ASTM D3628-08

(Practice)Standard Practice for Selection and Use of Emulsified Asphalts

Standard Practice for Selection and Use of Emulsified Asphalts

SIGNIFICANCE AND USE

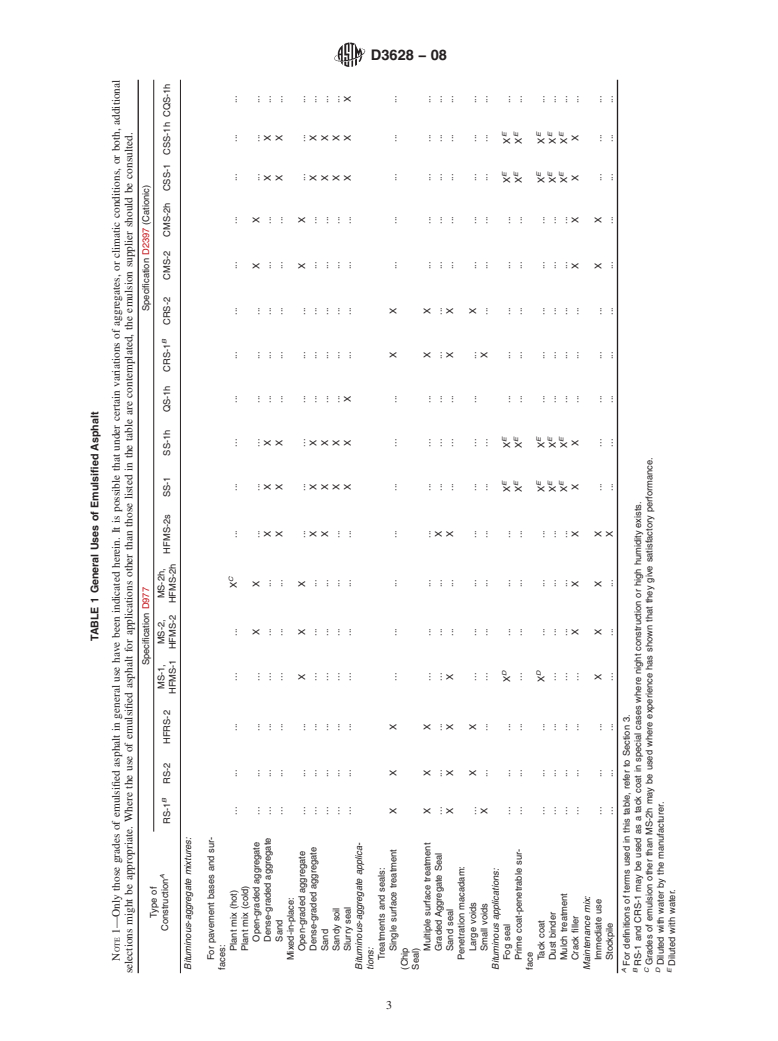

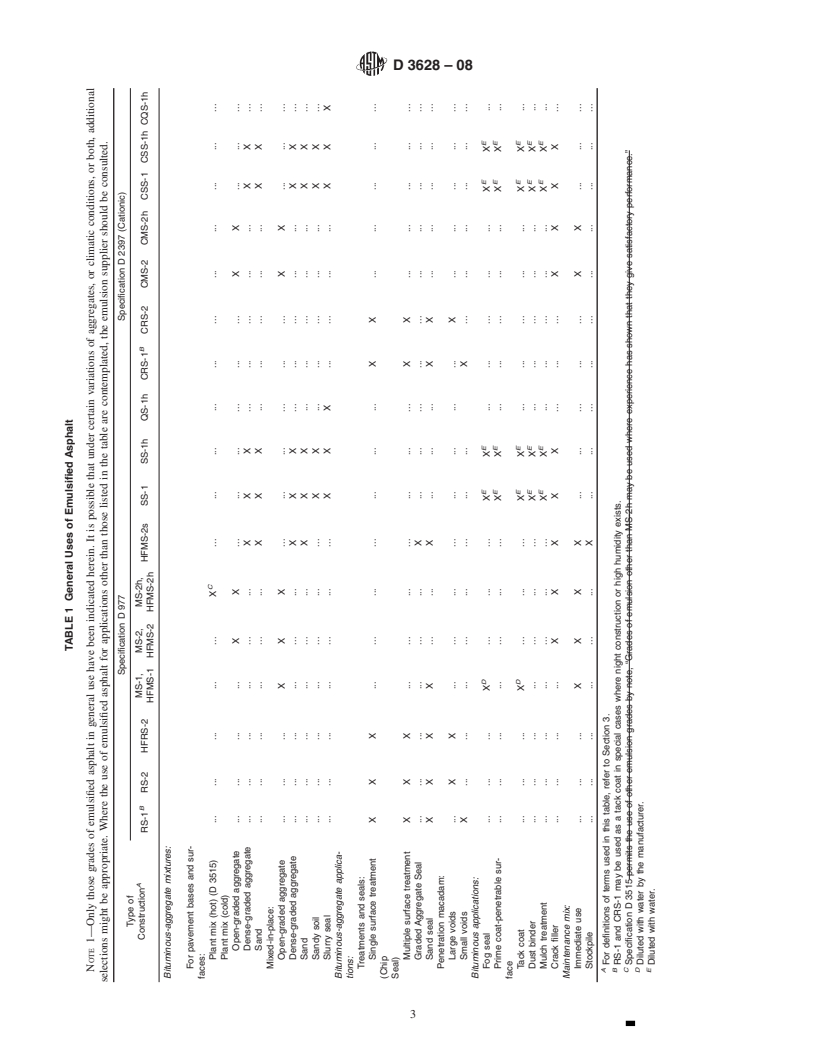

As indicated by Specifications D 977 and D 2397, emulsified asphalts are classified by type (rapid medium or slow setting) and by grade within type (viscosity in the case of the rapid-setting type or characteristic of the residual asphalt in the case of the medium and slow-setting types). Selection for use of a particular type and grade is controlled by type of construction (whether an application or a mix type), properties of the mineral aggregate (both grading and mineral composition), and environmental conditions during construction. For surface treatments and seals, emulsions are formulated to set rapidly upon contact with the mineral aggregate or pavement surface. When used in mix types, slower breaking is required to allow time for mixing and laydown. If the mix aggregate is open graded without appreciable fines, a medium-setting emulsion may be used that deposits a relatively hard asphalt. If the aggregate is dense-graded but does not contain a large amount of very fine material (dust), a medium-setting emulsion with a soft residue may be a good choice. However, if the dense-graded aggregate contains a large amount of very fine mineral matter, a slow-setting emulsion may be required.

SCOPE

1.1 This practice covers the selection of emulsified asphalts for various paving and allied uses.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Practice

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3628 −08

StandardPractice for

1

Selection and Use of Emulsified Asphalts

This standard is issued under the fixed designation D3628; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.6 dust binder—a light application of bituminous mate-

rial for the express purpose of laying and bonding loose dust.

1.1 This practice covers the selection of emulsified asphalts

3.1.7 fog seal—a light spray application of asphalt to an

for various paving and allied uses.

