ASTM D4950-95(2000)e1

(Classification)Standard Classification and Specification of Automotive Service Greases

Standard Classification and Specification of Automotive Service Greases

SCOPE

1.1 This specification covers lubricating greases suitable for the periodic relubrication of chassis systems and wheel bearings of passenger cars, trucks, and other vehicles.

1.2 This specification defines the requirements used to describe the properties and performance characteristics of chassis greases and wheel bearing greases for service-fill applications.

1.3 The test requirements (acceptance limits) given in this specification are, as the case may be, minimum or maximum acceptable values for valid duplicate test results. No additional corrections for test precision, such as described in Practice D3244, are to be applied inasmuch as the precision of the test methods was taken into account in the determination of the requirements.

1.4 The values stated in SI units are to be regarded as the standard. The values given in inch-pound units are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: D 4950 – 95 (Reapproved 2000) An American National Standard

Standard Classification and Specification for

1,2

Automotive Service Greases

This standard is issued under the fixed designation D 4950; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial corrections were made throughout in April 2000.

INTRODUCTION

This specification describes current categories of lubricating greases for automotive service-fill

applications. A specific designation is assigned to each category. The system is open ended, that is,

new designations are assigned for use with new categories as each new set of grease performance

characteristics is defined. Grease categories are referenced by automotive manufacturers in making

lubrication recommendations and used by grease suppliers and users in identifying products for

specific applications.

1. Scope Lubricating Greases

D 1742 Test Method for Oil Separation from Lubricating

1.1 This specification covers lubricating greases suitable for

Grease During Storage

the periodic relubrication of chassis systems and wheel bear-

D 1743 Test Method for Corrosion Preventive Properties of

ings of passenger cars, trucks, and other vehicles.

Lubricating Greases

1.2 This specification defines the requirements used to

D 2265 Test Method for Dropping Point of Lubricating

describe the properties and performance characteristics of

Grease over Wide Temperature Range

chassis greases and wheel bearing greases for service-fill

D 2266 Test Method for Wear Preventive Characteristics of

applications.

Lubricating Grease (Four-Ball Method)

1.3 The test requirements (acceptance limits) given in this

D 2596 Test Method for Measurement of Extreme-Pressure

specification are, as the case may be, minimum or maximum

Properties of Lubricating Grease (Four-Ball Method)

acceptable values for valid duplicate test results. No additional

D 3244 Practice for Utilization of Test Data to Determine

corrections for test precision, such as described in Practice

Conformance with Specifications

D 3244, are to be applied inasmuch as the precision of the test

D 3527 Test Method for Life Performance of Automotive

methods was taken into account in the determination of the

Wheel Bearing Grease

requirements.

D 4170 Test Method for Fretting Wear Protection by Lubri-

1.4 The values stated in SI units are to be regarded as the

cating Greases

standard. The values given in inch-pound units are for infor-

D 4175 Terminology Relating to Petroleum, Petroleum

mation only.

Products, and Lubricants

2. Referenced Documents

D 4289 Test Method for Compatibility of Lubricating

Grease with Elastomers

2.1 ASTM Standards:

D 4290 Test Method for Determining the Leakage Tenden-

D 217 Test Methods for Cone Penetration of Lubricating

cies of Automotive Wheel Bearing Grease Under Acceler-

Grease

ated Conditions

D 566 Test Method for Dropping Point of Lubricating

D 4693 Test Method for Low-Temperature Torque of

Grease

Grease-Lubricated Wheel Bearings

D 1264 Test Method for Water Washout Characteristics of

2.2 SAE Standards:

AMS 3217A Standard Elastomer Stock-Test Slabs

AMS 3217/2A Test Slabs, Acrylonitrile Butadiene (NBR-

This classification and specification is under the jurisdiction of ASTM

Committee D-2 on Petroleum Products and Lubricants and is the direct responsi-

L)-Low Acrylonitrile, 65-75

bility of Subcommittee D02.B0.04 on Automotive Greases. Current edition ap-

proved Sept. 10, 1995. Published November 1995.

Originally published as D 4950 – 89. Last previous edition D 495 – 89 (1994)e .

2 4

This classification and specification was developed as a cooperative effort Annual Book of ASTM Standards, Vol 05.02.

among the American Society for Testing and Materials, the National Lubricating Annual Book of ASTM Standards, Vol 05.03.

