ASTM E894-88(1998)

(Test Method)Standard Test Method for Anchorage of Permanent Metal Railing Systems and Rails for Buildings

Standard Test Method for Anchorage of Permanent Metal Railing Systems and Rails for Buildings

SCOPE

1.1 This test method describes procedures to be followed in testing the performance of the anchorage of all types of new and existing permanent metal railing systems (guard, stair, and ramp-rail systems), and rails (hand, grab, and transfer rails) installed in and for agricultural, assembly, commercial, educational, industrial, institutional, recreational, and residential buildings.

1.2 This test method is applicable to railing systems and rails having major structural components made of metal and secondary components made of metal or other materials such as wood, plastics, and glass.

1.3 The test method described can be used to determine whether the anchorage of permanent metal railing systems and rails complies with anticipated performance requirements.

1.4 Specifically, this test method covers procedures for determining the static tension, shear, and moment resistance of anchorages for permanent metal railing systems, and rails in structural elements made of concrete, masonry, wood, and metal as well as related products.

1.5 No consideration is given in this test method to any possible deterioration of anchorage systems, resulting from adverse environmental conditions. The performance of special tests covering this aspect may be desirable.

1.6 Should computations make it possible to provide the needed information, testing may be employed for purposes of verification.

1.7 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: E 894 – 88 (Reapproved 1998)

Standard Test Method for

Anchorage of Permanent Metal Railing Systems and Rails

for Buildings

This standard is issued under the fixed designation E 894; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method describes procedures to be followed in 2.1 ASTM Standards:

testing the performance of the anchorage of all types of new E 4 Practices for Force Verification of Testing Machines

and existing permanent metal railing systems (guard, stair, and E 488 Test Methods for Strength of Anchors in Concrete

ramp-rail systems), and rails (hand, grab, and transfer rails) and Masonry Elements

installed in and for agricultural, assembly, commercial, educa- E 575 Practice for Reporting Data from Structural Tests of

tional, industrial, institutional, recreational, and residential Building Constructions, Elements, Connections, and As-

buildings. semblies

1.2 This test method is applicable to railing systems and E 631 Terminology of Building Constructions

rails having major structural components made of metal and E 985 Specification for Permanent Metal Railing Systems

secondary components made of metal or other materials such and Rails for Buildings

as wood, plastics, and glass.

3. Terminology

1.3 The test method described can be used to determine

whether the anchorage of permanent metal railing systems and 3.1 Definitions—For definitions of terms used in this test

method, see Terminology E 631 and Specification E 985.

rails complies with anticipated performance requirements.

1.4 Specifically, this test method covers procedures for

4. Significance and Use

determining the static tension, shear, and moment resistance of

4.1 This test method is intended to provide data from which

anchorages for permanent metal railing systems, and rails in

applicable design data can be derived for a given anchorage.

structural elements made of concrete, masonry, wood, and

metal as well as related products.

5. Apparatus

1.5 No consideration is given in this test method to any

5.1 Testing Machine—Any testing machine or loading sys-

possible deterioration of anchorage systems, resulting from

tem capable of imposing forces accurate to within 61 %, when

adverse environmental conditions. The performance of special

calibrated in accordance with Practice E 4, is suitable and may

tests covering this aspect may be desirable.

be used, provided the requirements of specified rate of loading

1.6 Should computations make it possible to provide the

and recovery are met. The testing device shall be of sufficient

needed information, testing may be employed for purposes of

capacity to prevent yielding of its various components and

verification.

shall ensure that the applied tension load remains parallel to the

1.7 This standard does not purport to address all of the

relevant axis of the anchorage assembly and that the applied

safety concerns, if any, associated with its use. It is the

shear load remains essentially parallel to the surface of the

responsibility of the user of this standard to establish appro-

structural anchorage element or component during testing.

priate safety and health practices and determine the applica-

5.1.1 Tension Test—Suitable systems for applying tension

bility of regulatory limitations prior to use. For specific hazard

forces to the anchorage assembly are shown in Fig. 1 for

statements, see Section 6.

laboratory testing and in Fig. 2 for field testing. The bearing

plates shall be of sufficient size to prevent failure of the

surrounding structural members or components. The loading

device shall be attached to the assembly by means of pins or a

This test method is under the jurisdiction of ASTM Committee E-6 on

Performance of Buildings, and is the direct responsibility of Subcommittee E06.56

on Performance of Railing Systems and Rails for Buildings.