existing pavement as a seal to inhibit raveling, or seal the

1.2 This standard does not purport to address all of the

surface, or both.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 3.1.8 graded aggregate seal, n—a single surface treatment

in which the aggregate is graded with little or no mineral filler,

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. typically with a nominal maximum size of about 19 mm, and

containing sufficient sand that the bituminous material will be

2. Referenced Documents

required to penetrate upward into the aggregate cover; the

2 nominal maximum aggregate size may vary depending on the

2.1 ASTM Standards:

course thickness desired and aggregate availability. It is an

D8 Terminology Relating to Materials for Roads and Pave-

application method used in lieu of a chip seal to provide a

ments

lower cost road.

D977 Specification for Emulsified Asphalt

3.1.8.1 Discussion—In this case, nominal maximum size

D2397 Specification for Cationic Emulsified Asphalt

refers to the definition in Terminology D8.

3. Terminology

3.1.9 maintenance mix—a mixture of bituminous material

and mineral aggregate applied at ambient temperature for use

3.1 Definitions:

in patching holes, depressions, and distress areas in existing

3.1.1 bituminous-aggregate applications—applications of

pavements, using appropriate hand or mechanical methods in

bituminous material to a prepared aggregate base or pavement

placing and compacting the mix.These mixes may be designed

surface followed by the application of aggregate.

for immediate use or for use out of a stockpile at a later date

3.1.2 bituminous-aggregate mixtures—a combination of bi-

without further processing.

tuminous material and aggregate that is physically mixed by

3.1.10 mixed-in-place—the procedures by which the bitu-

mechanical means, spread on the job site, and compacted.

minous material and mineral aggregrate are mixed on the job

3.1.3 bituminous applications—the application of sprayed

site by means of travel plants, blade mixing, or other special

bituminous coatings not involving the use of aggregates.

road-mixing equipment.

