ASTM A487/A487M-93(2012)

(Specification)Standard Specification for Steel Castings Suitable for Pressure Service

Standard Specification for Steel Castings Suitable for Pressure Service

ABSTRACT

This specification covers low-alloy steel and martensitic stainless steels in the normalized and tempered, or quenched and tempered conditions, suitable for pressure-containing parts. All castings shall receive the specified heat treatment requirement: austenitizing temperature, medium, quenching cool, and tempering temperature. Preliminary heat treatment and multiple tempering are permitted. Recording-type pyrometers shall be used to control the furnace temperature. The steel shall conform to the required chemical composition for carbon, manganese, phosphorus, sulfur, silicon, nickel, chromium, molybdenum, vanadium, boron, and copper. Residual elements include: copper, nickel, chromium, tungsten, molybdenum, and vanadium. Tensile properties of the steel shall conform to the requirements for tensile strength, yield strength, elongation, reduction of area, hardness, and maximum thickness. Product analysis tolerance is specified. Repair by welding may be done.

SCOPE

1.1 This specification covers low-alloy steels and martensitic stainless steels in the normalized and tempered, or quenched and tempered, condition suitable for pressure-containing parts. The weldability of the classes in this specification varies from readily weldable to weldable only with adequate precautions, and the weldability of each class should be considered prior to assembly by fusion welding.

1.2 Selection will depend on design, mechanical, and service conditions. Users should note that hardenability of some of the grades mentioned may restrict the maximum size at which the required mechanical properties are obtained.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. Inch-pound units are applicable for material ordered to Specification A487 and SI units for material ordered to Specification A487M.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A487/A487M −93(Reapproved 2012)

Standard Specification for

Steel Castings Suitable for Pressure Service

This standard is issued under the fixed designationA487/A487M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E165Practice for Liquid Penetrant Examination for General

2 Industry

1.1 This specification covers low-alloy steels and marten-

E709Guide for Magnetic Particle Testing

sitic stainless steels in the normalized and tempered, or

2.2 American Society of Mechanical Engineers:

quenched and tempered, condition suitable for pressure-

ASME Boiler and Pressure Vessel Code, Section IX

containing parts. The weldability of the classes in this speci-

fication varies from readily weldable to weldable only with

2.3 Manufacturers Standardization Society of the Valve and

adequate precautions, and the weldability of each class should Fittings Industry Standards:

be considered prior to assembly by fusion welding.

SP-55Quality Standard for Steel Castings-Visual Method

1.2 Selection will depend on design, mechanical, and ser-

3. General Conditions for Delivery

vice conditions. Users should note that hardenability of some

3.1 Material furnished to this specification shall conform to

of the grades mentioned may restrict the maximum size at

which the required mechanical properties are obtained. the requirements of Specification A703/A703M including any

supplementary requirements that are indicated in the purchase

1.3 The values stated in either inch-pound units or SI units

order. Failure to comply with the general requirements of

are to be regarded separately as standard. Within the text, the

Specification A703/A703M constitutes nonconformance with

SI units are shown in brackets. The values stated in each

this specification. In case of conflict between the requirements

system are not exact equivalents; therefore, each system must

of this specification and Specification A703/A703M, this

beusedindependentlyoftheother.Combiningvaluesfromthe

specification shall prevail.

two systems may result in nonconformance with the specifi-

cation. Inch-pound units are applicable for material ordered to

4. Ordering Information

Specification A487 and SI units for material ordered to

4.1 The inquiry and order should include or indicate the

Specification A487M.

following:

4.1.1 A description of the casting by pattern number or

2. Referenced Documents

drawing (dimensional tolerances shall be included on the

2.1 ASTM Standards:

casting drawing),

A370Test Methods and Definitions for Mechanical Testing

4.1.2 ASTM designation and year of issue,

of Steel Products

4.1.3 Grade and class of steel,

A488/A488MPractice for Steel Castings, Welding, Qualifi-

4.1.4 Options in the specification, and

cations of Procedures and Personnel

4.1.5 Thesupplementaryrequirementsdesiredincludingthe

A703/A703M Specification for Steel Castings, General

standard of acceptance.

