ASTM B559-93(2007)

(Specification)Standard Specification for Nickel-Coated, Copper-Clad Steel Wire for Electronic Application

Standard Specification for Nickel-Coated, Copper-Clad Steel Wire for Electronic Application

ABSTRACT

This specification covers nickel-coated, round, copper-clad steel wire for electronic applications. The nickel-coated wire shall consist of the basis wire coated with nickel. Tensile strength and elongation of the nickel-coated wire shall conform to the specified requirements for the applicable size and class of copper-clad steel wire. The electrical resistivity shall not exceed the values specified. Continuity, adherence, and mass of the coating shall be determined. Necessary joints in the wire and rod prior to final coating and drawing shall be made.

SCOPE

1.1 This specification covers nickel-coated, round, copper-clad steel wire for electronic application.

1.2 Nickel coatings in mass percentages of the total mass of the coated wire are as follows: 2, 4, 7, 10, and 27 %. Nickel-coated wire having different minimum mass percentages of nickel may be obtained by mutual agreement between the manufacturer and the purchaser. For information purposes, the thickness of coating in microinches provided by the percentages listed above is shown in .

1.3 Four classes of nickel-coated, copper-clad steel wire are covered as follows:

1.3.1 Class N30HS - Nominal 30 % conductivity, hard drawn.

1.3.2 Class N30A - Nominal 30 % conductivity, annealed.

1.3.3 Class N40HSNominal 40 % conductivity, hard drawn.

1.3.4 Class N40A - Nominal 40 % conductivity, annealed.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only, except for resistivity, where the SI units are to be regarded as the standard.

The following safety hazards caveat pertains only to the test method described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (Warning-Consideration should be given to toxicity and flammability when selecting solvent cleaners.)

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B559 −93(Reapproved 2007)

Standard Specification for

Nickel-Coated, Copper-Clad Steel Wire for Electronic

Application

This standard is issued under the fixed designation B559; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

2.1 The following documents of the issue in effect on date

1.1 This specification covers nickel-coated, round, copper-

of material purchase form a part of this specification to the

clad steel wire for electronic application.

extent referenced herein:

1.2 Nickel coatings in mass percentages of the total mass of

2.2 ASTM Standards:

the coated wire are as follows: 2, 4, 7, 10, and 27%.

B193Test Method for Resistivity of Electrical Conductor

Nickel-coated wire having different minimum mass percent-

Materials

ages of nickel may be obtained by mutual agreement between

B258 Specification for Nominal Diameters and Cross-

the manufacturer and the purchaser. For information purposes,

SectionalAreasofAWGSizesofSolidRoundWiresUsed

the thickness of coating in microinches provided by the

as Electrical Conductors

percentages listed above is shown in Table 1.

B452Specification for Copper-Clad Steel Wire for Elec-

tronic Application

1.3 Four classes of nickel-coated, copper-clad steel wire are

E75Test Methods for Chemical Analysis of Copper-Nickel

covered as follows:

and Copper-Nickel-Zinc Alloys (Withdrawn 2010)

1.3.1 Class N30HS—Nominal 30 % conductivity, hard

2.3 American Chemical Society:

drawn.

StandardReagents Tests

1.3.2 Class N30A—Nominal 30% conductivity, annealed.

2.4 NIST Standard:

1.3.3 Class N40HS—Nominal 40 % conductivity, hard

NBS Handbook 100 Copper Wire Tables

drawn.

1.3.4 Class N40A—Nominal 40% conductivity, annealed.

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

1.4 The values stated in inch-pound units are to be regarded

3.1.1 lot—any amount of wire of one class and size pre-

as the standard. The values given in parentheses are for

sented for acceptance at one time, such amount, however, not

information only, except for resistivity, where the SI units are

to exceed 10000 lb (4500 kg) (Note 1).

to be regarded as the standard.

