ASTM C657-93(1998)

(Test Method)Standard Test Method for D-C Volume Resistivity of Glass

Standard Test Method for D-C Volume Resistivity of Glass

SCOPE

1.1 This test method covers the determination of the dc volume resistivity of a smooth, preferably polished, glass by measuring the resistance to passage of a small amount of direct current through the glass at a voltage high enough to assure adequate sensitivity. This current must be measured under steady-state conditions that is neither a charging current nor a space-charge, build-up polarization current.

1.2 This test method is intended for the determination of sensitivities less than 10 [omega][dot]cm in the temperature range from 25°C to the annealing point of the glass.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 657 – 93 (Reapproved 1998)

Standard Test Method for

D-C Volume Resistivity of Glass

This standard is issued under the fixed designation C 657; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope space charge, buildup polarization effects, and surface conduc-

tances. The temperature range is limited to room temperature

1.1 This test method covers the determination of the dc

to the annealing point of the specimen glass.

volume resistivity of a smooth, preferably polished, glass by

measuring the resistance to passage of a small amount of direct

5. Cautions

current through the glass at a voltage high enough to assure

5.1 Thermal emfs should be avoided. Connections involv-

adequate sensitivity. This current must be measured under

ing dissimilar metals can cause measurement difficulties. Even

steady-state conditions that is neither a charging current nor a

copper-copper oxide junctions can produce high thermal emfs.

space-charge, buildup polarization current.

Clean, similar metals should be used for electrical junctions.

1.2 This test method is intended for the determination of

Platinum is recommended. Welded or crimped connections

resistivities less than 10 V·cm in the temperature range from

rather than soldered joints avoid difficulties. Specimen elec-

25°C to the annealing point of the glass.

trodes shall have sufficient cross section for adequate electrical

1.3 This standard does not purport to address all of the

conductance.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

6. Apparatus

priate safety and health practices and determine the applica-

6.1 Resistance-Measuring Devices, and the possible prob-

bility of regulatory limitations prior to use. For specific hazard

lems associated with them are discussed thoroughly in Section

statements, see Section 5.

9 and Appendixes A1 and A3 of Test Methods D 257. Further

2. Referenced Documents discussion of electrometer circuitry is covered in Annex A1 to

this test method.