Current edition approved April 10, 1988. Published June 1988. Originally Annual Book of ASTM Standards, Vol 03.01.

e1 3

published as E 894 – 82. Last previous edition E 894 – 88 (1993) . Annual Book of ASTM Standards, Vol 04.11.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 894 – 88 (1998)

ultimate capacity tests on the assembly. The bearing plates and

connections shall be of sufficient size to prevent local failure of

the structural member. The load shall be distributed by means

of a load-distribution device which makes it possible for the

force to be applied perpendicular to the long axes of the

anchors. The bearing plate and other tie-down devices provide

a means of holding the anchorage member or component at the

required elevation throughout the test. The loading devices

shall be of such material as to reduce any damage to the

loading contact area of the device to a minimum during

application of the shear force and shall be replaced when

damaged.

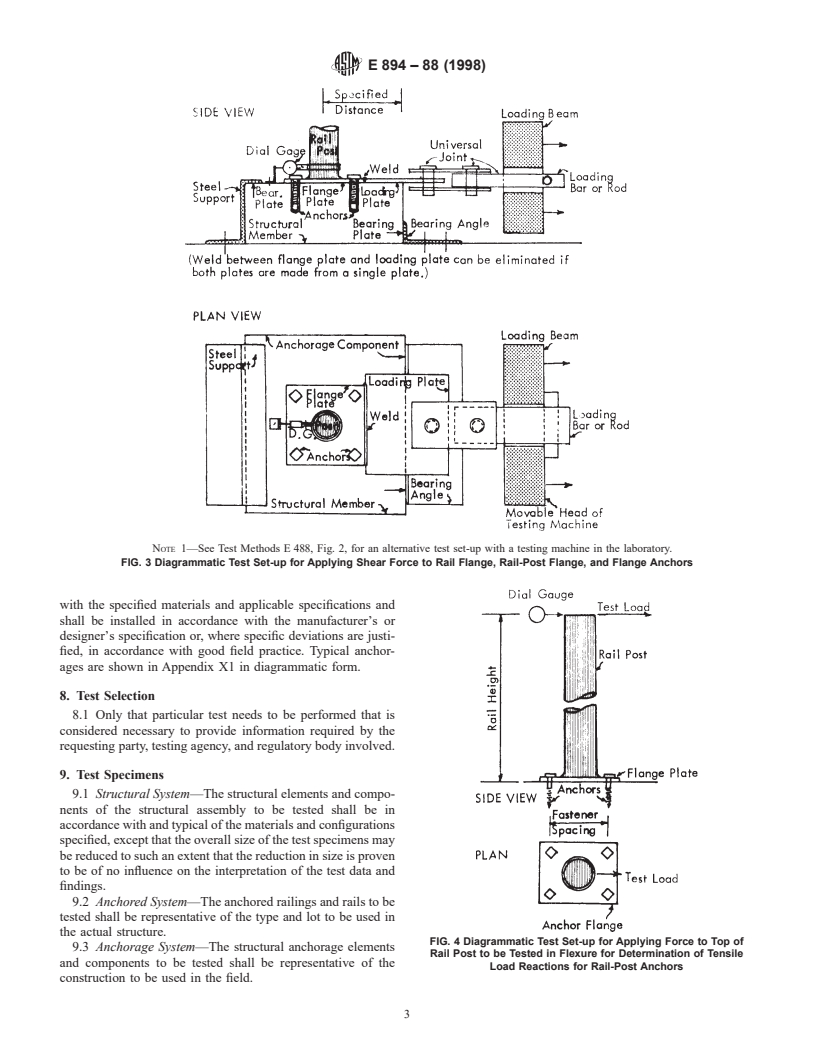

5.1.3 Flexural Test—A suitable system for applying tensile

forces to the top of the rail post is shown in Fig. 4. The

necessary test devices shall fulfill the requirements given in

5.1.2 and be applicable to the flexural test.

5.2 Anchorage Slip and Railing-System or Rail Deflection

Measurements:

5.2.1 Tension Test—Two dial gages, having a smallest

NOTE 1—See Test Method E 488, Fig. 1 for alternative test set-up with

division of not more than 0.025 mm (0.001 in.), or any suitable

a testing machine in the laboratory.

measurement device or calibrated sensor of at least comparable

FIG. 1 Diagrammatic Test Set-up for Applying Tensile Force to

accuracy and sensitivity shall be used to measure slip of the

Rail, Rail Post, Flange Plate, and Flange-Plate Anchors

anchored system relative to the anchorage elements or compo-

nents. The purpose of the instruments is to measure the vertical

movement of the anchored system with respect to such points

on the structural members or components which can serve as

reference points without being influenced by the force applied

by the anchoring system (see Fig. 1 and Fig. 2). The slip to be

used for the evaluation of the findings shall be the average

deformation indicated by the two dial gages, measurement

devices, or sensors.

5.2.2 Shear Test—A single dial gage, having a smallest

division of not more than 0.025 mm (0.001 in.), or any suitable

measurement device or calibrated sensor of at least comparable

accuracy and sensitivity shall be used to measure slip of the

anchored system relative to the anchorage elements or compo-

nents.

