ASTM B199-99

(Specification)Standard Specification for Magnesium-Alloy Permanent Mold Castings

Standard Specification for Magnesium-Alloy Permanent Mold Castings

SCOPE

1.1 This specification covers magnesium alloy permanent-mold casting alloys designated as shown in Table 1.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI values given in parentheses are provided for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 199 – 99

Standard Specification for

Magnesium-Alloy Permanent Mold Castings

This standard is issued under the fixed designation B 199; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

2.4 Military Specification:

1.1 This specification covers magnesium alloy permanent

MIL-M-6857 Heat Treatment of Magnesium Alloy Cast-

mold casting alloys designated as shown in Table 1.

ings

1.2 The values stated in inch-pound units are to be regarded

as the standard. The SI values given in parentheses are

3. Terminology

provided for information only.

3.1 Definitions:

2. Referenced Documents 3.1.1 permanent mold casting—a metal object produced by

introducing molten metal by gravity or low pressure into a

2.1 The following documents of the issue in effect on date

mold constructed of durable material, usually iron or steel, and

of order acceptance form a part of this specification to the

allowing it to solidify.

extent referenced herein:

3.1.2 semipermanent mold casting—apermanentmoldcast-

2.2 ASTM Standards:

ing which is made using an expendable core such as bonded

B 275 Practice for Codification of Certain Nonferrous Met-

sand.

als and Alloys, Cast and Wrought

B 296 Practice for Temper Designations of Magnesium

4. Ordering Information

Alloys, Cast and Wrought

4.1 Orders for castings under this specification shall include

B 557 Test Methods of Tension Testing Wrought and Cast

2 the following information:

Aluminum- and Magnesium-Alloy Products

4.1.1 Quantity of each casting,

B 660 Practices for Packaging/Packing of Aluminum and

2 4.1.2 Alloy (Section 7 and Table 1),

Magnesium Products

4.1.3 Temper (Section 8 and Table 2),

B 661 Practice for Heat Treatment of Magnesium Alloys

3 4.1.4 Minimum properties of specimens cut from castings,

E 8 Test Methods of Tension Testing of Metallic Materials

if required (see section 9.3),

E 29 Practice for Using Significant Digits in Test Data to

4 4.1.5 Drawing showing dimensions of the castings (the

Determine Conformance with Specification

amount of stock left for machine finish should be indicated),

E 35 Test Methods for Chemical Analysis of Magnesium

5 4.1.6 Surface treatment (see 10.1),

and Magnesium Alloys

4.1.7 Whether inspection is required at the manufacturer’s

E 88 Practice for Sampling Nonferrous Metals and Alloys

5 works (see section 11.1.1),

in Cast Form for Determination of Chemical Composition

6 4.1.8 Special inspection requirements (see 11.2),

E 94 Guide for Radiographic Testing

4.1.9 Whether certification is required (see 13.1), and

E 155 Reference Radiographs for Inspection of Aluminum

6 4.1.10 Whether marking for identification is required (see

and Magnesium Castings

6 14.1).

E 165 Test Methods for Liquid Penetrant Examination

E 527 Practice for Numbering Metals and Alloys (UNS)

5. Manufacture

2.3 Federal Standards:

5.1 The responsibility of furnishing castings that can be laid

out and machined to the finished dimensions within the

permissible variations specified, as shown on the blueprints or

This specification is under the jurisdiction of ASTM Committee B-7 on Light

Metals and Alloys and is the direct responsibility of Subcommittee B07.04 on drawings, shall rest with the supplier, except when molds are

Magnesium Alloy Cast and Wrought Products.

furnishedbythepurchaser.Sufficientstockshallbeallowedfor

Current edition approved Oct. 10, 1999. Published December 1999. Originally

shrinkage, and where requested, for finishing; castings of

e1

published as B 199–45T. Last previous edition B 199–87(1993) .

excessive weight shall not be furnished.

Annual Book of ASTM Standards, Vol 02.02.

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 03.05.