Requirements, for Pressure-Containing Parts

5. Heat Treatment

5.1 All castings shall receive a heat treatment indicated in

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee Table1.Preliminaryheattreatmentpriortofinalheattreatment

A01.18 on Castings.

as well as multiple tempering is permitted.

Current edition approved March 1, 2012. Published April 2012. Originally

approved in 1963. Last previous edition approved in 2007 as A487/A487M– 93

(2007). DOI: 10.1520/A0487_A0487M-93R12.

2 4

For ASME Boiler and Pressure Vessel Code applications see related Specifi- Available from American Society of Mechanical Engineers (ASME), ASME

cations SA-487 in Section II of that code. International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

For referenced ASTM standards, visit the ASTM website, www.astm.org, or www.asme.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

Standards volume information, refer to the standard’s Document Summary page on Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-

the ASTM website. hq.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A487/A487M−93 (2012)

TABLE 1 Heat Treat Requirement

Tempering

Austenitizing

Quenching Cool Temperature,

A

Grade Class Temperature, Media

B

Below °F [°C]

°F [°C]

min, °F [°C]

1 A 1600 [870] A 450 [230] 1100 [595]

1 B 1600 [870] L 500 [260] 1100 [595]

1 C 1600 [870] A or L 500 [260] 1150 [620]

2 A 1600 [870] A 450 [230] 1100 [595]

2 B 1600 [870] L 500 [260] 1100 [595]

2 C 1600 [870] A or L 500 [260] 1150 [620]

4 A 1600 [870] A or L 500 [260] 1100 [595]

4 B 1600 [870] L 500 [260] 1100 [595]

4 C 1600 [870] A or L 500 [260] 1150 [620]

4 D 1600 [870] L 500 [260] 1150 [620]

4 E 1600 [870] L 500 [260] 1100 [595]

6 A 1550 [845] A 500 [260] 1100 [595]

6 B 1550 [845] L 500 [260] 1100 [595]

7 A 1650 [900] L 600 [315] 1100 [595]

8 A 1750 [955] A 500 [260] 1250 [675]

8 B 1750 [955] L 500 [260] 1250 [675]

8 C 1750 [955] L 500 [260] 1250 [675]

9 A 1600 [870] A or L 500 [260] 1100 [595]

9 B 1600 [870] L 500 [260] 1100 [595]

9 C 1600 [870] A or L 500 [260] 1150 [620]

9 D 1600 [870] L 500 [260] 1150 [620]

9 E 1600 [870] L 500 [260] 1100 [595]

10 A 1550 [845] A 500 [260] 1100 [595]

10 B 1550 [845] L 500 [260] 1100 [595]

11 A 1650 [900] A 600 [315] 1100 [595]

11 B 1650 [900] L 600 [315] 1100 [595]

12 A 1750 [955] A 600 [315] 1100 [595]

12 B 1750 [955] L 400 [205] 1100 [595]

13 A 1550 [845] A 500 [260] 1100 [595]

13 B 1550 [845] L 500 [260] 1100 [595]

14 A 1550 [845] L 500 [260] 1100 [595]

C

16 (J31200) A 1600 [870] A 600 [315] 1100 [595]

CA15 A 1750 [955] A or L 400 [205] 900 [480]

CA15 B 1750 [955] A or L 400 [205] 1100 [595]

DE

CA15 C 1750 [955] A or L 400 [205] 1150 [620]

DE

CA15 D 1750 [955] A or L 400 [205] 1150 [260]

CA15M A 1750 [955] A or L 400 [205] 1100 [595]

CA6NM A 1850 [1010] A or L 200 [95] 1050–1150 [565–620]

E,F

CA6NM B 1850 [1010] A or L 200 [95] 1225–1275 [665–690]

G

1050–1150 [565–620]

A

A = air, L = Liquid.

B

Minimum temperature unless range is specified.

