ASTM B559-12

(Specification)Standard Specification for Nickel-Coated, Copper-Clad Steel Wire for Electronic Application

Standard Specification for Nickel-Coated, Copper-Clad Steel Wire for Electronic Application

ABSTRACT

This specification covers nickel-coated, round, copper-clad steel wire for electronic applications. The nickel-coated wire shall consist of the basis wire coated with nickel. Tensile strength and elongation of the nickel-coated wire shall conform to the specified requirements for the applicable size and class of copper-clad steel wire. The electrical resistivity shall not exceed the values specified. Continuity, adherence, and mass of the coating shall be determined. Necessary joints in the wire and rod prior to final coating and drawing shall be made.

SCOPE

1.1 This specification covers nickel-coated, round, copper-clad steel wire for electronic application.

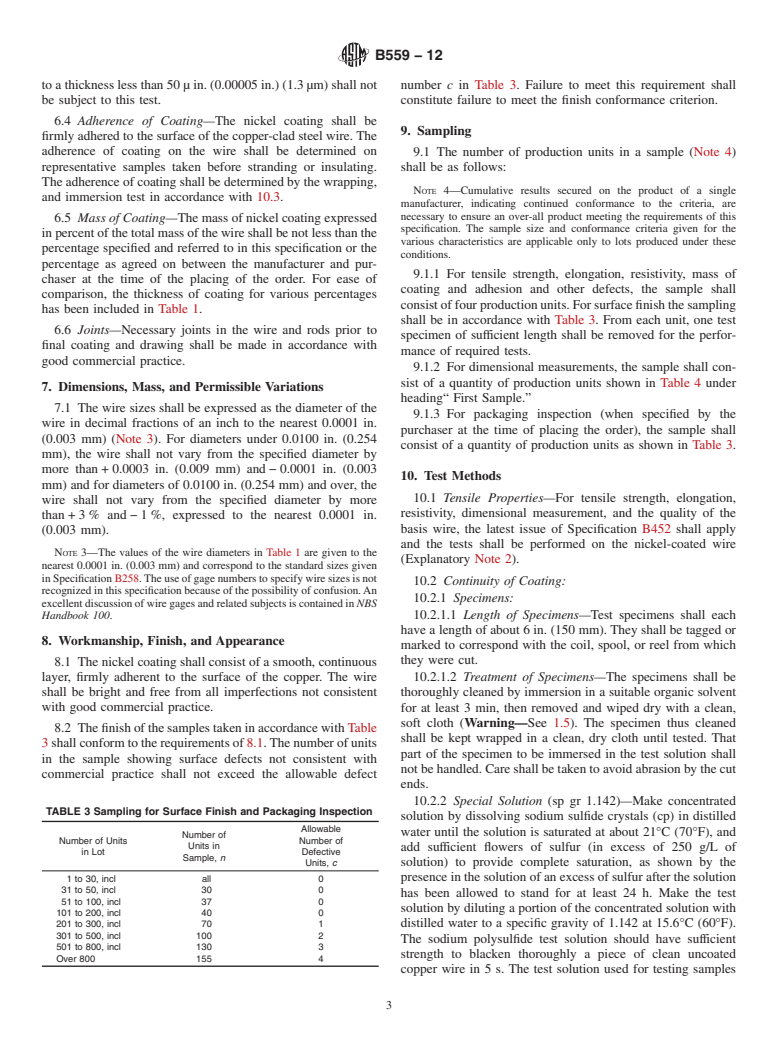

1.2 Nickel coatings in mass percentages of the total mass of the coated wire are as follows: 2, 4, 7, 10, and 27 %. Nickel-coated wire having different minimum mass percentages of nickel may be obtained by mutual agreement between the manufacturer and the purchaser. For information purposes, the thickness of coating in microinches provided by the percentages listed above is shown in Table 1.TABLE 1 Nickel Mass Percent and Thickness of Coating

Diameter

Cross-Sectional Area at 20°C

Thickness of Nickel,μ in.

