ASTM C912-93(2008)e1

(Practice)Standard Practice for Designing a Process for Cleaning Technical Glasses

Standard Practice for Designing a Process for Cleaning Technical Glasses

SIGNIFICANCE AND USE

Many of the low-silica technical glasses which contain soluble or reactive oxides require processing or involve applications that require cleaning. Very often these cleaning procedures have evolved over several decades and are considered an art. They usually contain numerous steps, some of questionable validity. It is the premise of this practice that cleaning glass can be more scientific. Design of a cleaning procedure should involve (1) a definition of the soil to be removed, (2) an awareness of the constraints imposed by the glass composition, and (3) a rational selection of alternative methods that will remove the soil and leave the glass in a condition suitable for its intended application. This practice provides information to assist in step (3). General references on glass cleaning and on various methods of evaluating cleanliness and associated information has been published.

SCOPE

1.1 This practice covers information that will permit design of a rational cleaning procedure that can be used with a glass that is somewhat soluble in many aqueous chemical solutions. Typically, this type of glass is used in applications such as optical ware, glass-to-metal seals, low dielectric loss products, glass fibers, infrared transmitting products, and products resistant to metallic vapors.

1.2 In most cases, this type of glass contains high concentrations of oxides that tend to react with a number of aqueous chemicals. Such oxides include B2O3, Al2O3, R2O, RO, La2O3, ZnO, PbO, P2O5, and Fe2O3. The more conventional high-silica glasses are usually more chemically resistant, but the cleaning principles outlined here also apply to them.

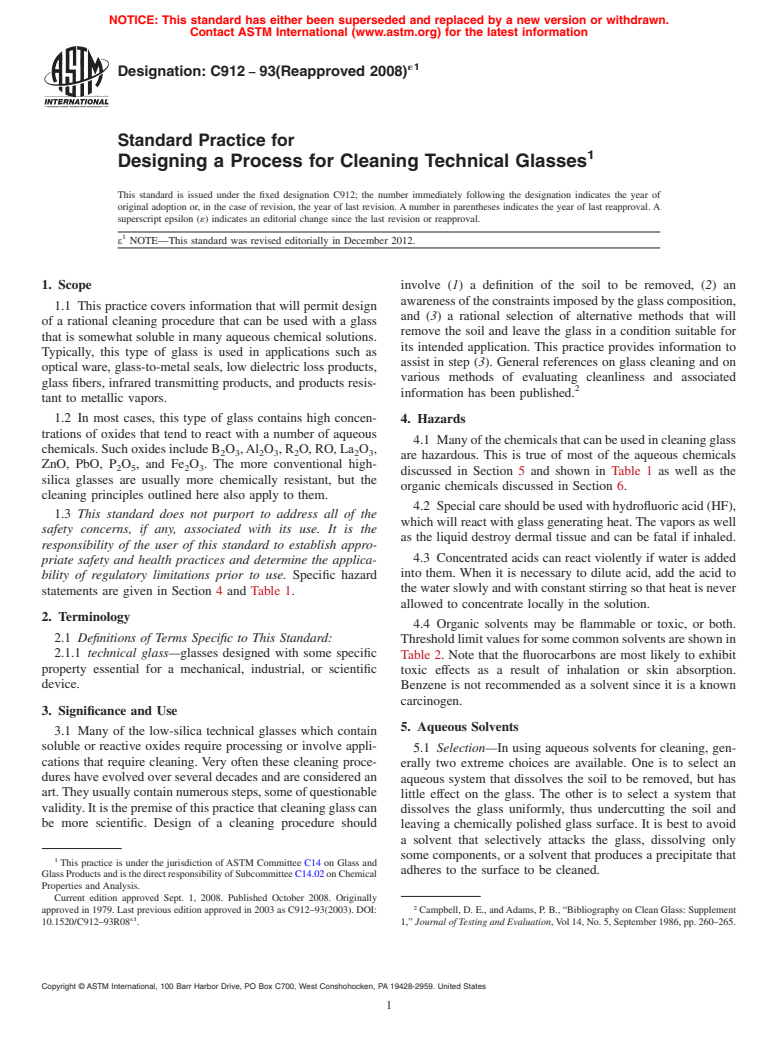

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 4 and Table 1.