C

Double austenitize.

D

Double temper with the final temper at a lower temperature than the intermediate temper.

E

Air cool to below 200°F [95°C] after first temper.

F

Intermediate.

G

Final.

5.2 Heat treatment shall be performed after the castings 7. Tensile Requirements

have been allowed to cool below the transformation range.

7.1 Tensile properties of steel used for the castings shall

5.3 The furnace temperature for heat treating shall be conform to the requirements prescribed in Table 3.

effectively controlled by use of recording-type pyrometers.

8. Quality

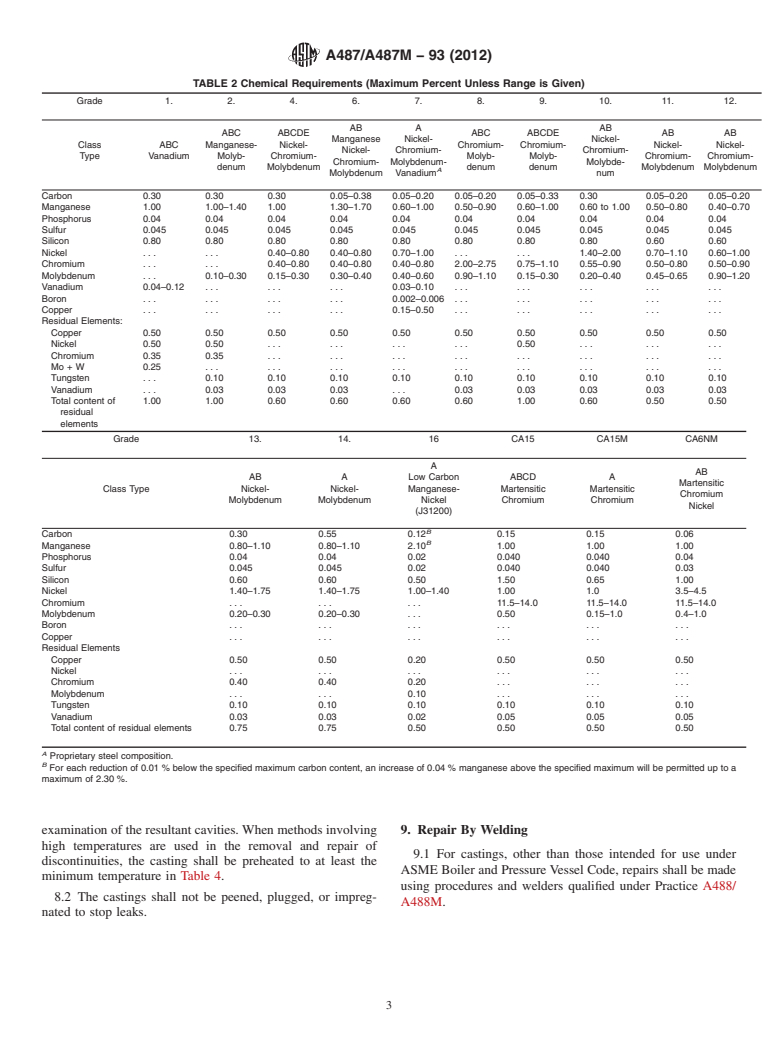

6. Chemical Composition

8.1 Thesurfaceofthecastingshallbefreeofadheringsand,

6.1 The steel shall conform to the requirements as to scale, cracks, and hot tears as determined by visual examina-

chemical composition prescribed in Table 2. Product analysis tion. Other surface discontinuities shall meet the visual accep-

tolerance shall conform to the product analysis tolerance tance standards specified in the order. Visual Method SP-55 or

shown in Specification A703/A703M. Product analysis toler- othervisualstandardsmaybeusedtodefineacceptablesurface

ances for stainless grades are not presently applicable pending discontinuities and finish. Unacceptable visual surface discon-

development of these limits. tinuities shall be removed and their removal verified by visual

A487/A487M−93 (2012)

TABLE 2 Chemical Requirements (Maximum Percent Unless Range is Given)

Grade 1. 2. 4. 6. 7. 8. 9. 10. 11. 12.