6 8

Annual Book of ASTM Standards, Vol 03.03. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Annual Book of ASTM Standards, Vol 01.01. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 199

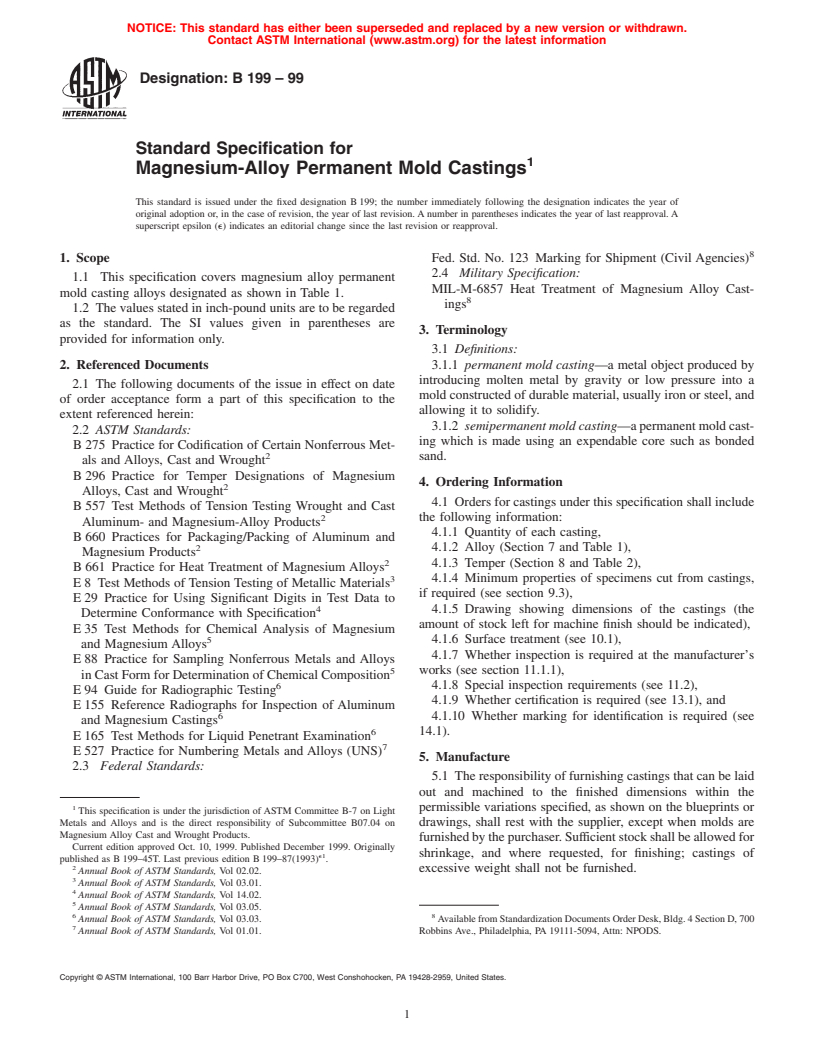

A

TABLE 1 Chemical Composition Limits

NOTE 1—Analysis shall regularly be made only for the elements specifically mentioned in this table. If, however, the presence of other elements is suspected or indicated in amounts greater than

the specified limits, further analysis shall be made to determine that these elements are not present in excess of the specified limits.

NOTE 2—The following applies to all specified limits in this table: For purposes of acceptance and rejection, an observed value or a calculated value obtained from analysis shall be rounded to

the nearest unit in the last right-hand place of figures used in expressing the specified limit.

B

Alloy Number Composition, %

C

Total

Other Others

ASTM UNS Iron Magnesium Aluminum Manganese Zinc Rare Earths Zirconium Silicon Copper Nickel

Impuri- Each

ties

AM100A M10100 . remainder 9.3 to 10.7 0.10–0.35 0.30 . . 0.30 0.10 0.01 0.30 .

AZ81A M11810 . remainder 7.0 to 8.1 0.13–0.35 0.40 to 1.0 . . 0.30 0.10 0.01 0.30 .