2.1 ASTM Standards:

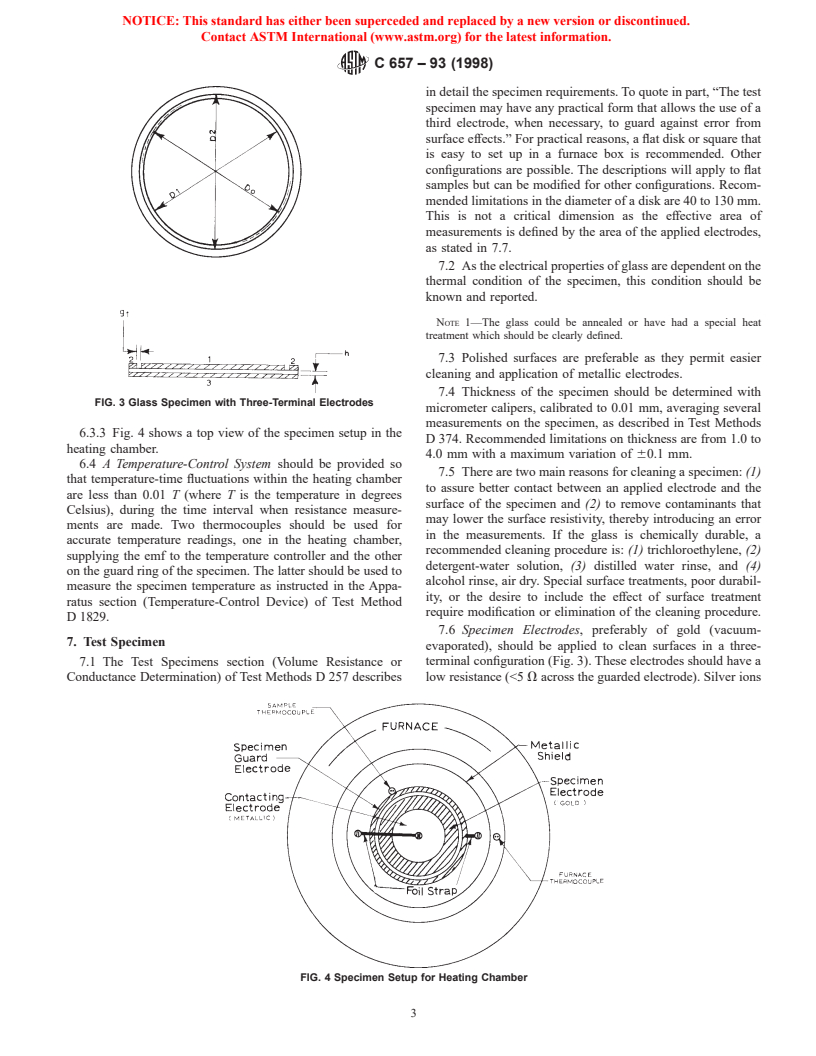

6.2 Heating Chamber (Fig. 1)—For heating the specimen, a

D 257 Test Methods for DC Resistance or Conductance of

2 suitable electric furnace shall be used. The construction of the

Insulating Materials

furnace shall be such that the specimen is subjected to a

D 374 Test Methods for Thickness of Solid Electrical Insu-

2 uniform heat application with a minimum of temperature

lation

2 fluctuation. An adequate muffle should be provided to shield

D 1711 Terminology Relating to Electrical Insulation

the specimen from direct radiation by the heating elements.

D 1829 Test Method for Electrical Resistance of Ceramic

This may be made of a ceramic such as aluminum oxide or

Materials at Elevated Temperatures

equivalent. A grounded metallic shield shall also be provided

3. Summary of Test Method within the furnace, preferably of silver, stainless steel, or

equivalent, to isolate electrically the specimen test circuit from

3.1 The dc volume resistance is measured in accordance

the heating element. Furnaces for more than one specimen can

with Test Methods D 257, with the specimen located in a

be constructed. The control thermocouple may be located in

heating chamber with adequate temperature control, electrical

the heating chamber outside the metallic shield, as shown in

shielding and insulation of the sample leads as described in

Fig. 1, or inside the metallic shield.

Test Method D 1829.

6.3 Two Flat Contacting Electrodes, smaller in diameter

4. Significance and Use

than the specimen electrodes (see 7.6), shall be used to

sandwich the specimen. Sufficient thickness should be used to

4.1 This experimental procedure yields meaningful data for

maintain an adequate pressure and to provide heat equalization

the dc volume resistivity of glass. It is designed to minimize

between the specimen and the contacting electrodes.

6.3.1 Fig. 2 shows the specimen setup in the heating

This test method is under the jurisdiction of ASTM Committee C-14 on Glass

chamber. The bottom electrode shall be placed at the end of a

and Glass Products and is the direct responsibility of Subcommittee C14.04 on

metal rod and shall support the specimen in the center of the

Physical and Mechanical Properties.

furnace. The unguarded specimen electrode, No. 3 of Fig. 3,

Current edition approved May 15, 1993. Published July 1993. Originally

published as C 657 – 70 T. Last previous edition C 657 – 88.

Annual Book of ASTM Standards, Vol 10.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 657 – 93 (1998)

NOTE 1—Heating elements attached to fused alumina core—covered with baked-on refractory cement.

FIG. 1 Heating Chamber

FIG. 2 Specimen Setup for Heating Chamber

shall be placed in contact with this bottom contacting elec- wire or strap. One end shall be connected to the specimen

trode. The top contacting electrode shall be placed on the guard electrode; the other end shall be connected to the metal

guarded, specimen electrode, No. 1 of Fig. 3. This top rod.

contacting electrode has leads connected to an off-center metal 6.3.2 All rods should be supported by insulation outside the

rod. The specimen guard electrode, No. 2 of Fig. 3, shall be furnace in a cool zone to minimize electrical leakage at

connected to the second off-center metal rod with platinum elevated temperatures.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 657 – 93 (1998)

