Performance criteria based on data from these procedures can ensure structural adequacy and effective service.

Concentrated Load—This concentrated load test shall be used to evaluate surface indentation of structural framing members.

These procedures will serve to evaluate performance of roof and floor segments under simulated service conditions. Diaphragm shear loading of roof and floor segments shall be evaluated under Method E 455. Impact loading shall be evaluated under Test Methods E 661 or E 695.

SCOPE

1.1 These test methods cover the following procedures for determining the structural properties of segments of floor and roof constructions:SectionTest SpecimensLoadingDeformation MeasurementsReportPrecision and BiasTesting FloorsTransverse LoadConcentrated LoadTesting RoofsTransverse LoadConcentrated Load

1.2 Metric units (SI) are to be considered as the primary standard units.

1.3 These test methods serve to evaluate the performance of floors and roofs panels subjected to (1) Uniform loading, and (2) Concentrated static loading, which represent conditions sustained in the actual performance of the element. The standard is not intended for the evaluation of individual structural framing and/or supporting members (floor joist, rafters and trusses).

1.4 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes, excluding those in tables and figures, shall not be considered as requirements of the standard.

1.5 This standard is not intended to cover concrete floor slabs.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2322–03

Standard Test Method for

Conducting Transverse and Concentrated Load Tests on

Panels used in Floor and Roof Construction

This standard is issued under the fixed designation E 2322; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 These test methods cover the following procedures for 2.1 ASTM Standards:

determining the structural properties of segments of floor and C 109 Test Method for Compressive Strength of Hydraulic

roof constructions: Cement Mortars

E4 Practices for Force Verification of Testing Machines

Section

Test Specimens 5

E72 Method of Conducting Strength Tests of Panels for

Loading 6

Building Construction

Deformation Measurements 7

E 73 Method of Testing Truss Assemblies

Report 8

Precision and Bias 9

E 196 Practice for Gravity Load Testing of Floors and Low

Testing Floors

Slope Roofs

Transverse Load 10

Concentrated Load 11 E 455 Method for Static Load Testing of Framed Floor or

Testing Roofs

Roof Diaphragm Constructions for Buildings

Transverse Load 12

E 575 Practice for Reporting Data from Structural Tests of

Concentrated Load 13

Building Constructions, Elements, Connections, and As-

1.2 Metric units (SI) are to be considered as the primary

semblies

standard units.

E 631 Terminology of Building Constructions

1.3 These test methods serve to evaluate the performance of

E 661 Test Method for Performance of Wood and Wood-

floors and roofs panels subjected to (1) Uniform loading, and

Based Floor and Roof Sheathing Under Concentrated

(2) Concentrated static loading, which represent conditions

Static and Impact Loads

sustained in the actual performance of the element. The

E 695 Test Method of Measuring Relative Resistance of

standard is not intended for the evaluation of individual

Wall, Floor, and Roof Constructions to Impact Loads

structural framing and/or supporting members (floor joist,

E 1592 Test Method for Structural Performance of Sheet

rafters and trusses).

Metal Roof and Siding Systems by Uniform Static Air

1.4 The text of this standard references notes and footnotes

Pressure Difference

whichprovideexplanatorymaterial.Thesenotesandfootnotes,

excludingthoseintablesandfigures,shallnotbeconsideredas 3. Terminology

requirements of the standard.

3.1 Definitions—Refer to E 631 for definitions of terms

1.5 This standard is not intended to cover concrete floor

used in these test methods.

slabs.

1.6 This standard does not purport to address all of the 4. Significance and Use

safety concerns, if any, associated with its use. It is the

4.1 Transverse Load—Theproceduresoutlinedwillserveto

responsibility of the user of this standard to establish appro-

evaluate the performance of floor and roof segments for

priate safety and health practices and determine the applica-

deflection, permanent set and ultimate capacity. Performance

bility of regulatory limitations prior to use.

criteria based on data from these procedures can ensure

structural adequacy and effective service.

This test method is under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.11 For referenced ASTM standards, visit the ASTM website, www.astm.org, or

on Horizontal and Vertical Structures/Structural Performance of Completed Struc- contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

tures. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2003. Published November 2003. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2322–03

4.2 Concentrated Load—This concentrated load test shall deformation curves. Maintain complete load-deformation time

be used to evaluate surface indentation of structural framing records throughout the test. If application of a given load is

members. required for a certain period, such as 24 h, take deformation

4.3 These procedures will serve to evaluate performance of readings at the end of this period, to allow the satisfactory

roof and floor segments under simulated service conditions. plotting of a time-deformation curve for the complete period.

Diaphragm shear loading of roof and floor segments shall be

NOTE 1—Reason for the 5-min application of constant-level increment

evaluated under Method E 455. Impact loading shall be evalu-

loads are as follows:

ated under Test Methods E 661 or E 695.

