ASTM D2111-95(2000)

(Test Method)Standard Test Methods for Specific Gravity of Halogenated Organic Solvents and Their Admixtures

Standard Test Methods for Specific Gravity of Halogenated Organic Solvents and Their Admixtures

SCOPE

1.1 These test methods cover the determination of the specific gravity of halogenated organic solvents and solvent admixtures. They define suitable apparatus and procedures and furnish details underlying the interpretation of test data and the selection of numerical limits for agreement among interested persons and agencies.

1.2 Two methods are covered as follows:

1.2.1 Method A , specific gravity by means of a hydrometer.

1.2.2 Method B , specific gravity by means of a pycnometer. Note 1-In referee problems, Method B may be used.

1.2.3 Method C , specific gravity by means of an electronic densitometer.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation: D 2111 – 95 (Reapproved 2000)

Standard Test Methods for

Specific Gravity of Halogenated Organic

Solvents and Their Admixtures

This standard is issued under the fixed designation D 2111; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

Specific gravity x/y°C, example 20/4°C (2)

1. Scope

When using an electronic densitometer to determine specific gravity,

1.1 These test methods cover the determination of the

the temperature of the material to be tested and the water reference will

specific gravity of halogenated organic solvents and solvent

be the same. Examples 25/25°C, 20/20°C.

admixtures. They define suitable apparatus and procedures and

3.1.2 density—the mass of a given material per unit volume.

furnish details underlying the interpretation of test data and the

3.1.2.1 Discussion—Density for chlorinated solvents is nor-

selection of numerical limits for agreement among interested

mally stated in grams per cubic centimetre. Pounds per gallon

persons and agencies.

is also commonly used.

1.2 Two methods are covered as follows:

1.2.1 Method A, specific gravity by means of a hydrometer.

4. Significance and Use

1.2.2 Method B, specific gravity by means of a pycnometer.

4.1 The density or specific gravity of a pure chlorinated

NOTE 1—In referee problems, Method B may be used.

solvent at a given temperature is constant. Density or specific

gravity can be used in identification of materials, the assay of

1.2.3 Method C, specific gravity by means of an electronic

binary mixtures, and as an indication of purity of a given

densitometer.

solvent.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Test Temperatures

responsibility of the user of this standard to establish appro-

5.1 ASTM specifications normally state the temperatures

priate safety and health practices and determine the applica-

for specific gravity of halogenated organic solvents at 25/25°C.

bility of regulatory limitations prior to use.

20/20°C and 60/60°F are other commonly used temperatures.