5.2.3 Flexural Test—A single dial gage for the test shown in

Fig. 4, having a smallest division of not more than 0.25 mm

(0.01 in.), or any suitable measurement device or calibrated

sensor of at least comparable accuracy and sensitivity shall be

used to measure the horizontal displacement of the top of the

rail post relative to its original location prior to load applica-

tion.

6. Hazards

6.1 Possible injury to personnel and damage to the test

equipment and instrumentation prior to, during, and after load

application by any unexpected release of potential strain

FIG. 2 Diagrammatic Test Set-up for Applying Tensile Force to

energy accumulated during testing can occur and must be given

Rail, Rail Post, Flange Plate, and Flange-Plate Anchors with

consideration.

Field-testing Device

6.2 If tests are conducted in a structure and not in a testing

laboratory, exercise caution against unwanted damage to the

swivel connector to prevent the direct transfer of bending

building, its components, and its finish.

stresses through the connection.

7. Anchorage Considerations

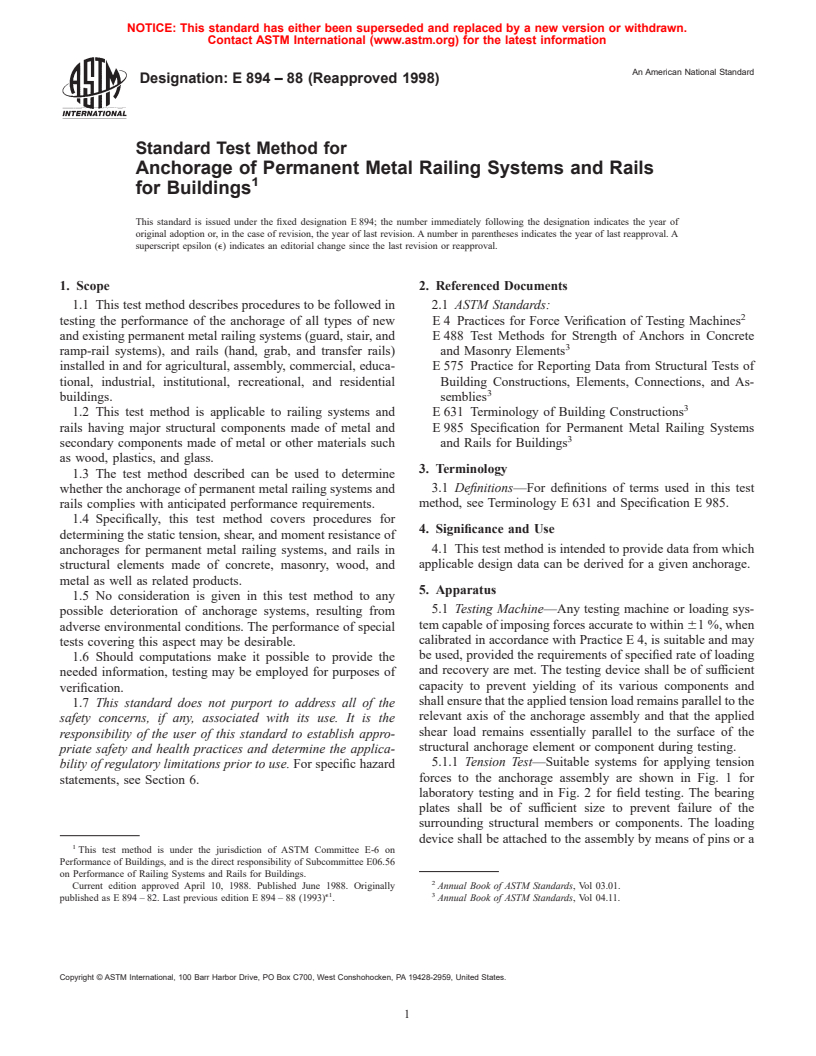

5.1.2 Shear Test—A suitable system for applying shear

forces to the anchorage assembly normal to the plane or major 7.1 Anchorage requirements should be based on design and

axis of the railing is shown in Fig. 3. The loading device shall performance requirements. The fastenings and fasteners used

be of sufficient strength to prevent its yielding during the for the anchorage to be tested shall be designed in accordance

E 894 – 88 (1998)

NOTE 1—See Test Methods E 488, Fig. 2, for an alternative test set-up with a testing machine in the laboratory.

FIG. 3 Diagrammatic Test Set-up for Applying Shear Force to Rail Flange, Rail-Post Flange, and Flange Anchors

with the specified materials and applicable specifications and

shall be installed in accordance with the manufacturer’s or

designer’s specification or, where specific deviations are justi-

fied, in accordance with good field practice. Typical anchor-

ages are shown in Appendix X1 in diagrammatic form.

