ASTM D6559-00a(2010)

(Test Method)Standard Test Method for Determination of Thermogravimetric (TGA) Air Reactivity of Baked Carbon Anodes and Cathode Blocks

Standard Test Method for Determination of Thermogravimetric (TGA) Air Reactivity of Baked Carbon Anodes and Cathode Blocks

SIGNIFICANCE AND USE

The air reactivity rates are used to quantify the tendency of a carbon artifact to react with air. Carbon consumed by this unwanted side reaction is unavailable for the primary reactions of reducing alumina to the primary metal. Air reactivity dusting rate is used by some companies to quantify the tendency of the coke aggregate or binder coke of a carbon artifact to selectively react with these gases. Preferential attack of the binder coke or coke aggregate of a carbon artifact by these gases causes some carbon to fall off or dust, making the carbon unavailable for the primary reaction of reducing alumina and, more importantly, reducing the efficiency of the aluminum reduction cell.

Comparison of air reactivity and dusting rates is useful in selecting raw materials for the manufacture of commercial anodes for specific smelting technologies in the aluminum reduction industry.

Air reactivity rates are used for evaluating effectiveness and beneficiation processes or for research purposes.

SCOPE

1.1 This test method covers the thermogravimetric (TGA) determination of air reactivity and dusting of shaped carbon anodes and cathode blocks used in the aluminum reduction industry. The apparatus selection covers a significant variety of types with various thermal conditions, sample size capability, materials of construction, and procedures for determining the mass loss and subsequent rate of reaction. This test method standardizes the variables of sample dimensions, reaction temperature, gas velocity over the exposed surfaces, and reaction time such that results obtained on different apparatuses are correlatable.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6559 − 00a(Reapproved 2010)

Standard Test Method for

Determination of Thermogravimetric (TGA) Air Reactivity of

Baked Carbon Anodes and Cathode Blocks

This standard is issued under the fixed designation D6559; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 dusting, n—the quantity of carbon that falls off the

carbonartifactwhileinthereactionchamberandiscollectedin

1.1 This test method covers the thermogravimetric (TGA)

the container at the bottom of the reaction chamber.

determination of air reactivity and dusting of shaped carbon

anodes and cathode blocks used in the aluminum reduction

3.1.2 final air reactivity, n—the mass loss of the carbon

industry.Theapparatusselectioncoversasignificantvarietyof

artifactduringthefinal30minofexposuretoairinthereaction

types with various thermal conditions, sample size capability,

chamber divided by the initial geometric (right cylindrical)

materials of construction, and procedures for determining the 2

exposed surface area of the sample, expressed as mg/cm -h.

mass loss and subsequent rate of reaction. This test method

3.1.3 initial air reactivity, n—the mass loss of the carbon

standardizes the variables of sample dimensions, reaction

artifactduringthefirst30minofexposuretoairinthereaction

temperature, gas velocity over the exposed surfaces, and

chamber divided by the initial geometric (right cylindrical)

reactiontimesuchthatresultsobtainedondifferentapparatuses

are correlatable. exposed surface area of the sample, expressed as mg/cm -h.

1.2 The values stated in SI units are to be regarded as

3.1.4 total air reactivity, n—thetotalmasslossofthecarbon

standard. No other units of measurement are included in this

artifact(includingdusting)duringthetotaltimethatthesample

standard.

is exposed to air (180 min) in the reaction chamber divided by

1.3 This standard does not purport to address all of the the initial geometric (right cylindrical) exposed surface area of

safety concerns, if any, associated with its use. It is the the sample, expressed as mg/cm -h.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 4. Summary of Test Method

bility of regulatory limitations prior to use.

4.1 Initial, final, and total air reactivity and dusting are

determined by passing air at flow rates, giving a standard

2. Referenced Documents

velocity of reactant gas around cylindrically shaped carbon

2.1 ASTM Standards:

artifacts under nearly isothermal conditions for a specified

D6353Guide for Sampling Plan and Core Sampling for

length of time. The reactivity is determined by continuously

Prebaked Anodes Used in Aluminum Production

monitoring the sample mass loss. The dusting term is deter-

D6354Guide for Sampling Plan and Core Sampling of

mined by collecting and determining the mass of carbon

Carbon Cathode Blocks Used in Aluminum Production

particles that fall off the sample during reaction.

E691Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

5. Significance and Use

3. Terminology

5.1 Theairreactivityratesareusedtoquantifythetendency

3.1 Definitions of Terms Specific to This Standard:

of a carbon artifact to react with air. Carbon consumed by this

unwantedsidereactionisunavailablefortheprimaryreactions

1 ofreducingaluminatotheprimarymetal.Airreactivitydusting

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricantsand is the direct responsibility of

rateisusedbysomecompaniestoquantifythetendencyofthe

SubcommitteeD02.05onPropertiesofFuels,PetroleumCokeandCarbonMaterial.

cokeaggregateorbindercokeofacarbonartifacttoselectively

Current edition approved May 1, 2010. Published May 2010. Originally

react with these gases. Preferential attack of the binder coke or

approved in 2000. Last previous edition approved in 2005 as D6559–00a (2005).