(1) To permit the assembly to come to a substantial rest prior to taking

the second set of readings. (Depending on the method employed for

5. Test Specimens

applying the test load, it may be necessary to continue, at a reduced rate,

5.1 Specimens—There shall be at least three replicate speci- the motion of the loading device in order to maintain the constant load

level during the 5-min period.)

mens for each test. Specimens shall be constructed to represent

(2) To observe any time-dependent deformation or load redistribution,

sections of the floor, or roof assembly including the means of

or both, and to record accurately the load level when time-dependent

the attachment when the load direction is away from the

deformation starts, that is, at the divergence of the immediate and delayed

supports. The specimens shall be representative in width and

load-deformation curves. This load level may, under certain conditions,

length as to the material and workmanship. The test specimen

have an important bearing on the design load.

shall not be less than the width and length of the tributary load

(3) To be able to stop the test, if this should be desirable, prior to total

area under actual conditions. If the tributary load area for the

failure, after initial failure has been anticipated as a result of the

test specimen exceeds the test equipment, a reduced specimen

observations.

that is representative in proportional width and length shall be (4) To assure uniformity in test performance and consistency in test

results.

tested. Unsymmetrical assemblies shall be tested in each axis.

If the structural properties of a particular construction are to be

7. Deformation Measurements

compared with another construction, widths of the specimens

shall be of comparable size. 7.1 Measure the deformations with sufficient precision to

define the load-deformation relationship, and report at least to

5.2 Age—Constructions, which include concrete and ma-

sonry for which the structural properties depend upon the age the nearest 0.25 mm (0.01 in.).

of the specimen, shall be aged not less than what is indicated

by the manufacturer and/or national standard. The age of the 8. Report

specimen shall be recorded in the report.

8.1 Prepare the report in accordance with Recommended

Practice E 575.

6. Loading

6.1 Apparatus—The testing machine or load-measuring ap-

9. Precision and Bias

paratus shall comply with the requirements prescribed in

9.1 It is not possible to specify the precision of the proce-

PracticesE4.

dure in Test Method E 2322 for measuring these test methods

6.2 Application of Load—Apply the load to each individual

because of the variety of materials and combinations of

specimen in increments so that a sufficient number of readings

materials involved.

will be obtained to determine definitely the load-deformation

curve (see 6.3) using the following sequence:

TESTING FLOORS

6.2.1 Prior to testing, apply a small initial load not greater

than 5 % of the ultimate capacity load expected and hold for 5

10. Transverse Load—Floor

min (6 1 min) and then release. Zero all measuring devices

and begin the test. 10.1 Test Specimen(s)—Test specimen(s) shall be con-

structed in accordance with Section 5.

6.2.2 Record the initial load and deformation reading of the

specimenandthenincreasetheloadonthespecimentothefirst 10.2 Apparatus—The apparatus shall be capable of apply-

ing a uniform load (such as air bag load or vacuum load),

predetermined increment.

6.2.3 Record the load and deformation reading and release gravity load or two point load and shall conform to the

the load back to the initial load and then record the set of the requirementsprescribedin10.2.1through10.2.3ortheequiva-

specimen. lent.

6.2.4 Increase the load to the next predetermined increment 10.2.1 Uniform Load—Uniformly distributed loading is a

and record the information as indicated in the first load satisfactory test method. Uniformly distributed load shall be

increment above. Follow this sequence of loading and reading appliedbyairpressure,eitherinabagorinavacuumchamber.

for all predetermined load increment(s). 10.2.1.1 The bag method of loading is schematically shown