TABLE 1 Relative Solubility of Various Glass Component Oxides in HF, Other Inorganic Acids, and NaOH, in Concentrated Solutions at Room Temperature

Note 1—Macro or minor/trace levels will determine degree of precipitation, especially in acids, for example, HNO3 (Sn, Sb, Mo).

Note 2—W is soluble in acid but heat may precipitate it, for example, H2WO4.

Note 3—Sn+4 is soluble in hot H2SO4; Sn+2 is soluble in other reagents as well.

Note 4—Most alkali solutions must be hot to effect solution.

Note 5—PbSO4 is soluble in hot concentrated H2SO4.

Note 6—Sb and Bi form insoluble oxychlorides in dilute HCl.

Note 7—Ba is insoluble in concentrated HNO3. Oxides ofHF

49 %H2SO4

96 %HNO3

70 %HCl

37 %HBrHIH3PO4

85 %NaOH

50 % Al sAsssiiis Sb iAiisssis Asssssssss Baiissssss Besssssssi Bisssssssi Bssssssss Cdssssssss Caisssssss Ceisiiiiii Criiiiiiii Cosssssssi Cusssssssi Erissssssi Euissssssi Gdissssssi Gasssssssi Gessssssss Auiiiiiiii Hfsiiiiiii Fesssssssi Laissssssi Pbiisiiiss Lissssssss Mgissssssi Mnsssssssi Moss iBsssss Ndissssssi Nisssssssi Nbsiiiiiii Pdssiiiiii Pssssssss Ptiiiiiiii Kssssssss Prissssssi Pmissssssi Rhissssssi Rbissssssi Ruissssssi Smissssssi Sessssssss Sisiiiiiis Agsssiiisi Nassssssss Sriiiiiiii Tasiiiiiii Tessssssss Tlssssiisi Ths sBiiiiii Snssssssss Tis sBisiiii Wsiiiiiis Usssiiiii Vssssssss Ybissssssi Yissssssi Znssssssss Zrs sBiiiiii

A s = relatively soluble, i = relatively insoluble.

B hot

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: C912 − 93(Reapproved 2008)

Standard Practice for

Designing a Process for Cleaning Technical Glasses

This standard is issued under the fixed designation C912; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—This standard was revised editorially in December 2012.

1. Scope involve (1) a definition of the soil to be removed, (2)an

awareness of the constraints imposed by the glass composition,

1.1 This practice covers information that will permit design

and (3) a rational selection of alternative methods that will

of a rational cleaning procedure that can be used with a glass

remove the soil and leave the glass in a condition suitable for

that is somewhat soluble in many aqueous chemical solutions.

its intended application. This practice provides information to

Typically, this type of glass is used in applications such as

assist in step (3). General references on glass cleaning and on

optical ware, glass-to-metal seals, low dielectric loss products,

various methods of evaluating cleanliness and associated

glass fibers, infrared transmitting products, and products resis-

information has been published.

tant to metallic vapors.

1.2 In most cases, this type of glass contains high concen- 4. Hazards

trations of oxides that tend to react with a number of aqueous

4.1 Manyofthechemicalsthatcanbeusedincleaningglass

chemicals. Such oxides include B O ,Al O ,R O, RO, La O ,

2 3 2 3 2 2 3

are hazardous. This is true of most of the aqueous chemicals

ZnO, PbO, P O , and Fe O . The more conventional high-

2 5 2 3

discussed in Section 5 and shown in Table 1 as well as the

silica glasses are usually more chemically resistant, but the

organic chemicals discussed in Section 6.

cleaning principles outlined here also apply to them.