AB A AB

ABC ABCDE ABC ABCDE AB AB

Manganese Nickel- Nickel-

Class ABC Manganese- Nickel- Chromium- Chromium- Nickel- Nickel-

Nickel- Chromium- Chromium-

Type Vanadium Molyb- Chromium- Molyb- Molyb- Chromium- Chromium-

Chromium- Molybdenum- Molybde-

denum Molybdenum denum denum Molybdenum Molybdenum

A

Molybdenum Vanadium num

Carbon 0.30 0.30 0.30 0.05–0.38 0.05–0.20 0.05–0.20 0.05–0.33 0.30 0.05–0.20 0.05–0.20

Manganese 1.00 1.00–1.40 1.00 1.30–1.70 0.60–1.00 0.50–0.90 0.60–1.00 0.60 to 1.00 0.50–0.80 0.40–0.70

Phosphorus 0.04 0.04 0.04 0.04 0.04 0.04 0.04 0.04 0.04 0.04

Sulfur 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045

Silicon 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.60 0.60

Nickel . . . . . . 0.40–0.80 0.40–0.80 0.70–1.00 . . . . . . 1.40–2.00 0.70–1.10 0.60–1.00

Chromium . . . . . . 0.40–0.80 0.40–0.80 0.40–0.80 2.00–2.75 0.75–1.10 0.55–0.90 0.50–0.80 0.50–0.90

Molybdenum . . . 0.10–0.30 0.15–0.30 0.30–0.40 0.40–0.60 0.90–1.10 0.15–0.30 0.20–0.40 0.45–0.65 0.90–1.20

Vanadium 0.04–0.12 . . . . . . . . . 0.03–0.10 . . . . . . . . . . . . . . .

Boron . . . . . . . . . . . . 0.002–0.006 . . . . . . . . . . . . . . .

Copper . . . . . . . . . . . . 0.15–0.50 . . . . . . . . . . . . . . .

Residual Elements:

Copper 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50

Nickel 0.50 0.50 . . . . . . . . . . . . 0.50 . . . . . . . . .

Chromium 0.35 0.35 . . . . . . . .

Mo + W 0.25 . . . . . . . . .

Tungsten . . . 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10

Vanadium . . . 0.03 0.03 0.03 . . . 0.03 0.03 0.03 0.03 0.03

Total content of 1.00 1.00 0.60 0.60 0.60 0.60 1.00 0.60 0.50 0.50

residual

elements

Grade 13. 14. 16 CA15 CA15M CA6NM

A

AB

AB A Low Carbon ABCD A

Martensitic

Clas

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A487/A487M–93 (Reapproved 2007) Designation: A487/A487M – 93

(Reapproved 2012)

Standard Specification for

Steel Castings Suitable for Pressure Service

This standard is issued under the fixed designationA487/A487M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 Thisspecification coverslow-alloysteelsandmartensiticstainlesssteelsinthenormalizedandtempered,orquenchedand

tempered, condition suitable for pressure-containing parts. The weldability of the classes in this specification varies from readily

weldable to weldable only with adequate precautions, and the weldability of each class should be considered prior to assembly by

fusion welding.

1.2 Selection will depend on design, mechanical, and service conditions. Users should note that hardenability of some of the

grades mentioned may restrict the maximum size at which the required mechanical properties are obtained.

1.3 Thevaluesstatedineitherinch-poundunitsorSIunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunits

are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used

independently of the other. Combining values from the two systems may result in nonconformance with the specification.

Inch-pound units are applicable for material ordered to Specification A487 and SI units for material ordered to Specification

A487M.