8. Test Selection

8.1 Only that particular test needs to be performed that is

considered necessary to provide information required by the

requesting party, testing agency, and regulatory body involved.

9. Test Specimens

9.1 Structural System—The structural elements and compo-

nents of the structural assembly to be tested shall be in

accordance with and typical of the materials and configurations

specified, except that the overall size of the test specimens may

be reduced to such an extent that the reduction in size is proven

to be of no influence on the interpretation of the test data and

findings.

9.2 Anchored System—The anchored railings and rails to be

tested shall be representative of the type and lot to be used in

the actual structure.

FIG. 4 Diagrammatic Test Set-up for Applying Force to Top of

9.3 Anchorage System—The structural anchorage elements

Rail Post to be Tested in Flexure for Determination of Tensile

and components to be tested shall be representative of the

Load Reactions for Rail-Post Anchors

construction to be used in the field.

E 894 – 88 (1998)

9.4 Anchoring System—The anchoring devices to be tested are present on the surface of the structural element or compo-

shall be representative of the type and lot to be used in field nent, provide a suitable bearing medium between the structural

construction and shall include, insofar as feasible, all accessory element or component and the support system, such as a paste

devices and hardware normally required for design and use. of calcined gypsum (plaster of paris) or high-strength gypsum.

9.5 Anchorage Installation—Install the anchoring devices Permit sufficient time before testing to develop the necessary

to be tested in accordance with field installation procedures to compressive strength of the bearing medium. For all types of

be used in the building for which the data are applicable. bearing media, follow the manufacturer’s recommendations as

9.6 Anchorage Placement—Test all individual anchoring to their use. In the final alignment of the test specimen, ensure

devices and systems used in a given installation individually. that the force to be applied through the loading rod is

Simultaneously test as a complete unit closely spaced anchor- perpendicular to the surface of the structural members or

ing devices and systems that may interact. components.

12.1.2 Shear Test (see Fig. 3)—Position and fasten the

10. Number of Test Specimens

structural members or components in the support system in

such a way that their test surfaces are parallel to the long axis

10.1 Determine suitable statistical parameters to evaluate

of the shearing devices. For structural members with unusual

the composite variability and to select the number of specimens

coarse-textured or finished surfaces, provide a suitable bearing

required to make a realistic determination of the performance

layer between the structural element or component and the

characteristics of the anchorage under examination. Consider

support system with a suitable bearing material as described in

triplicate test specimens a minimum for each type of anchorage

12.1.1.

system to be tested under given conditions. A larger number of

12.1.3 Flexural Test (see Fig. 4)—Position the railing post

specimens may be specified depending upon the design and

in such a way that the load is applied to the structural member

variability in the quality of the anchorage devices and the

horizontally and essentially perpendicular to the rail without

anchoring elements and components.

causing any local failure at the point of load application.

12.2 Mounting of Instruments:

11. Conditioning

12.2.1 Tension Test—Mount the two dial gages, measure-

11.1 Conditioning and Curing—If aging, seasoning, or

ment devices, or sensors as shown in Figs. 1 and 2. Place the

curing conditions affect the performance and capacity of the

sensing elements of the instruments in contact with and normal

anchorage system, take appropriate measures in accordance

to the surface of the structural anchorage element or compo-

with the recommendations of the anchor manufacturer, to age,

nent being tested in such a way as to measure displacement in

season, or cure the anchorage and anchoring system prior to

the direction of the applied load.

testing. Report such conditions in detail. Observe their physical

12.2.2 Shear Test—Mount the single dial gage, measure-

effects and fully describe them in the test report.

ment device, or sensor as shown in Fig. 3. Place the sensing

11.2 Moisture and Temperature Conditions (applicable only

element of the instrument against a plate fastened to the surface

to hygroscopic products)—If the prevailing moisture and

of the structural anchorage element or component in such a

temperature conditions can affect the performance of anchor-

way as to measure displacement in the direction of the applied

age systems, hold these parameters constant for a given series

load.

of tests on a given anchorage system. The choice of the

controlled conditions depends on the environment of the field 12.2.3 Flexural Test—Attach a single dial gage, measure-

conditions to be given consideration. Such field conditions may ment device, or sensor at the loading point as shown in Fig. 4.

be simulated. Testing shall begin only after the test specimens Place the sensing element of the instrument in such a way as to

have reached at least an approximately stable condition with measure displacement of the post top in the direction of the

regard to temperature and moisture content. applied load.

11.3 Description—Examples of typical test specimens are

12.3 Initial Loading—Apply an initial load corresponding

shown in Figs. 1-4 in diagrammatic form. The actual specimen

to approximately 5 % of the estimated maximum load capacity

design and size depends on the specific case involved and shall

o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.