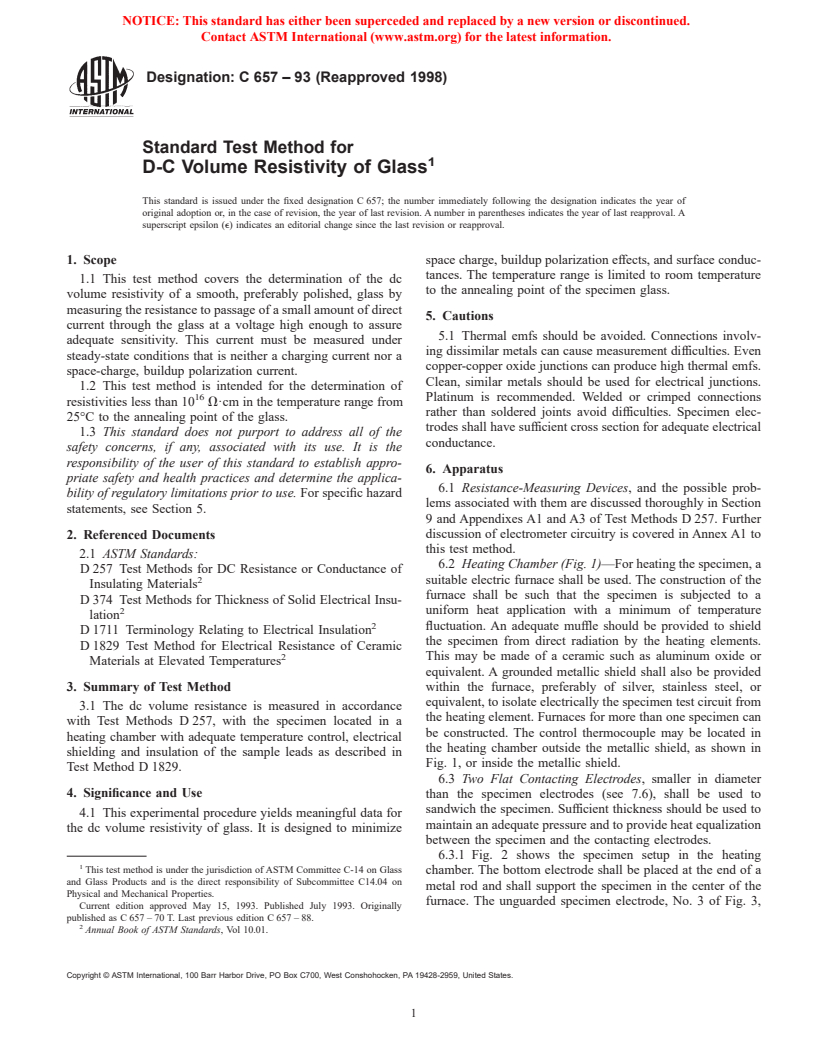

in detail the specimen requirements. To quote in part, “The test

specimen may have any practical form that allows the use of a

third electrode, when necessary, to guard against error from

surface effects.” For practical reasons, a flat disk or square that

is easy to set up in a furnace box is recommended. Other

configurations are possible. The descriptions will apply to flat

samples but can be modified for other configurations. Recom-

mended limitations in the diameter of a disk are 40 to 130 mm.

This is not a critical dimension as the effective area of

measurements is defined by the area of the applied electrodes,

as stated in 7.7.

7.2 As the electrical properties of glass are dependent on the

thermal condition of the specimen, this condition should be

known and reported.

NOTE 1—The glass could be annealed or have had a special heat

treatment which should be clearly defined.

7.3 Polished surfaces are preferable as they permit easier

cleaning and application of metallic electrodes.

7.4 Thickness of the specimen should be determined with

FIG. 3 Glass Specimen with Three-Terminal Electrodes

micrometer calipers, calibrated to 0.01 mm, averaging several

measurements on the specimen, as described in Test Methods

6.3.3 Fig. 4 shows a top view of the specimen setup in the

D 374. Recommended limitations on thickness are from 1.0 to

heating chamber.

4.0 mm with a maximum variation of 60.1 mm.

6.4 A Temperature-Control System should be provided so

7.5 There are two main reasons for cleaning a specimen: (1)

that temperature-time fluctuations within the heating chamber

to assure better contact between an applied electrode and the

are less than 0.01 T (where T is the temperature in degrees

surface of the specimen and (2) to remove contaminants that

Celsius), during the time interval when resistance measure-

may lower the surface resistivity, thereby introducing an error

ments are made. Two thermocouples should be used for

in the measurements. If the glass is chemically durable, a

accurate temperature readings, one in the heating chamber,

recommended cleaning procedure is: (1) trichloroethylene, (2)

supplying the emf to the temperature controller and the other

detergent-water solution, (3) distilled water rinse, and (4)

on the guard ring of the specimen. The latter should be used to

alcohol rinse, air dry. Special surface treatments, poor durabil-

measure the specimen temperature as instructed in the Appa-

ity, or the desire to include the effect of surface treatment

ratus section (Temperature-Control Device) of Test Method

require modification or elimination of the cleaning procedure.

D 1829.

7.6 Specimen Electrodes, preferably of gold (vacuum-

7. Test Specimen

evaporated), should be applied to clean surfaces in a t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.