2. Referenced Documents

METHOD A—SPECIFIC GRAVITY BY MEANS

2.1 ASTM Standards:

OF A HYDROMETER

E 1 Specification for ASTM Thermometers

E 100 Specification for ASTM Hydrometers

6. Apparatus

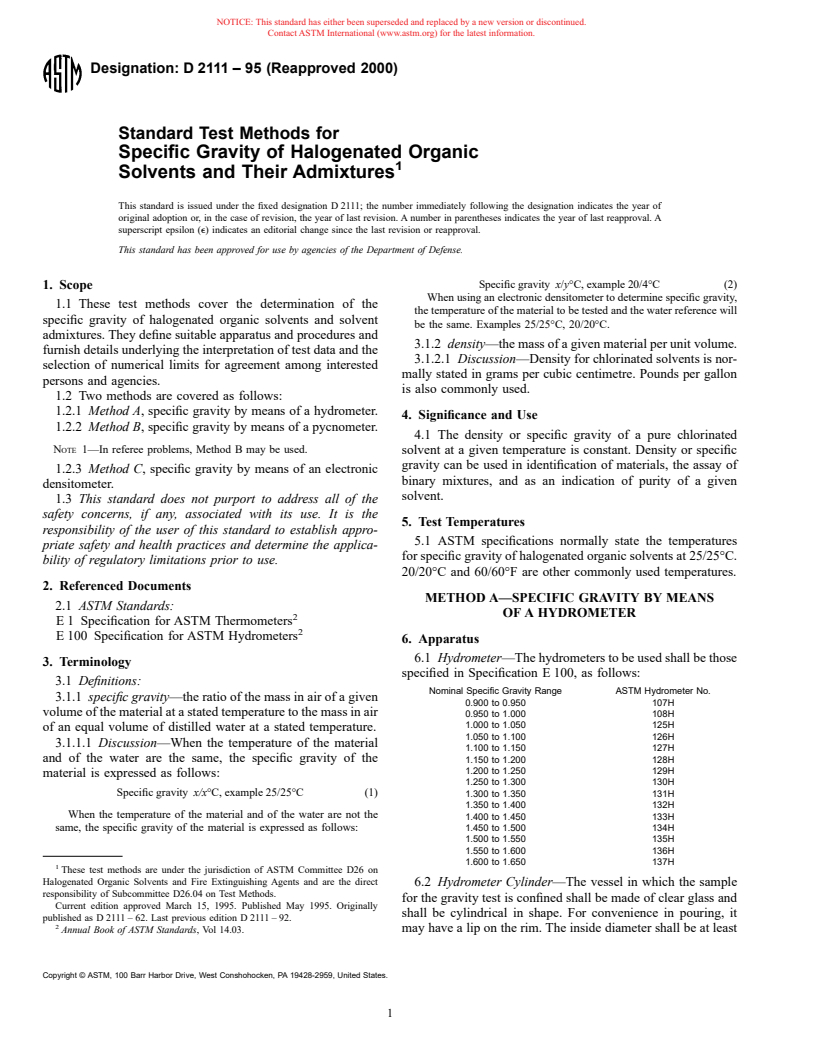

6.1 Hydrometer—The hydrometers to be used shall be those

3. Terminology

specified in Specification E 100, as follows:

3.1 Definitions:

Nominal Specific Gravity Range ASTM Hydrometer No.

3.1.1 specific gravity—the ratio of the mass in air of a given

0.900 to 0.950 107H

volume of the material at a stated temperature to the mass in air 0.950 to 1.000 108H

1.000 to 1.050 125H

of an equal volume of distilled water at a stated temperature.

1.050 to 1.100 126H

3.1.1.1 Discussion—When the temperature of the material

1.100 to 1.150 127H

and of the water are the same, the specific gravity of the 1.150 to 1.200 128H

1.200 to 1.250 129H

material is expressed as follows:

1.250 to 1.300 130H

Specific gravity x/x°C, example 25/25°C (1) 1.300 to 1.350 131H

1.350 to 1.400 132H

When the temperature of the material and of the water are not the

1.400 to 1.450 133H

same, the specific gravity of the material is expressed as follows: 1.450 to 1.500 134H

1.500 to 1.550 135H

1.550 to 1.600 136H

1.600 to 1.650 137H

These test methods are under the jurisdiction of ASTM Committee D26 on

Halogenated Organic Solvents and Fire Extinguishing Agents and are the direct

6.2 Hydrometer Cylinder—The vessel in which the sample

responsibility of Subcommittee D26.04 on Test Methods.

for the gravity test is confined shall be made of clear glass and

Current edition approved March 15, 1995. Published May 1995. Originally

shall be cylindrical in shape. For convenience in pouring, it

published as D 2111 – 62. Last previous edition D 2111 – 92.

Annual Book of ASTM Standards, Vol 14.03. may have a lip on the rim. The inside diameter shall be at least

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 2111

25.0 mm (1.0 in.) greater than the outside diameter of the freshly boiled distilled water that has been cooled to 22 to

hydrometer used in it. The height of the cylinder shall be such 24°C. Place it in the water bath maintained at 25.0 6 0.5°C

that the length of the column of sample it contains is greater by

until the pycnometer and its contents are at a constant volume

at least 25.0 mm than the portion of the hydrometer that is at 25°C.

immersed beneath the surface of the sample after a state of

9.2 After immersion in the bath for at least 30 min, adjust

equilibrium has been reached.

the level of liquid to the proper point on the pycnometer, put

6.3 Thermometer— An ASTM Gravity Thermometer hav-

the stopper in place, remove from the bath, wipe dry, and

ing a range from − 20 to + 102°C and conforming to the

weigh. The drying and weighing procedure should be carried

requirements for Thermometer 12C as prescribed in Specifi-

out as rapidly as possible to avoid changing the temperature

cation E 1.

from 25.0°C. Care should be taken to avoid touching the

6.4 Water Bath, capable of maintaining a temperature of

pycnometer with bare hands due to weight changes that will

25.0 6 0.5°C during the test.

occur from picking up moisture and oils. Empty the pycnom-

eter, rinse successively with alcohol and the solvent being

7. Procedure

tested, remove the vapor of the solvent, immerse in the bath,

7.1 Cool the sample in the original container to about 24°C.

and bring to 25.0°C as was done before. After immersion at

Rinse each piece of equipment with a portion of the sample.

25.0°C for at least 30 min, put the stopper in place, remove

Pour the sample into the clean hydrometer cylinder without

from the bath, wipe dry, and weigh. Subtract the weight of the

splashing, so as to avoid formation of air bubbles. Remove any

empty pycnometer from the weight when filled with water in

air bubbles adhering to the surface by touching them with a

order to get the weight of the contained water at 25.0°C in air.

piece of clean filter paper. Select a location that is free of air

Call this difference W.

currents. Place the cylinder vertically in the water bath and let

9.3 Cool the sample to 22 to 24°C, fill the pycnometer with

the temperature of the sample reach 25.0 6 0.5°C as follows:

it, immerse in the bath, and bring to 25.0°C as was done before.