AZ91C M11914 . remainder 8.1 to 9.3 0.13–0.35 0.40 to 1.0 . . 0.30 0.10 0.01 0.30 .

D

AZ91E M11919 0.005 remainder 8.1 to 9.3 0.17–0.35 0.40 to 1.0 . . 0.20 0.015 0.0010 0.30 0.01

AZ92A M11920 . remainder 8.3 to 9.7 0.10–0.35 1.6 to 2.4 . . 0.30 0.25 0.01 0.30 .

E F

EQ21A M18330 . remainder . . . 1.5 to 3.0 0.40 to 1.0 . 0.05–0.10 0.01 0.30 .

EZ33A M12330 . remainder . . 2.0 to 3.1 2.5 to 4.0 0.50 to 1.0 . 0.10 0.01 0.30 .

G E F

QE22A M18220 . remainder . . . 1.8 to 2.5 0.40 to 1.0 . 0.10 0.01 0.30 .

A

Limits are in weight percent max unless shown as a range or stated otherwise.

B

ASTM alloy designations were established in accordance with Practice B 275. UNS designations were established in accordance with Practice E 527.

C

Includes listed elements for which no specific limit is shown.

D

If iron exceeds 0.005 %, the iron to manganese ratio shall not exceed 0.032.

E

Silver content for Alloy EQ21A (M18330) shall be 1.3 to 1.7 %.

F

Rare earth elements are in the form of didymium.

G

Silver content for Alloy QE22A (M18220) shall be 2.0 to 3.0, inclusive.

B 199

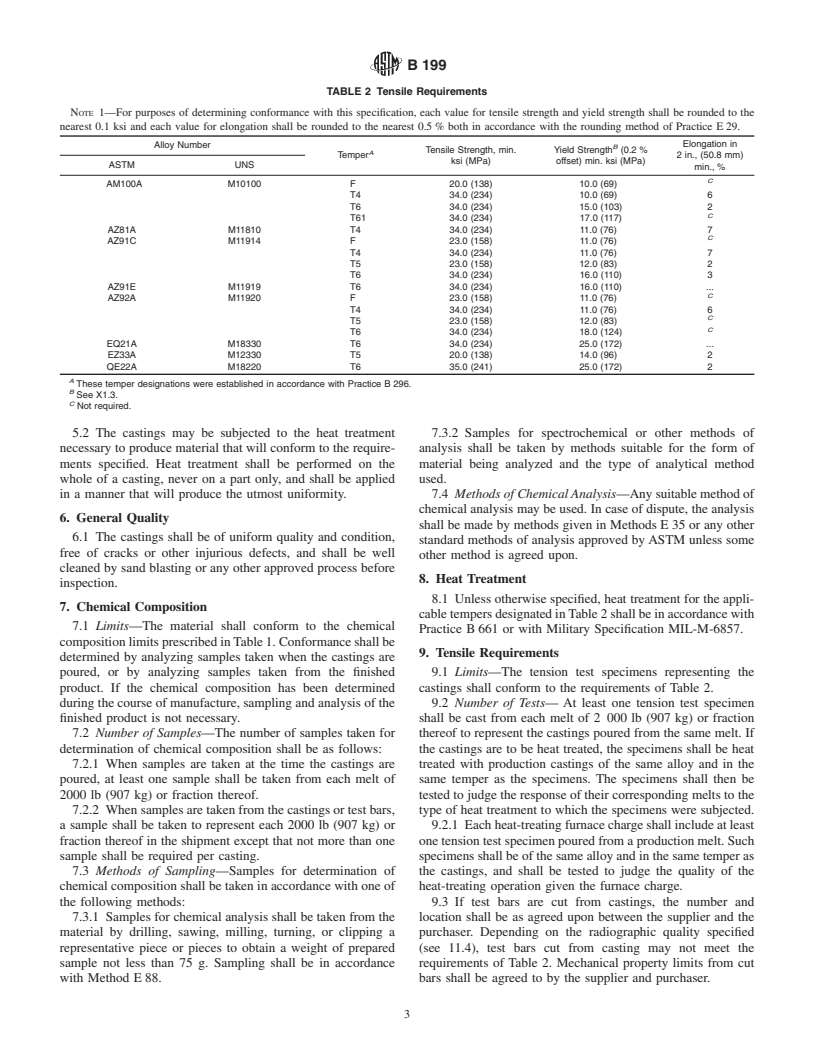

TABLE 2 Tensile Requirements

NOTE 1—For purposes of determining conformance with this specification, each value for tensile strength and yield strength shall be rounded to the