4.2 Specialcareshouldbeusedwithhydrofluoricacid(HF),

1.3 This standard does not purport to address all of the

which will react with glass generating heat. The vapors as well

safety concerns, if any, associated with its use. It is the

as the liquid destroy dermal tissue and can be fatal if inhaled.

responsibility of the user of this standard to establish appro-

4.3 Concentrated acids can react violently if water is added

priate safety and health practices and determine the applica-

into them. When it is necessary to dilute acid, add the acid to

bility of regulatory limitations prior to use. Specific hazard

the water slowly and with constant stirring so that heat is never

statements are given in Section 4 and Table 1.

allowed to concentrate locally in the solution.

2. Terminology

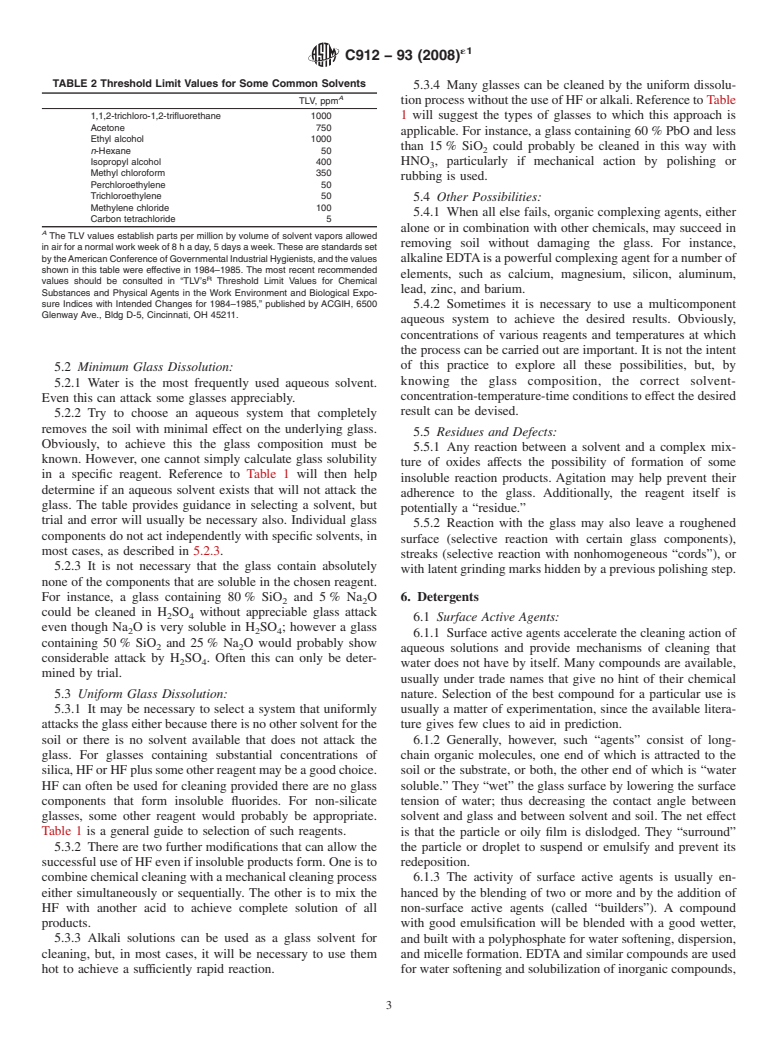

4.4 Organic solvents may be flammable or toxic, or both.

2.1 Definitions of Terms Specific to This Standard:

Thresholdlimitvaluesforsomecommonsolventsareshownin

2.1.1 technical glass—glasses designed with some specific

Table 2. Note that the fluorocarbons are most likely to exhibit

property essential for a mechanical, industrial, or scientific

toxic effects as a result of inhalation or skin absorption.

device.

Benzene is not recommended as a solvent since it is a known

carcinogen.