NOTE1—Alotshouldcomprisematerialtakenfromaproductregularly

1.5 The following safety hazards caveat pertains only to the

meeting the requirements of this specification. Inspection of individual

test method described in this specification.This standard does

lots of less than 500 lb (230 kg) of wire cannot be justified economically.

not purport to address all of the safety concerns, if any,

associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices 2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and determine the applicability of regulatory limitations prior

Standards volume information, refer to the standard’s Document Summary page on

to use. (Warning—Consideration should be given to toxicity

the ASTM website.

and flammability when selecting solvent cleaners.)

The last approved version of this historical standard is referenced on

www.astm.org.

Reagent Chemicals, American Chemical Society Specifications , American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

This specification is under the jurisdiction of ASTM Committee B01 on listed by the American Chemical Society, see Analar Standards for Laboratory

Electrical Conductors and is the direct responsibility of Subcommittee B01.06 on Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Composite Conductors. and National Formulary,U.S.PharmaceuticalConvention,Inc.(USPC),Rockville,

Current edition approved Oct. 1, 2007. Published October 2007. Originally MD.

´1 5

approved in 1972. Last previous edition approved in 2002 as B559–93 (2002) . Available from National Institute of Standards and Technology (NIST), 100

DOI: 10.1520/B0559-93R07. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B559−93 (2007)

TABLE 1 Nickel Mass Percent and Thickness of Coating

Thickness of Nickel,µ in.

Diameter Cross-Sectional Area at 20°C

(for information only)

2 2

in. mm cmil in. mm 2.0 % 4.0 % 7.0 % 10.0 % 27.0 %

0.0720 1.829 5 180 0.00407 2.63 334 637 1 181 1 703 4 892

0.0641 1.628 4 110 0.00323 2.08 298 566 1 050 1 514 4 349

0.0571 1.450 3 260 0.00256 1.65 266 505 936 1 350 3 880

0.0508 1.290 2 580 0.00203 1.31 236 450 833 1 200 3 452

0.0453 1.151 2 050 0.00161 1.04 211 401 743 1 071 3 077

0.0403 1.024 1 620 0.00128 0.823 202 357 661 953 2 738

0.0359 0.912 1 290 0.00101 0.653 167 318 589 849 2 439

0.0320 0.813 1 020 0.000804 0.519 149 283 525 757 2 174

0.0285 0.724 812 0.000638 0.412 133 252 467 686 1 937

0.0253 0.643 640 0.000503 0.324 118 224 415 598 1 719

0.0226 0.574 511 0.000401 0.259 105 200 371 535 1 536

0.0201 0.511 404 0.000317 0.205 94 178 330 475 1 366

0.0179 0.455 320 0.000252 0.162 83 158 294 423 1 216

0.0159 0.404 253 0.000199 0.128 74 141 261 376 1 080

0.0142 0.361 202 0.000158 0.102 66 126 233 336 965

0.0126 0.320 159 0.000125 0.0804 59 112 207 298 856

0.0113 0.287 128 0.000100 0.0647 53 100 185 267 768

0.0100 0.254 100 0.0000785 0.0507 47 89 164 237 680

0.0089 0.226 79.2 0.0000622 0.0401 41 80 146 211 605

0.0080 0.203 64.0 0.0000503 0.0324 . 71 131 189 544

0.0071 0.180 50.4 0.0000396 0.0255 . 63 116 168 482

0.0063 0.160 39.7 0.0000312 0.0201 . 56 103 149 428

0.0056 0.142 31.4 0.0000246 0.0159 . 50 92 132 381

0.0050 0.127 25.0 0.0000196 0.0127 . 44 82 118 340

0.0045 0.114 20.2 0.0000159 0.0103 . 40 74 106 306

0.0040 0.102 16.0 0.0000126 0.00811 . . 66 95 272

0.0035 0.089 12.2 0.00000962 0.00621 . . 57 83 238

0.0031 0.079 9.61 0.00000755 0.00487 . . 51 73 211

For small lots of 500 lb (230 kg) or less, the purchaser may agree to the NOTE2—Nickeloncopper-cladsteelwireprovidesaprotectivecoating

manufacturers’regularinspectionoftheproductasawholeasevidenceof for a prevention of oxidation of the copper either during fabrication or

acceptability of such small lots. service.