nearest 0.1 ksi and each value for elongation shall be rounded to the nearest 0.5 % both in accordance with the rounding method of Practice E 29.

Elongation in

Alloy Number B

Tensile Strength, min. Yield Strength (0.2 %

A

Temper 2 in., (50.8 mm)

ksi (MPa) offset) min. ksi (MPa)

ASTM UNS

min., %

C

AM100A M10100 F 20.0 (138) 10.0 (69)

T4 34.0 (234) 10.0 (69) 6

T6 34.0 (234) 15.0 (103) 2

C

T61 34.0 (234) 17.0 (117)

AZ81A M11810 T4 34.0 (234) 11.0 (76) 7

C

AZ91C M11914 F 23.0 (158) 11.0 (76)

T4 34.0 (234) 11.0 (76) 7

T5 23.0 (158) 12.0 (83) 2

T6 34.0 (234) 16.0 (110) 3

AZ91E M11919 T6 34.0 (234) 16.0 (110) .

C

AZ92A M11920 F 23.0 (158) 11.0 (76)

T4 34.0 (234) 11.0 (76) 6

C

T5 23.0 (158) 12.0 (83)

C

T6 34.0 (234) 18.0 (124)

EQ21A M18330 T6 34.0 (234) 25.0 (172) .

EZ33A M12330 T5 20.0 (138) 14.0 (96) 2

QE22A M18220 T6 35.0 (241) 25.0 (172) 2

A

These temper designations were established in accordance with Practice B 296.

B

See X1.3.

C

Not required.

5.2 The castings may be subjected to the heat treatment 7.3.2 Samples for spectrochemical or other methods of

necessary to produce material that will conform to the require- analysis shall be taken by methods suitable for the form of

ments specified. Heat treatment shall be performed on the material being analyzed and the type of analytical method

whole of a casting, never on a part only, and shall be applied used.

in a manner that will produce the utmost uniformity. 7.4 Methods of Chemical Analysis—Anysuitablemethodof

chemical analysis may be used. In case of dispute, the analysis

6. General Quality

shall be made by methods given in Methods E 35 or any other

6.1 The castings shall be of uniform quality and condition,

standard methods of analysis approved byASTM unless some

free of cracks or other injurious defects, and shall be well

other method is agreed upon.

cleaned by sand blasting or any other approved process before

8. Heat Treatment

inspection.

8.1 Unless otherwise specified, heat treatment for the appli-

7. Chemical Composition

cabletempersdesignatedinTable2shallbeinaccordancewith

7.1 Limits—The material shall conform to the chemical

Practice B 661 or with Military Specification MIL-M-6857.

compositionlimitsprescribedinTable1.Conformanceshallbe

9. Tensile Requirements

determined by analyzing samples taken when the castings are

poured, or by analyzing samples taken from the finished 9.1 Limits—The tension test specimens representing the

product. If the chemical composition has been determined castings shall conform to the requirements of Table 2.

during the course of manufacture, sampling and analysis of the 9.2 Number of Tests— At least one tension test specimen

finished product is not necessary. shall be cast from each melt of 2 000 lb (907 kg) or fraction

7.2 Number of Samples—The number of samples taken for thereof to represent the castings poured from the same melt. If

determination of chemical composition shall be as follows: the castings are to be heat treated, the specimens shall be heat

7.2.1 When samples are taken at the time the castings are treated with production castings of the same alloy and in the

poured, at least one sample shall be taken from each melt of same temper as the specimens. The specimens shall then be