3. Significance and Use

5. Aqueous Solvents

3.1 Many of the low-silica technical glasses which contain

soluble or reactive oxides require processing or involve appli-

5.1 Selection—In using aqueous solvents for cleaning, gen-

cations that require cleaning. Very often these cleaning proce-

erally two extreme choices are available. One is to select an

dures have evolved over several decades and are considered an

aqueous system that dissolves the soil to be removed, but has

art.Theyusuallycontainnumeroussteps,someofquestionable

little effect on the glass. The other is to select a system that

validity.Itisthepremiseofthispracticethatcleaningglasscan

dissolves the glass uniformly, thus undercutting the soil and

be more scientific. Design of a cleaning procedure should

leaving a chemically polished glass surface. It is best to avoid

a solvent that selectively attacks the glass, dissolving only

some components, or a solvent that produces a precipitate that

This practice is under the jurisdiction of ASTM Committee C14 on Glass and

adheres to the surface to be cleaned.

GlassProductsandisthedirectresponsibilityofSubcommitteeC14.02onChemical

Properties and Analysis.

Current edition approved Sept. 1, 2008. Published October 2008. Originally

approved in 1979. Last previous edition approved in 2003 as C912–93(2003). DOI: Campbell, D. E., andAdams, P. B., “Bibliography on Clean Glass: Supplement

ε1

10.1520/C912–93R08 . 1,” Journal of Testing and Evaluation,Vol 14, No. 5, September 1986, pp. 260–265.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

C912 − 93 (2008)

TABLE 1 Relative Solubility of Various Glass Component Oxides in HF, Other Inorganic Acids, and NaOH, in Concentrated Solutions at

Room Temperature

NOTE 1—Macro or minor/trace levels will determine degree of precipitation, especially in acids, for example, HNO (Sn, Sb, Mo).

NOTE 2—W is soluble in acid but heat may precipitate it, for example, H WO .

2 4

+4 +2

NOTE 3—Sn is soluble in hot H SO;Sn is soluble in other reagents as well.

2 4

NOTE 4—Most alkali solutions must be hot to effect solution.

NOTE 5—PbSO is soluble in hot concentrated H SO .

4 2 4

NOTE 6—Sb and Bi form insoluble oxychlorides in dilute HCl.

NOTE 7—Ba is insoluble in concentrated HNO .

HF H SO HNO HCl H PO NaOH

2 4 3 3 4

Oxides of HBr HI

49 % 96 % 70 % 37 % 85 % 50 %

A

Al s s s s iii s

A

Sb i i i sss i s

As s s s sssss

Ba i i s sssss

Be s s s ssss i

Bi s s s ssss i

B s s s sssss

Cd s s s sssss

Ca i s s sssss

Ce i s i iiiii

Cr i i i iiiii

Co s s s ssss i

Cu s s s ssss i

Er i s s ssss i

Eu i s s ssss i

Gd i s s ssss i

Ga s s s ssss i

Ge s s s sssss

Au i i i iiiii

Hf s i i iiiii

Fe s s s ssss i

La i s s ssss i

Pb i i s iii s s

Li s s s sssss

Mg i s s ssss i

Mn s s s ssss i

B

Mo s s i sssss

Nd i s s ssss i

Ni s s s ssss i

Nb s i i iiiii

Pd s s i iiiii

P s s s sssss

Pt i i i iiiii

K s s s sssss

Pr i s s ssss i

Pm i s s ssss i

Rh i s s ssss i

Rb i s s ssss i

Ru i s s ssss i

Sm i s s ssss i

Se s s s sssss

Si s i i iiii s

Ag s s s iii s i

Na s s s sssss

Sr i i i iiiii

Ta s i i iiiii

Te s s s sssss

Tl s s s s i i s i

B

i iiiii

Th s s

Sn s s s sssss

B

Ti s s i s iiii

W s i i iiii s

U s s s iiiii

V s s s sssss

Yb i s s ssss i

Y i s s ssss i

Zn s s s sssss

B

Zr s s i iiiii

A

s = relatively soluble, i = relatively insoluble.