(for information only)

in.

mm

cmil

in.2

mm2

2.0 %

4.0 %

7.0 %

10.0 %

27.0 %

0.0720

1.829

5 180

0.00407

2.63

334

637

1 181

1 703

4 892

0.0641

1.628

4 110

0.00323

2.08

298

566

1 050

1 514

4 349

0.0571

1.450

3 260

0.00256

1.65

266

505

936

1 350

3 880

0.0508

1.290

2 580

0.00203

1.31

236

450

833

1 200

3 452

0.0453

1.151

2 050

0.00161

1.04

211

401

743

1 071

3 077

0.0403

1.024

1 620

0.00128

0.823

202

357

661

953

2 738

0.0359

0.912

1 290

0.00101

0.653

167

318

589

849

2 439

0.0320

0.813

1 020

0.000804

0.519

149

283

525

757

2 174

0.0285

0.724

812

0.000638

0.412

133

252

467

686

1 937

0.0253

0.643

640

0.000503

0.324

118

224

415

598

1 719

0.0226

0.574

511

0.000401

0.259

105

200

371

535

1 536

0.0201

0.511

404

0.000317

0.205

94

178

330

475

1 366

0.0179

0.455

320

0.000252

0.162

83

158

294

423

1 216

0.0159

0.404

253

0.000199

0.128

74

141

261

376

1 080

0.0142

0.361

202

0.000158

0.102

66

126

233

336

965

0.0126

0.320

159

0.000125

0.0804

59

112

207

298

856

0.0113

0.287

128

0.000100

0.0647

53

100

185

267

768

0.0100

0.254

100

0.0000785

0.0507

47

89

164

237

680

0.0089

0.226

79.2

0.0000622

0.0401

41

80

146

211

605

0.0080

0.203

64.0

0.0000503

0.0324

...

71

131

189

544

0.0071

0.180

50.4

0.0000396

0.0255

...

63

116

168

482

0.0063

0.160

39.7

0.0000312

0.0201

...

56

103

149

428

0.0056

0.142

31.4

0.0000246

0.0159

...

50

92

132

381

0.0050

0.127

25.0

0.0000196

0.0127

...

44

82

118

340

0.0045

0.114

20.2

0.0000159

0.0103

...

40

74

106

306

0.0040

0.102

16.0

0.0000126

0.00811

...

...

66

95

272

0.0035

0.089

12.2

0.00000962

0.00621

...

...

57

83

238

0.0031

0.079

9.61

0.00000755

0.00487

...

...

51

73

211

1.3 Four classes of nickel-coated, copper-clad steel wire are covered as follows:

1.3.1 Class N30HS—Nominal 30 % conductivity, hard drawn.

1.3.2 Class N30A—Nominal 30 % conductiv...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B559 −12

Standard Specification for

Nickel-Coated, Copper-Clad Steel Wire for Electronic

1

Application

This standard is issued under the fixed designation B559; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2.1 The following documents of the issue in effect on date

1.1 This specification covers nickel-coated, round, copper-

of material purchase form a part of this specification to the

clad steel wire for electronic application.

extent referenced herein:

1.2 Nickel coatings in mass percentages of the total mass of

2

2.2 ASTM Standards:

the coated wire are as follows: 2, 4, 7, 10, and 27%.

B193Test Method for Resistivity of Electrical Conductor

Nickel-coated wire having different minimum mass percent-

Materials

ages of nickel may be obtained by mutual agreement between

B258 Specification for Nominal Diameters and Cross-

the manufacturer and the purchaser. For information purposes,

SectionalAreasofAWGSizesofSolidRoundWiresUsed

the thickness of coating in microinches provided by the

as Electrical Conductors

percentages listed above is shown in Table 1.

B452Specification for Copper-Clad Steel Wire for Elec-

1.3 Four classes of nickel-coated, copper-clad steel wire are

tronic Application

covered as follows:

E75Test Methods for Chemical Analysis of Copper-Nickel

1.3.1 Class N30HS—Nominal 30 % conductivity, hard 3

and Copper-Nickel-Zinc Alloys (Withdrawn 2010)

drawn.