Grease Institute (NLGI), and the Society of Automotive Engineers (SAE). Available from Society of Automotive Engineers, 400 Commonwealth Drive,

Annual Book of ASTM Standards, Vol 05.01. Warrendale, PA 15096.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 4950

AMS 3217/3B Test Slabs Chloroprene (CR)-65-75 4. Performance Classification

SAE J310 Automotive Lubricating Greases

4.1 Automotive service greases are classified into two

general groups. Those designated with an “L” prefix (chassis

3. Terminology

greases) are intended for the service lubrication of ball joints,

3.1 Definitions:

steering pivots, universal joints, and other chassis components

3.1.1 lubricant, n—any material interposed between two

as designated by the equipment manufacturer. Those desig-

surfaces that reduces the friction or wear between them.

nated with a “G” prefix are intended primarily for the service

D 4175

lubrication of wheel bearings. These groups are further subdi-

3.1.2 lubricating grease, n—a semi-fluid to solid product of

vided into categories with intended service applications as

a dispersion of a thickener in a liquid lubricant.

follows:

3.1.2.1 Discussion—The dispersion of the thickener forms a

4.1.1 LA—Service typical of chassis components and uni-

two-phase system and immobilizes the liquid lubricant by

versal joints in passenger cars, trucks, and other vehicles under

surface tension and other physical forces. Other ingredients

mild duty only. Mild duty will be encountered in vehicles

imparting special properties are often included. D 217

operated with frequent relubrication in noncritical applications.

3.1.3 thickener, n—in lubricating grease, a substance com-

4.1.2 LB—Service typical of chassis components and uni-

posed of finely-divided particles dispersed in a liquid to form

versal joints in passenger cars, trucks, and other vehicles under

the product’s structure.

mild to severe duty. Severe duty will be encountered in

3.1.3.1 Discussion—The thickener can be fibers (such as

vehicles operated under conditions which may include pro-

various metallic soaps) or plates or spheres (such as certain

longed relubrication intervals, or high loads, severe vibration,

non-soap thickeners) which are insoluble or, at the most, only

exposure to water or other contaminants, etc.

very slightly soluble in the liquid lubricant. The general

4.1.3 GA—Service typical of wheel bearings operating in

requirements are that the solid particles be extremely small,

passenger cars, trucks, and other vehicles under mild duty.

uniformly dispersed, and capable of forming a relatively stable,

Mild duty will be encountered in vehicles operated with

gel-like structure with the liquid lubricant. D 217

frequent relubrication in noncritical applications.

3.2 Definitions of Terms Specific to This Standard:

4.1.4 GB—Service typical of wheel bearings operating in

3.2.1 automotive service grease—a lubricating grease suit-

passenger cars, trucks, and other vehicles under mild to

able for the periodic relubrication of serviceable-type, chassis

moderate duty. Moderate duty will be encountered in most

components or wheel bearings of passenger cars, trucks, and

vehicles operated under normal urban, highway, and off-

other vehicles and distinct from factory-fill greases (also

highway service.

known as initial-fill and OEM greases) initially installed by the

4.1.5 GC—Service typical of wheel bearings operating in

original equipment manufacturer.

passenger cars, trucks, and other vehicles under mild to severe

3.2.2 category—with respect to automotive service grease,

duty. Severe duty will be encountered in certain vehicles

a designation, such as LB, GC, etc., for a given level of

operated under conditions resulting in high bearing tempera-

performance in standardized tests.

tures. This includes vehicles operated under frequent stop-

3.2.3 chassis grease—an automotive service grease used to

and-go service (buses, taxis, urban police cars, etc), or under

lubricate ball joints, steering pivots, universal joints, and, other

severe braking service (trailer towing, heavy loading, mountain

lubrication points designated in the vehicle owner’s service

driving, etc.).

guide.

3.2.4 classification—with respect to automotive service

5. Performance Description

grease, the systematic arrangement into categories according to

5.1 The performance characteristics of the several catego-

differing levels of performance.

ries of automotive service greases are described as follows:

3.2.5 “G” category group—automotive service greases of

5.1.1 LA—The grease shall satisfactorily lubricate chassis

such composition, properties, and performance characteristics

components and universal joints where frequent relubrication

as to be suitable for the service lubrication of those types of

is practiced (at intervals of 3200 km or 2000 miles or less for

wheel bearings that require periodic relubrication.

passenger cars). During its service life, the grease should resist

3.2.6 “L” category group—automotive service greases of

such composition, properties, and performance characteristics

as to be suitable for the service lubrication of those types of

The letter designations for the grease categories and the corresponding

Performance Classification descriptions in Section 4 were developed by an ad hoc

suspension, steering, and drive-line components that require

panel of the NLGI Literature Subcommittee in cooperation with ASTM

periodic relubrication.