B

hot

´1

C912 − 93 (2008)

TABLE 2 Threshold Limit Values for Some Common Solvents

5.3.4 Many glasses can be cleaned by the uniform dissolu-

A

TLV, ppm tionprocesswithouttheuseofHForalkali.ReferencetoTable

1,1,2-trichloro-1,2-trifluorethane 1000 1 will suggest the types of glasses to which this approach is

Acetone 750

applicable. For instance, a glass containing 60 % PbO and less

Ethyl alcohol 1000

than 15 % SiO could probably be cleaned in this way with

n-Hexane 50

Isopropyl alcohol 400 HNO , particularly if mechanical action by polishing or

Methyl chloroform 350

rubbing is used.

Perchloroethylene 50

Trichloroethylene 50

5.4 Other Possibilities:

Methylene chloride 100

5.4.1 When all else fails, organic complexing agents, either

Carbon tetrachloride 5

alone or in combination with other chemicals, may succeed in

A

The TLV values establish parts per million by volume of solvent vapors allowed

removing soil without damaging the glass. For instance,

in air for a normal work week of8haday,5 days a week.These are standards set

bytheAmericanConferenceofGovernmentalIndustrialHygienists,andthevalues

alkaline EDTAis a powerful complexing agent for a number of

shown in this table were effective in 1984–1985. The most recent recommended

elements, such as calcium, magnesium, silicon, aluminum,

R

values should be consulted in “TLV’s Threshold Limit Values for Chemical

lead, zinc, and barium.

Substances and Physical Agents in the Work Environment and Biological Expo-

sure Indices with Intended Changes for 1984–1985,” published by ACGIH, 6500

5.4.2 Sometimes it is necessary to use a multicomponent

Glenway Ave., Bldg D-5, Cincinnati, OH 45211.

aqueous system to achieve the desired results. Obviously,

concentrations of various reagents and temperatures at which

the process can be carried out are important. It is not the intent

of this practice to explore all these possibilities, but, by

5.2 Minimum Glass Dissolution:

knowing the glass composition, the correct solvent-

5.2.1 Water is the most frequently used aqueous solvent.

concentration-temperature-time conditions to effect the desired

Even this can attack some glasses appreciably.

result can be devised.

5.2.2 Try to choose an aqueous system that completely

removes the soil with minimal effect on the underlying glass.

5.5 Residues and Defects:

Obviously, to achieve this the glass composition must be

5.5.1 Any reaction between a solvent and a complex mix-

known. However, one cannot simply calculate glass solubility

ture of oxides affects the possibility of formation of some

in a specific reagent. Reference to Table 1 will then help

insoluble reaction products. Agitation may help prevent their

determine if an aqueous solvent exists that will not attack the

adherence to the glass. Additionally, the reagent itself is

glass. The table provides guidance in selecting a solvent, but

potentially a “residue.”

trial and error will usually be necessary also. Individual glass

5.5.2 Reaction with the glass may also leave a roughened

components do not act independently with specific solvents, in

surface (selective reaction with certain glass components),

most cases, as described in 5.2.3.

streaks (selective reaction with nonhomogeneous “cords”), or

5.2.3 It is not necessary that the glass contain absolutely

with latent grinding marks hidden by a previous polishing step.

none of the components that are soluble in the chosen reagent.