Stir the contents of the cylinder, being careful to avoid

After immersion at 25.0°C for at least 30 min, adjust the liquid

formation of air bubbles. When the temperature of the sample

level, put the stopper in place, remove from the bath, wipe dry,

is 24.5°C, slowly and carefully lower the hydrometer into the

and weigh. Subtract the weight of the empty pycnometer from

sample to a level two smallest scale divisions below that at

the weight when filled with sample in order to obtain the

which it will float and then release the hydrometer. After it has

weight of the contained sample at 25.0°C. Call this difference

come to rest and floats freely away from the walls of the

S.

cylinder, read the gravity as the point at which the surface of

the sample apparently cuts the hydrometer scale.

10. Calculation

7.2 When the temperature is 25.0°C, make this observation

by placing the eye slightly below the level of the liquid and

10.1 Calculate the specific gravity at 25/25°C (in air) as

slowly raise the eye until the surface of the sample first seen as

follows:

a distorted ellipse seems to become a straight line cutting the

Specific gravity 25/25°C 5 S/W (3)

hydrometer scale. Determine the temperature of the sample just

10.2 Material specifications often specify different tempera-

before and also, for referee tests, just after reading the

tures at which specific gravity shall be measured. In order to

hydrometer.

convert to any selected temperature, the coefficient of cubical

METHOD B—SPECIFIC GRAVITY BY MEANS

expansion for the material being tested must be used. In

OF A PYCNOMETER

addition, the absolute density of water at the desired tempera-

ture is taken. The absolute densities of water at different

8. Apparatus

temperatures are tabulated in various handbooks. In converting

8.1 Pycnometer, 25-mL capacity with a ground-glass stop-

to any desired temperature basis the following equation is used:

per having a capillary opening, a chamber to provide for

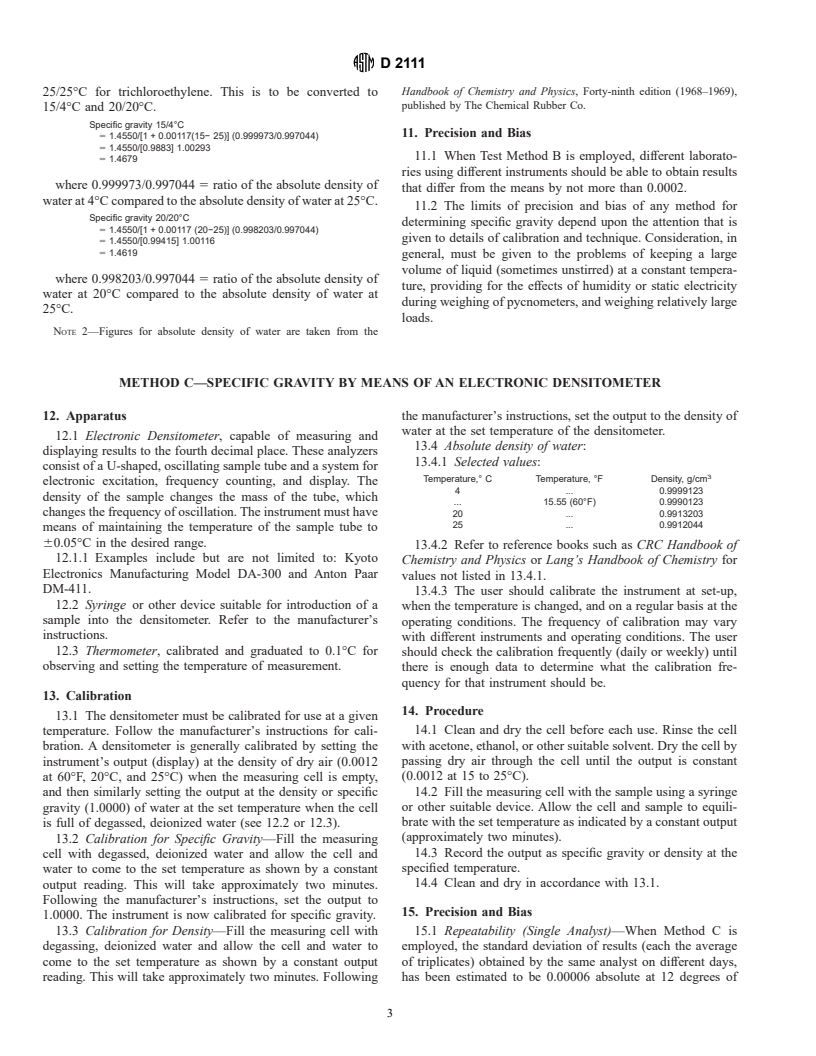

5 specific gravit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.