DOI: 10.1520/D6559-00AR10.

coke aggregate of a carbon artifact by these gases causes some

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

carbontofalloffor dust,makingthecarbonunavailableforthe

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

primary reaction of reducing alumina and, more importantly,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. reducing the efficiency of the aluminum reduction cell.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6559 − 00a (2010)

5.2 Comparison of air reactivity and dusting rates is useful 6.1.2 Reaction Chamber, consisting of a vertical tube con-

in selecting raw materials for the manufacture of commercial structed of a material capable of withstanding the temperature

anodes for specific smelting technologies in the aluminum

ofthereactionwithsufficientinsidediameter(ID)toacceptthe

reduction industry.

sample and sample holder while not affecting the gas flow to

and from the sample (100 6 25-mm ID is recommended).The

5.3 Air reactivity rates are used for evaluating effectiveness

reactionchamberistobeconstructedwithadustcollectioncup

and beneficiation processes or for research purposes.

at the bottom, which is removable and capable of capturing all

6. Apparatus

the dust that falls off the sample during the test. The most

common materials of construction are quartz and Inconel.

6.1 Theapparatustobeusedshouldbeassimpleaspossible

andbecommensuratewithwhatistobeachieved,theprincipal

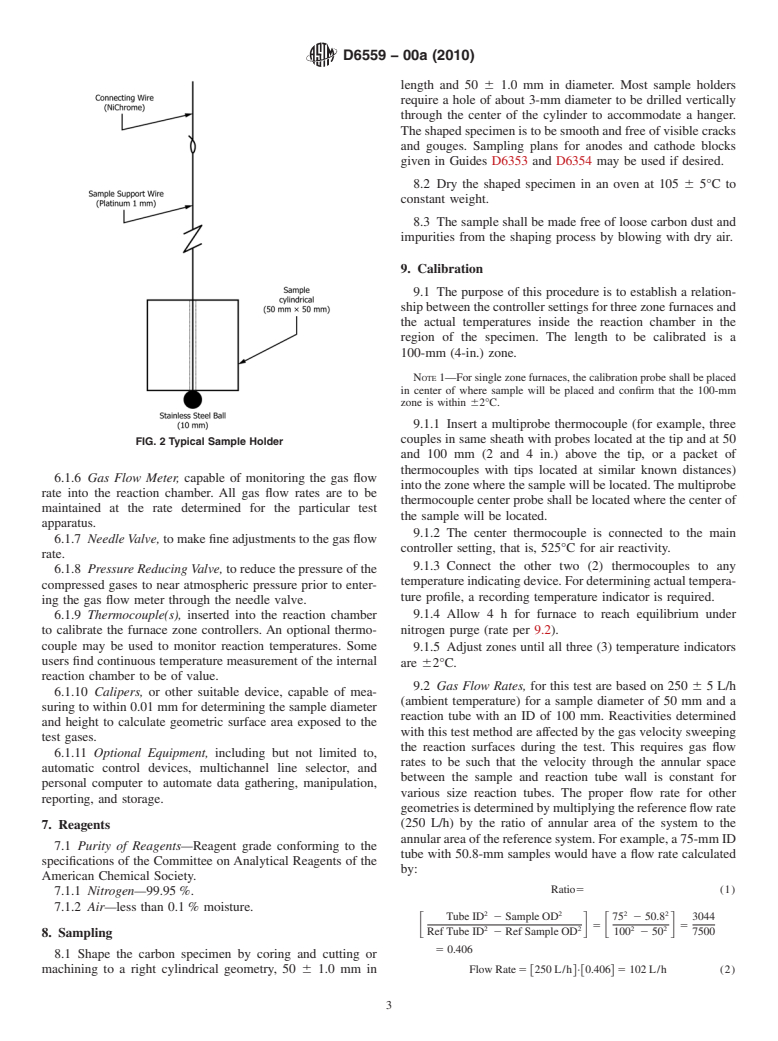

6.1.3 Sample Holders, capable of supporting the sample in

criteria being that the reaction rate is to be determined under

the reaction chamber for the duration of the test and should be

isothermal conditions and unaffected by physical and chemical

capable of being reusable. The sample holder shall not change

properties inherent to the apparatus (such as gas diffusion

in mass during the test, affect the diffusion pattern of the gases

patterns, gas temperature, exposed sample surface area, and so

to or from the sample, limit the gas accessible surface area of

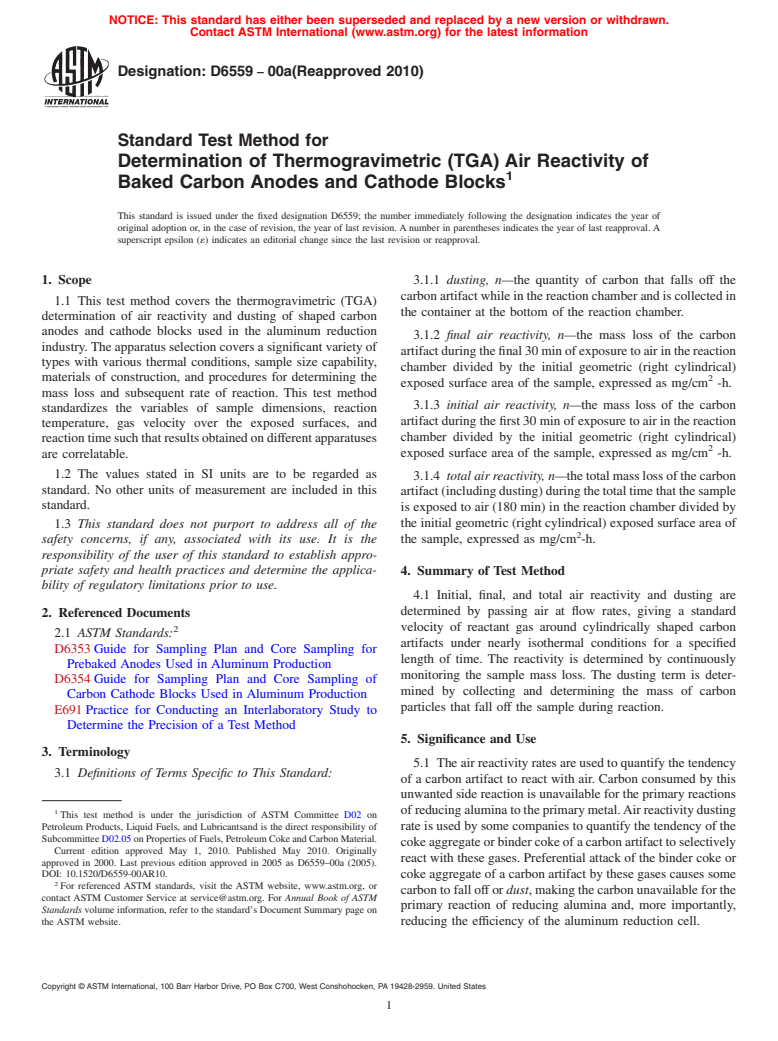

forth).Atypical apparatus that has been found to be suitable is

the test sample, or interfere with the free fall of dust from the

illustrated in Fig. 1.

sample. A typical sample holder is illustrated in Fig. 2.

6.1.1 Furnace and Controller, capable of maintaining con-

6.1.4 Gas Preheat Tube,extendingintothefirstheatzoneof

stant temperature within 62°C in the 100-mm region centered

the reaction chamber to preheat the gases prior to entering the

on the specimen. The example apparatus of Fig. 1 employs a

reactionchamber.Thelengthanddiameterofthetubecanvary