For instance, a glass containing 80 % SiO and 5 % Na O 6. Detergents

2 2

could be cleaned in H SO without appreciable glass attack

2 4

6.1 Surface Active Agents:

even though Na O is very soluble in H SO ; however a glass

2 2 4

6.1.1 Surface active agents accelerate the cleaning action of

containing 50 % SiO and 25 % Na O would probably show

2 2

aqueous solutions and provide mechanisms of cleaning that

considerable attack by H SO . Often this can only be deter-

2 4

water does not have by itself. Many compounds are available,

mined by trial.

usually under trade names that give no hint of their chemical

5.3 Uniform Glass Dissolution:

nature. Selection of the best compound for a particular use is

5.3.1 It may be necessary to select a system that uniformly usually a matter of experimentation, since the available litera-

attacks the glass either because there is no other solvent for the ture gives few clues to aid in prediction.

soil or there is no solvent available that does not attack the 6.1.2 Generally, however, such “agents” consist of long-

glass. For glasses containing substantial concentrations of chain organic molecules, one end of which is attracted to the

silica,HForHFplussomeotherreagentmaybeagoodchoice. soil or the substrate, or both, the other end of which is “water

HF can often be used for cleaning provided there are no glass soluble.” They “wet” the glass surface by lowering the surface

components that form insoluble fluorides. For non-silicate tension of water; thus decreasing the contact angle between

glasses, some other reagent would probably be appropriate. solvent and glass and between solvent and soil. The net effect

Table 1 is a general guide to selection of such reagents. is that the particle or oily film is dislodged. They “surround”

5.3.2 There are two further modifications that can allow the the particle or droplet to suspend or emulsify and prevent its

successful use of HF even if insoluble products form. One is to redeposition.

combinechemicalcleaningwithamechanicalcleaningprocess 6.1.3 The activity of surface active agents is usually en-

either simultaneously or sequentially. The other is to mix the hanced by the blending of two or more and by the addition of

HF with another acid to achieve complete solution of all non-surface active agents (called “builders”). A compound

products. with good emulsification will be blended with a good wetter,

5.3.3 Alkali solutions can be used as a glass solvent for and built with a polyphosphate for water softening, dispersion,

cleaning, but, in most cases, it will be necessary to use them and micelle formation. EDTAand similar compounds are used

hot to achieve a sufficiently rapid reaction. for water softening and solubilization of inorganic compounds,

´1

C912 − 93 (2008)

TABLE 3 Relative Solvent Power of Some Organics (Removal of

soda ash, and ammonia for pH regulation and sodium silicates

Stearic Acid from Glass by a 30-s Soak at the Boiling Point)

for achieving high alkalinity while inhibiting attack on the

Stearic Acid

glass.

Solvent

Remaining, %

6.1.4 The builders can either promote or inhibit solution of

A

Combination No. 1 35.0

glasses, depending on whether the reaction products or the A

Combination No. 2 2.4

A

builder and the glass components are soluble or insoluble. Combination No. 3 1.4

Trichlorotrifluoroethane 74.0

Polyphosphates and EDTA, in particular, will chelate with and

Acetone 1.3

solubilize metallic ions, promoting a preferential leaching and

Methanol 0.30

leaving a porous or etched surface on the glass. Hexane 44.0

Methyl chloroform 1.6

6.1.5 Water-soluble surface active agents are usually long-

Benzene 6.7

chain organic molecules with a hydrophobic end and a hydro-

Isopropanol 0.60

philic end. The ionic nature of the hydrophilic end determines Trichloroethylene 0.80

Perchloroethylene 1.0

the broad basic classification of the material—if negative, it is

A

See Table 4 for description.

anionic, if positive, cationic, and if the material is not ionized,

it is nonionic. There are a few amphoteric materials available,

and these hybrids can be either cationic or anionic, depending

7.1.1 Hydrocarbons such as hexane can be used to remove

on the pH of the solution.

oils and other nonpolar contaminants from glass. However, for

6.2 Anionic Agents—The oldest, and one of the most effec-

the removal of adsorbed polar compounds or intermediate size

tive anionic detergents if used in “soft” water, is soap. The

particulate matter (0.1 to 1000 µm), more active solvent

largest class of synthetic anionic detergents is the sulfonated

systems such as those shown

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.