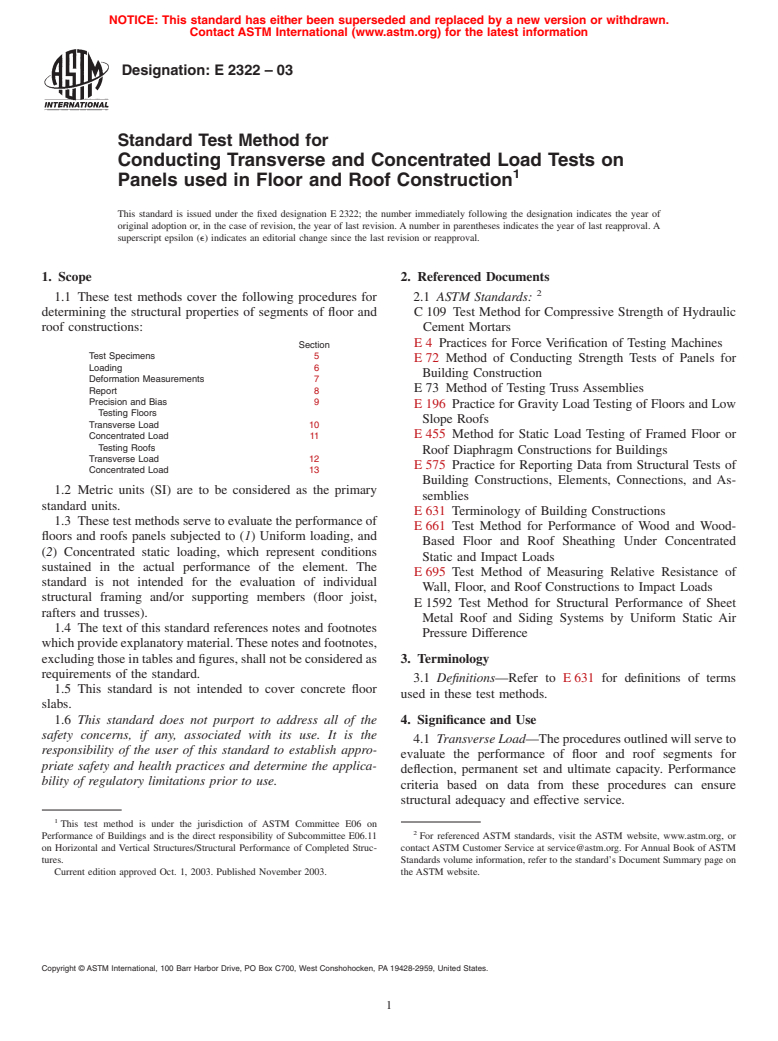

6.3 Duration of Load Application—After each increment of in Fig. 1. Connect a reaction platform parallel to the face to be

load is applied, maintain the load level as constant as possible loaded and wider than the specimen to the supports by tie rods.

for a period of 5 min (see Note 1). Take deformation readings Placeanairtightbagaswideasthespecimenandaslongasthe

as soon as practical after load application, at the end of the span between the specimen and the reaction platform. Apply

5-min period under constant load, and immediately and at the transverse load to the specimen by increasing the air pressure

end of the 5-min period after any partial or complete load in the bag. Measure the difference in pressure by means of a

release. Plot initial and 5-min readings in the form of load- manometer or other pressure measuring device. The error of

E2322–03

FIG. 1 Apparatus for Uniformly Distributed Transverse Load (Bag Method)

the pressure reading shall not exceed 1 % of the full-scale at a distance of one-quarter of the span from the supports,