2000 lb (907 kg) or fraction thereof. tested to judge the response of their corresponding melts to the

7.2.2 When samples are taken from the castings or test bars, type of heat treatment to which the specimens were subjected.

a sample shall be taken to represent each 2000 lb (907 kg) or 9.2.1 Eachheat-treatingfurnacechargeshallincludeatleast

fraction thereof in the shipment except that not more than one one tension test specimen poured from a production melt. Such

sample shall be required per casting. specimens shall be of the same alloy and in the same temper as

7.3 Methods of Sampling—Samples for determination of the castings, and shall be tested to judge the quality of the

chemical composition shall be taken in accordance with one of heat-treating operation given the furnace charge.

the following methods: 9.3 If test bars are cut from castings, the number and

7.3.1 Samples for chemical analysis shall be taken from the location shall be as agreed upon between the supplier and the

material by drilling, sawing, milling, turning, or clipping a purchaser. Depending on the radiographic quality specified

representative piece or pieces to obtain a weight of prepared (see 11.4), test bars cut from casting may not meet the

sample not less than 75 g. Sampling shall be in accordance requirements of Table 2. Mechanical property limits from cut

with Method E 88. bars shall be agreed to by the supplier and purchaser.

B 199

9.4 Test Specimens—The tension test specimens shall be table, the frequency per unit area, and location should also be

separately cast in a permanent mold and shall be cast to size in agreed upon.

accordance with the dimensions shown in Fig. 8 of Method 11.4.3 The number, film size, and orientation of radiographs

B 557. They shall not be machined prior to testing except to and the number of castings radiographically inspected shall be

adaptthegripendstotheholdersofthetestingmachineinsuch agreed upon between the supplier and the purchaser.

a manner as to ensure an axial load.

12. Rejection and Retest

9.4.1 If any tension test specimen is improperly machined

or shows flaws upon testing, it may be discarded and another

12.1 Material failing to conform to the requirements of this

specimen from the same heat or melt used instead. If no

specification may be rejected. If rejected, the supplier shall be

additionalspecimenisavailable,thesupplierandthepurchaser responsible only for replacement of the material to the pur-

shall agree on an alternative procedure.

chaser. As much as possible of the rejected original material

9.5 Test Methods— The tension tests shall be made in shall be returned to the supplier.

accordance with Method B 557.

12.2 Retests—If the results of the tension tests of alloys in

heat-treated tempers do not conform to the requirements

10. Finish

prescribed in Table 2, the castings may be re-heat treated once

in an attempt to meet the required properties. The results of

10.1 Depending on casting processing and end use require-

acceptable tests shall conform to the tensile properties require-

ments, castings should be protected by the use of chrome

ments specified in Table 2. Castings still not conforming after

pickling, anodizing, resin sealing, or other approved methods

the re-heat treatment shall be rejected.

prior to shipment (see X1.4).

13. Certification

11. Inspection

13.1 The supplier shall, on request, furnish to the purchaser

11.1 If the purchaser desires that inspection be made at the

a certificate stating that the material has been sampled, tested,

supplier’s works where the material is made, it shall be so

and inspected in accordance with this specification and has met

stated in the contract or purchase order.

the requirements

11.1.1 If the purchaser elects to have the inspection made at

the supplier’s works, the supplier shall afford the inspector

14. Product Marking

representing the purchaser all reasonable facilities to satisfy

14.1 Unless otherwise specified, each casting shall be

him that the material is being furnished in accordance with this

marked with the applicable drawing or part number.

specification.All tests and inspections shall be so conducted as

not to interfere unnecessarily with the operation of the works.

15. Packaging and Package Marking

11.2 Special inspection requirements such as simulated

service, pressure testing, X-ray, or fluorescent penetrant must 15.1 Packaging—Unless otherwise specified: castings shall

be stated on the order. be packaged to provide adequate protection during normal

11.3 Liquid Penetrant Inspection: handling and transportation; each package shall contain only

11.3.1 When specified, liquid penetrant inspection shall be one type of item; and the type of packaging and gross weight

in accordance with Practice

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.