3.1.2 sample—a quantity of production units (coils, reels,

6. General Requirements

etc.) selected at random from the lot for the purpose of

6.1 Tensile strength and elongation of the nickel-coated

determining conformance of the lot to the requirements of this

wire shall conform to the requirements of Specification B452

specification.

for the applicable size and class of copper-clad steel wire.

3.1.3 specimen—a length of wire removed for test purposes

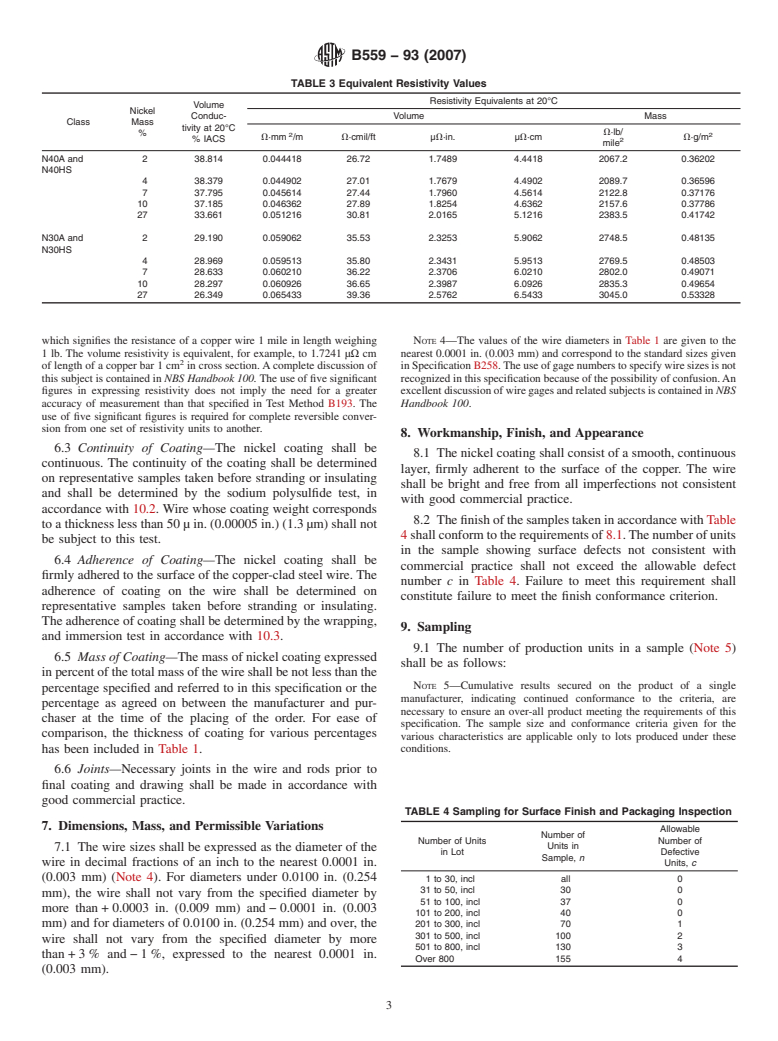

6.2 Resistivity—The electrical resistivity at a temperature of

from any individual production unit of the sample.

20°C shall not exceed the values prescribed in Table 2. See

4. Ordering Information

Note 3 for calculating electrical resistance.