3.1.4 crack filler—the bituminous material used to fill and

3.1.11 mulch treatment—a spray application of bituminous

seal cracks in existing pavements.

material used to temporarily stabilize a recently seeded area.

3.1.5 dense-graded aggregate—aggregate that is graded

The bituminous material can be applied to the soil or to a straw

from the maximum size, down to and including filler, with the

or hay mulch as a tie-down.

object of obtaining a bituminous mix with a controlled void

3.1.12 multiple surface treatment—two or more single sur-

content and high stability.

face treatments placed one on the other. The maximum

aggregate size of each successive treatment is usually one half

that of the previous one, and the total thickness is about the

1

This practice is under the jurisdiction of ASTM Committee D04 on Road and

same as the nominal maximum size aggregate particles of the

Paving Materials and is the direct responsibility of D04.41 on Emulsified Asphalt

first course.

Specifications.

Current edition approved Jan. 1, 2008. Published January 2008. Originally

3.1.13 open-graded aggregate—aggregate containing little

approved in 1978. Last previous edition approved in 2006 as D3628 – 06. DOI:

or no mineral filler and in which the void spaces in the

10.1520/D3628-08.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

compacted aggregate are relatively large.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.1.14 pavement bases and surfaces—the lower or underly-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ing pavement course atop the subbase or subgrade and the top

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3628−0

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3628–06 Designation: D 3628 – 08

Standard Practice for

1

Selection and Use of Emulsified Asphalts

This standard is issued under the fixed designation D 3628; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the selection of emulsified asphalts for various paving and allied uses.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 8 Terminology Relating to Materials for Roads and Pavements

D 977 Specification for Emulsified Asphalt

D 2397Specification for Cationic Emulsified Asphalt

D3515Specification for Hot-Mixed, Hot-Laid Bituminous Paving Mixtures Specification for Cationic Emulsified Asphalt

3. Terminology

3.1 Definitions:

3.1.1 bituminous-aggregate applications—applications of bituminous material to a prepared aggregate base or pavement

surface followed by the application of aggregate.

3.1.2 bituminous-aggregate mixtures—a combination of bituminous material and aggregate that is physically mixed by

mechanical means, spread on the job site, and compacted.

3.1.3 bituminous applications—the application of sprayed bituminous coatings not involving the use of aggregates.

3.1.4 crack filler—the bituminous material used to fill and seal cracks in existing pavements.

3.1.5 dense-graded aggregate—aggregate that is graded from the maximum size, down to and including filler, with the object

of obtaining a bituminous mix with a controlled void content and high stability.

3.1.6 dust binder—a light application of bituminous material for the express purpose of laying and bonding loose dust.

3.1.7 fog seal—a light spray application of asphalt to an existing pavement as a seal to inhibit raveling, or seal the surface, or

both.

3.1.8 graded aggregate seal, n—a single surface treatment in which the aggregate is graded with little or no mineral filler,

typically with a nominal maximum size of about 19 mm, and containing sufficient sand that the bituminous material will be

required to penetrate upward into the aggregate cover; the nominal maximum aggregate size may vary depending on the course

thickness desired and aggregate availability. It is an application method used in lieu of a chip seal to provide a lower cost road.

3.1.8.1 Discussion—In this case, nominal maximum size refers to the definition in Terminology D 8.

3.1.9 maintenance mix—a mixture of bituminous material and mineral aggregate applied at ambient temperature for use in

patchingholes,depressions,anddistressareasinexistingpavements,usingappropriatehandormechanicalmethodsinplacingand

compacting the mix. These mixes may be designed for immediate use or for use out of a stockpile at a later date without further

processing.

3.1.10 mixed-in-place—the procedures by which the bituminous material and mineral aggregrate are mixed on the job site by

means of travel plants, blade mixing, or other special road-mixing equipment.

3.1.11 mulch treatment—a spray application of bituminous material used to temporarily stabilize a recently seeded area. The

bituminous material can be applied to the soil or to a straw or hay mulch as a tie-down.

3.1.12 multiple surface treatment—two or more single surface treatments placed one on the other.The maximum aggregate size

1

This practice is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommitee D04 .41 D04.41 on

Emulsified Asphalt Specifications.

Current edition approved JuneJan. 1, 2006.2008. Published June 2006.January 2008. Originally approved in 1978. Last previous edition approved in 20012006 as

D 3628 – 016.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3628–08

of each successive treatment is usually one ha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.