ASTM B580-79(2004)

(Specification)Standard Specification for Anodic Oxide Coatings on Aluminum

Standard Specification for Anodic Oxide Coatings on Aluminum

ABSTRACT

This specification covers the requirements for porous oxide coatings deposited by electrolysis on aluminum and aluminum alloy parts. These coatings should have good appearance, abrasion resistance, electrical properties, and protection against corrosion and does not include nonporous barrier layer anodic coatings that are used for electrical capacitors. The basis metals for these coatings should be subjected to mechanical finishing operations, cleaning, and chemical or electrolytic pre-treatments to yield coatings with fine quality and appearance. Anodized parts should be sealed in water or aqueous chemical solutions except when otherwise specified. Each anodic coating should be continuous, smooth, adherent, uniform in appearance, and free of powdery areas (burns, loose films, stains, discolorations, and discontinuities.

SCOPE

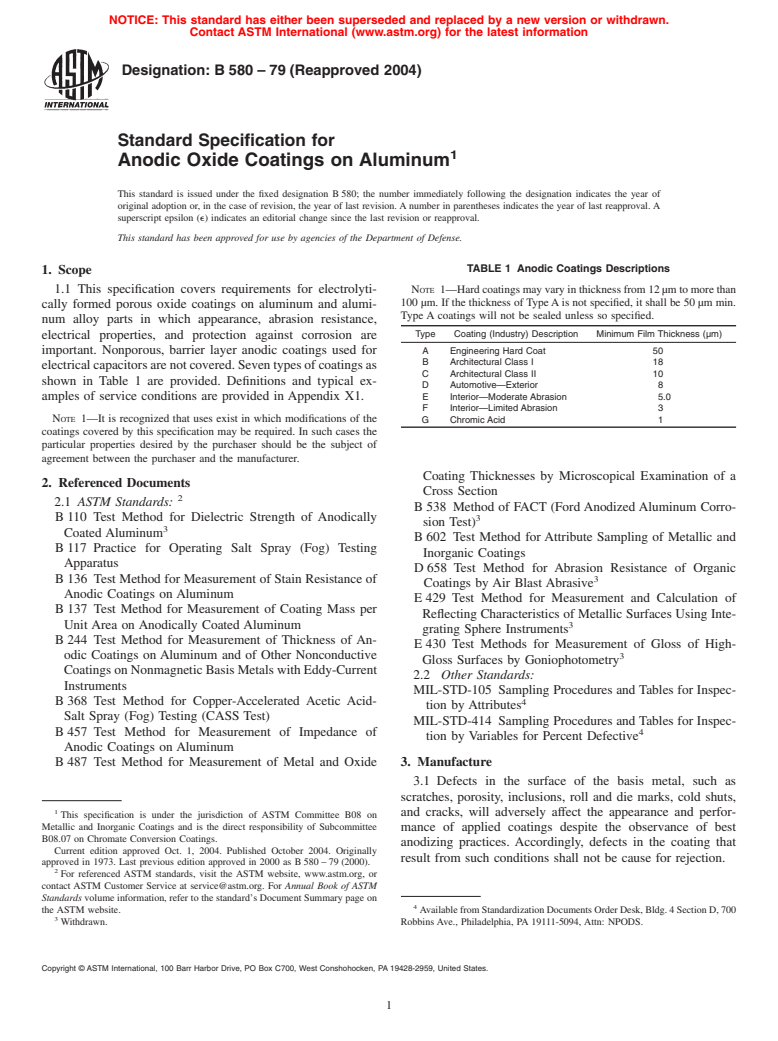

1.1 This specification covers requirements for electrolytically formed porous oxide coatings on aluminum and aluminum alloy parts in which appearance, abrasion resistance, electrical properties, and protection against corrosion are important. Nonporous, barrier layer anodic coatings used for electrical capacitors are not covered. Seven types of coatings as shown in are provided. Definitions and typical examples of service conditions are provided in Appendix X1.