4.1 Ordersformaterialunderthisspecificationshallinclude

NOTE 3—Relationships which may be useful in connection with the

the following information:

values of electrical resistivity prescribed in this specification are shown in

2 2

Table 3. Resistivity units ⁄58Ω-mm /m and 0.15328Ω-g/m at 20°C are

4.1.1 Quantity of each size.

respectivelytheinternationalequivalentofvolumeandmassresistivityof

4.1.2 Wire size (see Section 7 and Table 1).

annealed copper equal to 100% conductivity. The latter term means that

4.1.3 Class of basis wire (see 1.3).

a copper wire1min length and weighing 1 g would have a resistance of

4.1.4 Mass percentage of nickel coating (see 1.2 and

0.15328Ω. This is equivalent to a resistivity value of 875.20Ω·lb/mile ,

Table 1).

4.1.5 Package size (see 14.2 and Section 14). Packaging

TABLE 2 Resistivity

inspection, if required (see 9.1.3).

Resistivity, max at 20°C

4.1.6 Special package marking, if required.

Class of Wire Nickel V-mm /m

4.1.7 Place of inspection (see 13.1).

Mass %

N30A and N30HS 2 0.05906 (0.059062)

5. Materials and Manufacture

4 0.05951 (0.059513)

7 0.06021 (0.060210)

5.1 Thebasismaterialshallconsistofcopper-cladsteelwire

10 0.06093 (0.060926)

conforming to the product description, quality and specifica-

27 0.06543 (0.065433)

tion requirements of Specification B452.

N40A and N40HS 2 0.04442 (0.044418)

5.2 The nickel-coated wire shall consist of the basis wire 4 0.04490 (0.044902)

7 0.04561 (0.045614)

coated with nickel (Note 2). The quality of the nickel-coated

10 0.04636 (0.046362)

wireshallbesuchthatthefinishedproductmeetstheproperties

27 0.05122 (0.051216)

and requirements in this specification.

B559−93 (2007)

TABLE 3 Equivalent Resistivity Values

Resistivity Equivalents at 20°C

Volume

Nickel

Conduc- Volume Mass

Class Mass

tivity at 20°C

V·lb/

% 2 2

V·mm /m V·cmil/ft µV·in. µV·cm V·g/m

% IACS

mile

N40A and 2 38.814 0.044418 26.72 1.7489 4.4418 2067.2 0.36202

N40HS

4 38.379 0.044902 27.01 1.7679 4.4902 2089.7 0.36596

7 37.795 0.045614 27.44 1.7960 4.5614 2122.8 0.37176

10 37.185 0.046362 27.89 1.8254 4.6362 2157.6 0.37786

27 33.661 0.051216 30.81 2.0165 5.1216 2383.5 0.41742

N30A and 2 29.190 0.059062 35.53 2.3253 5.9062 2748.5 0.48135

N30HS

4 28.969 0.059513 35.80 2.3431 5.9513 2769.5 0.48503

7 28.633 0.060210 36.22 2.3706 6.0210 2802.0 0.49071

10 28.297 0.060926 36.65 2.3987 6.0926 2835.3 0.49654

27 26.349 0.065433 39.36 2.5762 6.5433 3045.0 0.53328

which signifies the resistance of a copper wire 1 mile in length weighing NOTE 4—The values of the wire diameters in Table 1 are given to the

1 lb. The volume resistivity is equivalent, for example, to 1.7241 µΩ cm nearest 0.0001 in. (0.003 mm) and correspond to the standard sizes given

of length of a copper bar 1 cm in cross section.Acomplete discussion of inSpecificationB258.Theuseofgagenumberstospecifywiresizesisnot

thissubjectiscontainedin NBS Handbook 100.Theuseoffivesignificant recognizedinthisspecificationbecauseofthepossibilityofconfusion.An

figures in expressing resistivity does not imply the need for a greater excellentdiscussionofwiregagesandrelatedsubjectsiscontainedin NBS

accuracy of measurement than that specified in Test Method B193. The Handbook 100.

use of five significant figures is required for complete reversible conver-

sion from one set of resistivity units to another.