2. Referenced Documents

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A488/A488M Practice for Steel Castings, Welding, Qualifications of Procedures and Personnel

A703/A703M Specification for Steel Castings, General Requirements, for Pressure-Containing Parts

E165 Practice for Liquid Penetrant Examination for General Industry

E709 Guide for Magnetic Particle Testing

2.2 American Society of Mechanical Engineers:

ASME Boiler and Pressure Vessel Code, Section IX

2.3 Manufacturers Standardization Society of the Valve and Fittings Industry Standards:

SP-55 Quality Standard for Steel Castings-Visual Method

3. General Conditions for Delivery

3.1 Material furnished to this specification shall conform to the requirements of Specification A703/A703M including any

supplementary requirements that are indicated in the purchase order. Failure to comply with the general requirements of

SpecificationA703/A703Mconstitutesnonconformancewiththisspecification.Incaseofconflictbetweentherequirementsofthis

specification and Specification A703/A703M, this specification shall prevail.

4. Ordering Information

4.1 The inquiry and order should include or indicate the following:

ThisspecificationisunderthejurisdictionofASTMCommitteeA01onSteel,StainlessSteelandRelatedAlloysandisthedirectresponsibilityofSubcommitteeA01.18

on Castings.

Current edition approved Nov.March 1, 2007.2012. Published November 2007.April 2012. Originally approved in 1963. Last previous edition approved in 20032007 as

A487/A487M– 93 (2003).(2007). DOI: 10.1520/A0487_A0487M-93R0712.

For ASME Boiler and Pressure Vessel Code applications see related Specifications SA-487 in Section II of that code.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

www.asme.org.

Available from Manufacturers Standardization Society of the Valve and Fittings Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-hq.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A487/A487M – 93 (2012)

4.1.1 A description of the casting by pattern number or drawing (dimensional tolerances shall be included on the casting

drawing),

4.1.2 ASTM designation and year of issue,

4.1.3 Grade and class of steel,

4.1.4 Options in the specification, and

4.1.5 The supplementary requirements desired including the standard of acceptance.

5. Heat Treatment

5.1 All castings shall receive a heat treatment indicated in Table 1. Preliminary heat treatment prior to final heat treatment as

well as multiple tempering is permitted.