4

2.3 American Chemical Society:

1.3.2 Class N30A—Nominal 30% conductivity, annealed.

StandardReagents Tests

1.3.3 Class N40HS—Nominal 40 % conductivity, hard 5

2.4 NIST Standard:

drawn.

NBS Handbook 100 Copper Wire Tables

1.3.4 Class N40A—Nominal 40% conductivity, annealed.

3. Terminology

1.4 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical 3.1 Definitions of Terms Specific to This Standard:

conversions to SI units that are provided for information only 3.1.1 lot—any amount of wire of one class and size pre-

and are not considered standard. sented for acceptance at one time, such amount, however, not

1.4.1 Exception—The SI values for resistivity are to be to exceed 10000 lb (4500 kg) (Note 1).

regarded as standard.

NOTE1—Alotshouldcomprisematerialtakenfromaproductregularly

meeting the requirements of this specification. Inspection of individual

1.5 The following safety hazards caveat pertains only to the

lots of less than 500 lb (230 kg) of wire cannot be justified economically.

test method described in this specification. This standard does

For small lots of 500 lb (230 kg) or less, the purchaser may agree to the

not purport to address all of the safety concerns, if any,

associated with its use. It is the responsibility of the user of this

2

standard to establish appropriate safety and health practices

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and determine the applicability of regulatory limitations prior

Standards volume information, refer to the standard’s Document Summary page on

to use.(Warning—Consideration should be given to toxicity

the ASTM website.

and flammability when selecting solvent cleaners.)

3

The last approved version of this historical standard is referenced on

www.astm.org.

4

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

1

This specification is under the jurisdiction of ASTM Committee B01 on listed by the American Chemical Society, see Analar Standards for Laboratory

Electrical Conductors and is the direct responsibility of Subcommittee B01.06 on Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Bi-Metallic Conductors. and National Formulary,U.S.PharmaceuticalConvention,Inc.(USPC),Rockville,

Current edition approved Oct. 15, 2012. Published November 2012. Originally MD.

5

approved in 1972. Last previous edition approved in 2007 as B559–93 (2007). Available from National Institute of Standards and Technology (NIST), 100

DOI: 10.1520/B0559-12. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B559−12