reading. Deflection measurement shall be measured following

toward the middle of the span. For floor specimens tested

10.4. See Fig. 1.

horizontally(Fig.1),theloadonthespecimenshallincludethe

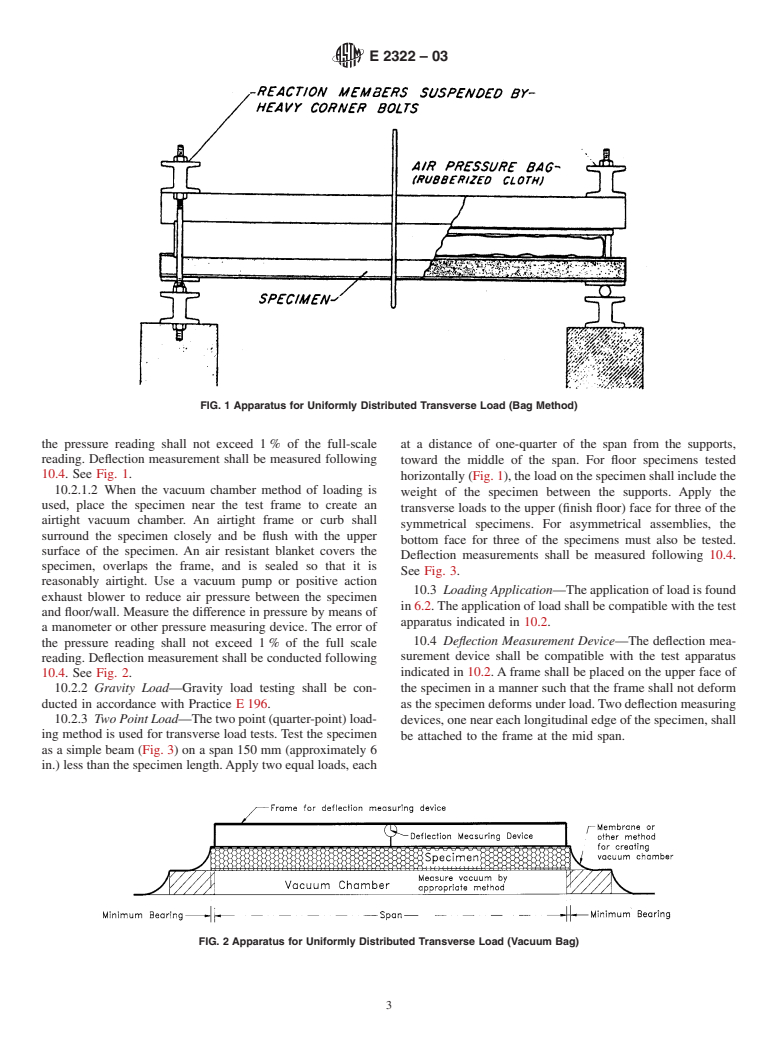

10.2.1.2 When the vacuum chamber method of loading is

weight of the specimen between the supports. Apply the

used, place the specimen near the test frame to create an

transverse loads to the upper (finish floor) face for three of the

airtight vacuum chamber. An airtight frame or curb shall

symmetrical specimens. For asymmetrical assemblies, the

surround the specimen closely and be flush with the upper

bottom face for three of the specimens must also be tested.

surface of the specimen. An air resistant blanket covers the

Deflection measurements shall be measured following 10.4.

specimen, overlaps the frame, and is sealed so that it is

See Fig. 3.

reasonably airtight. Use a vacuum pump or positive action

10.3 Loading Application—The application of load is found

exhaust blower to reduce air pressure between the specimen

in 6.2.The application of load shall be compatible with the test

and floor/wall. Measure the difference in pressure by means of

apparatus indicated in 10.2.

a manometer or other pressure measuring device. The error of

10.4 Deflection Measurement Device—The deflection mea-

the pressure reading shall not exceed 1 % of the full scale

surement device shall be compatible with the test apparatus

reading. Deflection measurement shall be conducted following

indicated in 10.2.Aframe shall be placed on the upper face of

10.4. See Fig. 2.

10.2.2 Gravity Load—Gravity load testing shall be con- the specimen in a manner such that the frame shall not deform

ducted in accordance with Practice E 196. as the specimen deforms under load.Two deflection measuring

10.2.3 Two Point Load—Thetwopoint(quarter-point)load-

devices, one near each longitudinal edge of the specimen, shall

ing method is used for transverse load tests. Test the specimen

be attached to the frame at the mid span.

as a simple beam (Fig. 3) on a span 150 mm (approximately 6

in.) less than the specimen length.Apply two equal loads, each

FIG. 2 Apparatus for Uniformly Distributed Transverse Load (Vacuum Bag)

E2322–03

FIG. 3 Quarter Point Loading

10.4.1 Method A—Deflection Measuring Device Top of shall be notched to permit placing the measuring device

Panel—Midspandeflectionshallbemeasuredonthetopofthe directly adjacent to the bar and shall be long enough to permit

panel. The deflection measurement should be referenced to the placing the supporting elements on undisturbed areas of the

panel deflection at the end supports. face of the specimen.

10.4.2 Method B—Deflection Measuring Device Bottom of

11.2.3 Loading Device—Any convenient means for apply-

Panel—Mid span deflection shall be measured on the bottom

ing a compressive load up to 5 kN (1100 lbf) and means for

of the panel. The deflection measurement should be referenced

measuring the load within 1 %. See Fig. 4.

to the panel deflection at the end supports.

11.3 Procedure:

10.5 Calculations and Report:

11.3.1 Loading—Place the entire specimen or portion of the

10.5.1 Load-Deflection Data—For each deflection measur-

specimen on a horizontal support and level the specimen.

ing device, calculate the deflection under a given load as the

Apply the loads on the face of the specimen. Place the steel bar

differencebetweenthereadingwhentheloadisappliedandthe

on the surface of the specimen at what is judged to be the

initial reading. Calculate the deflection of the specimen for the

weakest place and, also, at what is judged to be the strongest

spanastheaverageofthedeflectionsobtainedfromeachofthe

place.Applyaloadverticallydownwardtotheuppersurfaceof

measuring devices. Calculate the sets under the initial load by

the bar. Continue loading until maximum load or 4.45 kN

using a similar method. Record the maximum load for each

(1000 lbf) is attained on the steel bar. Application of load is

specimen.

found in 5.2.

10.5.2 Data Presentation—Report the results in the form of

11.3.2 Depth of Indentation—Measure the depth of inden-

a graph in accordance with Section 8.

tation, by means of the depth gage, and record the reading of

the gage to the nearest 0.025 mm (0.001 in.).

11. Concentrated Load—Floor

11.4 Calculations and Report:

11.1 Test Specimens—Tests shall be made on each of the

11.4.1 Depth of Indentation—Calculate the depth of inden-

transverse specimens after the transverse tests are completed.

tation (set) after a given load has been applied and the bar

11.2 Apparatus—The apparatus shall be assembled as

removed to the nearest 0.025 mm (0.001 in.) as the difference

shown in Fig. 4 and shall conform to the requirements for

between the depth for that load and the initial rea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.