5.2 Heat treatment shall be performed after the castings have been allowed to cool below the transformation range.

5.3 The furnace temperature for heat treating shall be effectively controlled by use of recording-type pyrometers.

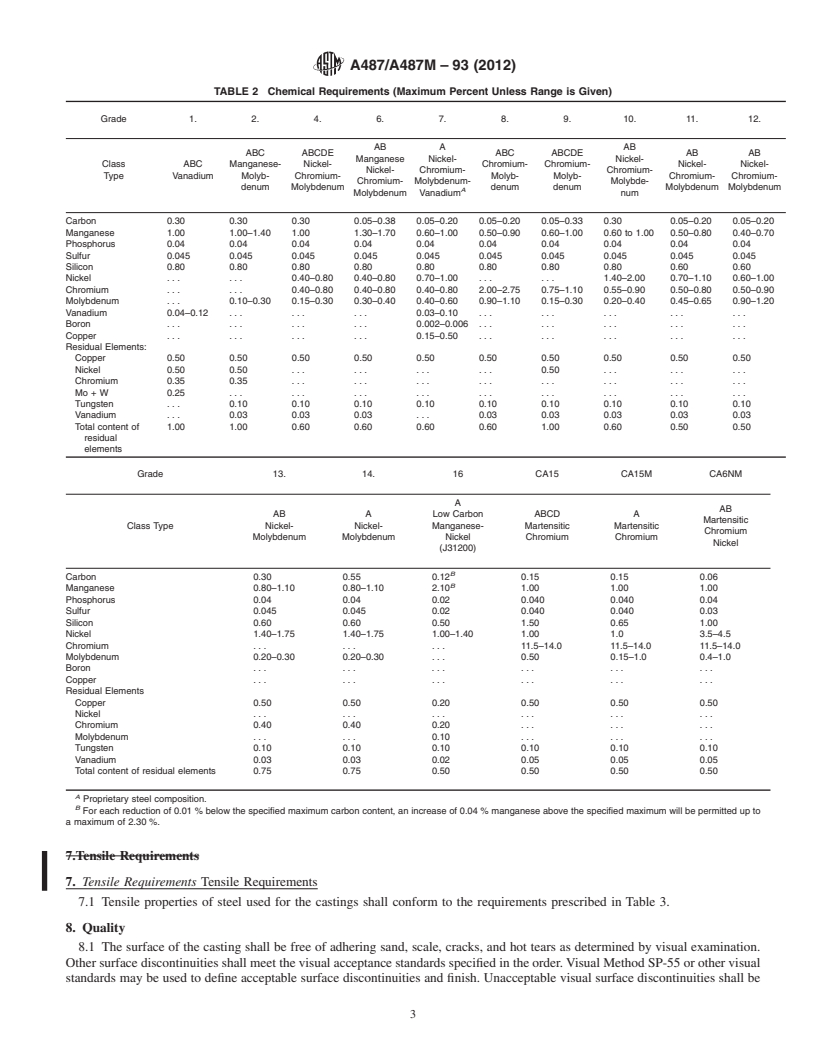

6. Chemical Composition

6.1 The steel shall conform to the requirements as to chemical composition prescribed in Table 2. Product analysis tolerance

shall conform to the product analysis tolerance shown in Specification A703/A703M. Product analysis tolerances for stainless

grades are not presently applicable pending development of these limits.

TABLE 1 Heat Treat Requirement

Austenitizing Tempering

Quenching Cool

A

Grade Class Temperature, Media Temperature,

Below °F [°C]

B

min, °F [°C] °F [°C]

1 A 1600 [870] A 450 [230] 1100 [595]

1 B 1600 [870] L 500 [260] 1100 [595]

1 C 1600 [870] A or L 500 [260] 1150 [620]

2 A 1600 [870] A 450 [230] 1100 [595]

2 B 1600 [870] L 500 [260] 1100 [595]

2 C 1600 [870] A or L 500 [260] 1150 [620]

4 A 1600 [870] A or L 500 [260] 1100 [595]

4 B 1600 [870] L 500 [260] 1100 [595]

4 C 1600 [870] A or L 500 [260] 1150 [620]

4 D 1600 [870] L 500 [260] 1150 [620]

4 E 1600 [870] L 500 [260] 1100 [595]

6 A 1550 [845] A 500 [260] 1100 [595]

6 B 1550 [845] L 500 [260] 1100 [595]

7 A 1650 [900] L 600 [315] 1100 [595]

8 A 1750 [955] A 500 [260] 1250 [675]

8 B 1750 [955] L 500 [260] 1250 [675]

8 C 1750 [955] L 500 [260] 1250 [675]

9 A 1600 [870] A or L 500 [260] 1100 [595]

9 B 1600 [870] L 500 [260] 1100 [595]

9 C 1600 [870] A or L 500 [260] 1150 [620]

9 D 1600 [870] L 500 [260] 1150 [620]

9 E 1600 [870] L 500 [260] 1100 [595]

10 A 1550 [845] A 500 [260] 1100 [595]

10 B 1550 [845] L 500 [260] 1100 [595]

11 A 1650 [900] A 600 [315] 1100 [595]

11 B 1650 [900] L 600 [315] 1100 [595]

12 A 1750 [955] A 600 [315] 1100 [595]

12 B 1750 [955] L 400 [205] 1100 [595]

13 A 1550 [845] A 500 [260] 1100 [595]

13 B 1550 [845] L 500 [260] 1100 [595]

14 A 1550 [845] L 500 [260] 1100 [595]

C

16 (J31200) A 1600 [870] A 600 [315] 1100 [595]

CA15 A 1750 [955] A or L 400 [205] 900 [480]

CA15 B 1750 [955] A or L 400 [205] 1100 [595]

DE

CA15 C 1750 [955] A or L 400 [205] 1150 [620]

DE

CA15 D 1750 [955] A or L 400 [205] 1150 [260]

CA15M A 1750 [955] A or L 400 [205] 1100 [595]

CA6NM A 1850 [1010] A or L 200 [95] 1050–1150 [565–620]

E,F

CA6NM B 1850 [1010] A or L 200 [95] 1225–1275 [665–690]

G

1050–1150 [565–620]

A

A = air, L = Liquid.