three zone heating element and associated controls to accom-

as long as the gases exiting the tube are the same temperature

plish this, but other methods such as tapered windings or long

as the reaction chamber. The inlet gas shall exit the preheat

linear heaters are also suitable. The control thermocouple is a

tube downward to prevent channeling of the gas through the

groundedtypeandshallbelocatedwithinthereactionchamber

reaction chamber and to prevent plugging of the preheat tube

near the surface of the test sample to allow the furnace

with carbon dust.

controller to adjust to the exothermic reaction that occurs

6.1.5 Balance, capable of measuring the weight of the

duringtheairreactivitytest.Thecontrolthermocoupleshallbe

positioned 4 6 1 mm from the side sample surface and sample and sample holder (approximately 200 g maximum)

centeredverticallywithin5mmofthecenter.Thefurnaceshall continuously throughout the duration of the test to the nearest

be large enough to accept the reaction chamber. 0.01 g.

FIG. 1 Typical Air Reactivity Apparatus

D6559 − 00a (2010)

length and 50 6 1.0 mm in diameter. Most sample holders

require a hole of about 3-mm diameter to be drilled vertically

through the center of the cylinder to accommodate a hanger.

Theshapedspecimenistobesmoothandfreeofvisiblecracks

and gouges. Sampling plans for anodes and cathode blocks

given in Guides D6353 and D6354 may be used if desired.

8.2 Dry the shaped specimen in an oven at 105 6 5°C to

constant weight.

8.3 The sample shall be made free of loose carbon dust and

impurities from the shaping process by blowing with dry air.

9. Calibration

9.1 The purpose of this procedure is to establish a relation-

shipbetweenthecontrollersettingsforthreezonefurnacesand

the actual temperatures inside the reaction chamber in the

region of the specimen. The length to be calibrated is a

100-mm (4-in.) zone.

NOTE1—Forsinglezonefurnaces,thecalibrationprobeshallbeplaced

in center of where sample will be placed and confirm that the 100-mm

zone is within 62°C.

9.1.1 Insert a multiprobe thermocouple (for example, three

couples in same sheath with probes located at the tip and at 50

FIG. 2 Typical Sample Holder

and 100 mm (2 and 4 in.) above the tip, or a packet of

thermocouples with tips located at similar known distances)

6.1.6 Gas Flow Meter, capable of monitoring the gas flow

intothezonewherethesamplewillbelocated.Themultiprobe

rate into the reaction chamber. All gas flow rates are to be

thermocouple center probe shall be located where the center of

maintained at the rate determined for t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.