D02.B0.04.02, (Subsection on) Automotive Grease Specifications. Although these

3.2.7 multipurpose grease—an automotive service grease

designations and descriptions of the categories have been adopted in toto in this

standard, the NLGI Literature Subcommittee retains jurisdiction over them as

suitable for both chassis and wheel bearing lubrication.

published in, “Chassis and Wheel Bearing Service Classification System,” available

3.2.7.1 Discussion—Commercial lubricating greases other

from the National Lubricating Grease Institute, 4635 Wyandotte Street, Kansas City,

than automotive service greases are often designated as mul-

MO 64112. It is the intention of Subcommittee D02.B to include in this standard

tipurpose greases.

future revisions to these descriptions providing they are deemed acceptable by

ASTM.

3.3 Abbreviations:

The Performance Descriptions and Performance Requirements for the grease

ASTM—American Society for Testing and Materials

categories, as described in Sections 5 and 6, were developed by ASTM

NLGI—National Lubricating Grease Institute

D02.B0.04.02 in cooperation with the NLGI Literature Subcommittee. ASTM

SAE—Society of Automotive Engineers Subcommittee D02.B retains jurisdiction over these descriptions (see Footnote 7).

D 4950

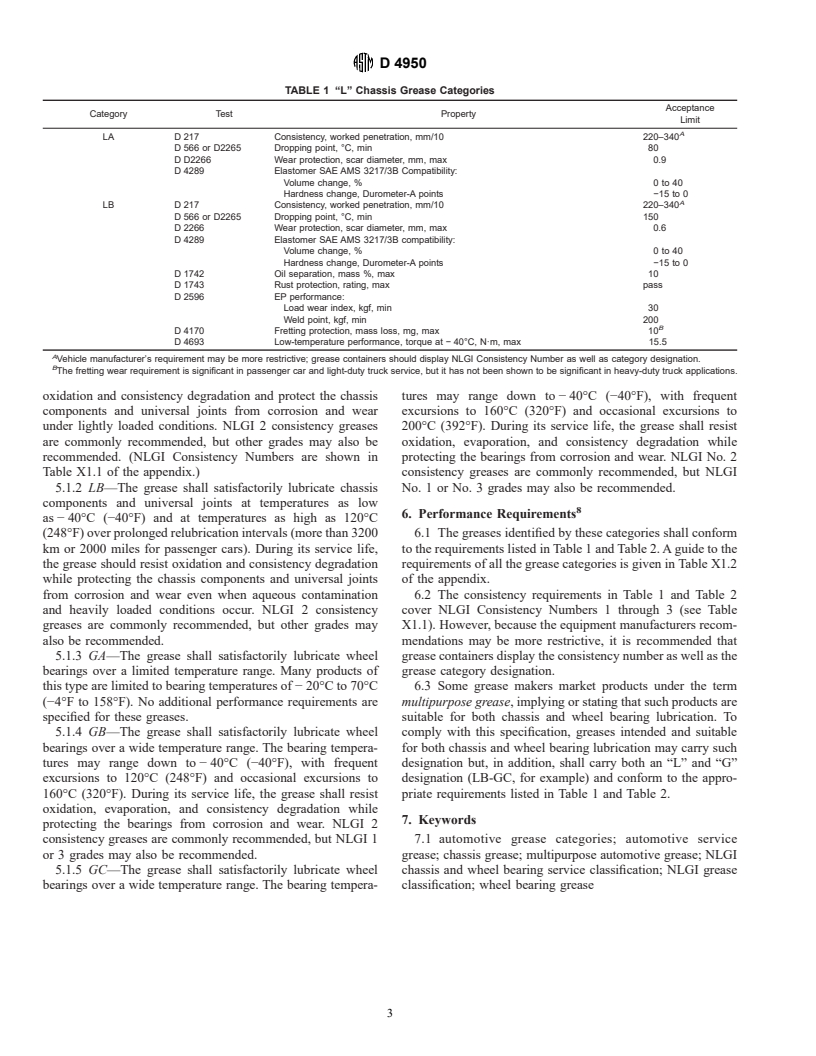

TABLE 1 “L” Chassis Grease Categories

Acceptance

Category Test Property

Limit

A

LA D 217 Consistency, wor

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.