8. Workmanship, Finish, and Appearance

6.3 Continuity of Coating—The nickel coating shall be

8.1 Thenickelcoatingshallconsistofasmooth,continuous

continuous. The continuity of the coating shall be determined

layer, firmly adherent to the surface of the copper. The wire

on representative samples taken before stranding or insulating

shall be bright and free from all imperfections not consistent

and shall be determined by the sodium polysulfide test, in

with good commercial practice.

accordance with 10.2.Wire whose coating weight corresponds

8.2 ThefinishofthesamplestakeninaccordancewithTable

toathicknesslessthan50µin.(0.00005in.)(1.3µm)shallnot

4shallconformtotherequirementsof8.1.Thenumberofunits

be subject to this test.

in the sample showing surface defects not consistent with

6.4 Adherence of Coating—The nickel coating shall be

commercial practice shall not exceed the allowable defect

firmlyadheredtothesurfaceofthecopper-cladsteelwire.The

number c in Table 4. Failure to meet this requirement shall

adherence of coating on the wire shall be determined on

constitute failure to meet the finish conformance criterion.

representative samples taken before stranding or insulating.

Theadherenceofcoatingshallbedeterminedbythewrapping,

9. Sampling

and immersion test in accordance with 10.3.

9.1 The number of production units in a sample (Note 5)

6.5 Mass of Coating—Themassofnickelcoatingexpressed

shall be as follows:

inpercentofthetotalmassofthewireshallbenotlessthanthe

NOTE 5—Cumulative results secured on the product of a single

percentage specified and referred to in this specification or the

manufacturer, indicating continued conformance to the criteria, are

percentage as agreed on between the manufacturer and pur-

necessary to ensure an over-all product meeting the requirements of this

chaser at the time of the placing of the order. For ease of

specification. The sample size and conformance criteria given for the

comparison, the thickness of coating for various percentages

various characteristics are applicable only to lots produced under these

conditions.

has been included in Table 1.

6.6 Joints—Necessary joints in the wire and rods prior to

final coating and drawing shall be made in accordance with

good commercial practice.

TABLE 4 Sampling for Surface Finish and Packaging Inspection

7. Dimensions, Mass, and Permissible Variations

Allowable

Number of

Number of Units Number of

Units in

7.1 The wire sizes shall be expressed as the diameter of the

in Lot Defective

Sample, n

wire in decimal fractions of an inch to the nearest 0.0001 in. Units, c

(0.003 mm) (Note 4). For diameters under 0.0100 in. (0.254 1 to 30, incl all 0

31 to 50, incl 30 0

mm), the wire shall not vary from the specified diameter by

51 to 100, incl 37 0

more than+0.0003 in. (0.009 mm) and−0.0001 in. (0.003

101 to 200, incl 40 0

mm) and for diameters of 0.0100 in. (0.254 mm) and over, the 201 to 300, incl 70 1

301 to 500, incl 100 2

wire shall not vary from the specified diameter by more

501 to 800, incl 130 3

than+3% and−1%, expressed to the nearest 0.0001 in.

Over 800 155 4

(0.003 mm).

B559−93 (2007)

9.1.1 For tensile strength, elongation, resistivity, mass of 10.2.2 Special Solution (sp gr 1.142) —Make concentrated

coating and adhesion and other defects, the sample shall solution by dissolving sodium sulfide crystals (cp) in distilled

consistoffourproductionunits.Forsurfacefinishthesampling water until the solution is saturated at about 21°C (70°F), and

shall be in accordance with Table 4. From each unit, one test add sufficient flowers of sulfur (in excess of 250 g/L of

specimen of sufficient length shall be removed for the perfor- solution) to provide complete saturation, as shown by the

mance of required tests. presenceinthesolutionofanexcessofsulfurafterthesolution

9.1.2 For dimensional measurements, the sample shall con- has been allowed to stand for at least 24 h. Make the test

sist of a quantity of production units shown in Table 5 under solution by diluting a portion of the concentrated solution with

heading“ First Sample.” distilled water to a speci

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.