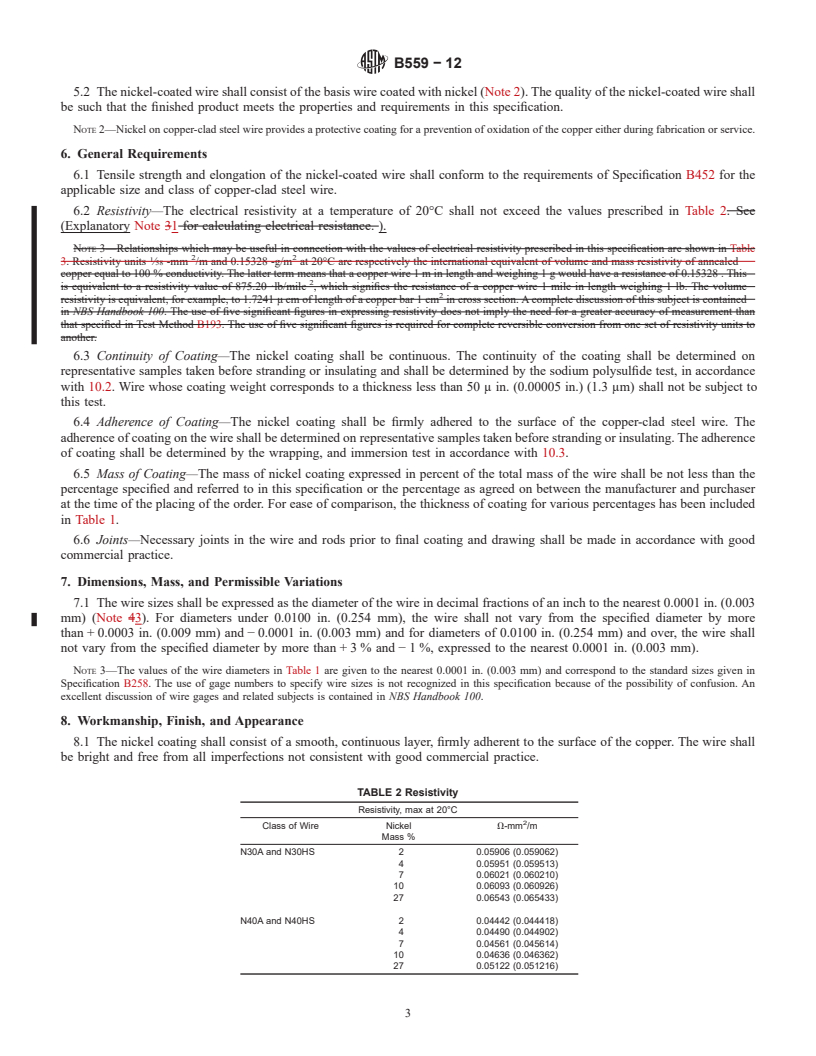

TABLE 1 Nickel Mass Percent and Thickness of Coating

Thickness of Nickel,µ in.

Diameter Cross-Sectional Area at 2

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B559 − 93 (Reapproved 2007) B559 − 12

Standard Specification for

Nickel-Coated, Copper-Clad Steel Wire for Electronic

1

Application

This standard is issued under the fixed designation B559; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers nickel-coated, round, copper-clad steel wire for electronic application.

1.2 Nickel coatings in mass percentages of the total mass of the coated wire are as follows: 2, 4, 7, 10, and 27 %. Nickel-coated

wire having different minimum mass percentages of nickel may be obtained by mutual agreement between the manufacturer and

the purchaser. For information purposes, the thickness of coating in microinches provided by the percentages listed above is shown

in Table 1.

1.3 Four classes of nickel-coated, copper-clad steel wire are covered as follows:

1.3.1 Class N30HS—Nominal 30 % conductivity, hard drawn.

1.3.2 Class N30A—Nominal 30 % conductivity, annealed.

1.3.3 Class N40HS—Nominal 40 % conductivity, hard drawn.

1.3.4 Class N40A—Nominal 40 % conductivity, annealed.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only, except for resistivity, where the SI units are to be regarded as the mathematical conversions to SI units that are provided for

information only and are not considered standard.

1.4.1 Exception—The SI values for resistivity are to be regarded as standard.

1.5 The following safety hazards caveat pertains only to the test method described in this specification.This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

(Warning—Consideration should be given to toxicity and flammability when selecting solvent cleaners.)

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

2

2.2 ASTM Standards:

B193 Test Method for Resistivity of Electrical Conductor Materials

B258 Specification for Nominal Diameters and Cross-Sectional Areas of AWG Sizes of Solid Round Wires Used as Electrical

Conductors

B452 Specification for Copper-Clad Steel Wire for Electronic Application

3

E75 Test Methods for Chemical Analysis of Copper-Nickel and Copper-Nickel-Zinc Alloys (Withdrawn 2010)

4

2.3 American Chemical Society:

Standard Reagents Tests

1

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.06 on Composite

Conductors.

Current edition approved Oct. 1, 2007Oct. 15, 2012. Published October 2007November 2012. Originally approved in 1972. Last previous edition approved in 20022007

ε1

as B559 – 93 (2002)(2007). . DOI: 10.1520/B0559-93R07.10.1520/B0559-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

4

Reagent Chemicals, American Chemical Society Specifications , American Chemical Society, Washington, DC. For suggestions on the testing of reagents not listed by

the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville, MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B559 − 12

TABLE 1 Nickel Mass Percent and Thickness of Coating

Thickness of Nickel,μ in.

Diameter Cross-Sectional Area at 20°C

(for information only)

2 2

in. mm cmil in. mm 2.0 % 4.0 % 7.0 % 10.0 % 27.0 %

0.0720 1.829 5 180 0.00407 2.63 334 637 1 181 1 703 4 892

0.0641 1.628 4 110 0.00323 2.08 298 566 1 050 1 514 4 349

0.0571 1.450 3 260 0.00256 1.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.