Note 1—It is recognized that uses exist in which modifications of the coatings covered by this specification may be required. In such cases the particular properties desired by the purchaser should be the subject of agreement between the purchaser and the manufacturer.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 580 – 79 (Reapproved 2004)

Standard Specification for

Anodic Oxide Coatings on Aluminum

This standard is issued under the fixed designation B 580; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

TABLE 1 Anodic Coatings Descriptions

1. Scope

1.1 This specification covers requirements for electrolyti- NOTE 1—Hardcoatingsmayvaryinthicknessfrom12µmtomorethan

100 µm. If the thickness of TypeAis not specified, it shall be 50 µm min.

cally formed porous oxide coatings on aluminum and alumi-

Type A coatings will not be sealed unless so specified.

num alloy parts in which appearance, abrasion resistance,

Type Coating (Industry) Description Minimum Film Thickness (µm)

electrical properties, and protection against corrosion are

important. Nonporous, barrier layer anodic coatings used for A Engineering Hard Coat 50

B Architectural Class I 18

electricalcapacitorsarenotcovered.Seventypesofcoatingsas

C Architectural Class II 10

shown in Table 1 are provided. Definitions and typical ex-

D Automotive—Exterior 8

amples of service conditions are provided in Appendix X1. E Interior—Moderate Abrasion 5.0

F Interior—Limited Abrasion 3

NOTE 1—It is recognized that uses exist in which modifications of the

G Chromic Acid 1

coatings covered by this specification may be required. In such cases the

particular properties desired by the purchaser should be the subject of

agreement between the purchaser and the manufacturer.

Coating Thicknesses by Microscopical Examination of a

2. Referenced Documents

Cross Section

2.1 ASTM Standards:

B 538 Method of FACT (Ford Anodized Aluminum Corro-

B 110 Test Method for Dielectric Strength of Anodically 3

sion Test)

Coated Aluminum

B 602 Test Method for Attribute Sampling of Metallic and

B 117 Practice for Operating Salt Spray (Fog) Testing

Inorganic Coatings

Apparatus

D 658 Test Method for Abrasion Resistance of Organic

B 136 Test Method for Measurement of Stain Resistance of 3

Coatings by Air Blast Abrasive

Anodic Coatings on Aluminum

E 429 Test Method for Measurement and Calculation of

B 137 Test Method for Measurement of Coating Mass per

Reflecting Characteristics of Metallic Surfaces Using Inte-

Unit Area on Anodically Coated Aluminum 3

grating Sphere Instruments

B 244 Test Method for Measurement of Thickness of An-

E 430 Test Methods for Measurement of Gloss of High-

odic Coatings on Aluminum and of Other Nonconductive 3

Gloss Surfaces by Goniophotometry

CoatingsonNonmagneticBasisMetalswithEddy-Current

2.2 Other Standards:

Instruments

MIL-STD-105 Sampling Procedures and Tables for Inspec-

B 368 Test Method for Copper-Accelerated Acetic Acid-

tion by Attributes

Salt Spray (Fog) Testing (CASS Test)

MIL-STD-414 Sampling Procedures and Tables for Inspec-

B 457 Test Method for Measurement of Impedance of

tion by Variables for Percent Defective

Anodic Coatings on Aluminum

B 487 Test Method for Measurement of Metal and Oxide 3. Manufacture

3.1 Defects in the surface of the basis metal, such as

scratches, porosity, inclusions, roll and die marks, cold shuts,

and cracks, will adversely affect the appearance and perfor-

This specification is under the jurisdiction of ASTM Committee B08 on

Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee

mance of applied coatings despite the observance of best

B08.07 on Chromate Conversion Coatings.

anodizing practices. Accordingly, defects in the coating that

Current edition approved Oct. 1, 2004. Published October 2004. Originally

result from such conditions shall not be cause for rejection.

approved in 1973. Last previous edition approved in 2000 as B 580 – 79 (2000).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Withdrawn. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 580 – 79 (2004)

NOTE 2—To minimize problems of this sort, the specifications covering

have all of these characteristics. Therefore, the quality assur-

the basis material or the item to be anodized should contain appropriate

ance requirements for a given coating should be selected to

limitations on such basis metal conditions.

control those properties necessary to the expected end use for

3.2 The basis metal shall be subjected to such mechanical

the product.

finishing operations, cleaning, and chemical or electrolytic

6.2 Anodic coatings supplied under this specification shall

pre-treatments as are necessary to yield anodic coatings with

meet the minimum requirements for film thickness as stated in

the final quality and appearance specified by the purchaser.

Table 1.

3.3 Exceptwherespecificallyexcluded,anodizedpartsshall

6.3 The following ASTM test methods are applicable to

be sealed in water or aqueous chemical solutions of such

anodic coatings within the scope of this specification: B 110,

purity, composition, pH, and temperature, as to impart the

B 117, B 136, B 137, B 244, B 368, B 457, B 487, B 538,

properties specified herein.

D 658, E 429, and E 430. The selection of tests to be required

and the level of performance against each test, with the

4. Significant Surfaces

exception of minimum film thickness, shall be subject to

4.1 Significant surfaces are defined as those normally vis-

agreementbetweenpurchaserandmanufacturer.TheDyeSt

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.