B

Minimum temperature unless range is specified.

C

Double austenitize.

D

Double temper with the final temper at a lower temperature than the intermediate temper.

E

Air cool to below 200°F [95°C] after first temper.

F

Intermediate.

G

Final.

A487/A487M – 93 (2012)

TABLE 2 Chemical Requirements (Maximum Percent Unless Range is Given)

Grade 1. 2. 4. 6. 7. 8. 9. 10. 11. 12.

AB A AB

ABC ABCDE ABC ABCDE AB AB

Manganese Nickel- Nickel-

Class ABC Manganese- Nickel- Chromium- Chromium- Nickel- Nickel-

Nickel- Chromium- Chromium-

Type Vanadium Molyb- Chromium- Molyb- Molyb- Chromium- Chromium-

Chromium- Molybdenum- Molybde-

denum Molybdenum denum denum Molybdenum Molybdenum

A

Molybdenum Vanadium num

Carbon 0.30 0.30 0.30 0.05–0.38 0.05–0.20 0.05–0.20 0.05–0.33 0.30 0.05–0.20 0.05–0.20

Manganese 1.00 1.00–1.40 1.00 1.30–1.70 0.60–1.00 0.50–0.90 0.60–1.00 0.60 to 1.00 0.50–0.80 0.40–0.70

Phosphorus 0.04 0.04 0.04 0.04 0.04 0.04 0.04 0.04 0.04 0.04

Sulfur 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045

Silicon 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.60 0.60

Nickel . . . . . . 0.40–0.80 0.40–0.80 0.70–1.00 . . . . . . 1.40–2.00 0.70–1.10 0.60–1.00

Chromium . . . . . . 0.40–0.80 0.40–0.80 0.40–0.80 2.00–2.75 0.75–1.10 0.55–0.90 0.50–0.80 0.50–0.90

Molybdenum . . . 0.10–0.30 0.15–0.30 0.30–0.40 0.40–0.60 0.90–1.10 0.15–0.30 0.20–0.40 0.45–0.65 0.90–1.20

Vanadium 0.04–0.12 . . . . . . . . . 0.03–0.10 . . . . . . . . . . . . . . .

Boron . . . . . . . . . . . . 0.002–0.006 . . . . . . . . . . . . . . .

Copper . . . . . . . . . . . . 0.15–0.50 . . . . . . . . . . . . . . .

Residual Elements:

Copper 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50

Nickel 0.50 0.50 . . . . . . . . . . . . 0.50 . . . . . . . . .

Chromium 0.35 0.35 . . . . . . . .

Mo + W 0.25 . . . . . . . . .

Tungsten . . . 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10

Vanadium . . . 0.03 0.03 0.03 . . . 0.03 0.03 0.03 0.03 0.03

Total content of 1.00 1.00 0.60 0.60 0.60 0.60 1.00 0.60 0.50 0.50

residual

elements

Grade 13. 14. 16 CA15 CA15M CA6NM

A

AB

AB A Low Carbon ABCD A

Martensitic

Class Type Nickel- Nickel- Manganese- Martensitic Martensitic

Chromium

Molybdenum Molybdenum Nickel Chromium Chromium

Nickel

(J31200)

B

Carbon 0.30 0.55 0.12 0.15 0.15 0.06

B

Manganese 0.80–1.10 0.80–1.10 2.10 1.00 1.00 1.00

Phosphorus 0.04 0.04 0.02 0.040 0.040 0.04

Sulfur 0.045 0.045 0.02 0.040 0.040 0.03

Silicon 0.60 0.60 0.50 1.50 0.65 1.00

Nickel 1.40–1.75 1.40–1.75 1.00–1.40 1.00 1.0 3.5–4.5

Chromium . . . . . . . . . 11.5–14.0 11.5

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.